Patents

Literature

40 results about "2-Octanol" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

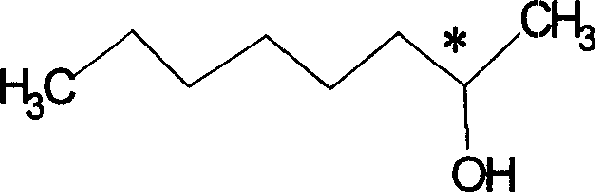

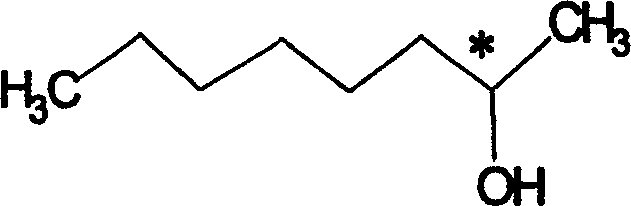

2-Octanol (octan-2-ol, 2-OH) is a fatty alcohol. It is a secondary eight-carbon chiral compound. 2-Octanol is a colorless liquid that is poorly soluble in water but soluble in most organic solvents. It is used such as or as a raw material in various applications: flavors and fragrances, paints and coatings, inks, adhesives, home care, lubricants and fuels. 2-Octanol can be a biobased alternative of 2-ethylhexanol and its derivates in numerous applications.

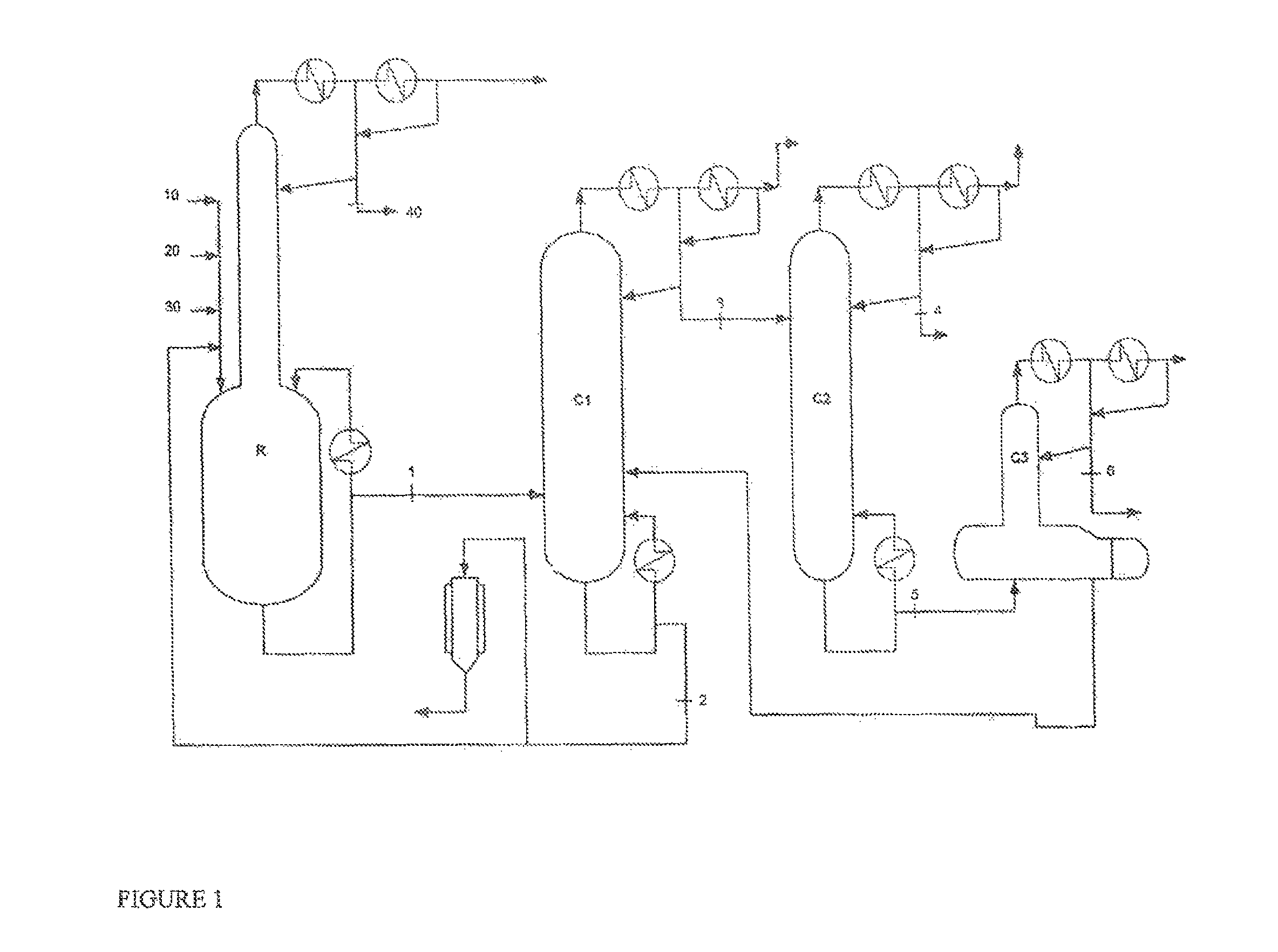

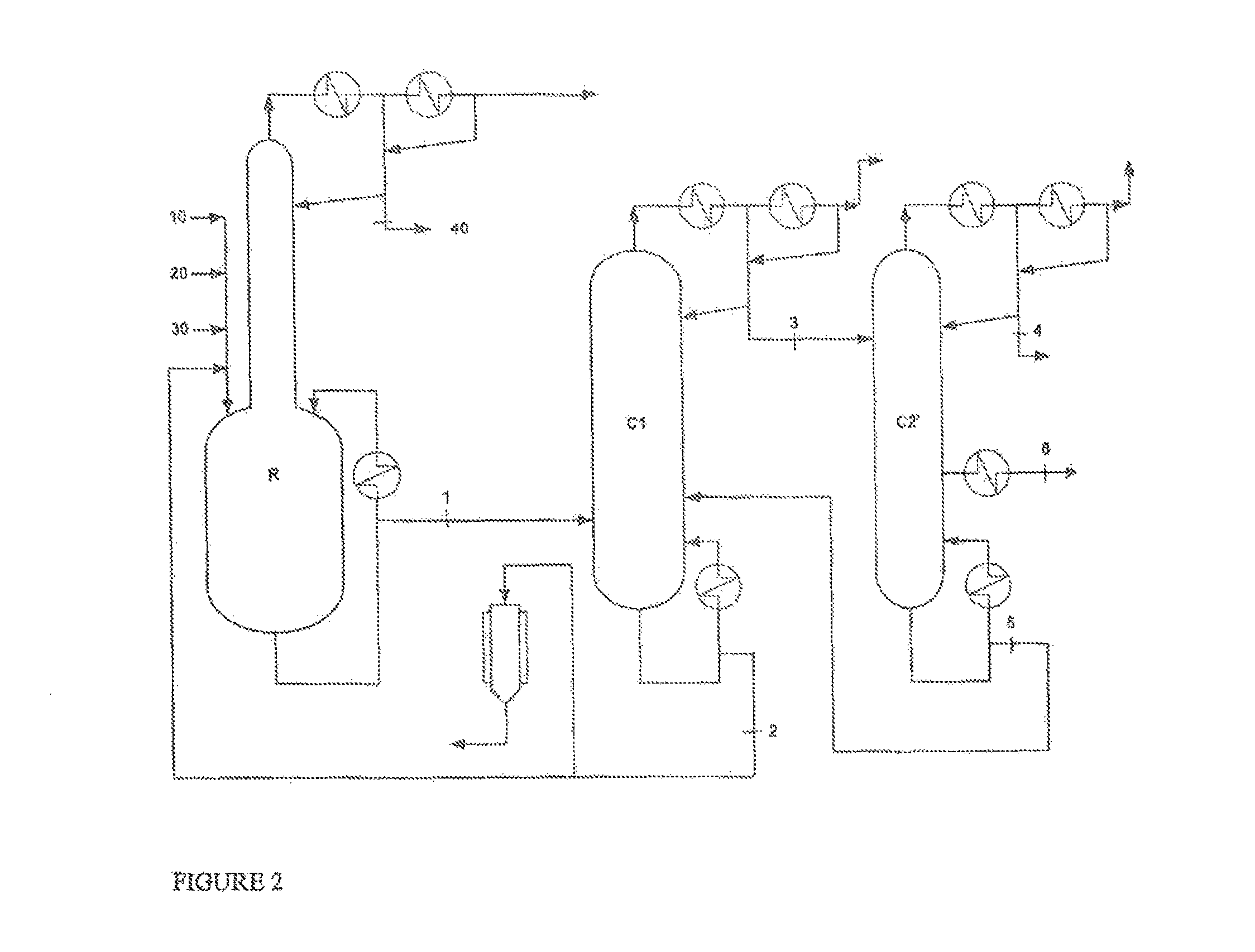

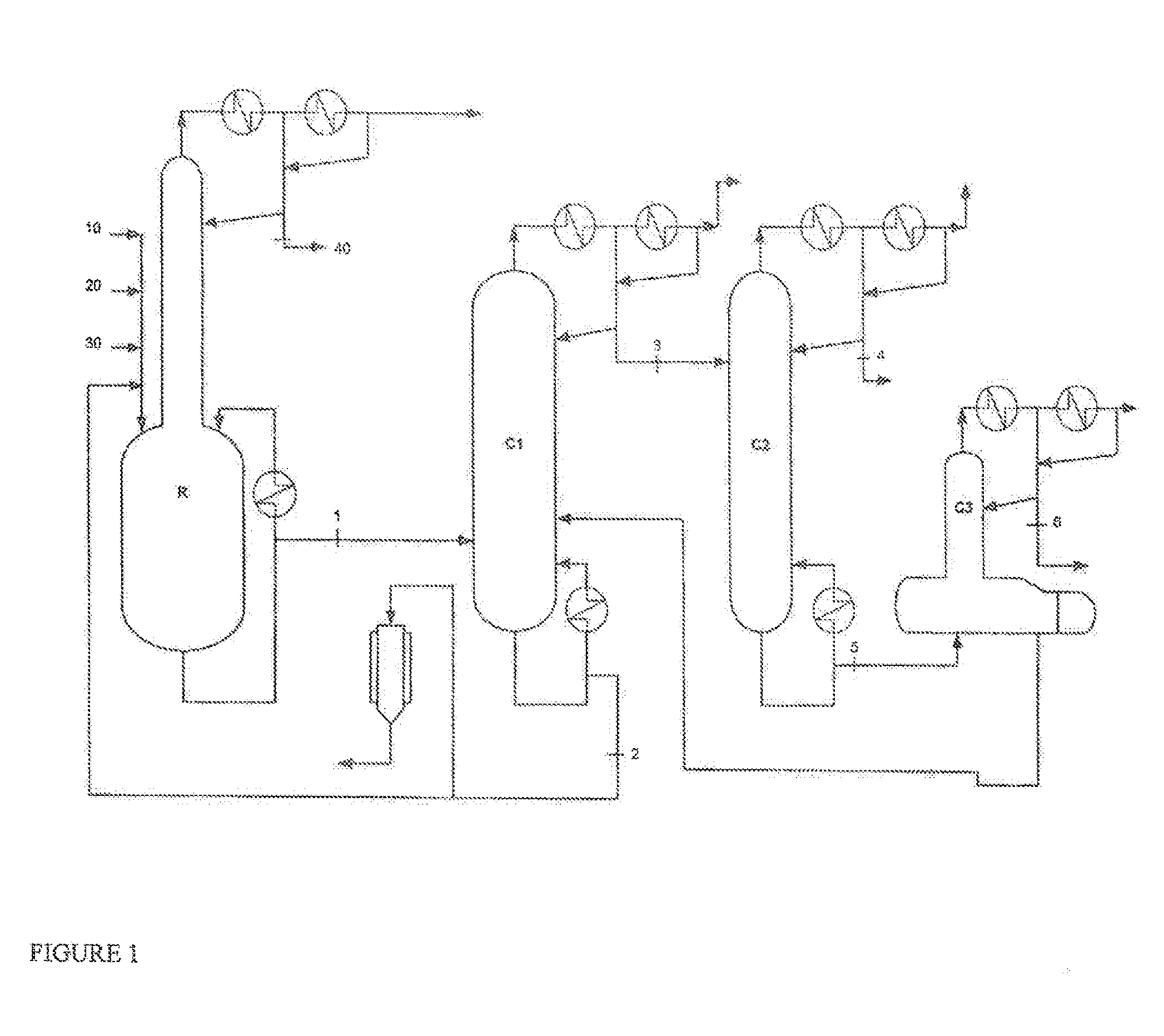

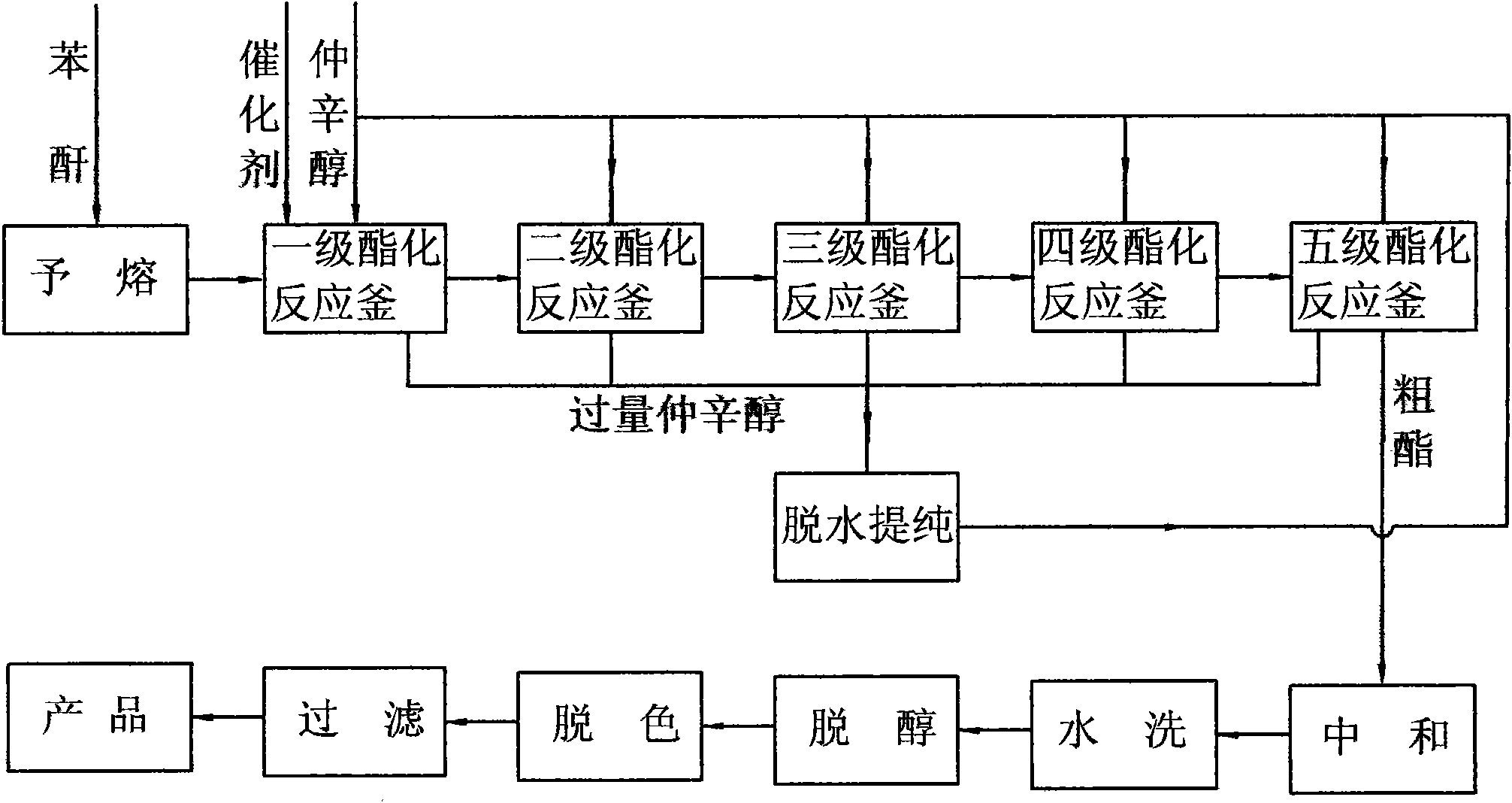

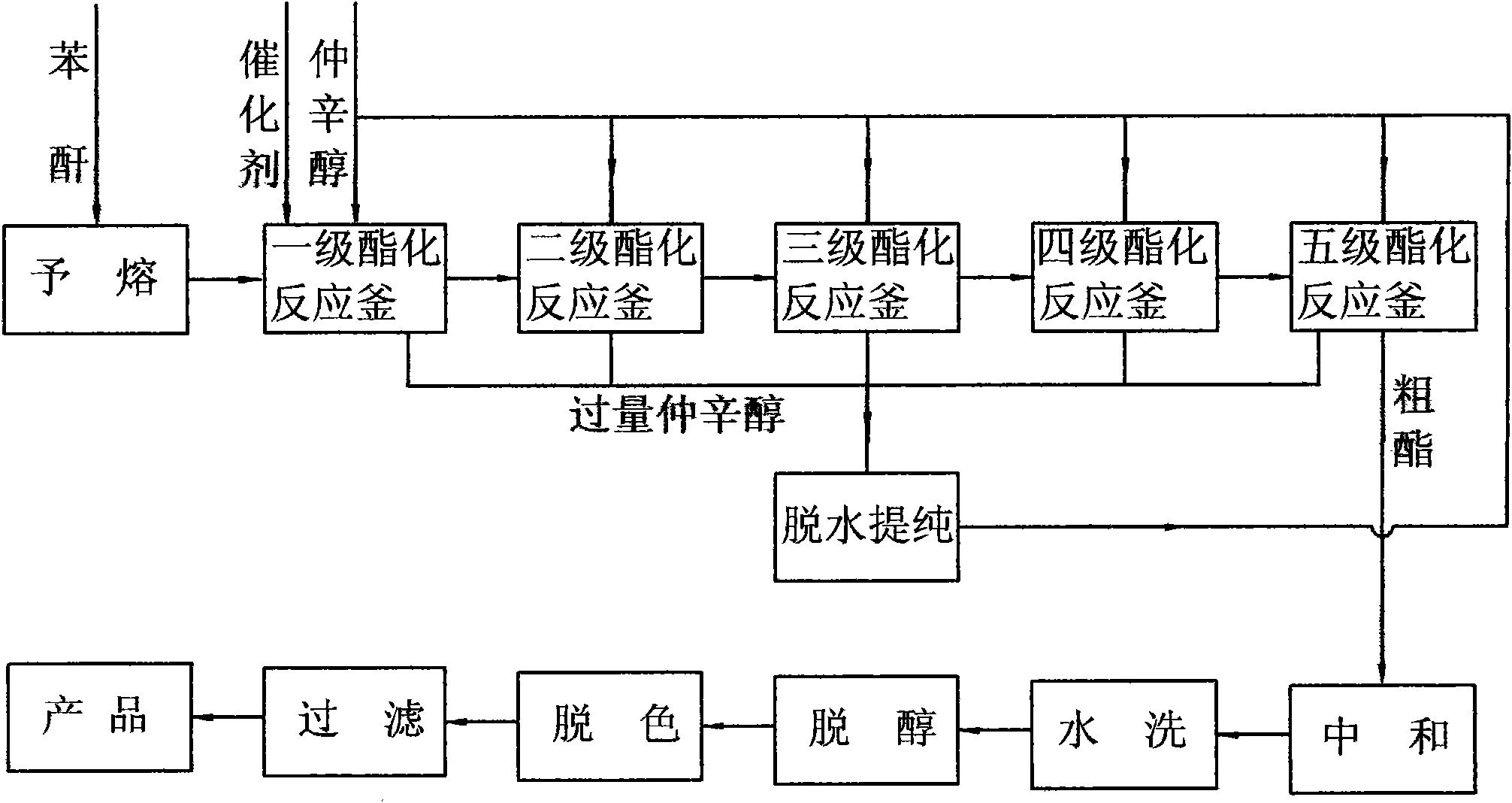

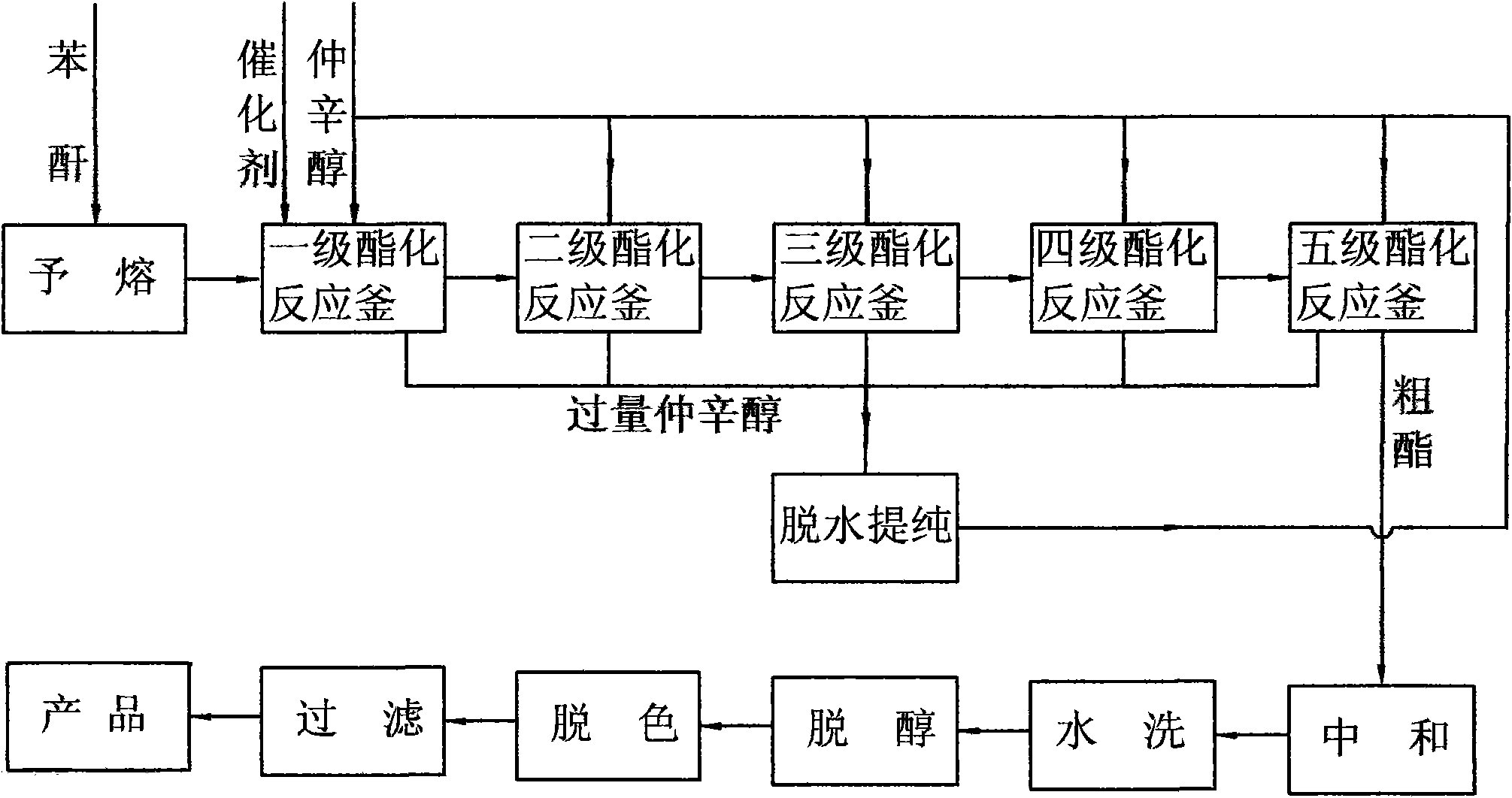

Continuous esterification production method of di-sec-octyl phthalate

ActiveCN101891620AImprove quality and efficiencyIncrease productivityOrganic compound preparationCarboxylic acid esters preparation2-OctanolAcid value

The invention discloses a continuous esterification production method of di-sec-octyl phthalate. The method comprises the following steps: using phthalic anhydride and 2-octanol to perform an esterification reaction under the existence of catalyst and obtain raw ester, and post-processing raw ester to obtain the product di-sec-octyl phthalate, wherein the esterification reaction is a multistage esterification reaction that phthalic anhydride and 2-octanol perform a plurality of esterification continuously. The esterification reaction of the invention adopts the production method of continuous esterification, the esterification reaction is complete, the conversion rate is high, the acid value of the product is low and the purity is high; and the time of esterification is short, the energy consumption is low, the product quality is stable, and the quality and production efficiency of di-sec-octyl phthalate can be effectively increased.

Owner:WEIFANG YUANLI CHEM

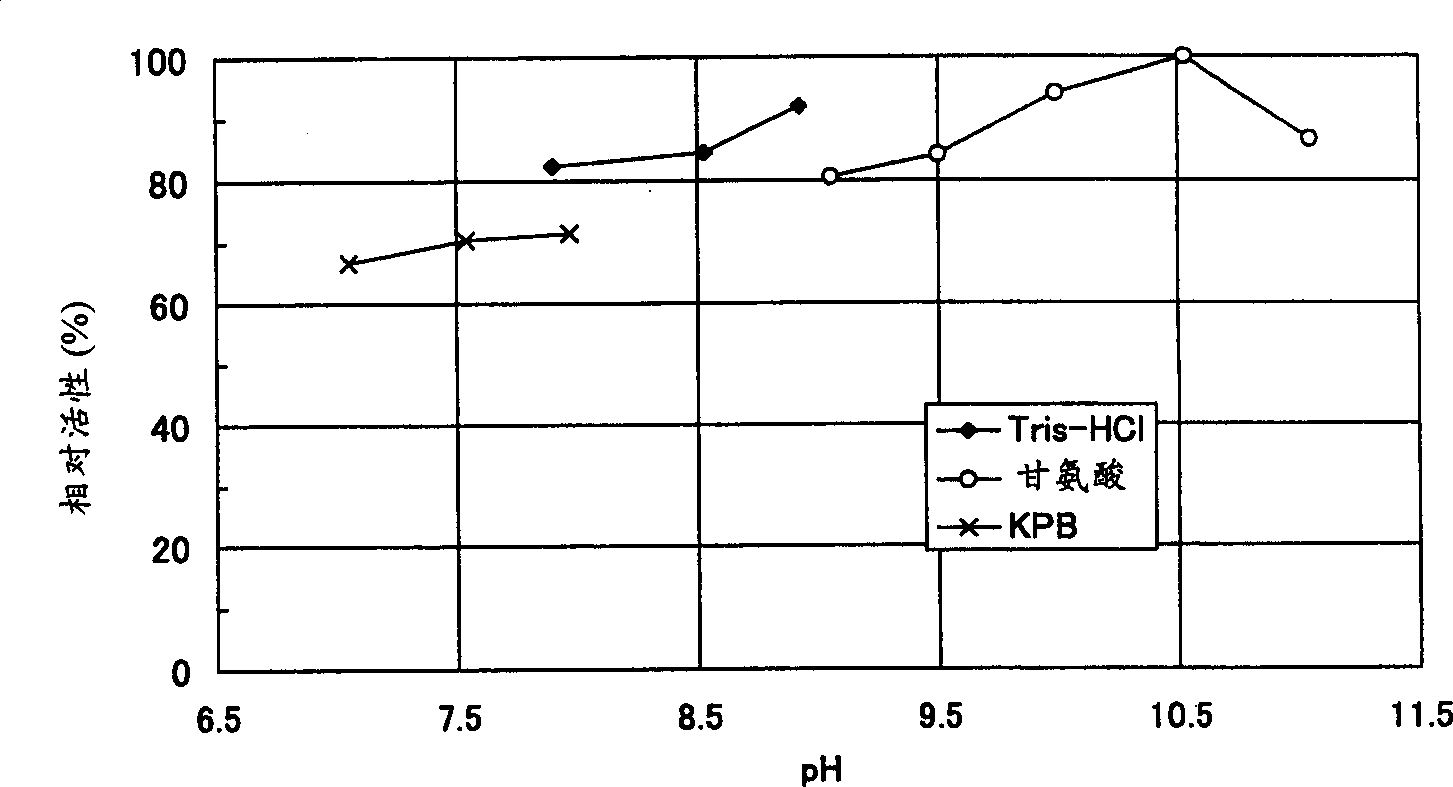

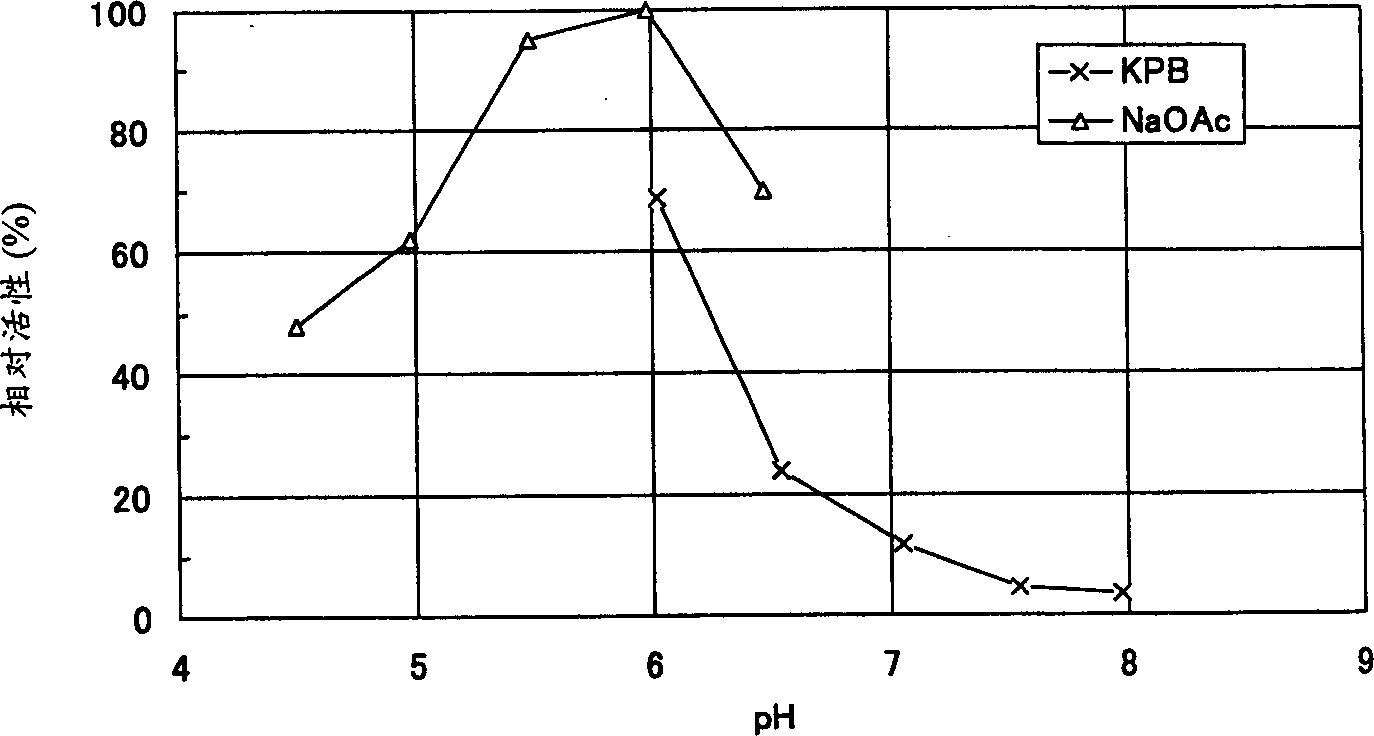

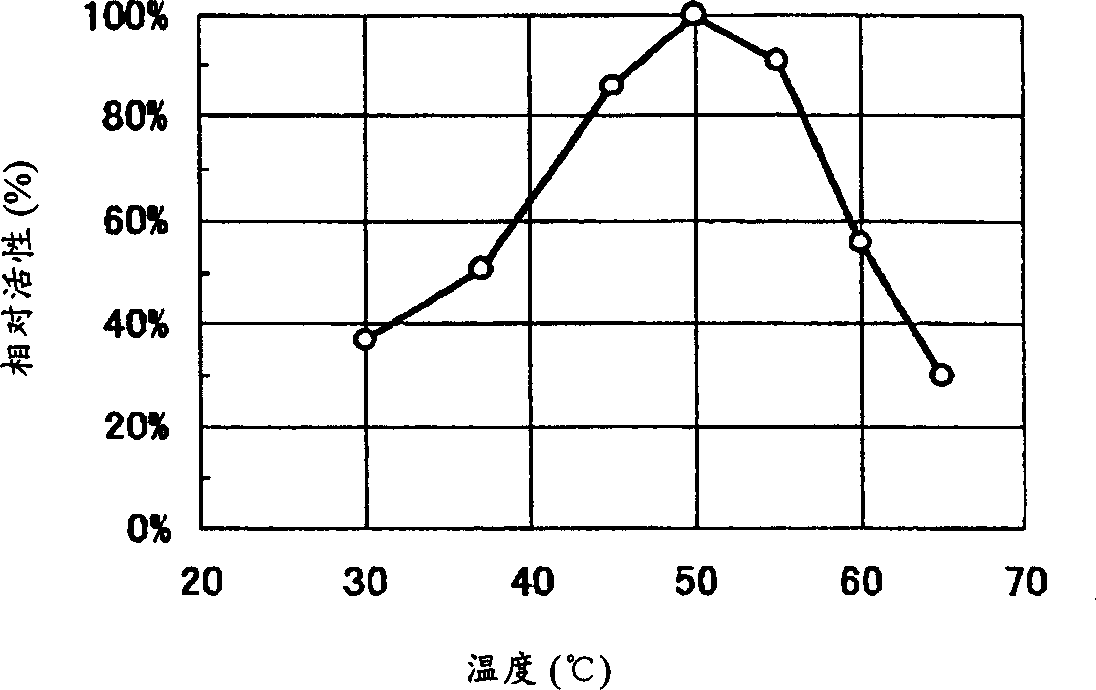

(R)-2-octanol dehydrogenase, process for producing enzyme, DNA encoding enzyme and process for producing alcohol by using same

This invention provides (R)-2-octanol dehydrogenase that catalyzes oxidation-reduction reaction using NAD<+> (NADH) as a coenzyme and the genes that encodes them. The enzymes of this invention can be obtained from microorganisms such as the genera Pichia, Candida, and Ogataea, and so on. It is possible to produce alcohols, in particular, alcohols such as (S)-4-halo-3-hydroxybutyric acid esters and (R)-propoxybenzene derivatives by reducing ketones with this (R)-2-octanol dehydrogenase. Moreover, the (R)-2-octanol dehydrogenase of this invention is excellent in activity and stereoselectivity.

Owner:DAICEL CHEM IND LTD

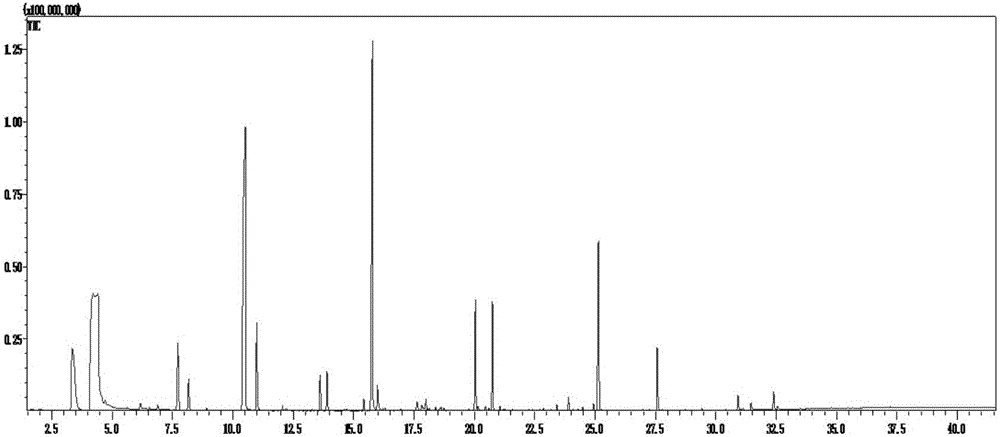

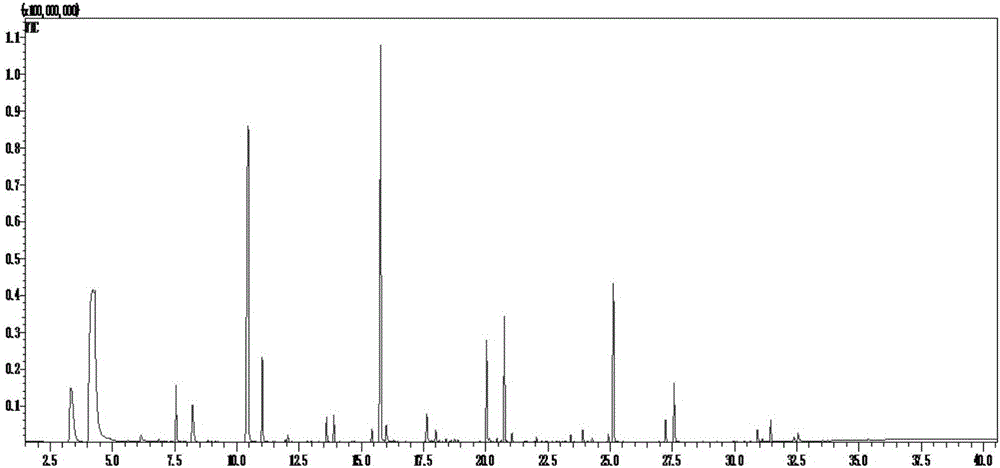

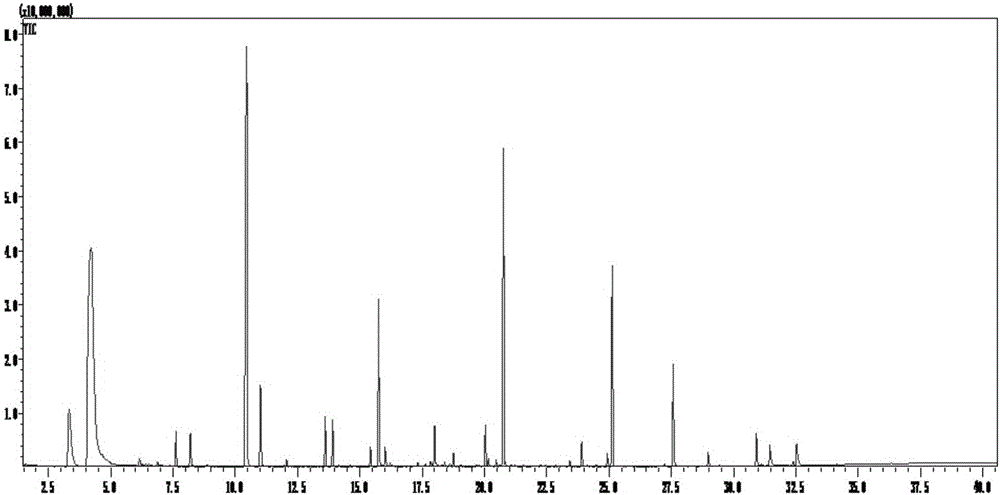

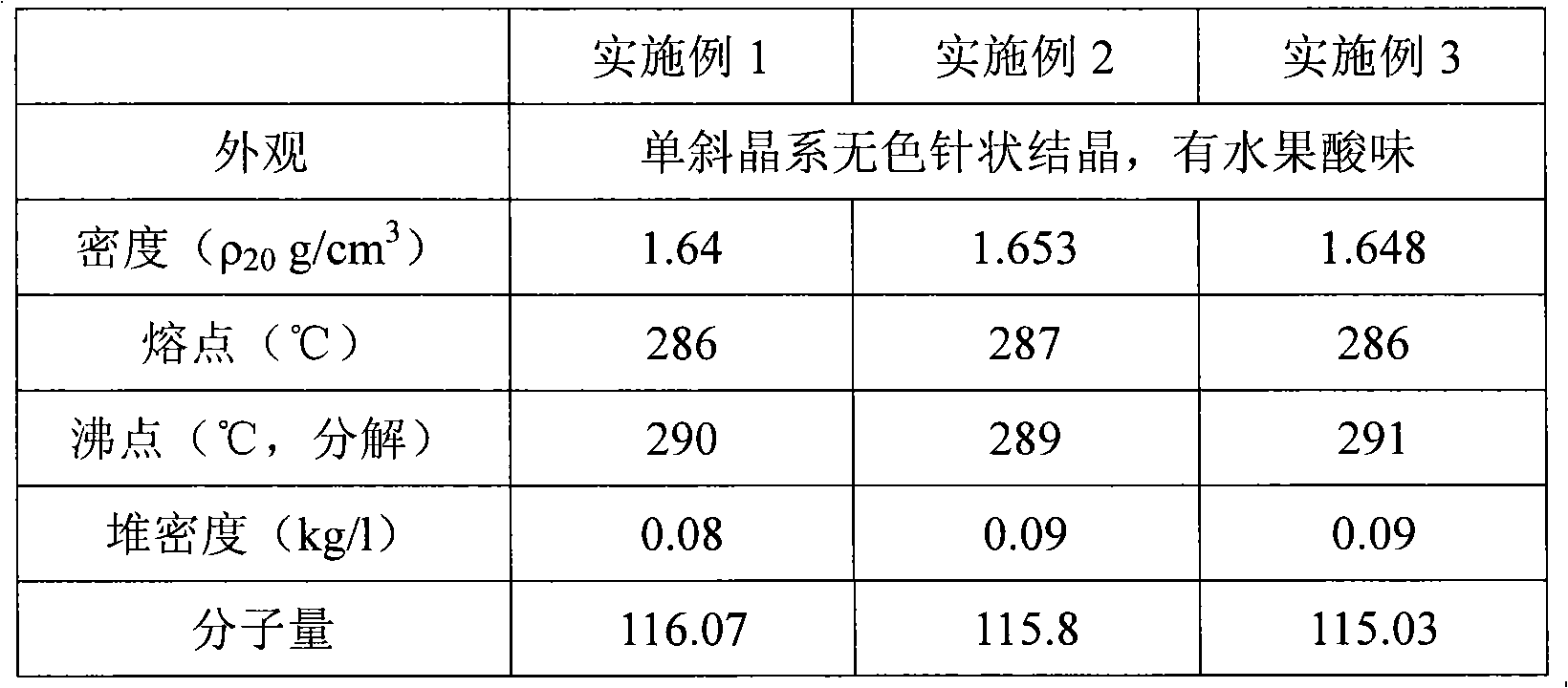

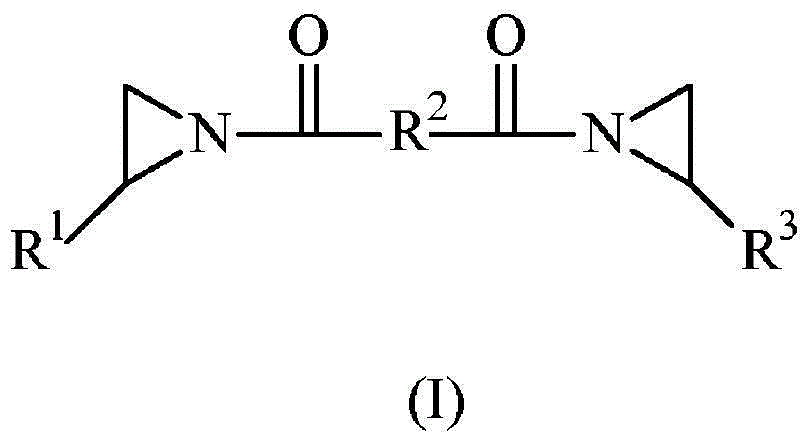

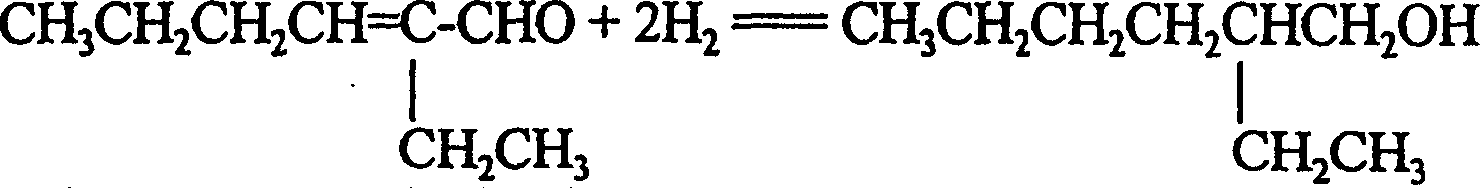

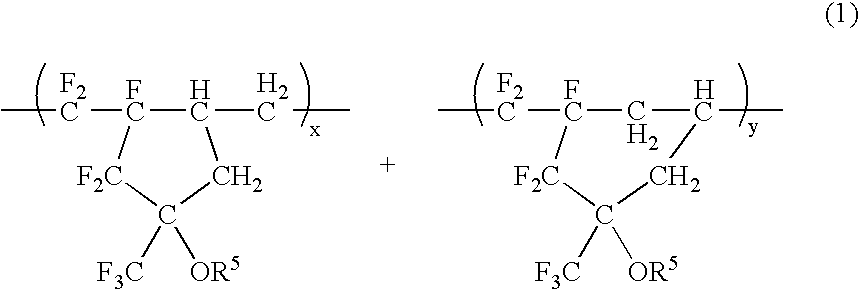

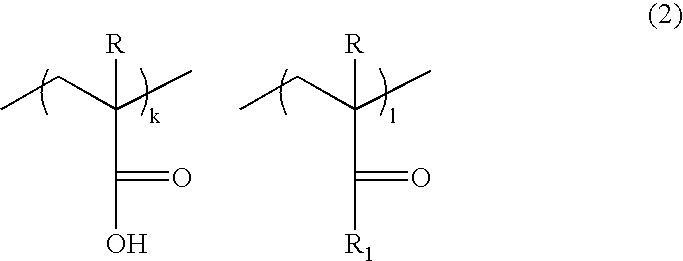

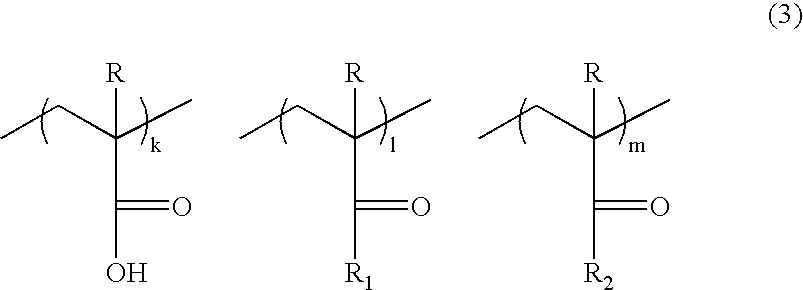

Method for synthesizing [(4-amino-3,5-dichloro-6-fluoro-2-pyridinyl)oxy]acetic acid by using one-pot method

The invention discloses a method for synthesizing [(4-amino-3,5-dichloro-6-fluoro-2-pyridinyl)oxy]acetic acid by using a one-pot method. The method comprises the following steps of: carrying out esterification reaction between glycolic acid and DL-2-Octanol under the action of a catalyst (I), subsequently feeding [(4-amino-3,5-dichloro-6-fluoro-2-pyridinyl)oxy]acetic acid, an acid-binding agent and a catalyst (II), heating and keeping the temperature till the condensation reaction is completely accomplished, and carrying out aftertreatment so as to obtain [(4-amino-3,5-dichloro-6-fluoro-2-pyridinyl)oxy]acetic acid. The method has the beneficial effects that firstly, the five main steps of the conventional preparation method are reduced to three steps, and the catalysts are introduced, so that the yield is kept be at a higher level, the raw material consumption is reduced, and the cost is lowered; secondly, the steps of separation and drying are canceled, so that the equipment consumption and the energy consumption are reduced, and no pyridol compounds which have serious pollution to the environment are generated, thereby being environmental-friendly; and thirdly, the preparation method is simple in process, simple and convenient to operate and high in yield, and is applicable to large-scale industrial production.

Owner:YONGNONG BIOSCI

Method for identifying wine country on basis of metabonomics research means

InactiveCN106770875AProduction areaThe detection method is accurate and simpleComponent separation2-OctanolMass chromatography

The invention discloses a method for identifying a wine country on the basis of a metabonomics research means, and belongs to the technical field of wine country identification. The method comprises the main steps of: (1) extracting a volatile component of a wine sample by utilizing a solid-phase micro extraction technology; (2) analyzing the volatile component of wine by utilizing a gas chromatography-mass spectrometry combined technology to obtain a reconstructed total ion chromatogram; (3) carrying out retrieval and analysis by NIST2014, WILEY8.0 spectrum library to obtain compound information corresponding to each peak, and representing relative content of each substance with a ratio of an area of each compound peak to an area of an internal labeled 2-octanol peak; (4) establishing PCA and OPLS-DA models by utilizing SIMCA13.0, and finding out different metabolism. The wine country tracing method disclosed by the invention is simple to preprocess, simple and convenient to operate, high in identification rate and beneficial to health development of the wine market.

Owner:JIANGNAN UNIV

Formula of promoter for binding cobalt salt, and preparation method

This invention relates to a method for preparing cobalt salt adherence accelerator, which can make cobalt salt product form a network molecular structure, thus improving the crosslinking acceleration performance of the product in rubber products. The cobalt salt adherence accelerator is composed of: 2-octanol solvent 30-50 parts, Co(OH)2 31.54-33.2 parts, decanoic acid 56-65 parts, mixed valeric acid 10-15 parts, and mixed acetic acid and propionic acid 5-8 parts. The method comprises: adding the raw materials into a reaction kettle, stirring, heating to 80-85 deg.C, reacting for 2 h, heating to remove water and solvent, and distilling at 170-190 deg.C and below 0.05 MPa to remove the trace solvent and unreacted materials.

Owner:JINSHENGDA CHEM TECH SHANDONG

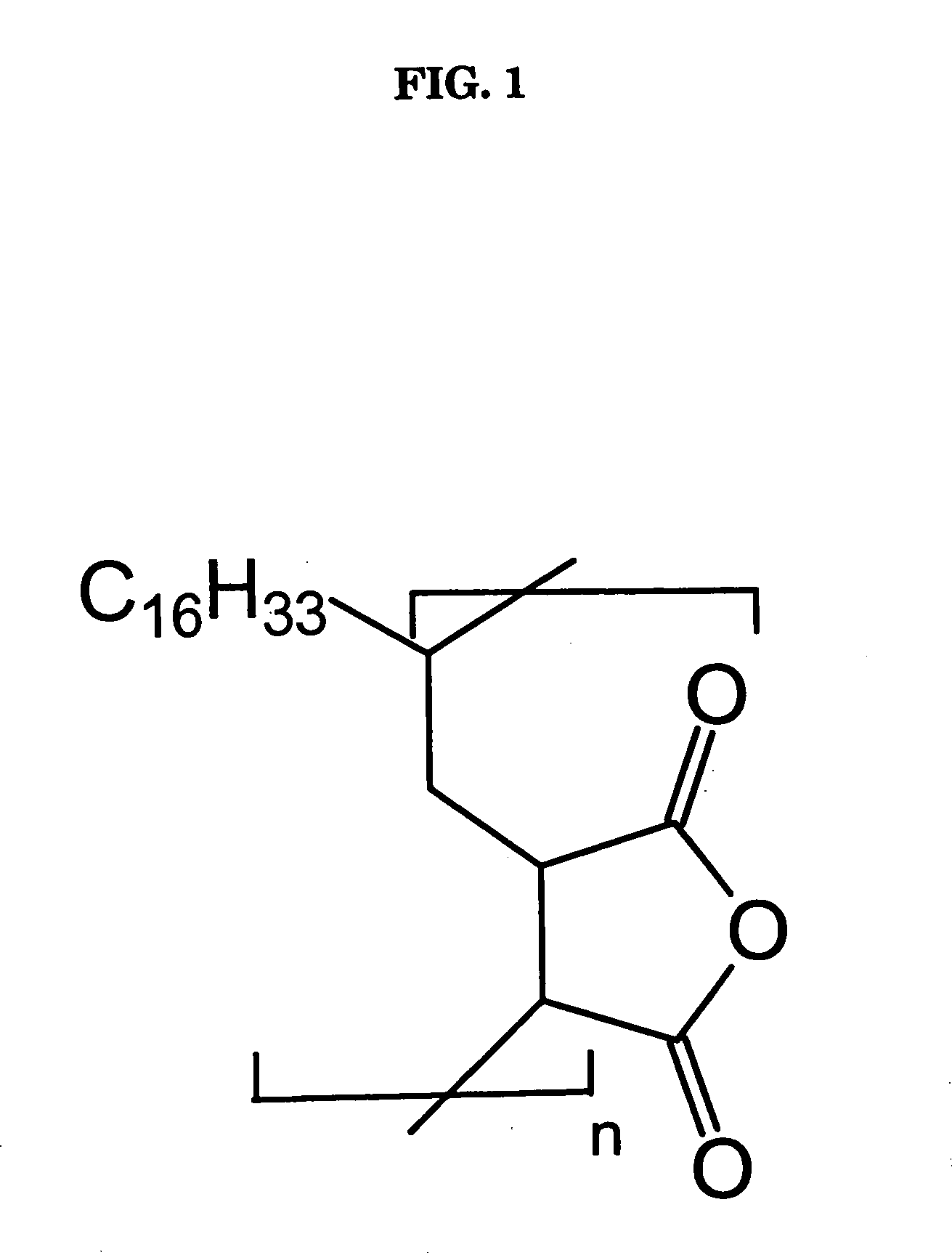

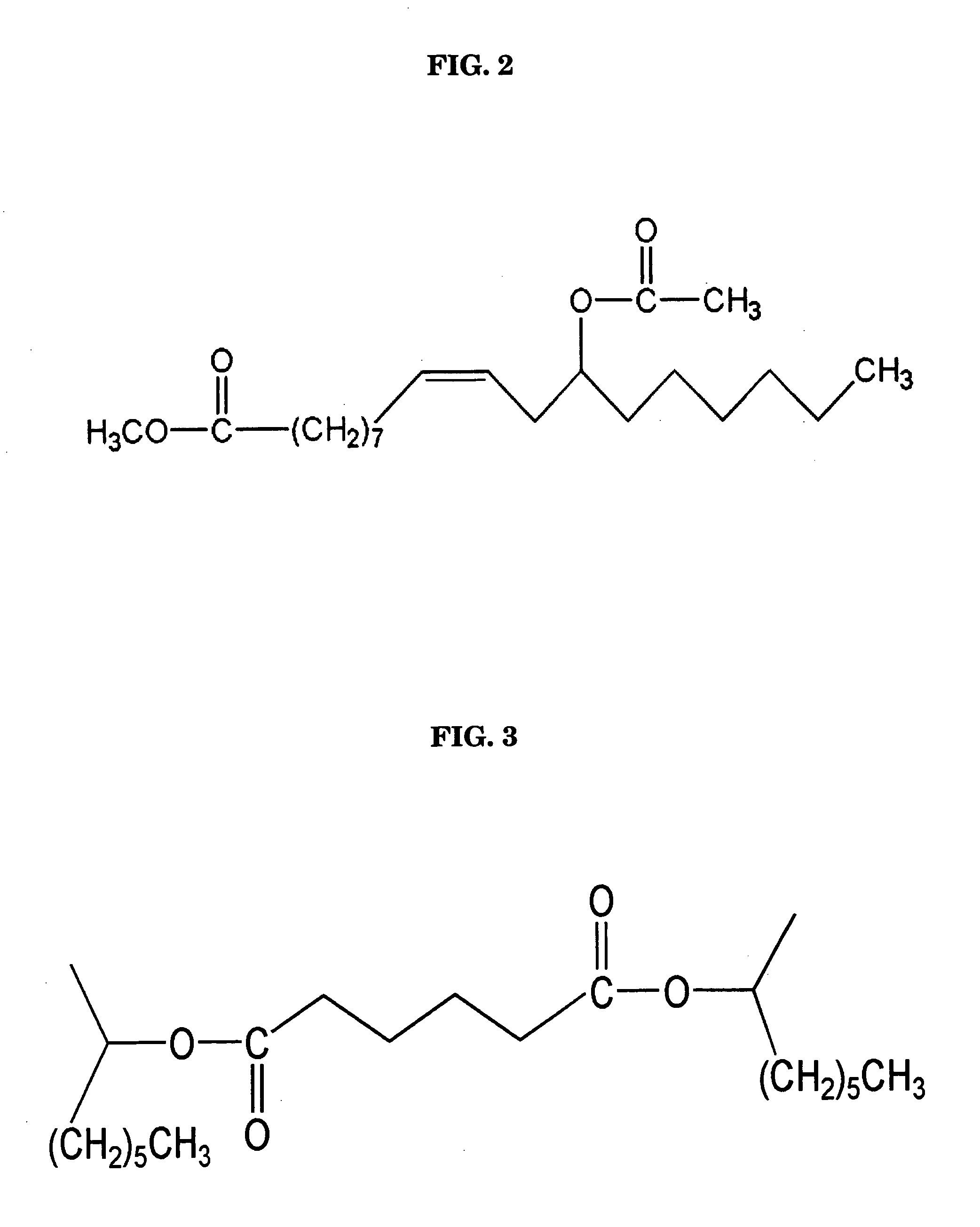

Delivery system for film-forming polymer

A film-forming composition formed by solubilizing higher concentrations of polyanhydride resins using a mixture of a fatty acid triglyceride derivative and a diester of 2-Octanol and Adipic Acid. In one embodiment, a composition in accordance with the invention comprises between about 1% and 55% by weight of Furandione (2,5)-Polymer with 1-Octadecene; between about 10% and 35% by weight of Dicapryl Adipate; and between about 10% and 35% by weight of Methyl Acetyl Ricinoleate. Such a composition may impart a water resistant property to oil-in-water and water-in-oil emulsions, and to anhydrous solid and semi-solid preparations, while remaining solubilized, stable and pourable at 25° C.

Owner:VERTELLUS PERFORMANCE MATERIALS

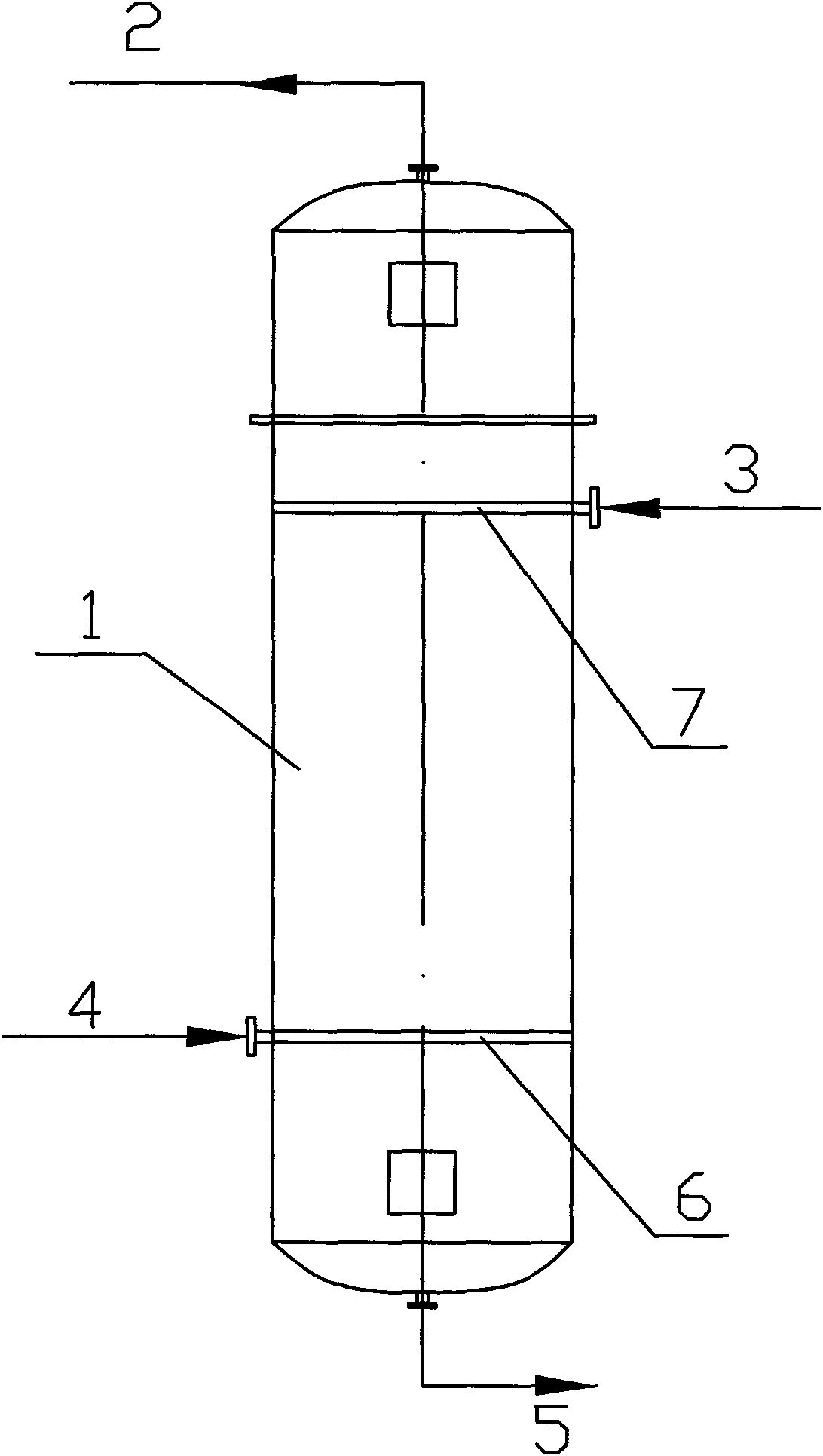

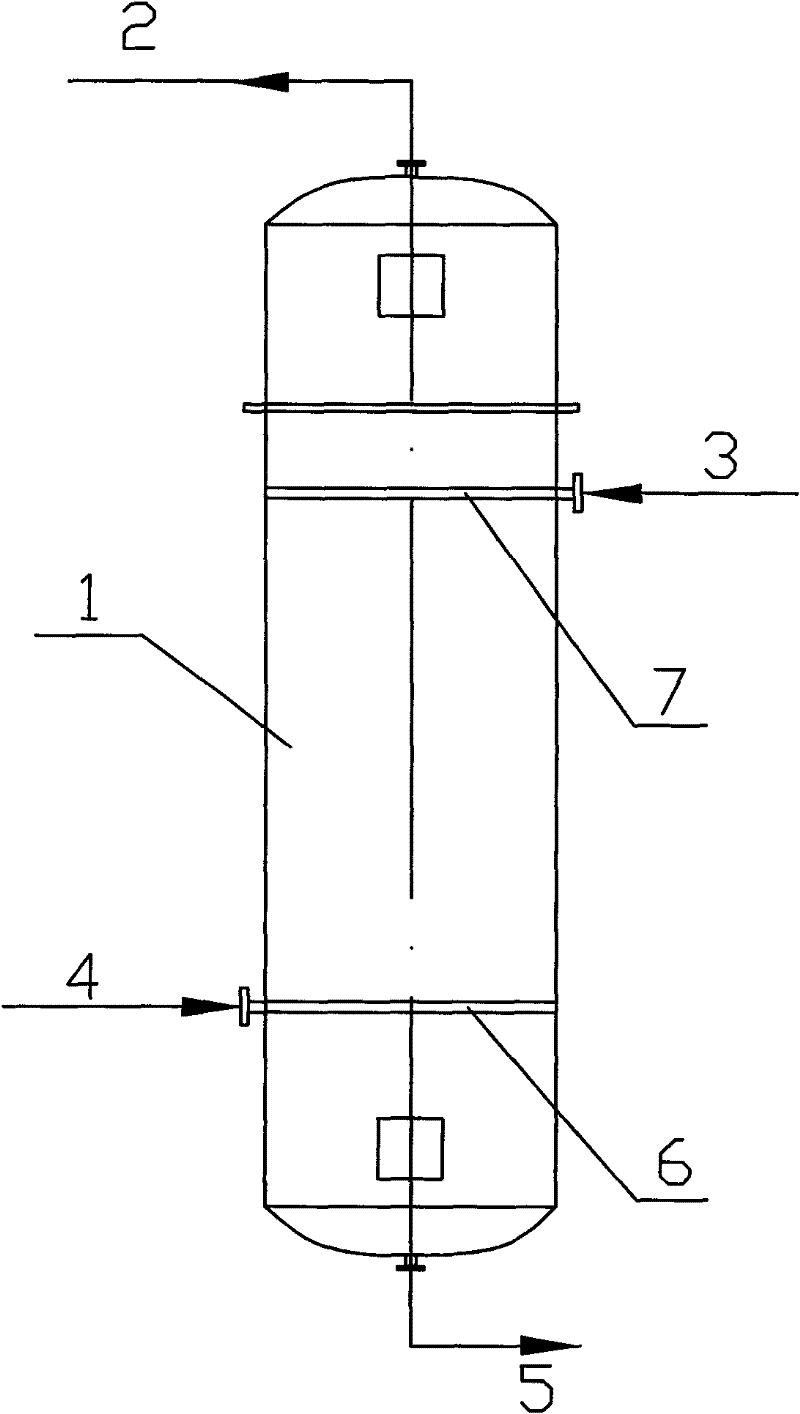

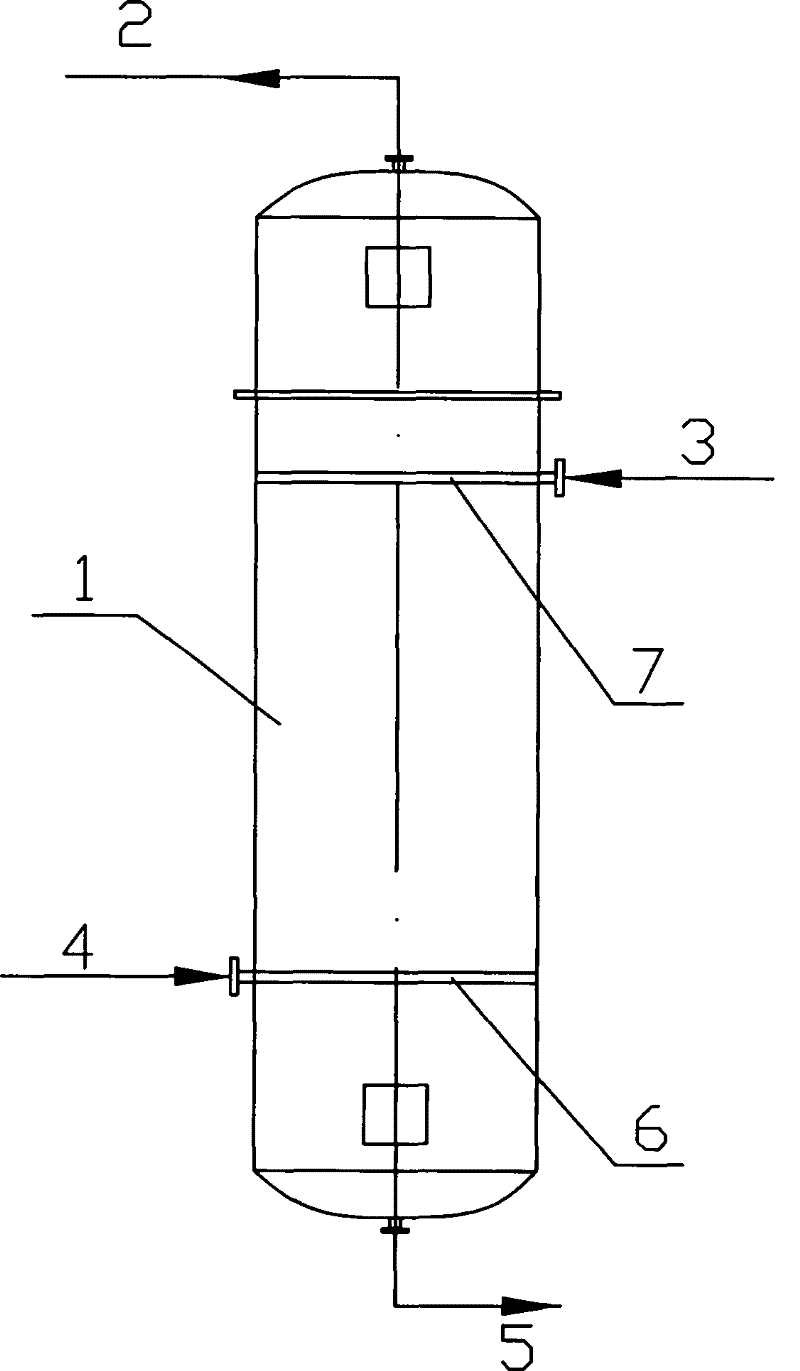

Method and device for preparing lincomycin hydrochloride

ActiveCN101624411AEfficient separationQuality improvementSugar derivativesAntiinfectives2-OctanolLincomycin Hydrochloride

The invention relates to a method and a device for preparing lincomycin hydrochloride. On the basis of the prior lincomycin hydrochloride production, repurifying processing procedure is added to prepare lincomycin hydrochloride with lincomycin B component less than or equal to 0.1 percent. The method is characterized by comprising the following steps: lincomycin hydrochloride with B component less than or equal to 1.0 percent is dissolved to have thetconcentration of 80000-100000 microgramme / ml, the pH value is adjusted to 10-11, extraction is carried out in extraction tower with 1 / 2-1 / 3 (weight ratio) of 2-octanol, the extraction temperature is 20-30 DEG C, the pH value of extraction liquid is adjusted to 2-4 by hydrochloric acid for back extraction, and acetone is used for crystallization. By adopting the method and the extraction tower device, the concentration of B component in lincomycin hydrochloride can be effectively reduced to be less than or equal to 0.1 percent, so that the quality of lincomycin hydrochloride is improved, and the yield is increased by 5-7 percent.

Owner:XINYU PHARM CO LTD

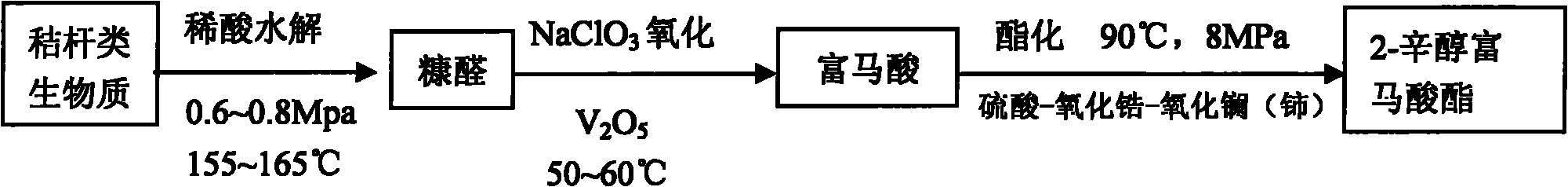

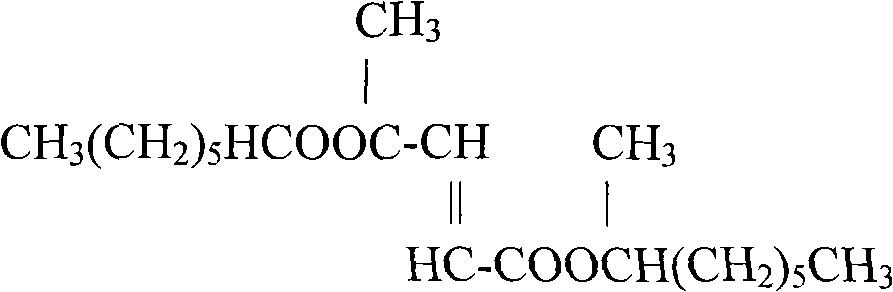

Method for preparing fumaric acid ester by using plant straws

InactiveCN101863765AHigh yieldHigh purityOrganic compound preparationCarboxylic acid esters preparationFumaropimaric acidPolyester

The invention discloses a method for preparing fumaric acid ester by using plant straws. The method comprises the following sequential steps: 1) leading the plant straws to carry out acid hydrolysis reaction so as to prepare furfural; 2) leading the furfural to carry out oxidation reaction so as to prepare fumaric acid; and 3) leading the fumaric acid and 2-octanol to carry out esterification reaction so as to prepare the fumaric acid ester. The 2-octanol fumaric acid ester prepared by the method not only is the main indispensable raw material for producing novel high-performance synthetic lubricating oil polyester oil, but also has high product purity and high yield; and in addition, the invention also opens up a new material resource and method for producing the 2-octanol fumaric acid ester, and provides a practical way for industrial production of the 2-octanol fumaric acid ester and the plant straws and comprehensive utilization of the plant straws.

Owner:北京雷恩新材料科技有限公司

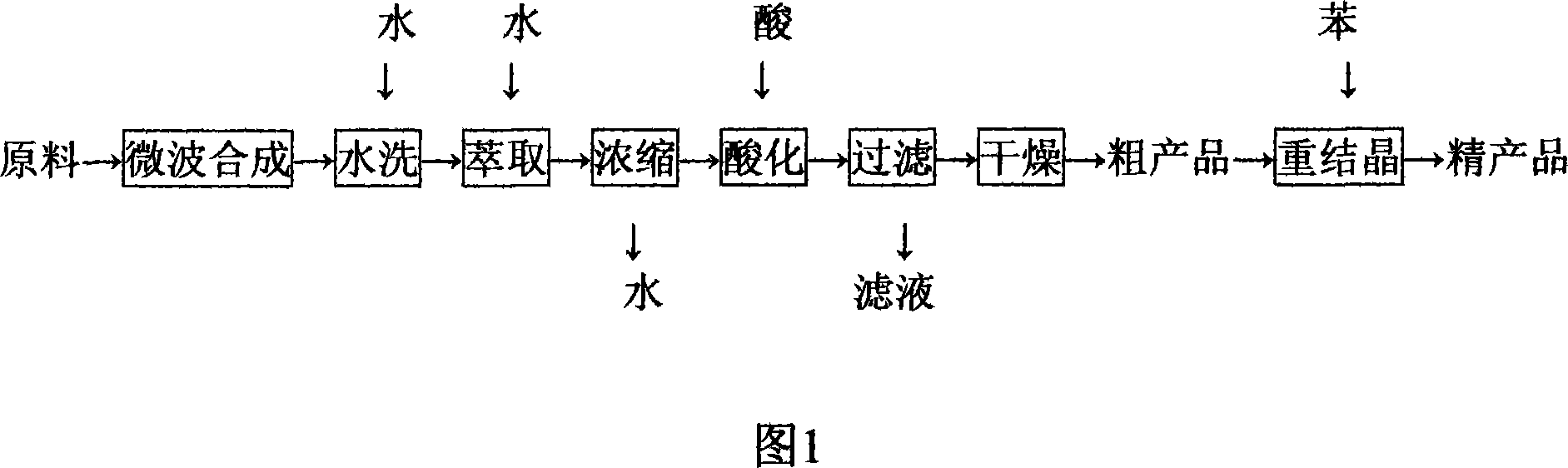

Method for preparing 10 - hydroxy capric acid

InactiveCN101092346ASave energyShort reaction timeOrganic compound preparationCarboxylic compound preparation2-OctanolCapric Acid

This invention discloses a method for synthesizing 10-hydroxyl capric acid. The method comprises: dropping a mixture of castor oil and 2-octanol into a mixed system of 2-octanol and alkali already subjected to microwave radiation, reacting at a high temperature, washing the product with water, extracting with water, acidifying, filtering, and separating to obtain 10-hydroxyl capric acid. The method utilizes microwave to synthesize 10-hydroxyl capric acid, and can selectively heat the target compound, thus has such advantages as high heating efficiency, low energy consumption, short reaction time, normal pressure reaction and high safety.

Owner:GUANGDONG IND TECHN COLLEGE

Treatment method for aluminum-containing waste sulfuric acid

ActiveCN109516443AImprove product qualitySolve the waste of resourcesSulfur-trioxide/sulfuric-acidAluminium sulfatesAluminium sulfate2-Octanol

The invention discloses a treatment method for aluminum-containing waste sulfuric acid. The treatment method comprises the following steps: removing impurities from aluminum-containing waste sulfuricacid, and then adding organic phases for performing multistage extraction on sulfuric acid, and separating, thereby acquiring sulfuric acid extract liquor and raffinate containing aluminum sulfate, wherein the organic phases include an extraction agent tri-iso-octylamine and a diluent 2-octanol; the sulfuric acid extract liquor is subjected to multistage back extraction, so as to acquire a sulfuric acid solution; water is taken as a back extraction agent. The resource recycling method adopts an extraction method for separating sulfuric acid from aluminum sulfate; the separation effect is thorough; the sulfuric acid solution is served as a back extraction phase and can be reused for production; the raffinate is a low-concentration aluminum sulfate solution which can be concentrated for preparing a water purifier aluminum sulfate; H2SO4 content is below 0.25%; aluminum content is 6.5-8%, counted by Al2O3; the product quality is stable; the treatment method can be widely used for treatingvarious domestic wastewater and printing and dyeing wastewater.

Owner:CHANGZHOU WUJIN YOUBANG WATER PURIFICATION MATERIALS

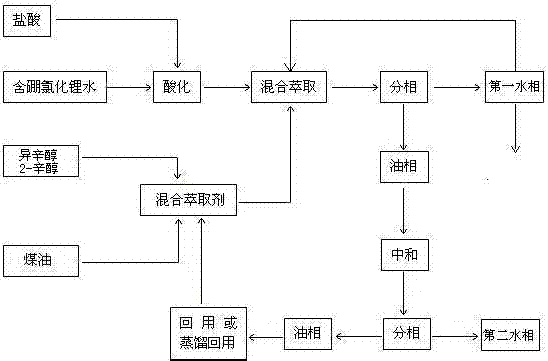

Extraction and boron removal method for lithium-containing brine

InactiveCN107459163AImprove solubilityEasy to separateWater contaminantsHydrocarbon distillation2-OctanolLithium chloride

The invention discloses an extraction and boron removal method for lithium-containing brine. The extraction and boron removal method comprises the following steps that 1, acidification is performed, wherein the pH value of a lithium chloride water solution containing boron is acidized to 1-3 by using hydrochloric acid; 2, mixing and extraction are performed, wherein isooctyl alcohol and 2-octanol are mixed according to the ratio of 10-18 to 1 to obtain an octanol mixed solution; the octanol mixed solution is mixed with kerosene to prepare a mixed extracting agent, the kerosene accounts for 30-70% of the total volume of the mixed extracting agent, and standing is performed for 1-3 hours after the acidized lithium chloride water solution containing boron and the mixed extracting agent are fully mixed; 3, phase splitting is performed, wherein a mixed liquid phase of the lithium chloride water solution containing boron and the mixed extracting agent is divided into an oil phase and a first water phase after standing; 4, recovery is performed, wherein the first water phase is guided out, the boron content is detected, the first water phase is re-guided back to the step 2 under the situation that the boron content exceeds the standard and serves as lithium chloride water containing boron to perform extraction, the operation is repeated till the boron content of the water phase is up to the standard. The lithium-containing brine can be extracted in a low-cost and efficient mode, treated waste water can be secondarily utilized, and environmental pollution can be reduced.

Owner:JIANGSU CHANGJILI NEW ENERGY TECH CO LTD

Method for preparing optical pure (R)-2-octanol by immobilized cell

InactiveCN101503711AGood physical and chemical stabilityToxic reductionMicroorganism based processesOn/in organic carrier2-OctanolSynthesis methods

The invention discloses a method for preparing high optical pure (R)-2-octanol by a microbiological method, and a microorganism thereof. An immobilized-cell synthesis method of the invention has the advantages that: 1, compared with free cells, immobilized cells can greatly improve the physical-chemical stability of enzyme, have excellent catalytic effect and can be repeatedly used; 2, the immobilized cells prepared from a polymeric membrane carrier are easy to separate from reaction products, and catalysts can be repeatedly used; 3, subsequent treatment is simple and convenient for continuous large-scale production; 4, as reaction is carried out in two phases of organic solvent / buffer solution, the toxic action of the organic solvent on the cells can be reduced, and the catalytic activity of the organic solvent is improved; 5, the preparation of the optical pure (R)-2-octanol through the immobilized yeast cells is simple in process, mild in condition, short in reaction time, nearly free from byproducts and up to 90.25 percent e.e. in optical purity; and 6, the method greatly reduces environmental pollution.

Owner:XIANGTAN UNIV

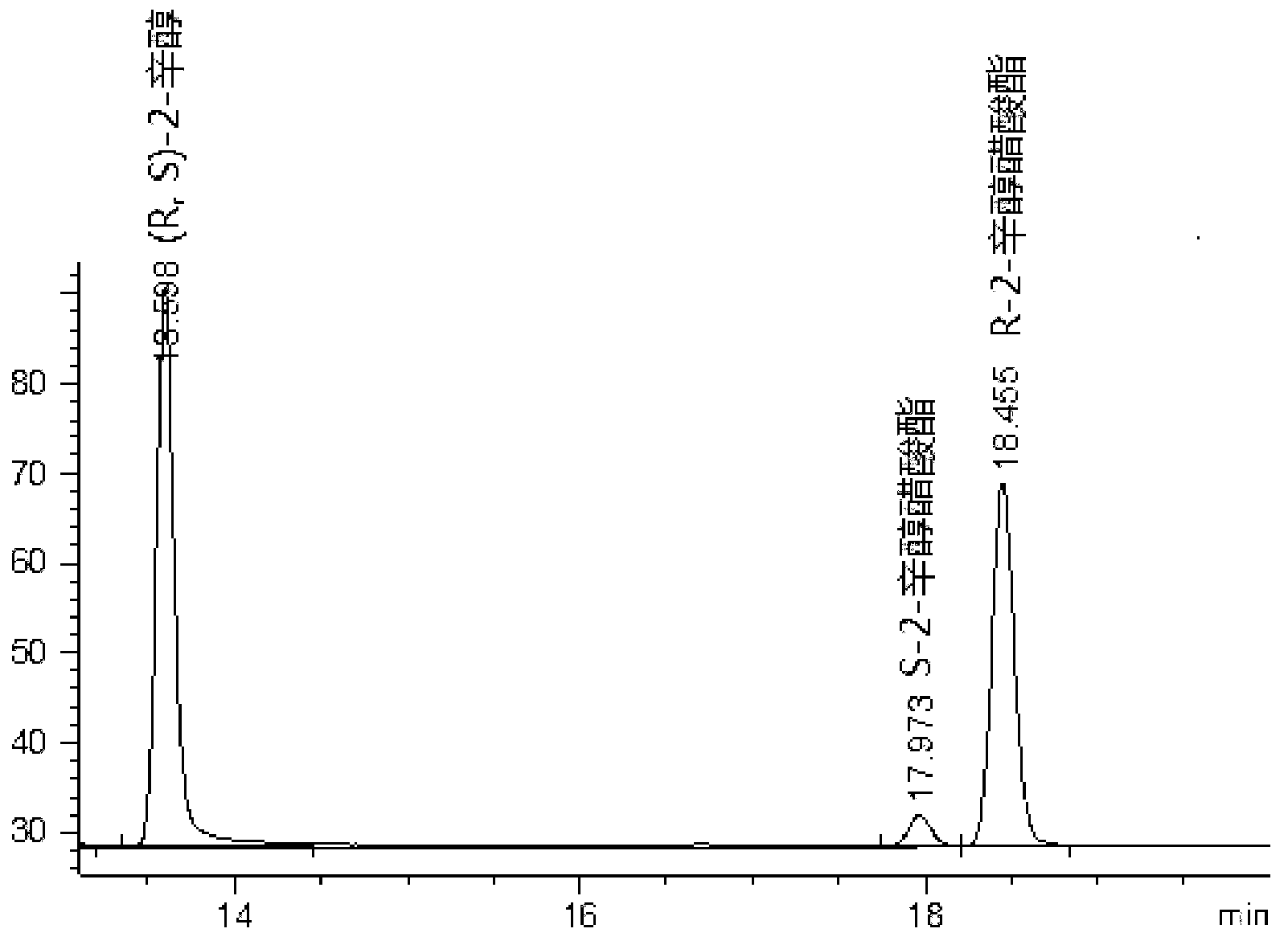

Method for splitting optically pure 2-octyl alcohol by adopting enzyme catalysis

The invention provides a novel method for preparing optically pure 2-octyl alcohol and multiple R-2-octyl alcohol esters by catalysis. The method provided by the invention comprises the following steps of: carrying out transesterification on racemization 2-octyl alcohol and ester or anhydride by utilizing extracellular lipase from Yarrowia lipolytica, and esterfying racemization 2-octyl alcohol and fatty acid to obtain S-2-octyl alcohol and R-2-octyl alcohol ester. The invention further relates to a method for preparing R-2-octyl alcohol by hydrolyzing R-2-octyl alcohol ester.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Method for preparing optical pure (R)-2-octanol by immobilized microorganism

InactiveCN101503712AToxic reductionEasy to separateChemical industryMicroorganism based processes2-OctanolSynthesis methods

The invention discloses a method for preparing high optical pure (R)-2-octanol by a microbiological method, and a microorganism thereof. An immobilized-cell synthesis method of the invention has the advantages that: 1, an immobilization process is simple, and immobilized yeast cells have certain poison resistance, have excellent catalytic effect and can be repeatedly used in a reaction system; 2, the immobilized cells prepared by taking non-polar macroporous absorbent resin as a carrier are good in elasticity, strong in tolerance to temperature and pH, high in mechanical strength, stable in enzyme activity and long in half-life period; 3, as reaction is carried out in two phases of organic solvent / buffer solution, the toxic action of the organic solvent on the cells can be reduced, and the catalytic activity of the organic solvent is improved; and 4, the preparation of the optical pure (R)-2-octanol through the immobilized yeast cells is simple in process, free from need for no expensive coenzyme, mild in condition, short in reaction time, nearly free from byproducts, up to 90.25 percent e.e. in optical purity, simple in subsequent treatment, easy in product separation and friendly to environment.

Owner:XIANGTAN UNIV

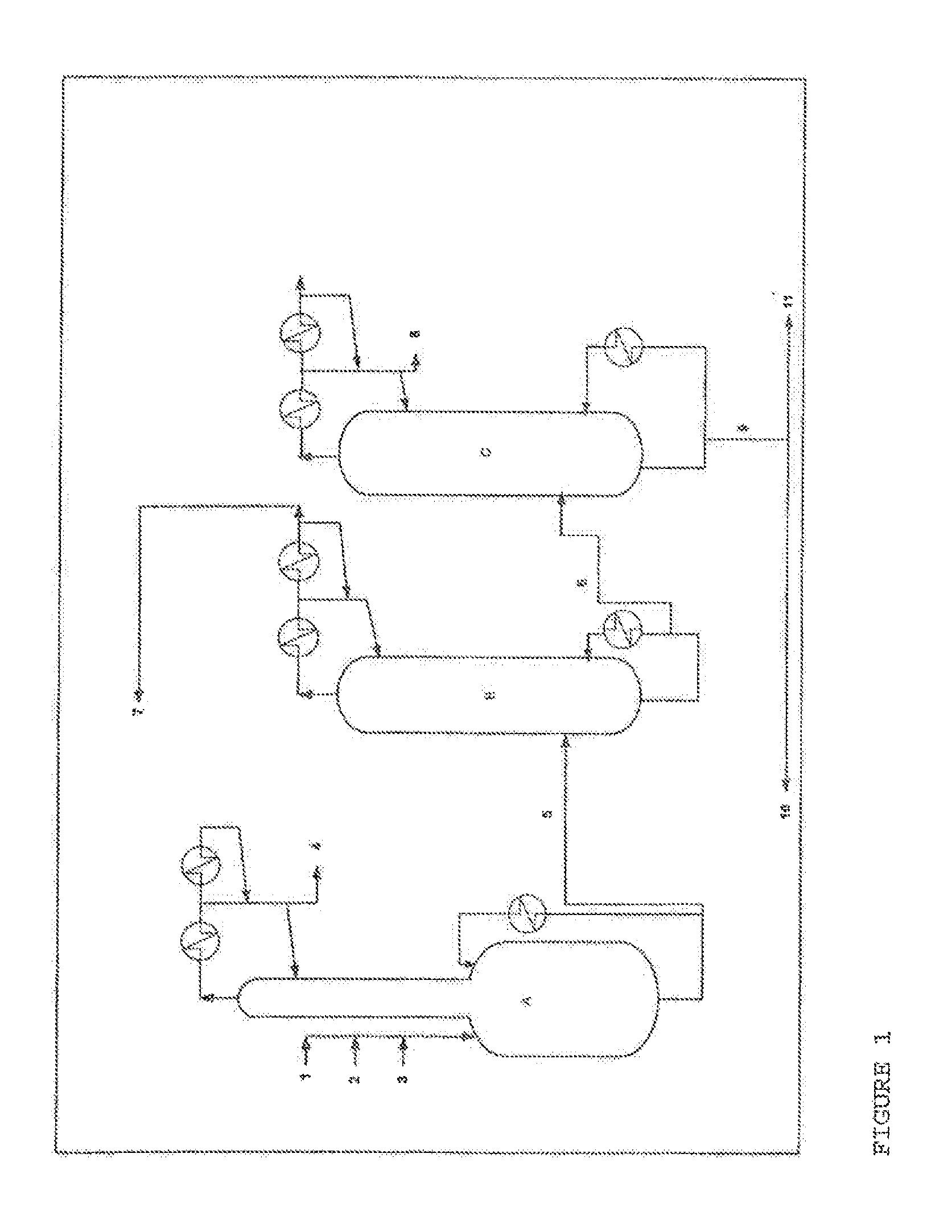

Method for the production of 2-octyl acrylate by means of transesterification

ActiveUS9018410B2Organic compound preparationPreparation by ester-hydroxy reaction2-OctanolTransesterification

The invention relates to the production of 2-octylacrylate of high purity and in good yield using ethyl titanate in solution in 2-octanol or 2-octyl titanate as a transesterification catalyst.

Owner:ARKEMA FRANCE SA

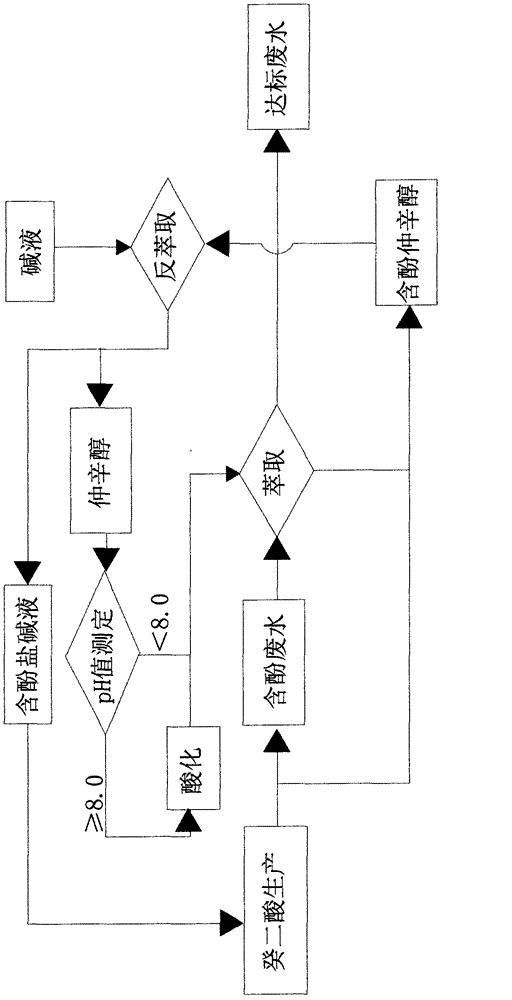

Waste water treatment process in sebacic acid production

InactiveCN102745760AReduce solubilityAvoid lostNature of treatment waterWater/sewage treatment by extraction2-OctanolWastewater

The invention relates to a waste water treatment process in sebacic acid production. The process comprises the following steps: adopting an extractant to extract phenol in waste water, separating the phenol-containing extracted solution and a raffinate, carrying out dephenolizing and reutilizing on the phenol-containing extracted solution, and discharging the raffinate, wherein DL-2-octanol is adopted as the extractant to extract the phenol-containing waste water in sebacic acid production in the extraction process. The process of the present invention has the following advantages that: 1, the phenol content in the sebacic acid production waste water is significantly reduced, and the waste water after the extraction can meet the discharge standard; 2, with the extractant DL-2-octanol, an internal circulation of the production system is realized; and 3, the DL-2-octanol is the by-product of the sebacic acid production process, such that advantages of easily available DL-2-octanol, low cost and low operation cost are provided for sebacic acid production enterprises.

Owner:HEBEI CASDA BIOMATERIALS

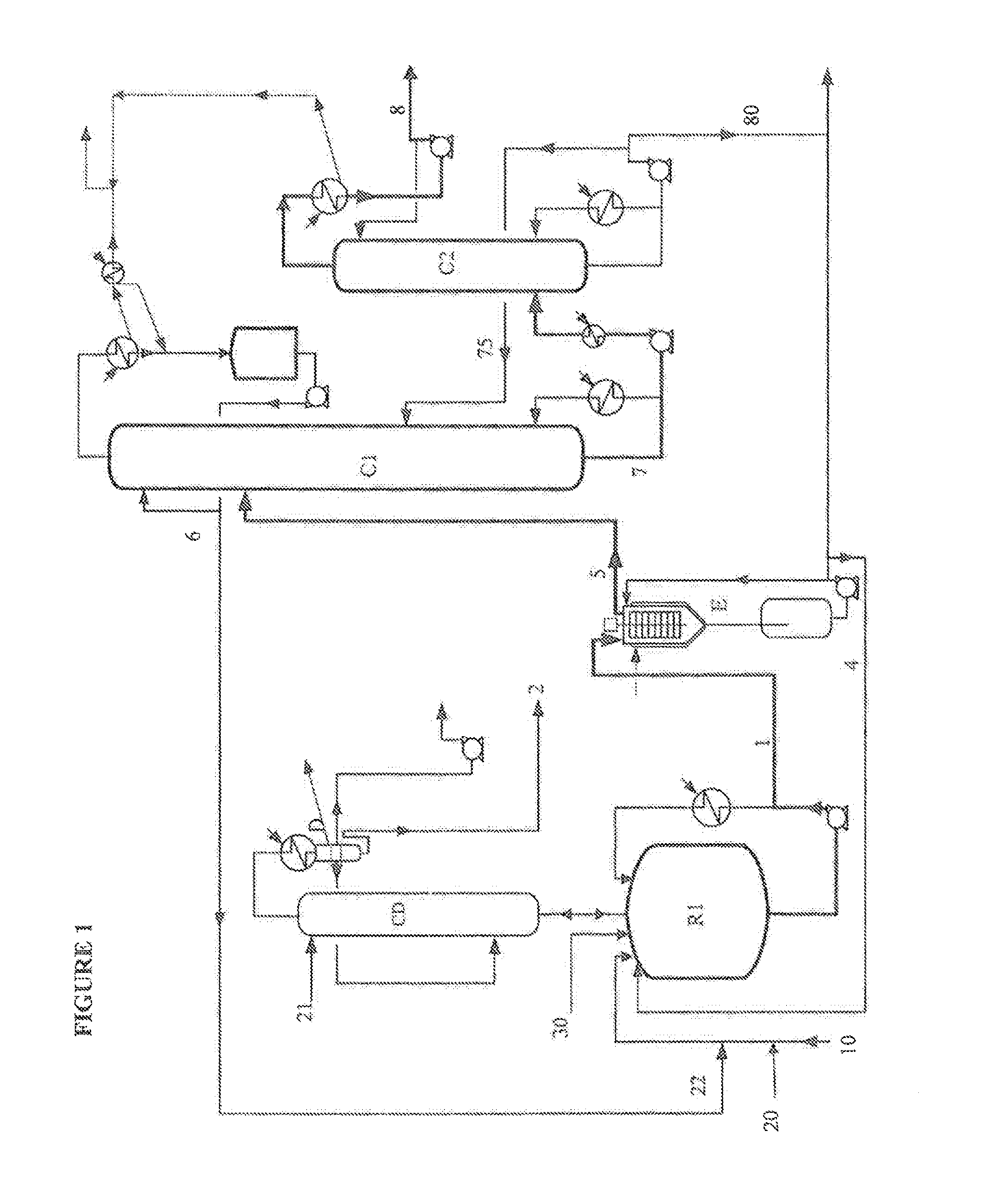

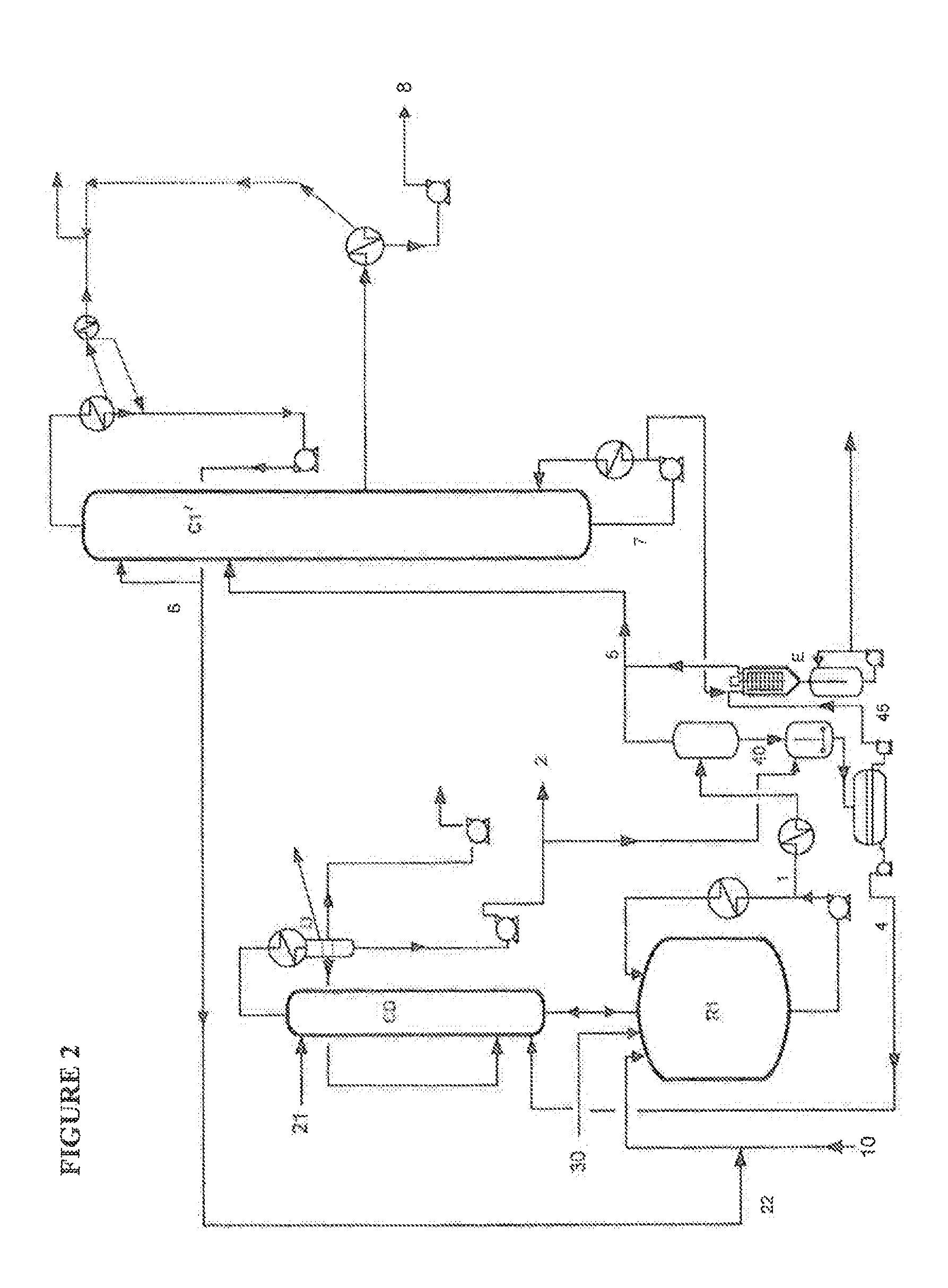

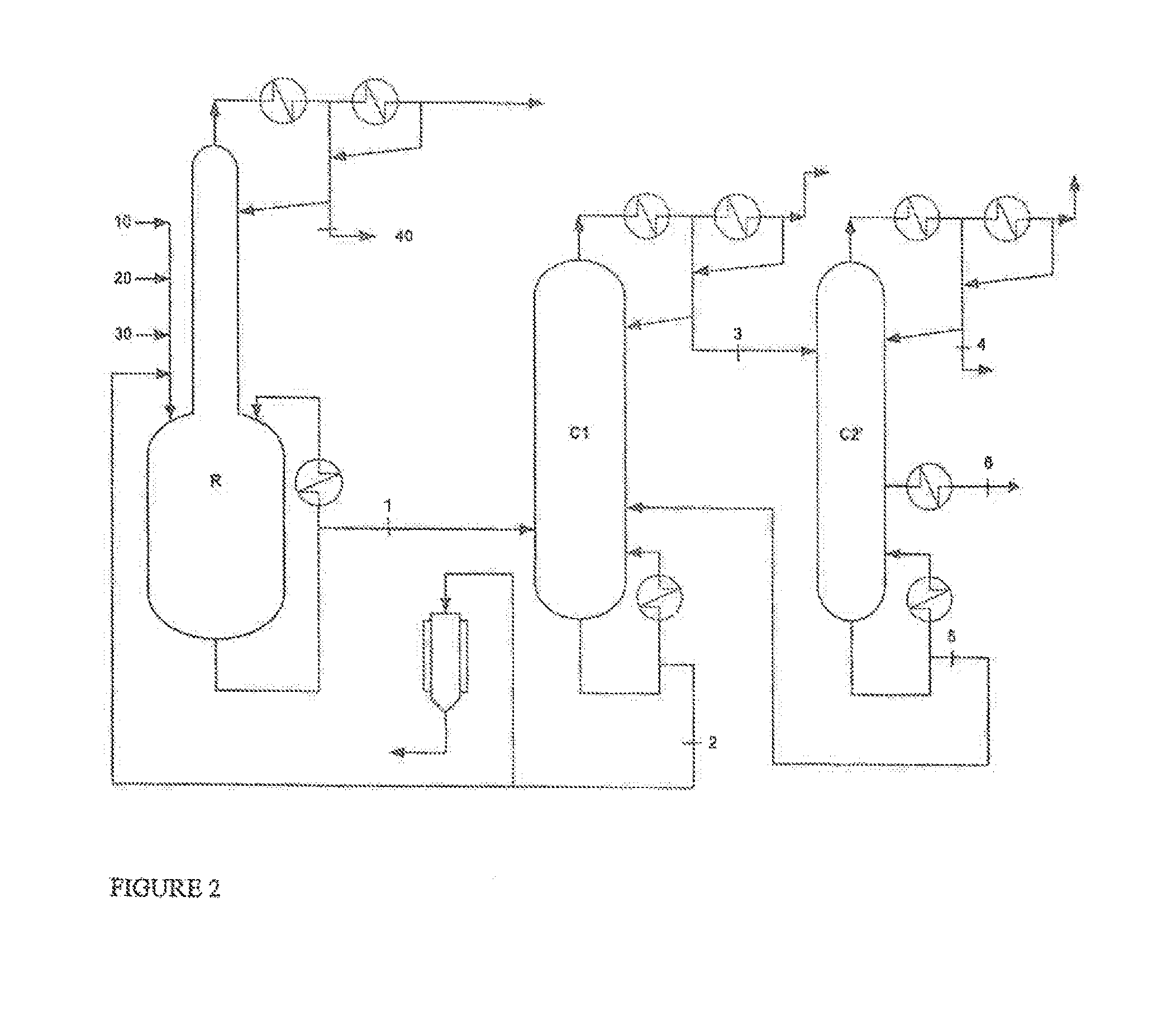

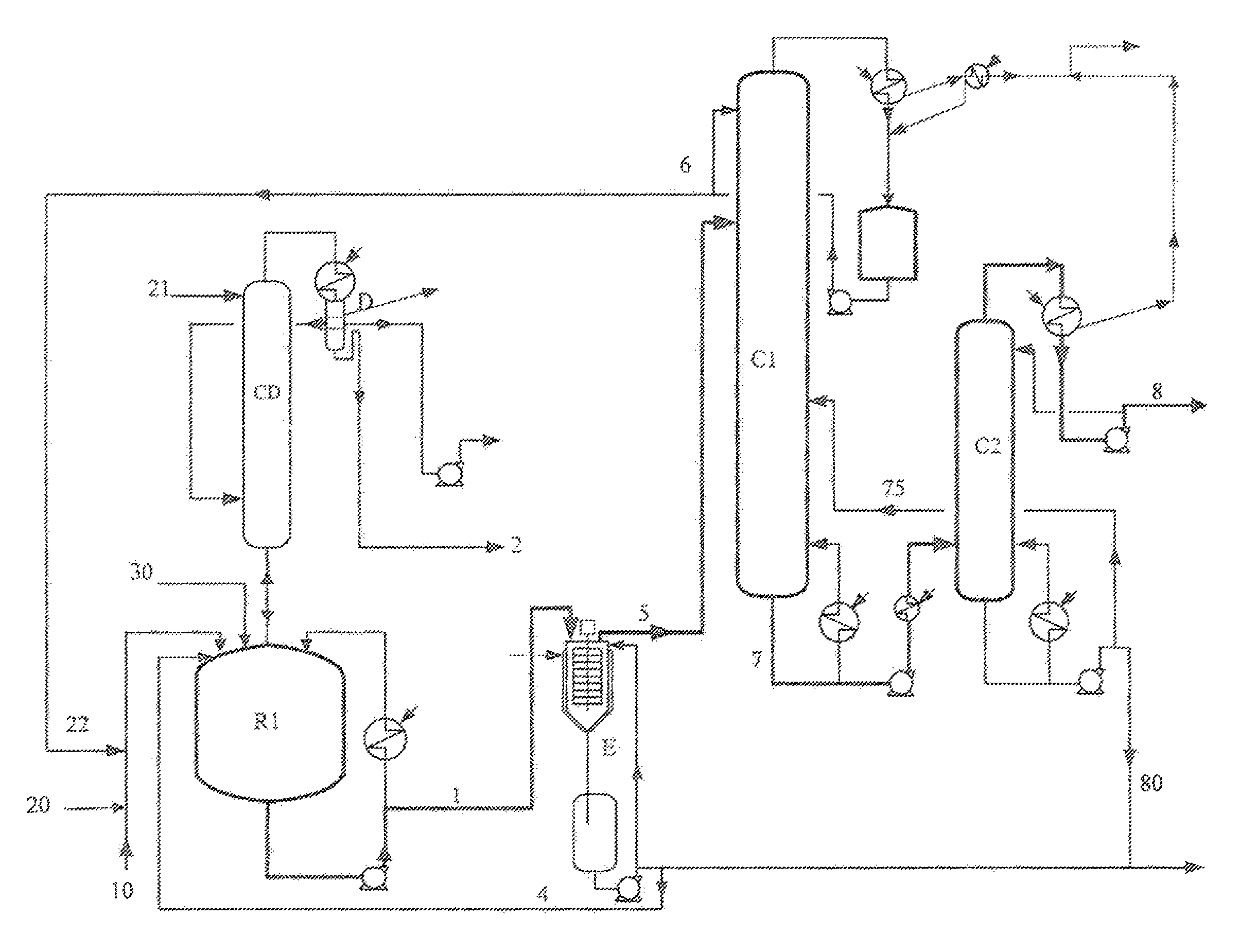

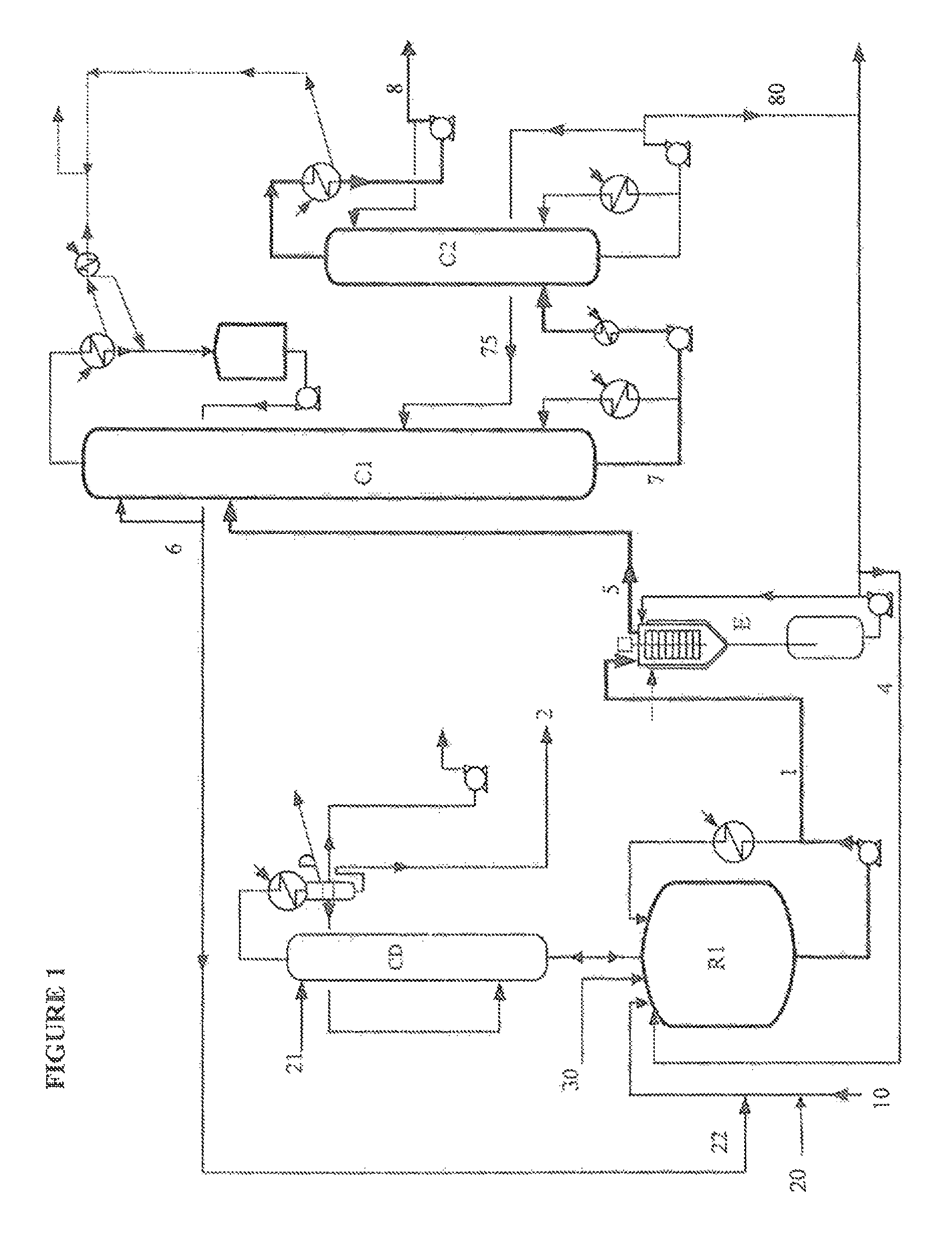

Method for producing 2-octyl acrylate by direct esterification

ActiveUS20150299093A1Organic compound preparationCarboxylic acid esters separation/purification2-OctanolDistillation

The invention relates to a process for continuously producing 2-octyl acrylate by reacting acrylic acid and 2-octanol in the presence of a sulfonic acid esterification catalyst and at least one polymerization inhibitor. The water formed by the esterification reaction is entrained by distillation in a column surmounting the reactor in the form of a heteroazeotropic mixture with the 2-octanol which is then subjected, after condensation, to separation in a decanter so as to give an upper organic phase and a lower aqueous phase. The reaction mixture containing the reaction product and residual by-products are purified by separation means in order to obtain: (1) pure 2-octyl acrylate and (2) unreacted 2-octanol and acrylic acid compounds that will be recycled along with the catalyst.

Owner:ARKEMA FRANCE SA

Prepn process of fluoride and nano composite fluoride particle

InactiveCN1169709CEvenly distributedFluoride preparationCalcium/strontium/barium fluorides2-OctanolRoom temperature

By means of reverse micelle process, nanometer LiBaF3, BaF2, SrF2, CaF2 and BaF2:Ce particles are prepared in a cetyl trimethyl ammonium bromide-2-octanol-water microemulsion system. In the system, the ratio between cetyl trimethyl ammonium bromide and 2-octanol is 1 to 4-6, water content is 9.04-14.2 wt%. The material weight ratio between M(NO3)2 and NH4F is 1 to 1.5-2.5, where M is Ca, Sr and Ba; and that among Ba(NO3), LiNo3 and NH4F is 1 to 1-2 to 1-4. The reaction time at room temperature is 5-15 min. The process of the present invention can prepare nano particle with homogeneously distributed size smaller than 100 nm.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

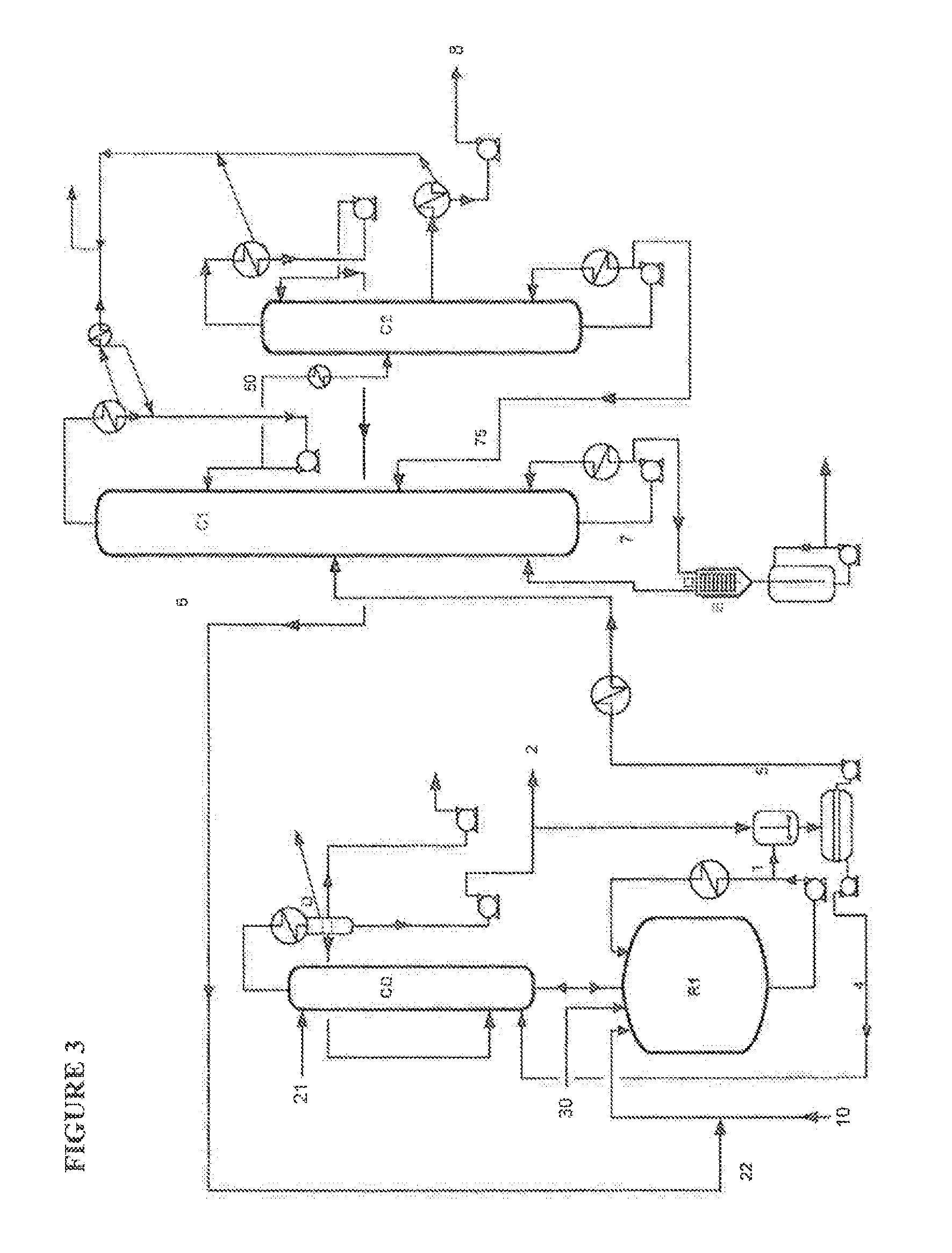

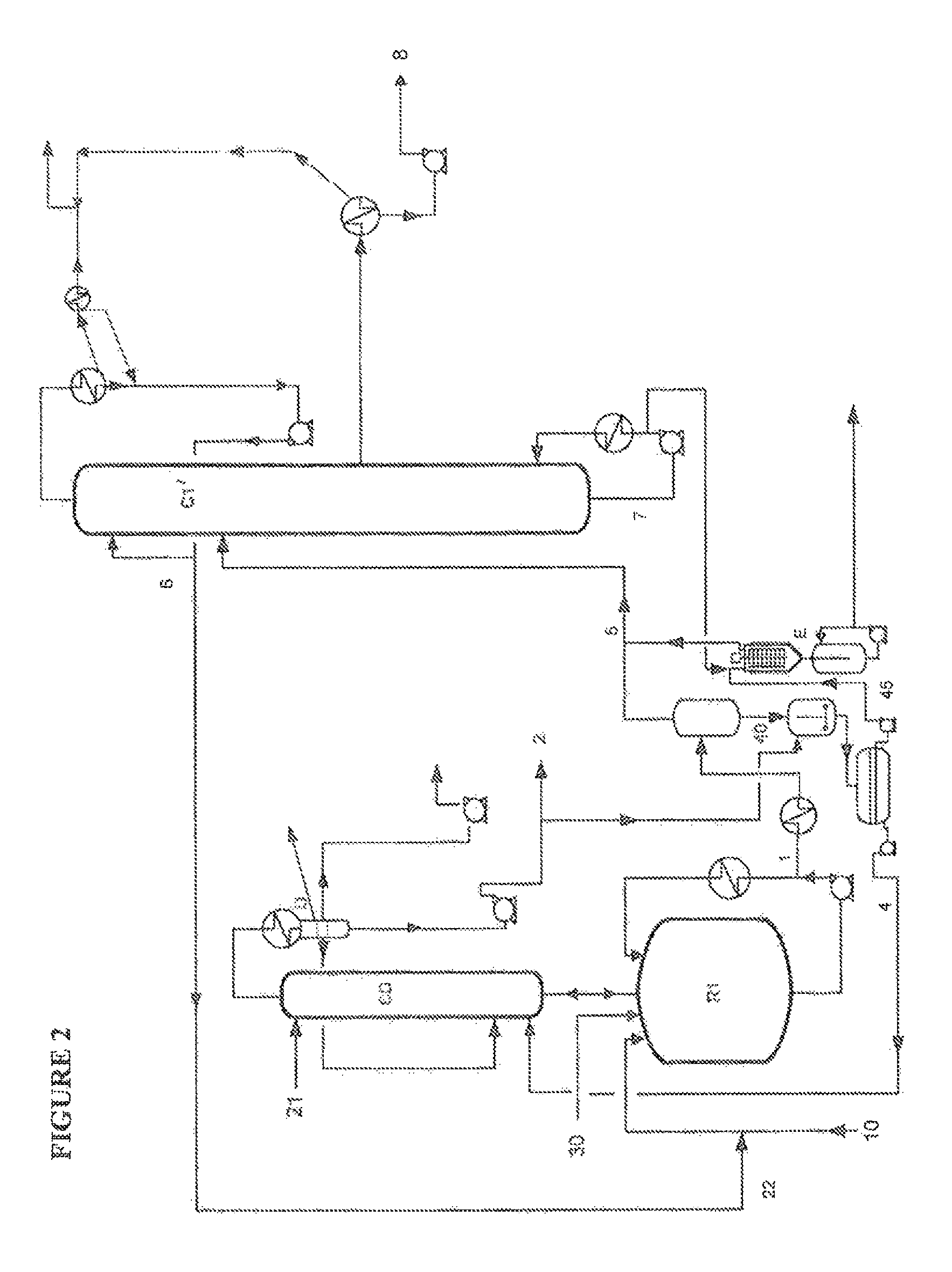

Method for the production of 2-octyl acrylate by means of transesterification

ActiveUS20150203436A1Preparation by ester-hydroxy reactionOrganic compound preparation2-OctanolTransesterification

The invention relates to the industrial production of 2-octyl acrylate of very high purity and with a high yield, using a continuous transesterification process. The method of the invention uses ethyl titanate in solution in 2-octanol or 2-octyl titanate as a transesterification catalyst, and employs a purification train comprising two distillation columns.

Owner:ARKEMA FRANCE SA

Selective synthesis of 2-octyl acrylate by acid catalyzed esterification of 2-octanol and acrylic acid

InactiveCN105073704AContribute to the rateOrganic compound preparationCarboxylic acid esters preparation2-OctanolAcid catalyzed

A method of making 2-octyl acrylate comprising reacting 2-octanol with acrylic acid in the presence of an acid catalyst and added water is described. The 2-octanol may be derived from renewable resources, such as castor oil. The method is efficient and provides selectivity for 2-octyl acrylate.

Owner:3M INNOVATIVE PROPERTIES CO

Technology of hydrogenatioin to produce iso octanol using iso octaldehyde mixture and its catalyst

InactiveCN1268595CImprove pore structureReasonable hole distributionCatalyst activation/preparationPreparation by oxygen reduction2-OctanolAlcohol

A process and catalyst for preparing isooctanol by liquid-phase hydrogenation of the mixture of isooctanal and octylene alcohol is disclosed. Said catalyst is prepared from metallic Ni, alkali-earth metal oxide and / or alumina, and Si-contained compound as carrier through code position of Ni and carrier, kneading, and calcining at 300-800 deg.C. Its advantages are good porous structure, and high strength, hydrogenating activity, and output rate of isooctanol.

Owner:CHINA PETROLEUM & CHEM CORP

Solvent For Cleaning Semiconductor Manufacturing Apparatus

InactiveUS20080132740A1Easy to cleanHigh transparencyOrganic compound preparationDetergent mixture composition preparation2-OctanolIsobutyl alcohol

A cleaning solvent is disclosed for removing residual resin compositions. The cleaning solvent contains at least an alcohol solvent having a boiling point of at least 100° C. The alcohol solvent having a boiling point of at least 100° C. is preferably constituted of at least one solvent selected from n-butyl alcohol, isobutyl alcohol, n-pentanol, 4-methyl-2-pentanol, and 2-octanol. It is more preferable that the alcohol solvent is an isobutyl alcohol.

Owner:TOKYO OHKA KOGYO CO LTD

Method for the production of 2-octyl acrylate by means of transesterification

ActiveUS20140371482A1Preparation by ester-hydroxy reactionOrganic compound preparation2-OctanolTransesterification

The invention relates to the production of 2-octylacrylate of high purity and in good yield using ethyl titanate in solution in 2-octanol or 2-octyl titanate as a transesterification catalyst.

Owner:ARKEMA FRANCE SA

Method for preparing lincomycin hydrochloride

ActiveCN101624411BEfficient separationQuality improvementSugar derivativesAntiinfectives2-OctanolLincomycin Hydrochloride

Owner:XINYU PHARM CO LTD

Method for producing 2-octyl acrylate by direct esterification

ActiveUS9403750B2Organic compound preparationCarboxylic acid esters separation/purification2-OctanolDistillation

Owner:ARKEMA FRANCE SA

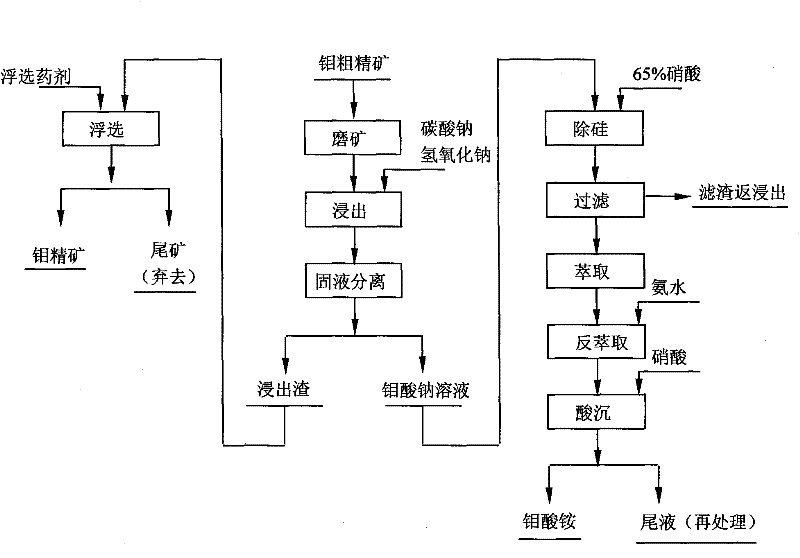

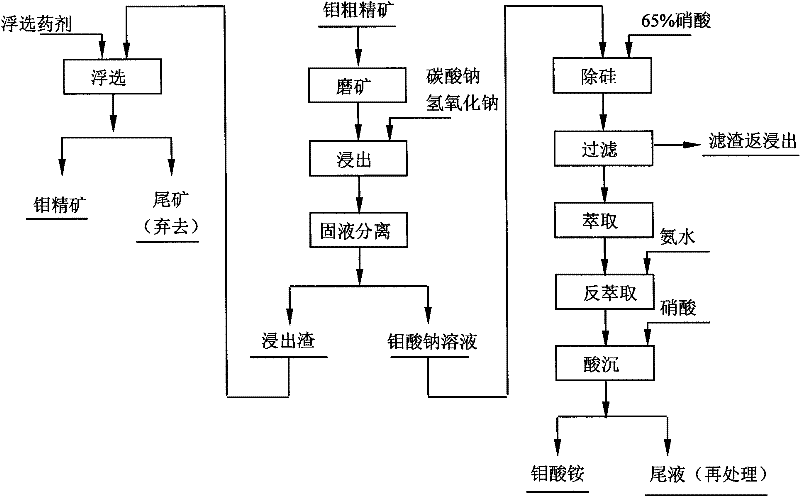

Processing for recovering low-grade molybdenum oxide concentrate through wet process

The invention relates to a processing for recovering low-grade molybdenum oxide concentrate through a wet process, belonging to the technical field of metallurgy. The process comprises the following steps: 1) grinding molybdenum rough concentrate, then adding sodium carbonate for leaching sodium hydroxide medicament, and carrying out solid-liquid separation on the concentrate slurry after leaching to obtain a sodium molybdate solution and leached slag; 2) carrying out flotation on the leached slag to prepare molybdenum concentrate; and 3) preparing ammonium molybdate by utilizing the solution of sodium molybdate: adding acid into the sodium molybdate solution to regulate the pH value to be 5-7, heating to 65-70 DEG C, filtering for removing silicon, extracting the filtered solution with the mixed solvent of N235, 2-octanol and kerosene, taking organic phases, adding ammonia water for back extraction to obtain an ammonium molybdate solution, and carrying out acid precipitation on the ammonium molybdate solution to obtain ammonium molybdate products. The scheme realizes the purpose of preparing two types of products by using one process and is used for processing the molybdenum oxide rough concentrate of which the molybdenum oxidation rate is 50-90% and the molybdenum grade is 5-35% to obtain the ammonium molybdate products of which the purity is greater than 56% and the molybdenum concentrate of which the grade is greater than 40%, and the recovery rate of molybdenum in the whole process is 80-96%.

Owner:LINGBAO CITY JINYUAN MINING

A kind of preparation method of dimethyl heptyl methylphosphonate

ActiveCN106749397BStable in natureEasy to storeGroup 5/15 element organic compounds2-OctanolMethylphosphinic acid

Owner:XIAN ORIGIN CHEM TECH

Continuous esterification production method of di-sec-octyl phthalate

ActiveCN101891620BImprove quality and efficiencyIncrease productivityOrganic compound preparationCarboxylic acid esters preparation2-OctanolAcid value

The invention discloses a continuous esterification production method of di-sec-octyl phthalate. The method comprises the following steps: using phthalic anhydride and 2-octanol to perform an esterification reaction under the existence of catalyst and obtain raw ester, and post-processing raw ester to obtain the product di-sec-octyl phthalate, wherein the esterification reaction is a multistage esterification reaction that phthalic anhydride and 2-octanol perform a plurality of esterification continuously. The esterification reaction of the invention adopts the production method of continuous esterification, the esterification reaction is complete, the conversion rate is high, the acid value of the product is low and the purity is high; and the time of esterification is short, the energy consumption is low, the product quality is stable, and the quality and production efficiency of di-sec-octyl phthalate can be effectively increased.

Owner:WEIFANG YUANLI CHEM

Process for preparing optical pure (S)-2-octanol by microorganism and its special microorganism

The invention is a method for preparing optically pure (S)-2-n-octyl alcohol by microbial method and its special microbe, screening and obtaining bacterial strain Pseudomonas maltophiliaSYB-4, CTCC M204042.It uses the bacterial strain to make cultivation and full-cell preparation, uses racemic2-n-octyl alcohol as substrate to make catalytic conversion reaction on microbe cell, and obtain a product (S)-2-n-octyl alcohol by nonsymmetrical conversion of the racemic2-n-octyl alcohol, where the optical purity of the product reaches above 80%e.e. The invention determines a reacting system and reacting conditions of full-cell nonsymmetrical conversion of racemic2-n-octyl alcohol for the bacterial strain, increasing the optical purity of the product.

Owner:JIANGNAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

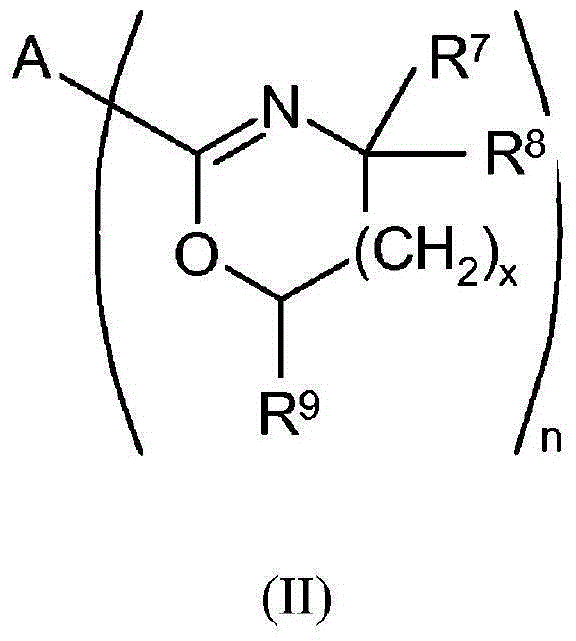

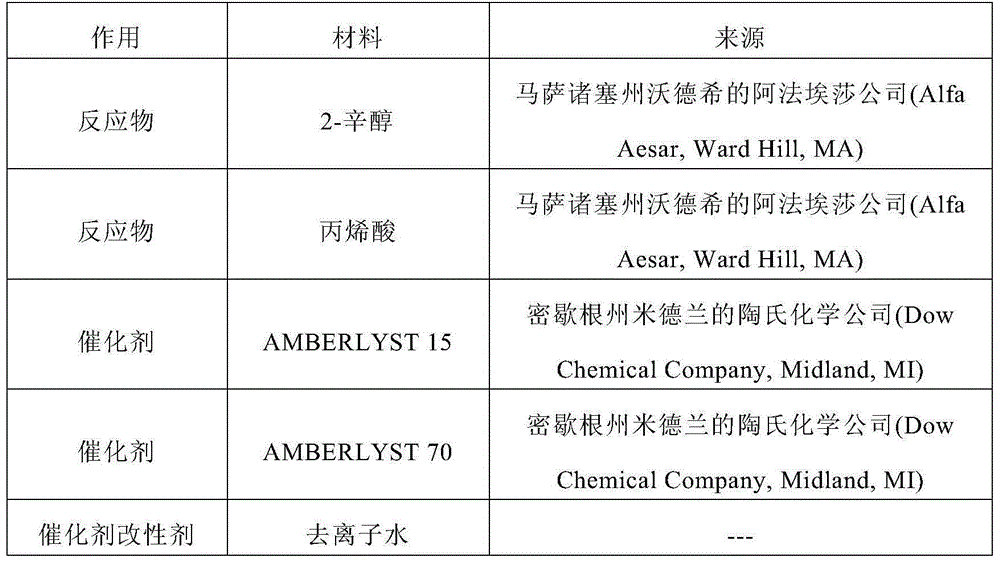

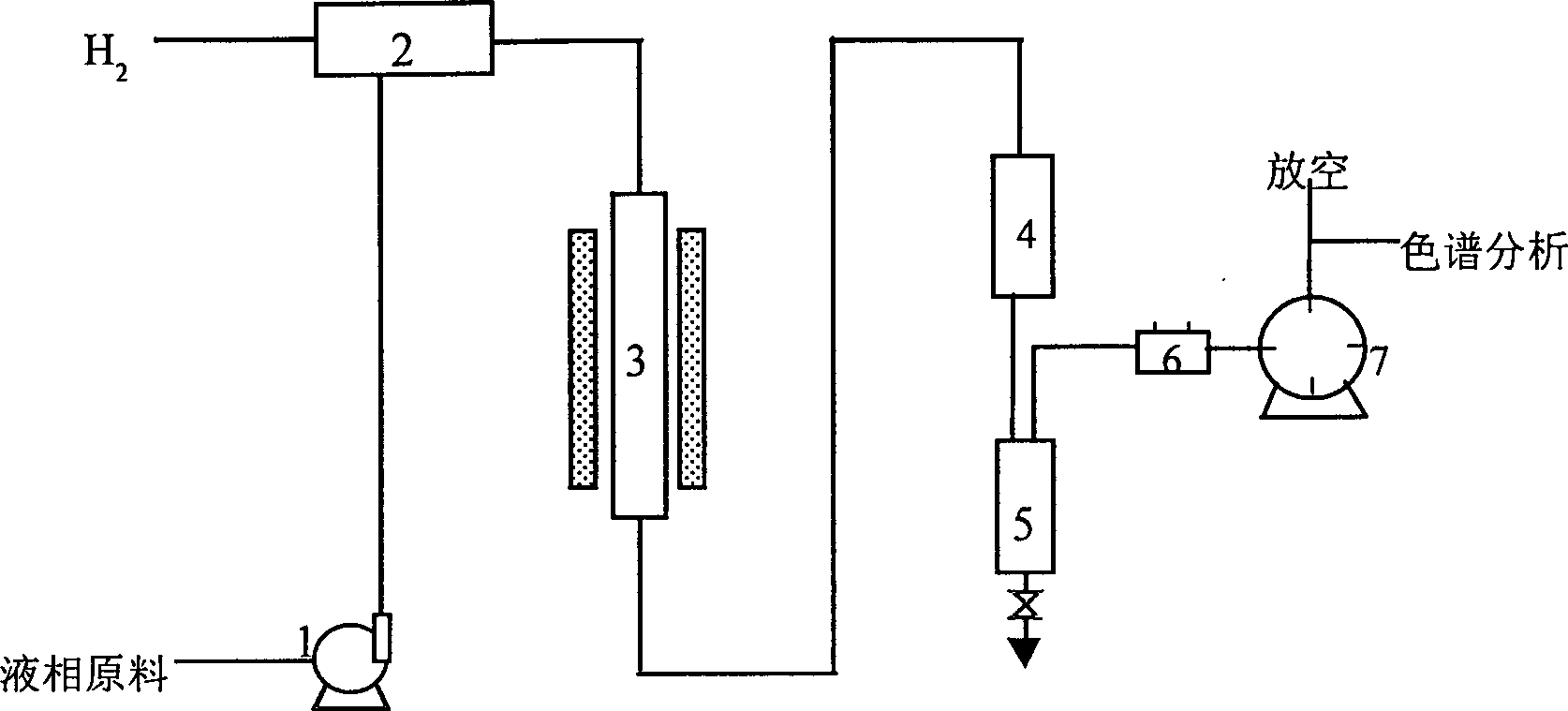

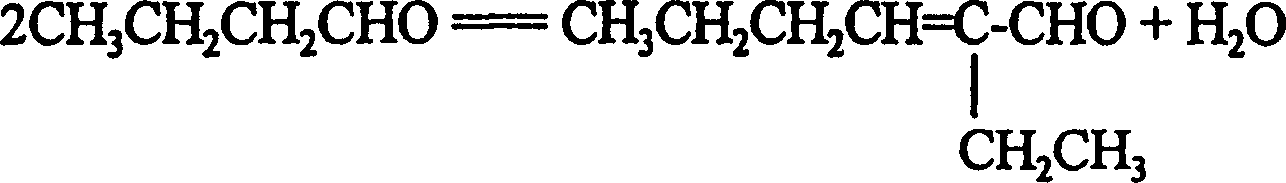

![Method for synthesizing [(4-amino-3,5-dichloro-6-fluoro-2-pyridinyl)oxy]acetic acid by using one-pot method Method for synthesizing [(4-amino-3,5-dichloro-6-fluoro-2-pyridinyl)oxy]acetic acid by using one-pot method](https://images-eureka.patsnap.com/patent_img/55015677-d2c8-4080-8d64-322d100440ea/BDA00002928050100021.PNG)

![Method for synthesizing [(4-amino-3,5-dichloro-6-fluoro-2-pyridinyl)oxy]acetic acid by using one-pot method Method for synthesizing [(4-amino-3,5-dichloro-6-fluoro-2-pyridinyl)oxy]acetic acid by using one-pot method](https://images-eureka.patsnap.com/patent_img/55015677-d2c8-4080-8d64-322d100440ea/BDA00002928050100022.PNG)

![Method for synthesizing [(4-amino-3,5-dichloro-6-fluoro-2-pyridinyl)oxy]acetic acid by using one-pot method Method for synthesizing [(4-amino-3,5-dichloro-6-fluoro-2-pyridinyl)oxy]acetic acid by using one-pot method](https://images-eureka.patsnap.com/patent_img/55015677-d2c8-4080-8d64-322d100440ea/BDA00002928050100023.PNG)