Extraction and boron removal method for lithium-containing brine

An extraction and brine technology, applied in chemical instruments and methods, water pollutants, flotation water/sewage treatment, etc., can solve the problems of octanol dissolution loss and low extraction precision, and achieve the effect of increasing solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

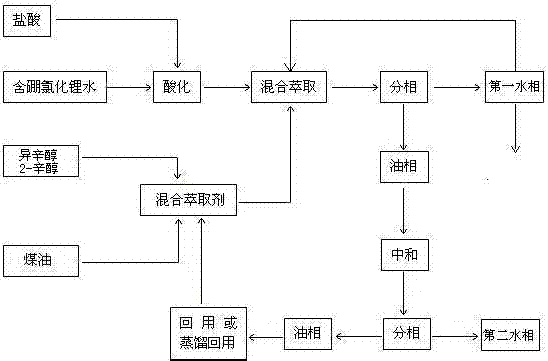

Image

Examples

Embodiment 1

[0034] The boron-containing lithium chloride aqueous solution to be treated has a boron content of 600 ppm, and the boron-containing lithium chloride aqueous solution is acidified to pH 2 with hydrochloric acid;

[0035] Mix iso-octanol and 2-octanol in a volume ratio of 11:1 to obtain an octanol mixed solution, and mix an octanol mixed solution with kerosene in a volume ratio of 6:4; make a mixed extractant, which can be used in the environment The temperature is 25°C, after fully mixing the acidified boron-containing lithium chloride water and the mixed extractant, let it stand for 2 hours;

[0036] After standing still, the mixed liquid phase separation of boron-containing lithium chloride water and mixed extractant is an oil phase and a first water phase;

[0037] Export the first aqueous phase and detect the boron content. If the boron content exceeds the standard, it is returned to step (2) and extracted as boron-containing lithium chloride water. The operation is repeat...

Embodiment 2

[0040] The boron-containing lithium chloride aqueous solution to be treated has a boron content of 600 ppm, and the boron-containing lithium chloride aqueous solution is acidified to pH 2 with hydrochloric acid;

[0041] Mix iso-octanol and 2-octanol in a volume ratio of 13:1 to obtain octanol mixed solution, and mix octanol mixed solution with kerosene in a volume ratio of 6:4; make a mixed extractant, which can be used in the environment The temperature is 25°C, after fully mixing the acidified boron-containing lithium chloride water and the mixed extractant, let it stand for 2 hours;

[0042] After standing still, the mixed liquid phase separation of boron-containing lithium chloride water and mixed extractant is an oil phase and a first water phase;

[0043] Export the first aqueous phase and detect the boron content. If the boron content exceeds the standard, it is returned to step (2) and extracted as boron-containing lithium chloride water. The operation is repeated 3 t...

Embodiment 3

[0046] The boron-containing lithium chloride aqueous solution to be treated has a boron content of 600 ppm, and the boron-containing lithium chloride aqueous solution is acidified to pH 2 with hydrochloric acid;

[0047] Mix iso-octanol and 2-octanol in a volume ratio of 14:1 to obtain an octanol mixed solution, and mix an octanol mixed solution with kerosene in a volume ratio of 6:4; prepare a mixed extractant, which can be used in the environment The temperature is 25°C, after fully mixing the acidified boron-containing lithium chloride water and the mixed extractant, let it stand for 2 hours;

[0048] After standing still, the mixed liquid phase separation of boron-containing lithium chloride water and mixed extractant is an oil phase and a first water phase;

[0049]Export the first aqueous phase and detect the boron content. If the boron content exceeds the standard, it is returned to step (2) and extracted as boron-containing lithium chloride water. The operation is repe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com