Patents

Literature

35results about How to "Reasonable hole distribution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Boiling bed hydrogenation treatment catalyst and its preparing process

ActiveCN101240190AThe reaction equipment is simpleReduce operating costsRefining to eliminate hetero atomsLow speedSpherical shaped

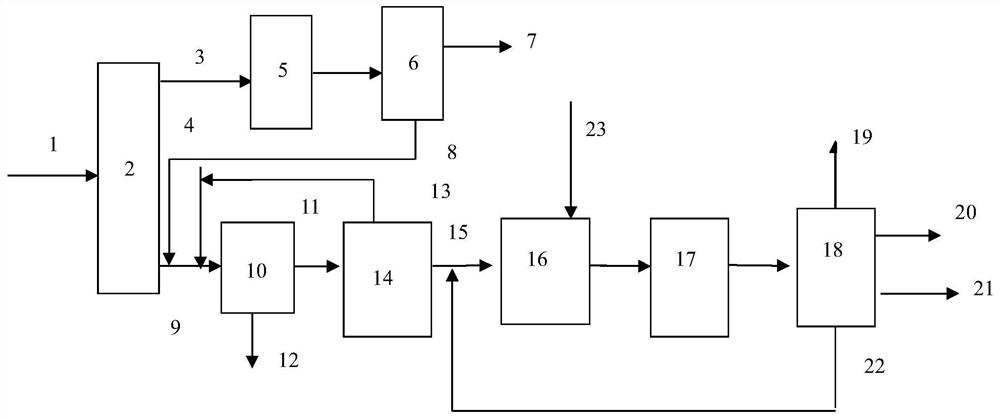

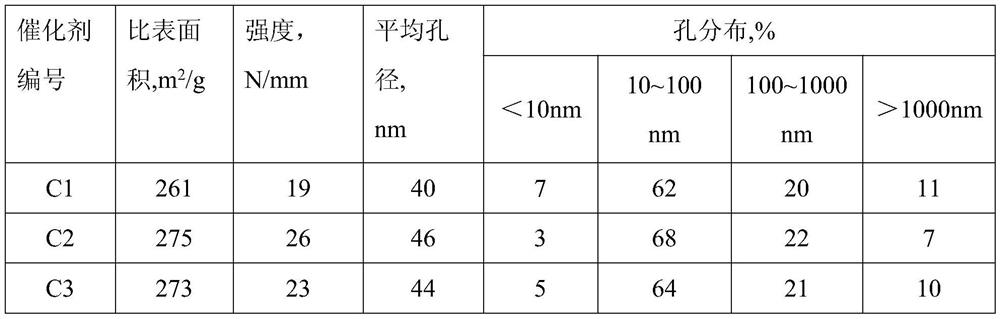

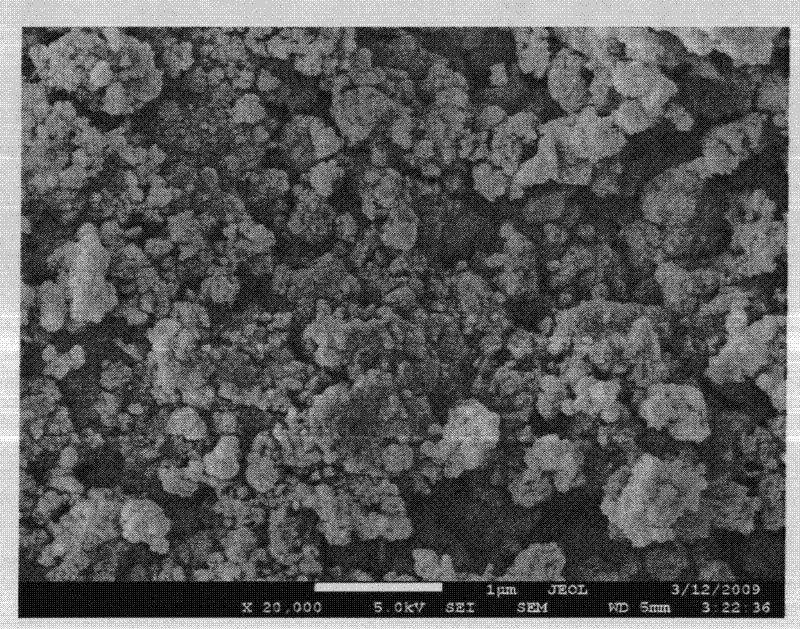

The invention relates to a boiling bed hydrogenation catalyst and a preparation method. The boiling bed hydrogenation catalyst of the invention is spherical shape which diameter is 0.1mm to 0.8mm, and has appropriate amount of additives and hydrogenation of metal components, and has reasonable hole distribution. The catalyst preparation method of the invention is spherical carrier impregnation, the process of spherical carrier preparation is following: making catalyst carrier raw material which is in appropriate temperature into appropriate size grain, then spheroidizing the grain, heating the conglobation and making them into spherical catalyst carrier. The process for making the catalyst carrier raw material into the appropriate size grain is that wet stock passes screen stencil by mechanical action and generates grain. Between the processes of the making grain and nodularization, granular material primely is placed for a period of time or operates in low-speed in nodularization device for a period of time. The catalyst of the invention appropriately conducts the boiling bed hydrogenation for heavy oil, residual oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

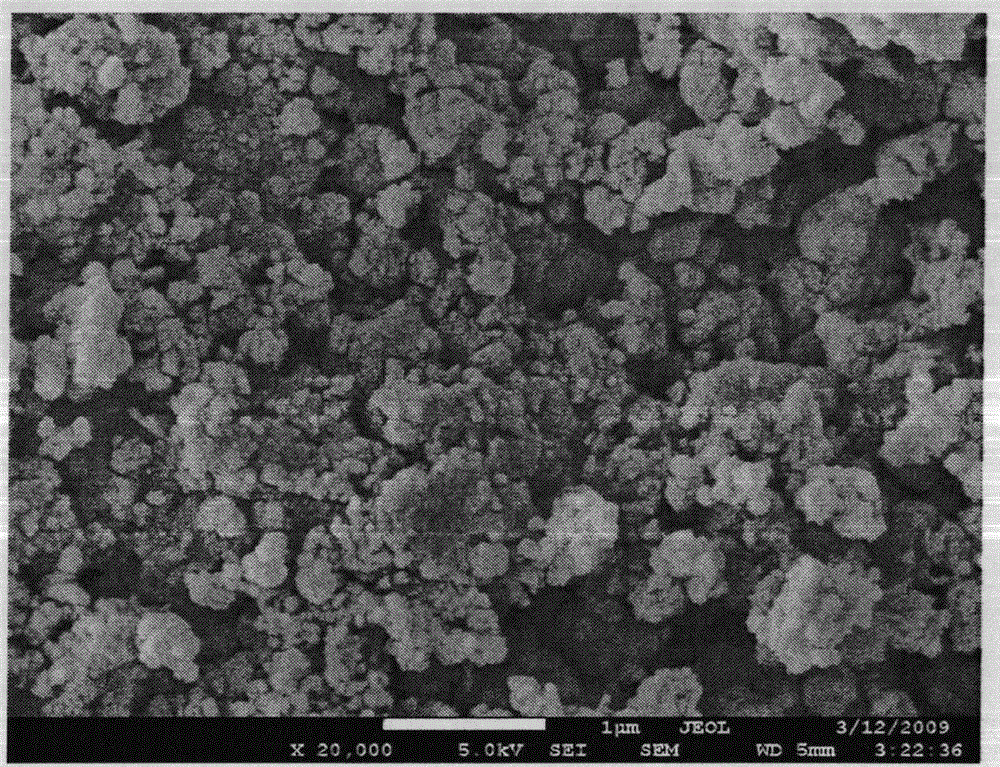

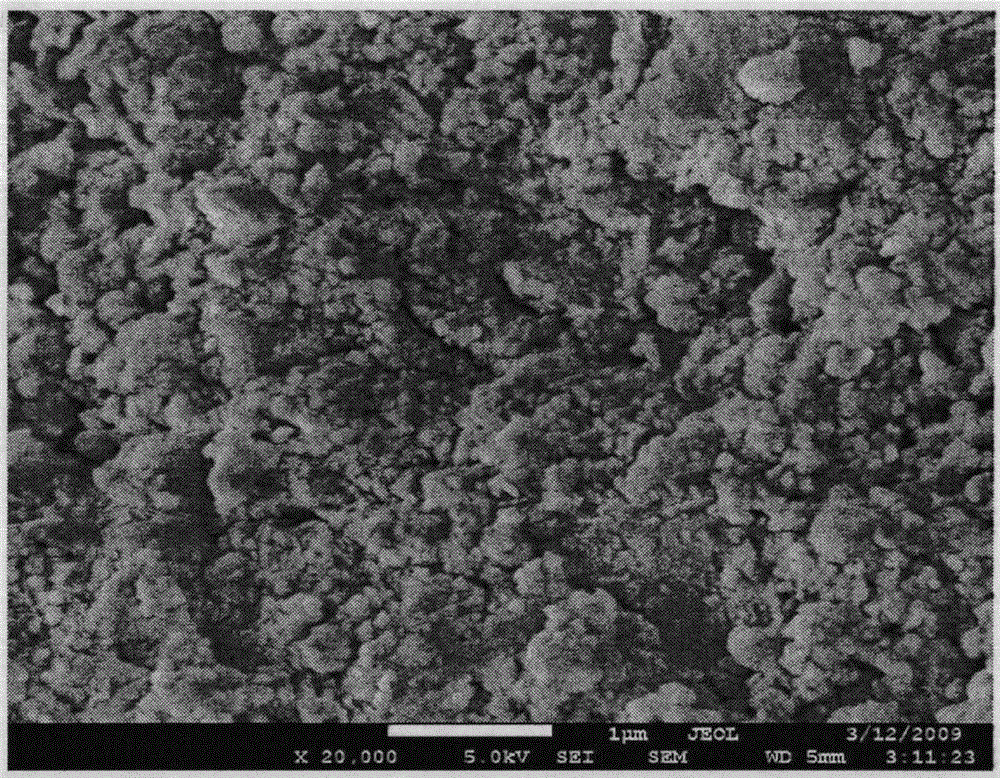

Preparation method of hydrocracking catalyst

ActiveCN103055923AUnlimited capacityGood dispersionMolecular sieve catalystsHydrocarbon oil crackingMolecular sieveDispersity

The invention discloses a preparation method of a hydrocracking catalyst. The method comprises the steps of preparing an acidic mixed solution A containing hydrogenation reactive metals and silicon, preparing a sodium metaaluminate alkaline solution B, and then adding the acidic mixed solution A, the alkaline solution B and CO2 to a reaction tank filled with clear water in parallel to prepare gel; and then adding turbid liquid of a Y type molecular sieve, mixing the substances uniformly, filtering, drying and forming the mixture, and then washing, drying and roasting the product, thus preparing the hydrocracking catalyst. The method has the beneficial effects that a clean preparation method is adopted, so not only can the catalyst be easily formed and the strength of the catalyst be improved, but also the pore volume and specific surface area of the catalyst can be increased and the dispersity of metals in the catalyst can be improved, thus the catalyst has higher hydrocracking activity, middle oil selectivity and stability; and the catalyst prepared by the method can be used for a single-section hydrocracking process of a non-refining section or a one-section serial hydrocracking process of a refining section.

Owner:CHINA PETROLEUM & CHEM CORP +1

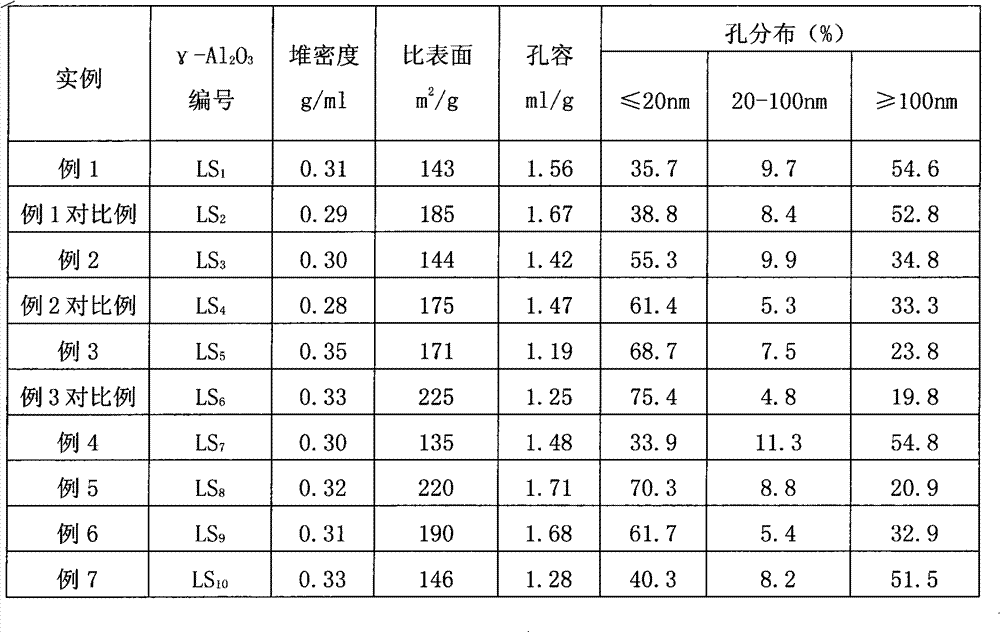

Preparation process for large pore volume and light bulk density activated alumina

InactiveCN102730724AChange the stacking methodFine grainAluminium oxides/hydroxidesWater vaporSodium aluminate

The invention relates to a preparation process for large pore volume and light bulk density activated alumina, and belongs to the technical field of activated alumina preparation. According to the process, an aluminum sulfate solution and a sodium aluminate solution form a glue in a stainless steel neutralization kettle through a continuous co-current flow method; then an aging treatment is performed for a certain time in a stainless steel aging washing tank; the resulting material is pressed to a plate and frame filter press with a material pressing pump to carry out continuous washing to prepare primary pseudo-boehmite particles with large grains; the removed filter cake is acidified, and proper amounts of a pore expanding agent and a surfactant are added during the acidification process to carry out forming; the formed wet balls are placed in a drying box to carry out drying; and the dried small balls are loaded into a calcination activation furnace to carry out high temperature calcination and pore expanding. The process of the present invention has characteristics of low cost and low equipment corrosion, can performs continuous washing cycle, and has advantages of low wastewater discharging, less pollution, and the like. With the process of the present invention, the production cycle can be reduced, the labor intensity can be reduced, and various performance indicators of the prepared gamma-Al2O3 can meet the international advanced level after pore expanding by water vapor.

Owner:JIANGSU JINGJING NEW MATERIALS

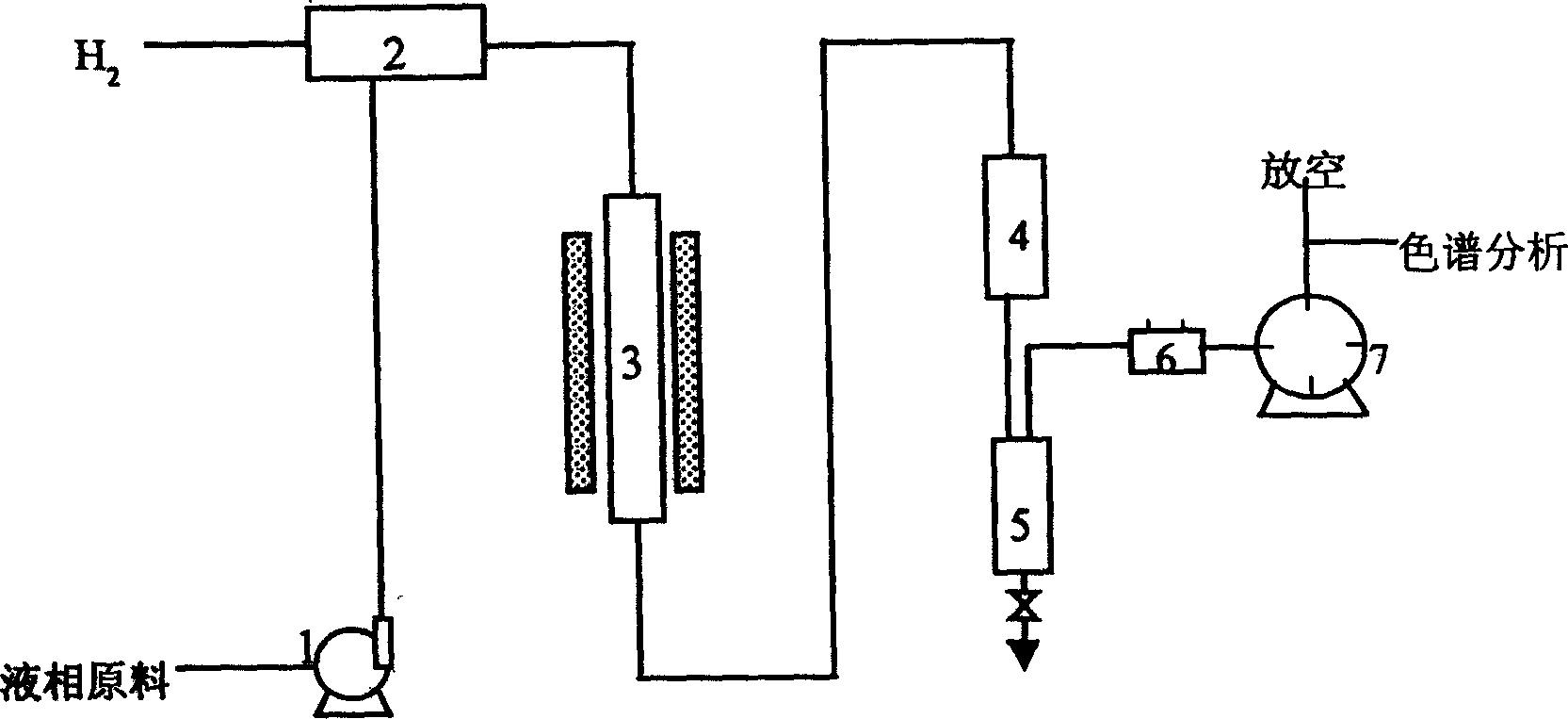

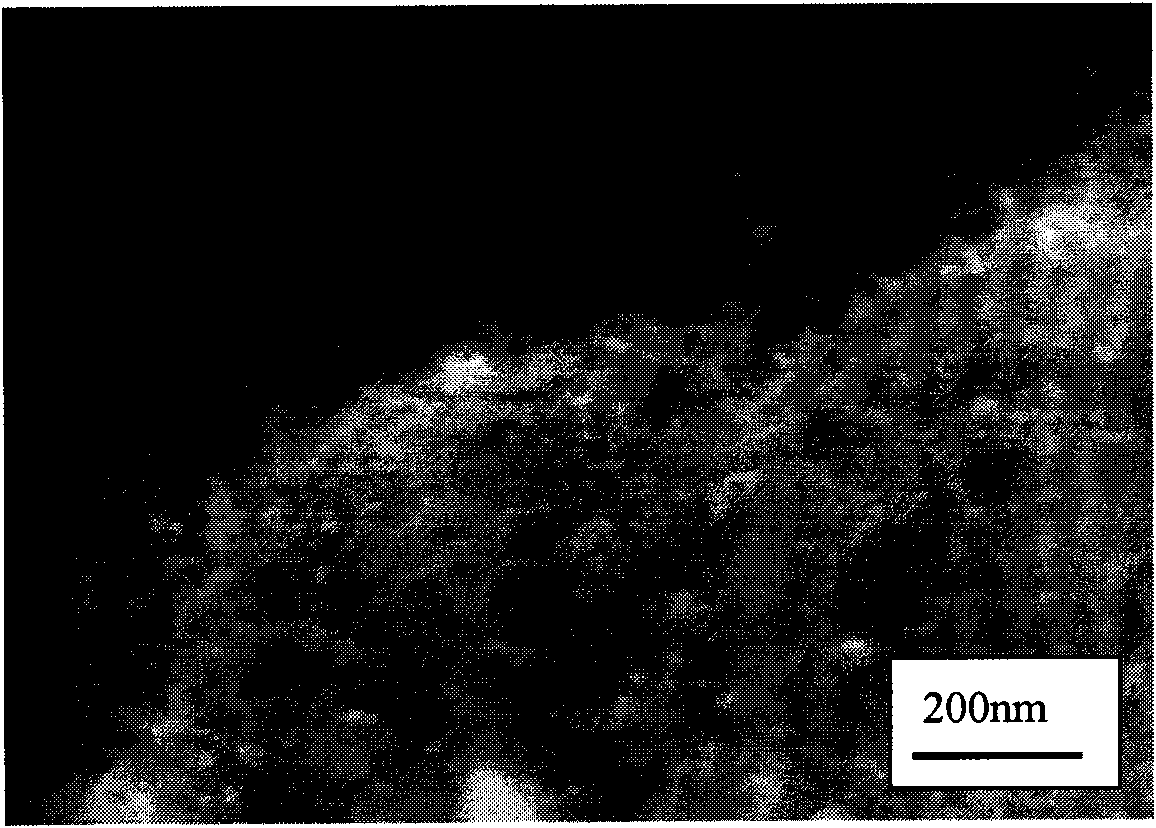

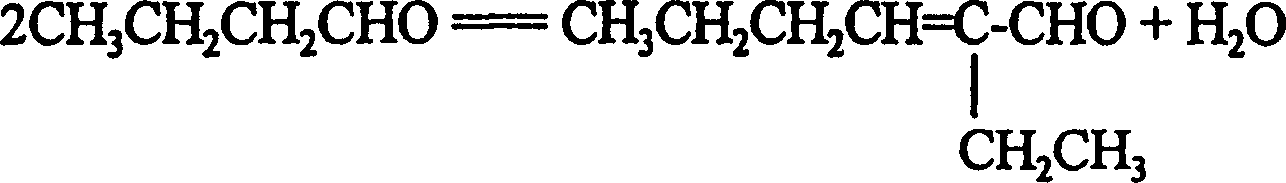

Technology of hydrogenatioin to produce iso octanol using iso octaldehyde mixture and its catalyst

InactiveCN1478596AStrong abilityImprove hydrogenation activityCatalyst activation/preparationPreparation by oxygen reductionAldehydeNickel

A process and catalyst for preparing isooctanol by liquid-phase hydrogenation of the mixture of isooctanal and octylene alcohol is disclosed. Said catalyst is prepared from metallic Ni, alkali-earth metal oxide and / or alumina, and Si-contained compound as carrier through code position of Ni and carrier, kneading, and calcining at 300-800 deg.C. Its advantages are good porous structure, and high strength, hydrogenating activity, and output rate of isooctanol.

Owner:CHINA PETROLEUM & CHEM CORP

Preparation method of super capacitor

InactiveCN101661840AEasy to manufactureLower internal resistanceElectrolytic capacitorsHybrid/EDL manufactureGas phaseArgon atmosphere

The invention relates to a preparation method for a super capacitor, comprising the following steps: (1) placing a foam nickel substrate in a chemical gas phase deposition reacting furnace, introducing argon for 10-60 minutes, exhausting air in the furnace, then heating the furnace to 450-750 DEG C, introducing hydrocarbon gases in an argon atmosphere at a flow rate between 25ml / min and 40ml / min,reacting the mixture for 30 seconds to 50 minutes at a temperature of 450-750 DEG C, and obtaining foam nickel on which carbon nano tubes grow after finishing the reaction; (2) removing surface loosing layer products, directly using the foam nickel substrate on which the carbon nano tubes grow as electrodes of the super capacitor; and (3) drying the electrodes with same thickness and size, which are obtained from the step (2), fully soaking the electrode with electrolyte for 1-36 hours, separating a diaphragm soaked with the electrolyte and assembling the components to obtain the super capacitor; and the hydrocarbon gases are acetylene, methane, ethylene or propylene. The carbon nano tubes directly grow on the foam substrate without a binding agent; and the foam nickel is used as the substrate, the volume density of electrode substances is higher and holes are reasonably distributed.

Owner:JIANGSU CHUANGLAN SOLAR AIR CONDITIONER

Preparation method of bulk phase hydrocracking catalyst

ActiveCN103055922BLarge specific surface areaLarge hole volumeMolecular sieve catalystsHydrocarbon oil crackingMolecular sievePolymer science

The invention discloses a preparation method of a bulk phase hydrocracking catalyst. The method comprises the steps of preparing an acidic mixed solution A containing hydrogenation reactive metals, silicon and organic solvents, and preparing a sodium metaaluminate alkaline solution B; filling clear water into a reaction tank and filling CO2 into the clear water; and then adding the acidic mixed solution A and the alkaline solution B to the reaction tank in parallel to prepare gel, controlling the pH value of pulp in the reaction tank to be 7.0-9.0, then adding turbid liquid of a Y type molecular sieve, mixing the substances uniformly, filtering and drying the obtained mixture, and then forming, washing, drying and roasting the filter cake, thus preparing the hydrocracking catalyst. The catalyst prepared by the method has the advantages of big specific surface area, big pore volume, high strength and high dispersibility of reactive metal components, and is especially suitable to serve as a high-activity middle oil type hydrocracking catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

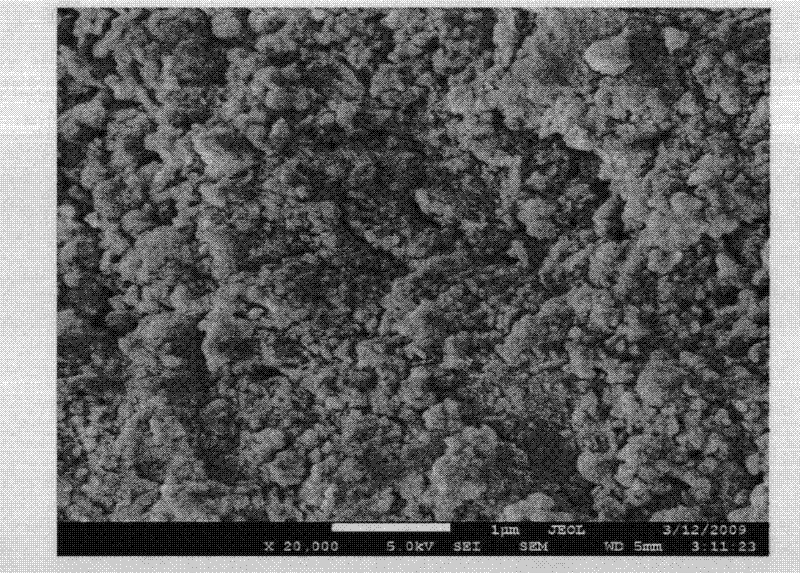

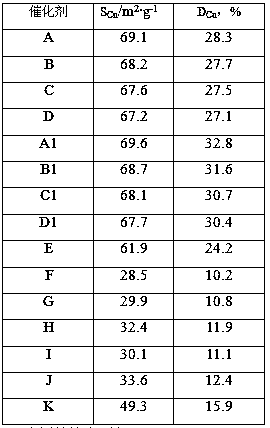

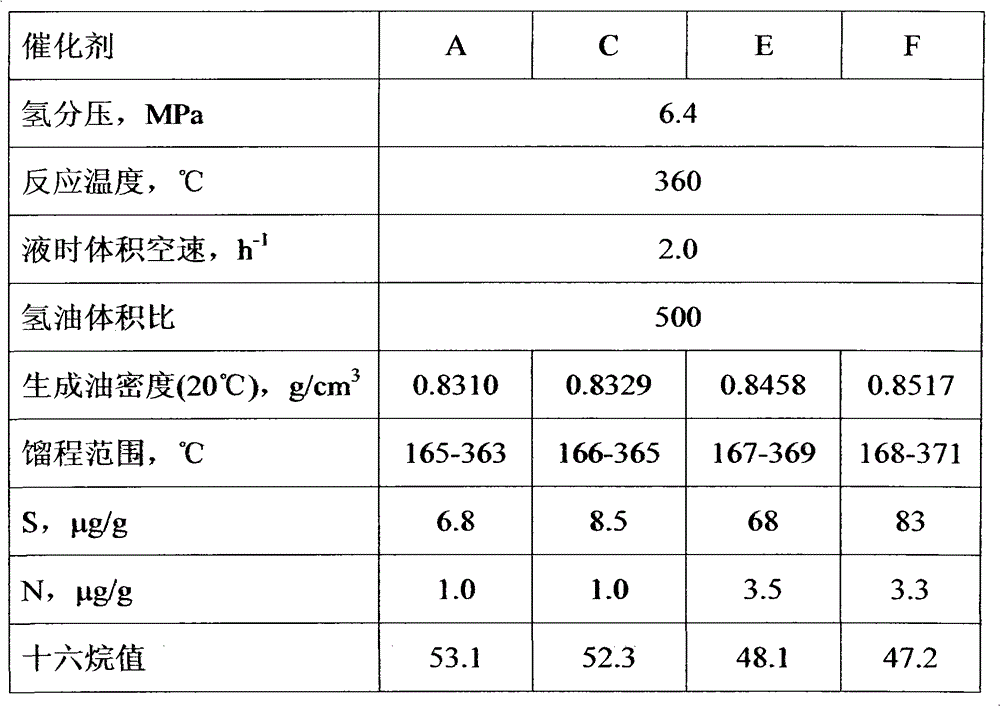

Preparation method of hydrotreating catalyst composition

ActiveCN103055887AImprove adhesionUniform grain sizeMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsPore distributionSlurry

The invention discloses a preparation method of a hydrotreating catalyst composition. The method comprises the steps of subjecting a salt mixed solution A in which CO2 is dissolved to react with an alkaline solution B containing aluminium to prepare gel, when reaction is completed, controlling the pH value of pulp in a reaction tank to be 7.0-9.0, preparing a mixture of an NixWyOz composite oxide precursor and an Al2O3 precursor, pulping the mixture and MoO3 to prepare a dry body, and then forming, drying and roasting the dry body to obtain a final catalyst, wherein the salt mixed solution A contains components Ni and W. The method has the beneficial effects that the problem that bulk phase catalysts are difficult to form is solved; the physical and chemical properties of the catalyst are adjusted, and the catalyst has the advantages of larger specific surface area, uniform pore distribution and high effective utilization rate of reactive metals; and the catalyst is especially suitable for the ultra-deep desulfurization reaction for producing ultra-clean diesel.

Owner:CHINA PETROLEUM & CHEM CORP +1

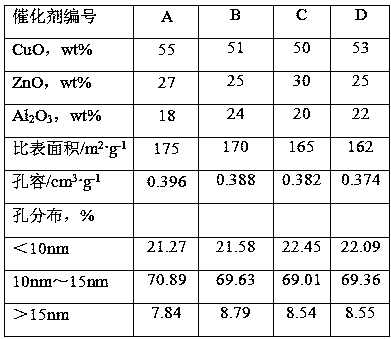

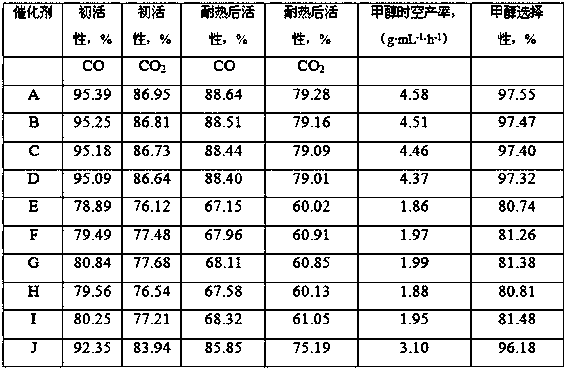

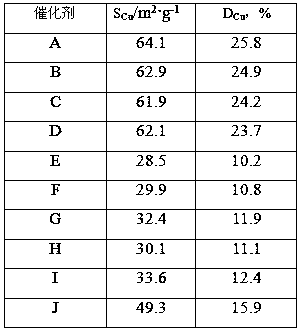

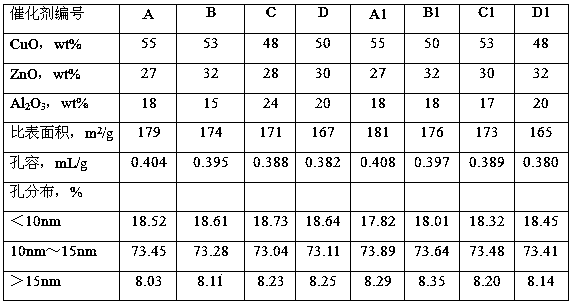

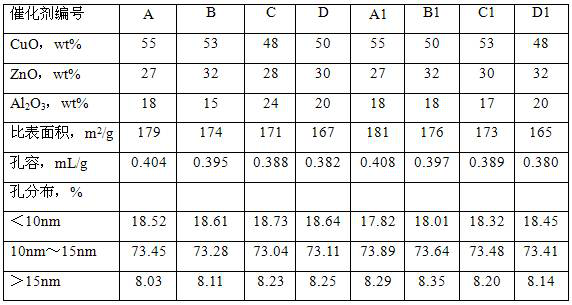

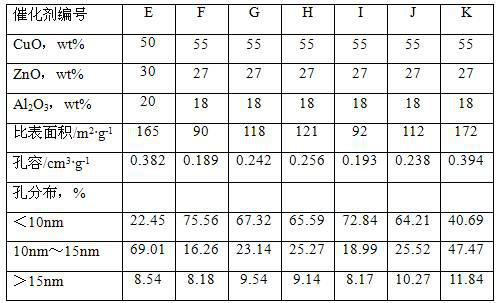

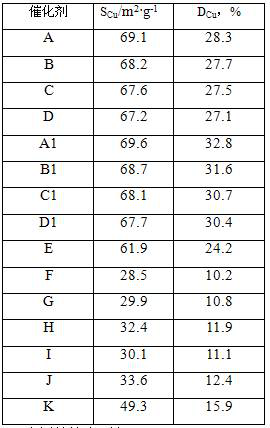

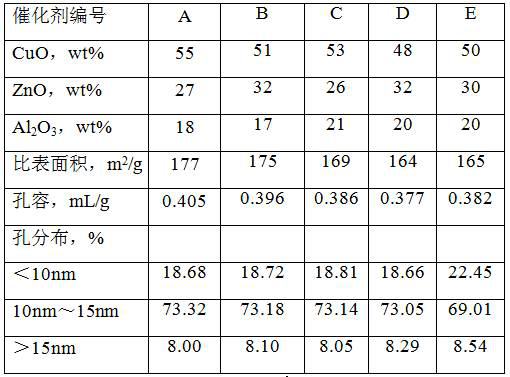

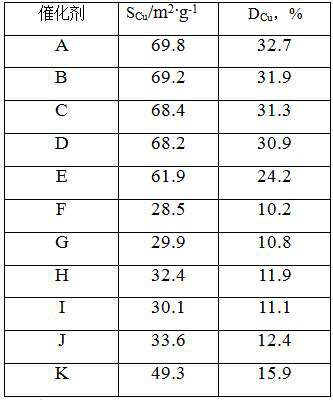

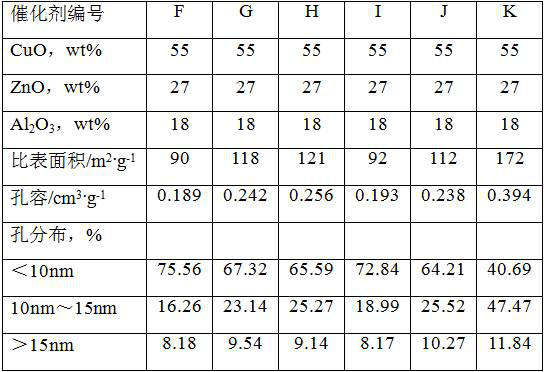

Preparation method of copper-containing catalyst

ActiveCN111686739AEvenly dispersedGood dispersionOrganic compound preparationHydroxy compound preparationPtru catalystSodium aluminate

The invention discloses a preparation method of a copper-containing catalyst, which comprises the following steps: (1) carrying out parallel flow gelatinization reaction on a mixed solution A and a sodium metaaluminate solution to obtain slurry I, and aging the slurry I; (2) dropwise adding the mixed solution B and a sodium carbonate solution into the aged slurry I obtained in the step (1) in a parallel flow manner, carrying out a gelling reaction to obtain slurry II, and aging the slurry II; and (3) carrying out solid-liquid separation on the material obtained in the step (2), and drying, roasting and molding the solid phase to obtain the catalyst, wherein a quaternary ammonium salt compound is added before the gelling reaction in the step (1), wherein the mixed solution A is an aqueous solution containing a soluble copper salt, a soluble zinc salt and an organic auxiliary agent, and the mixed solution B is an aqueous solution containing a soluble copper salt and a soluble aluminum salt. The catalyst has characteristics of uniform active metal copper distribution, good synergistic effect, large active metal active center number, catalyst activity improving, catalyst selectivity improving, catalyst thermal stability improving, and good application prospect.

Owner:CHINA PETROLEUM & CHEM CORP +1

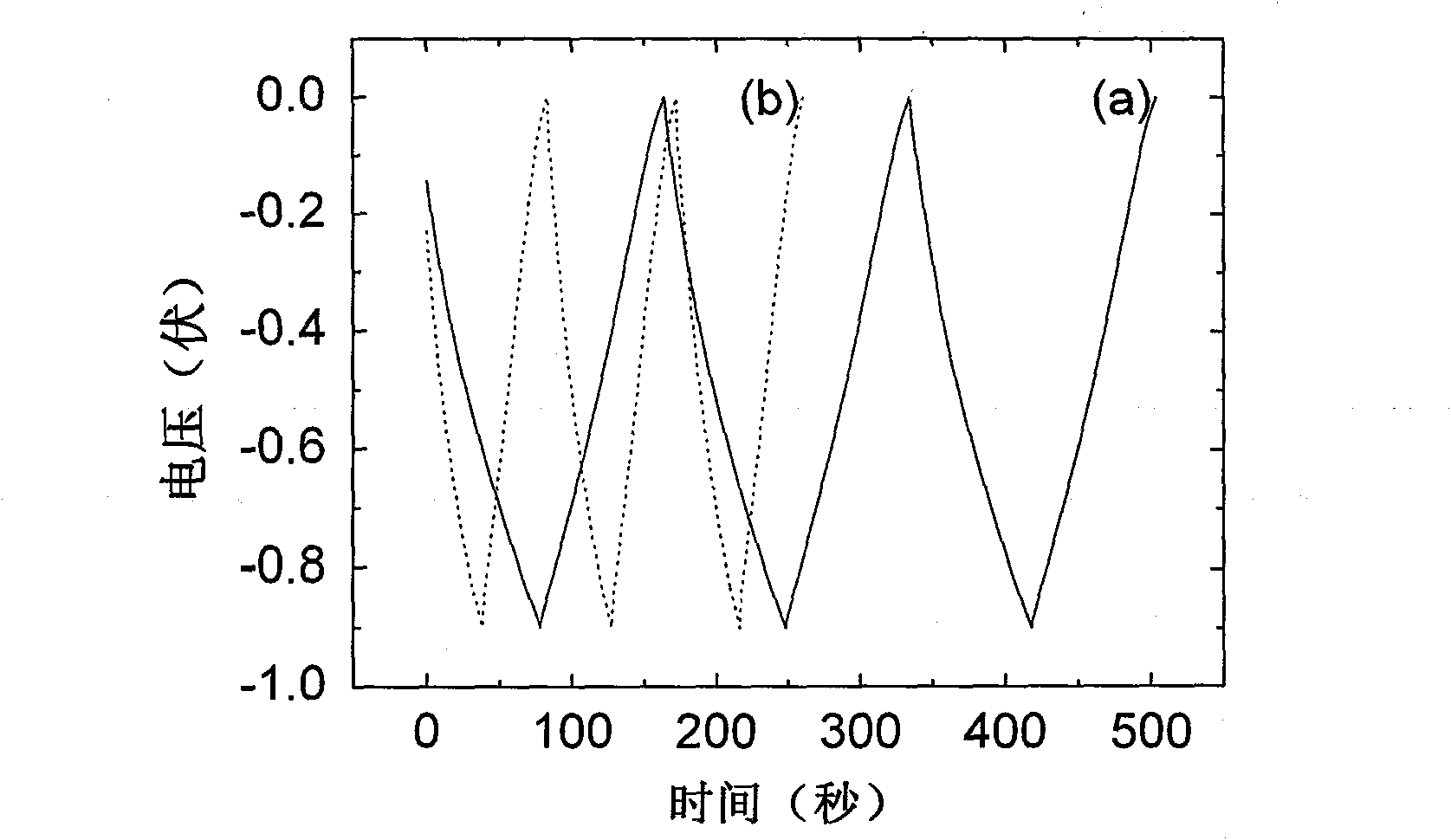

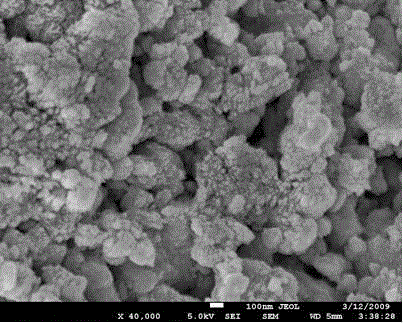

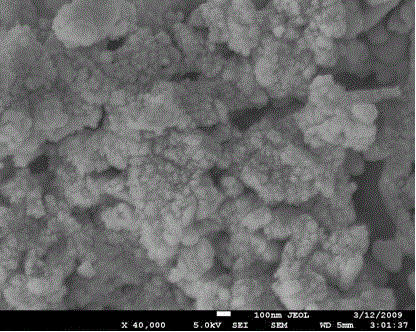

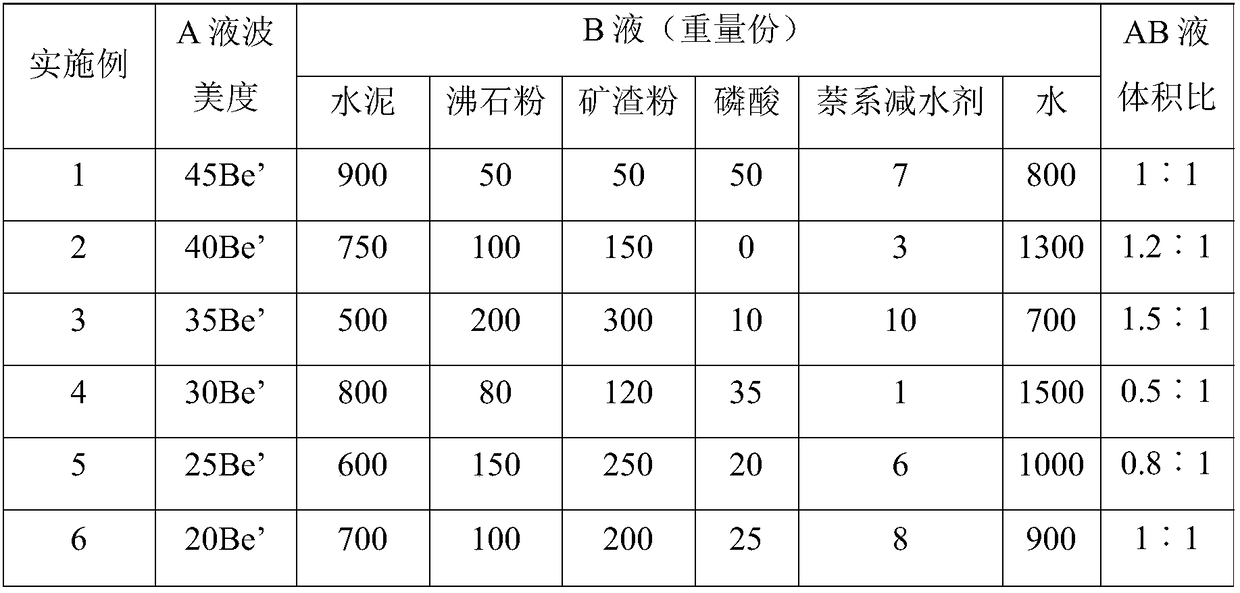

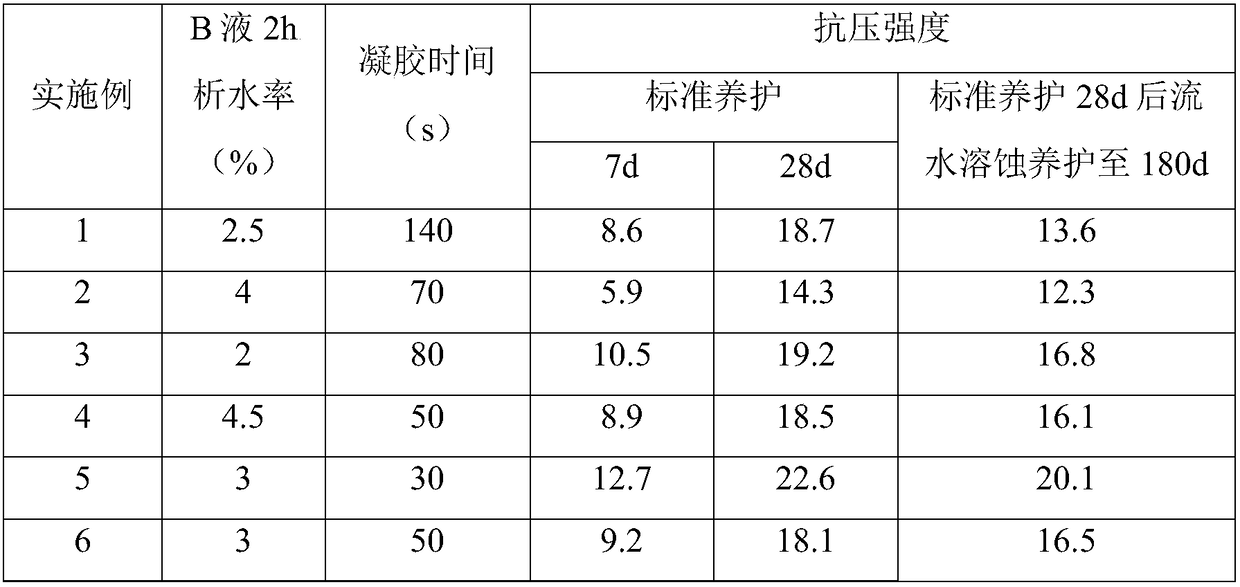

Modified double-liquid paste injection material

The invention discloses a modified double-liquid paste injection material and relates to soft stratum reinforcement of underground construction and anti-seepage water plugging paste injection. The modified double-liquid paste injection material comprises a liquid A and a liquid B, wherein the liquid A is sodium silicate which has a modus of 2.0-3.5 and a baume degree of 20-45Be'; the liquid B is modified cement slurry which consists of the following components in parts by weight: 500-900 parts of cement, 50-200 parts of zeolite powder, 50-300 parts of ore slag powder, 0-50 parts of phosphoricacid, 1-10 parts of a naphthalene water reducer and 700-1500 parts of water; when being used, the liquid A and the liquid B are uniformly mixed in a volume ratio of (0.5-1.5):1, and the modified double-liquid paste injection material is prepared. As a part of cement is replaced by the zeolite powder and the ore slag powder to react with the sodium silicate, the zeolite powder is of a micro porousstructure and is capable of improving the peaceability and the stability of the cement slurry, water energy adsorbed into pores of the zeolite powder can be released at a later hydration reaction stage, then a solid can be sufficiently hydrated, and the compactness and the strength can be improved.

Owner:建发合诚工程咨询股份有限公司

Preparation method of hydrotreating catalyst composition

ActiveCN103055887BImprove adhesionUniform grain sizeMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsPore distributionSlurry

The invention discloses a preparation method of a hydrotreating catalyst composition. The method comprises the steps of subjecting a salt mixed solution A in which CO2 is dissolved to react with an alkaline solution B containing aluminium to prepare gel, when reaction is completed, controlling the pH value of pulp in a reaction tank to be 7.0-9.0, preparing a mixture of an NixWyOz composite oxide precursor and an Al2O3 precursor, pulping the mixture and MoO3 to prepare a dry body, and then forming, drying and roasting the dry body to obtain a final catalyst, wherein the salt mixed solution A contains components Ni and W. The method has the beneficial effects that the problem that bulk phase catalysts are difficult to form is solved; the physical and chemical properties of the catalyst are adjusted, and the catalyst has the advantages of larger specific surface area, uniform pore distribution and high effective utilization rate of reactive metals; and the catalyst is especially suitable for the ultra-deep desulfurization reaction for producing ultra-clean diesel.

Owner:CHINA PETROLEUM & CHEM CORP +1

Activated carbon as well as preparation method and application thereof

ActiveCN113120903AReasonable distributionModerate surface areaCarbon compoundsOther chemical processesActivated carbonPetroleum coke

The invention discloses activated carbon as well as a preparation method and application thereof. The accessibility A of the activated carbon is 1.4-2.2, wherein the accessibility A is a parameter for representing the methane adsorption and storage performance of the activated carbon. The preparation method of the activated carbon comprises the following steps: firstly, uniformly mixing petroleum coke, an activating agent and a transition metal compound, and performing activation reaction; and washing and drying the obtained activated product to obtain the activated carbon. The activated carbon obtained by the method is reasonable in pore distribution, has a proper specific surface area, has micropores capable of adsorbing a large amount of methane and mesopores capable of accelerating mass transfer, and has the advantages of good methane storage effect, simple preparation method and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

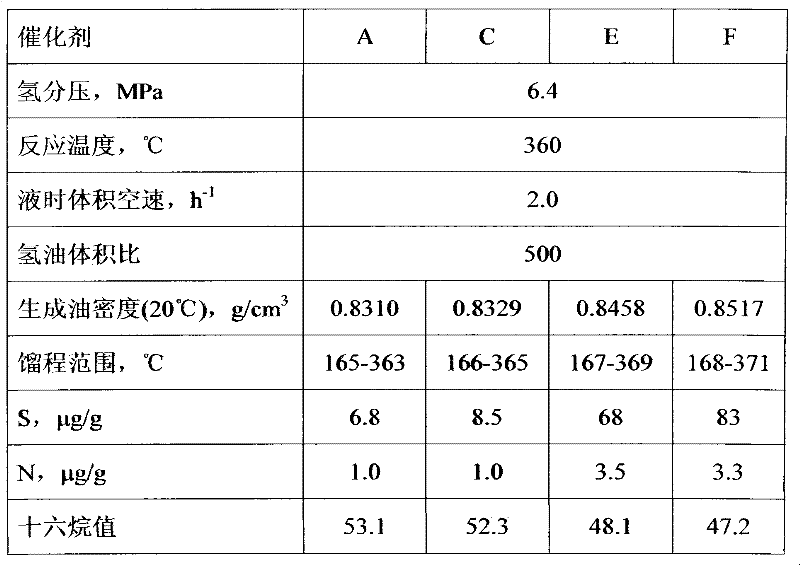

Method for preparing hydrofining catalyst

ActiveCN110038584APore structure is suitableOptimized areaHeterogenous catalyst chemical elementsCatalyst activation/preparationOrganic acidNitrogen

The invention discloses a method for preparing a hydrofining catalyst. According to the hydrofining catalyst, firstly, a mixed solution A containing Ni and W and a sodium metaaluminate alkaline solution react in a parallel flow manner, obtained slurry is aged, then, a mixed solution B containing W, Mo and Al components and ammonia water are added to the aged slurry in a parallel flow manner, agingis performed, then, first drying, forming and second drying are performed, treatment is performed with a mixed aqueous solution of aluminum salt and organic acid, washing, third drying, calcination and other steps are performed, and the hydrofining catalyst is prepared. The catalyst can be applied to super deep hydrodesulfurization and hydrodenitrification reactions of diesel fractions, has higher hydrodesulfurization and hydrodenitrification reaction activity and is particularly applied to tretament of diesel materials with high nitrogen and sulfur content.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of methanol synthesis catalyst

ActiveCN110935456AGood dispersionOptimized areaOrganic compound preparationHeterogenous catalyst chemical elementsPtru catalystSodium aluminate

The invention discloses a preparation method of a methanol synthesis catalyst. The preparation method comprises the following steps: (1) carrying out a parallel flow gelling reaction on a mixed solution A and a sodium metaaluminate solution to obtain a slurry I, and aging; (2) adding a mixed solution B and a sodium carbonate solution into the aged slurry I obtained in the step (1) in a dropwise and parallel flow manner, carrying out a gelling reaction to obtain a slurry II, and aging; and (3) carrying out solid-liquid separation on the material obtained in the step (2), and drying, roasting and molding the solid phase to obtain the catalyst, wherein the mixed solution A is an aqueous solution containing a soluble copper salt and a soluble zinc salt, and the mixed solution B is an aqueous solution containing a soluble copper salt and a soluble aluminum salt. The catalyst prepared by the method has the advantages of uniform distribution of active metal copper and auxiliary agent zinc, good synergistic effect, large number of active metal active centers, improved activity, improved selectivity, improved thermal stability and prolonged service life.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrotreatment method of inferior heavy oil, hydrogenation protection catalyst and application

ActiveCN112574780AIncrease profitImprove combined economicsCatalyst protectionTreatment with hydrotreatment processesPtru catalystFixed bed

The invention discloses a hydrotreatment method of inferior heavy oil, a hydrogenation protection catalyst and application. The hydrotreatment method comprises the following steps: carrying out fractionation treatment on inferior heavy oil to obtain a heavy fraction and a light fraction, uniformly mixing the heavy fraction and naphthalene rear fractions in the light fraction, and carrying out solvent extraction on the obtained mixture to obtain an aromatic-rich component and a colloid component; and making the aromatic-rich component and the hydrogenation tail oil contact with a hydrogenationprotection catalyst, and carrying out a hydrogenation protection reaction, a hydrofining reaction and a hydrocracking reaction to realize hydrotreatment of inferior heavy oil, wherein the hydrogenation protection catalyst comprises a metal active component and a carrier, wherein the carrier is mainly formed by mixing fullerene, naphthalene and aluminum oxide, carrying out extrusion molding, dryingand roasting. The processing method disclosed by the invention solves the problem that a fixed bed hydrogenation process cannot be directly adopted due to high asphaltene content in the inferior heavy oil, so that the inferior heavy oil full fraction is fully utilized, and the comprehensive economy of the inferior heavy oil is improved.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Method for preparing hydrotreating catalyst composition

ActiveCN102451707AEasy to shapeImprove adhesionMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsComposite oxideMetal

The invention discloses a method for preparing a hydrotreating catalyst composition. When a mixture of an NixWyOz composite oxide precursor and an Al2O3 precursor is prepared by a precipitation method, sodium metaaluminate is used as an aluminum source, and the sodium metaaluminate and CO2 gas are added in a swinging way in a gelling process, so that the resultant precipitate particles are large and uniform, and thereby the physical and chemical properties of the catalyst are improved, the catalyst has the characteristics of large pore volume, large specific surface area, reasonable pore size distribution, good dispersion of active metal and the like, and the problems that a bulk phase catalyst is difficult to mold is also solved. The catalyst prepared by the method provided by the invention is especially suitable for an ultra deep desulfurization reaction for producing ultra-clean diesel.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of copper-zinc catalyst

ActiveCN110935457AHigh activityGood synergyOrganic compound preparationHeterogenous catalyst chemical elementsPtru catalystSodium aluminate

The invention discloses a preparation method of a copper-zinc catalyst. The preparation method comprises the following steps: (1) carrying out a parallel flow gelling reaction on a mixed solution A and a sodium metaaluminate solution to obtain a slurry I, and aging; (2) adding a mixed solution B and a sodium carbonate solution into the aged slurry I obtained in the step (1) in a dropwise and parallel flow manner, carrying out a gelling reaction to obtain a slurry II, and aging; and (3) carrying out solid-liquid separation on the material obtained in the step (2), and drying, roasting and molding the solid phase to obtain the catalyst, wherein the mixed solution A is an aqueous solution containing a soluble copper salt, a soluble zinc salt and an organic auxiliary agent, and the mixed solution B is an aqueous solution containing a soluble copper salt and a soluble aluminum salt. The catalyst prepared by the method has the advantages of uniform distribution of active metal copper, good synergistic effect, large number of active metal active centers, improved activity, improved selectivity, improved thermal stability and prolonged service life.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing hydrotreating catalyst composition

ActiveCN102451707BEasy to shapeImprove adhesionMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsComposite oxideMetal

Owner:CHINA PETROLEUM & CHEM CORP +1

Processing method of inferior heavy oil, hydrogenation protection catalyst and application

ActiveCN112574779AIncrease profitImprove economyCatalyst protectionTreatment with hydrotreatment processesPtru catalystFixed bed

The invention discloses a processing method of inferior heavy oil, a hydrogenation protection catalyst and application. The processing method comprises the following steps: carrying out fractionationtreatment on inferior heavy oil to obtain a heavy fraction and a light fraction, and then carrying out solvent extraction on the heavy fraction to obtain an aromatic-rich component and a colloid component; and uniformly mixing the aromatic-rich component and the naphthalene rear fraction in the light fraction, making the obtained mixture contact with a hydrogenation protection catalyst, and carrying out a hydrogenation protection reaction, a hydrofining reaction and a hydrocracking reaction to achieve processing of inferior heavy oil, wherein the hydrogenation protection catalyst comprises a metal active component and a carrier, the carrier is mainly formed by mixing a toluene solution of fullerene and slurry alumina, carrying out extrusion molding, drying and roasting, and the metal active component comprises a metal oxide. The processing method disclosed by the invention solves the problem that a fixed bed hydrogenation process cannot be directly adopted due to high asphaltene content in the inferior heavy oil, so that the inferior heavy oil full fraction is fully utilized, and the comprehensive economy of the inferior heavy oil is improved.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Technology of hydrogenatioin to produce iso octanol using iso octaldehyde mixture and its catalyst

InactiveCN1268595CImprove pore structureReasonable hole distributionCatalyst activation/preparationPreparation by oxygen reduction2-OctanolAlcohol

A process and catalyst for preparing isooctanol by liquid-phase hydrogenation of the mixture of isooctanal and octylene alcohol is disclosed. Said catalyst is prepared from metallic Ni, alkali-earth metal oxide and / or alumina, and Si-contained compound as carrier through code position of Ni and carrier, kneading, and calcining at 300-800 deg.C. Its advantages are good porous structure, and high strength, hydrogenating activity, and output rate of isooctanol.

Owner:CHINA PETROLEUM & CHEM CORP

Preparation method of copper-zinc catalyst

ActiveCN111686738AHigh activityGood synergyOrganic compound preparationHeterogenous catalyst chemical elementsPtru catalystSodium aluminate

The invention discloses a preparation method of a copper-zinc catalyst, which comprises the following steps: (1) carrying out parallel flow gelatinization reaction on a mixed solution A and a sodium metaaluminate solution to obtain slurry I, and aging the slurry I; (2) dropwise adding the mixed solution B and a sodium carbonate solution into the aged slurry I obtained in the step (1) in a parallelflow manner, carrying out a gelling reaction to obtain slurry II, and aging the slurry II; (3) filtering and drying the material obtained in the step (2), and treating the material with a mixed aqueous solution containing aluminum salt and organic acid; and (4) preparing a catalyst product from the material obtained in the step (3), wherein the mixed solution A is an aqueous solution containing asoluble copper salt, a soluble zinc salt and an organic auxiliary agent, and the mixed solution B is an aqueous solution containing a soluble copper salt and a soluble aluminum salt. The catalyst prepared by the method disclosed by the invention is uniform in active metal distribution, has a good synergistic effect, has a large number of active metal active centers, improves the activity, selectivity and thermal stability of the catalyst, and has a good application prospect.

Owner:CHINA PETROLEUM & CHEM CORP +1

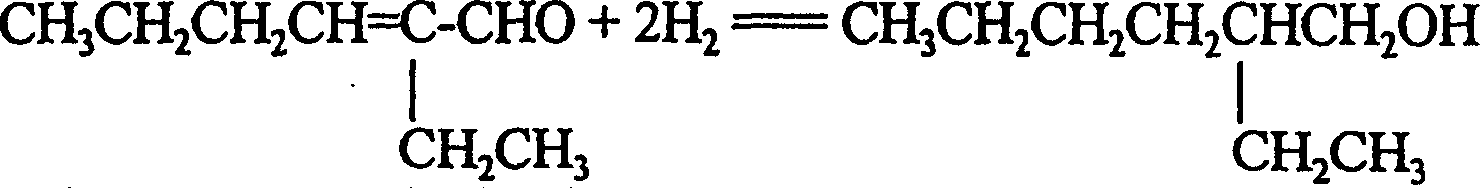

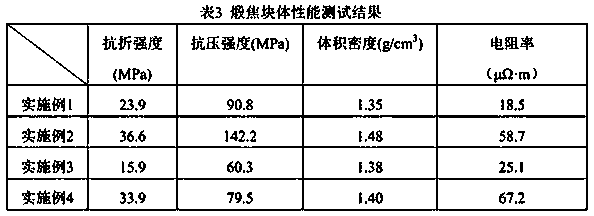

Preparation method of high-density and high-strength granular calcined coke

InactiveCN111534316ALower performance requirementsSimple preparation processCoking carbonaceous materialsCompression moldingCoke

A preparation method of high-density and high-strength granular calcined coke belongs to the technical field of carbon material preparation methods. According to the technical scheme, the method comprises the following steps of: crushing purchased green coke powder to a certain particle size to obtain green coke powder, and crushing asphalt with a softening point of 80-350 DEG C to a particle sizeof 1-200 microns to obtain asphalt powder; adding a certain amount of asphalt powder into the prepared green coke powder, uniformly mixing a mixture of the two kinds of powder to prepare compressed powder, and performing compression molding on the prepared compressed powder under a vacuumizing condition to obtain a green body; and putting the green body into a pot-type calcining furnace, and sintering by adopting a conventional calcining and heating process to obtain a calcined coke block. The method is simple in preparation process, low in equipment investment and low in raw material performance requirement of the green coke, sintering molding can be achieved by adding a small amount of asphalt or not adding asphalt according to the volatile matter content of the green coke, and the prepared calcined coke has the characteristics of high breaking strength, good compressive strength, low resistivity and reasonable pore distribution.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Preparation method of hydrocracking catalyst composition

ActiveCN103055926AImprove adhesionEasy to shapeMolecular sieve catalystsHydrocarbon oil crackingMolecular sievePtru catalyst

The invention discloses a preparation method of a hydrocracking catalyst composition. The method comprises the steps of preparing an acidic mixed solution A containing hydrogenation reactive metals and silicon, preparing a sodium metaaluminate alkaline solution B, adding clear water to a reaction tank, and then filling CO2 into the clear water; and then adding the acidic mixed solution A and the alkaline solution B to the reaction tank in parallel to prepare gel, then adding turbid liquid of a Y type molecular sieve, mixing the substances uniformly, filtering the obtained mixture, drying the obtained filter cake, and then forming, washing, drying and roasting the filter cake, thus preparing the hydrocracking catalyst composition. The hydrocracking catalyst composition prepared by the method has the advantages of big specific surface area, big pore volume, high strength and high effective utilization rate of reactive metal components, and is especially suitable for a hydrocracking process for producing more middle distillates.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of hydrocracking catalyst composition

ActiveCN103055925AHigh ratio of silicon to aluminumLarge specific surface areaMolecular sieve catalystsCatalyst activation/preparationDispersityMolecular sieve

The invention discloses a preparation method of a hydrocracking catalyst composition. The method comprises the steps of preparing an acidic mixed solution A containing hydrogenation reactive metals and silicon and filling CO2 into the solution A; and preparing a sodium metaaluminate alkaline solution B, subjecting the solution B to react with the solution A into which CO2 is filled to prepare gel, then adding turbid liquid of a Y type molecular sieve, mixing the substances uniformly, filtering the obtained mixture, drying the obtained filter cake, and then forming, washing, drying and roasting the filter cake, thus preparing the hydrocracking catalyst composition. The method has the beneficial effects that a clean preparation method is adopted, so not only can the catalyst be easily formed and the strength of the catalyst be improved, but also the pore volume and specific surface area of the catalyst can be increased and the dispersity of metals in the catalyst can be improved, thus the catalyst has higher hydrocracking activity, middle oil selectivity and stability; and the hydrocracking catalyst composition prepared by the method is especially suitable for producing more high-quality naphtha, jet fuel and diesel.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of preparation method of copper-zinc catalyst

ActiveCN110935457BEvenly dispersedGood dispersionOrganic compound preparationHeterogenous catalyst chemical elementsPtru catalystSodium aluminate

The invention discloses a preparation method of a copper-zinc catalyst, which includes the following contents: (1) co-flow gelling reaction of mixed solution A and sodium metaaluminate solution to obtain slurry I, and then aging; (2) mixing Solution B and sodium carbonate solution are added dropwise to the aged slurry I in step (1) for gelation reaction to obtain slurry II, and then aged; (3) The material obtained in step (2) is separated from solid and liquid, The solid phase is dried, calcined and shaped to obtain a catalyst; wherein the mixed solution A is an aqueous solution containing soluble copper salts, soluble zinc salts and organic additives, and the mixed solution B is an aqueous solution containing soluble copper salts and soluble aluminum salts. The catalyst active metal copper prepared by the method of the invention is evenly distributed, has good synergistic effect, and has a large number of active metal active centers, thereby improving the activity, selectivity and thermal stability of the synthetic copper-zinc catalyst and the service life of the catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

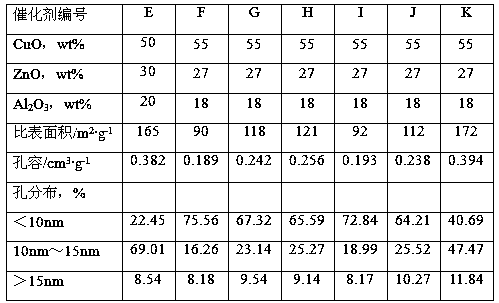

Hydrofining catalyst and preparation method thereof

ActiveCN111822016AImprove stabilityGood dispersionCatalyst activation/preparationBio-feedstockActive centerMaterials science

The invention discloses a hydrofining catalyst and a preparation method thereof. The catalyst is a catalyst containing transition metal phosphide, the catalyst comprises the transition metal phosphideand alumina, based on the weight of the catalyst, the total content of the transition metal phosphide is 40%-95%, the content of the alumina is 5%-45%, the dispersity of the transition metal phosphide is 16%-40%, and the average particle diameter of the transition metal phosphide is 3-8 nm. The catalyst is a phosphide catalyst with high transition metal content, has the advantages of large specific surface area, more active centers, favorable dispersity and higher hydrodesulfurization and hydrodenitrification reaction properties, and is suitable for being used in ultra-deep hydrodesulfurization and hydrodenitrification reactions of diesel fractions.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of hydrocracking catalyst composition

ActiveCN103055926BImprove adhesionEasy to shapeMolecular sieve catalystsHydrocarbon oil crackingMolecular sievePtru catalyst

The invention discloses a preparation method of a hydrocracking catalyst composition. The method comprises the steps of preparing an acidic mixed solution A containing hydrogenation reactive metals and silicon, preparing a sodium metaaluminate alkaline solution B, adding clear water to a reaction tank, and then filling CO2 into the clear water; and then adding the acidic mixed solution A and the alkaline solution B to the reaction tank in parallel to prepare gel, then adding turbid liquid of a Y type molecular sieve, mixing the substances uniformly, filtering the obtained mixture, drying the obtained filter cake, and then forming, washing, drying and roasting the filter cake, thus preparing the hydrocracking catalyst composition. The hydrocracking catalyst composition prepared by the method has the advantages of big specific surface area, big pore volume, high strength and high effective utilization rate of reactive metal components, and is especially suitable for a hydrocracking process for producing more middle distillates.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of copper-zinc catalyst

ActiveCN111686741AEvenly dispersedPore structure is suitableOrganic compound preparationHydroxy compound preparationSodium acid carbonateAluminium salts

The invention discloses a preparation method of a copper-zinc catalyst, which comprises the following steps: (1) carrying out parallel flow gelatinization reaction on a mixed solution A and a sodium metaaluminate solution to obtain slurry I, and aging the slurry I; (2) dropwise adding the mixed solution B and a sodium carbonate solution into the aged slurry I obtained in the step (1) in a parallelflow manner, carrying out a gelling reaction to obtain slurry II, and aging the slurry II; and (3) carrying out solid-liquid separation on the material obtained in the step (2), and drying, roastingand molding the solid phase to obtain the catalyst, wherein the mixed solution A is an aqueous solution containing soluble copper salt, soluble zinc salt and a surfactant P1, and the mixed solution Bis an aqueous solution containing soluble copper salt, soluble aluminum salt and a surfactant P2. The catalyst prepared by the method is uniform in active metal distribution, has a good synergistic effect, improves the activity, selectivity and thermal stability of the copper-zinc catalyst, and has a good application prospect.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing hydrorefining catalyst

ActiveCN110038584BPore structure is suitableOptimized areaHeterogenous catalyst chemical elementsCatalyst activation/preparationOrganic acidPtru catalyst

The invention discloses a preparation method of a hydrogenation refining catalyst. The hydrorefining catalyst is to react the mixed solution A containing Ni and W and the alkaline solution of sodium metaaluminate in parallel flow, and age the obtained slurry, and then mix the mixed solution B containing W, Mo and Al with the Ammonia water is added to the above-mentioned aged slurry in parallel, and then aged, and then treated with a mixed aqueous solution of aluminum salt and organic acid after the first drying, molding, and second drying, and then washed, thirdly dried, and roasted. Produced as a hydrorefining catalyst. The catalyst can be applied in ultra-deep hydrodesulfurization and denitrogenation reactions of diesel fractions, has high hydrodesulfurization and hydrodenitrogenation reaction activity, and is especially suitable for processing diesel raw materials with high nitrogen and high sulfur content.

Owner:CHINA PETROLEUM & CHEM CORP +1

Boiling bed hydrogenation treatment catalyst and its preparing process

ActiveCN101240190BUniform particlesIncrease profitRefining to eliminate hetero atomsSpherical shapedResidual oil

The invention relates to a boiling bed hydrogenation catalyst and a preparation method. The boiling bed hydrogenation catalyst of the invention is spherical shape which diameter is 0.1mm to 0.8mm, and has appropriate amount of additives and hydrogenation of metal components, and has reasonable hole distribution. The catalyst preparation method of the invention is spherical carrier impregnation, the process of spherical carrier preparation is following: making catalyst carrier raw material which is in appropriate temperature into appropriate size grain, then spheroidizing the grain, heating the conglobation and making them into spherical catalyst carrier. The process for making the catalyst carrier raw material into the appropriate size grain is that wet stock passes screen stencil by mechanical action and generates grain. Between the processes of the making grain and nodularization, granular material primely is placed for a period of time or operates in low-speed in nodularization device for a period of time. The catalyst of the invention appropriately conducts the boiling bed hydrogenation for heavy oil, residual oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of hydrocracking catalyst

ActiveCN103055927BUniform grainImprove adhesionMolecular sieve catalystsCatalyst activation/preparationDispersityMolecular sieve

The invention discloses a preparation method of a hydrocracking catalyst. The method comprises the steps of preparing an acidic mixed solution A containing hydrogenation reactive metals and silicon, and preparing a sodium metaaluminate alkaline solution B; adding part of the sodium metaaluminate alkaline solution B to the acidic mixed solution A, and then filling CO2; repeating the step 2 for one-six times; then adding turbid liquid of a Y type molecular sieve, mixing the substances uniformly, and aging the mixture; and filtering, drying and forming the mixture, and then washing, drying and roasting the mixture, thus preparing the hydrocracking catalyst. The method has the beneficial effects that not only can the catalyst be formed easily and the strength of the catalyst be improved, but also the pore volume and specific surface area of the catalyst can be increased, the dispersity of metals in the catalyst can be improved, and the capability of the catalyst in processing macromolecules in heavy oil is enhanced, so that the catalyst has higher hydrocracking activity, middle oil selectivity and stability; and the catalyst can be used for a single-section hydrocracking process of a non-refining section or a one-section serial hydrocracking process of a refining section.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com