Preparation method of copper-zinc catalyst

A catalyst, copper-zinc technology, which is applied in the field of preparation of copper-zinc catalysts, can solve the problems of insignificant dispersion effect of active components, affecting the physicochemical properties of catalysts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

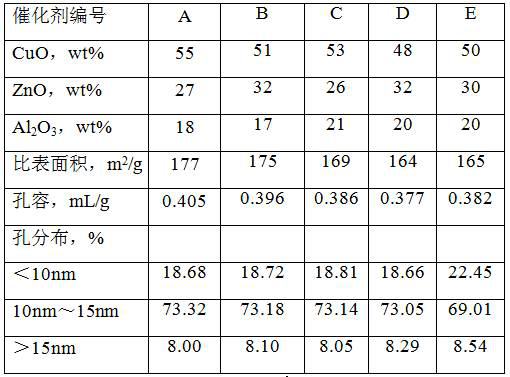

Embodiment 1

[0035] Cu(NO 3 ) 2 ·3H 2 O, Zn(NO 3 ) 2 ·6H 2 O was dissolved in deionized water, added sodium lignosulfonate and mixed evenly to prepare mixed solution A, Cu 2+ The concentration is 2.8mol / L, Zn 2+ The concentration is 2.5mol / L, and the weight concentration of sodium lignosulfonate is 55g / L. Cu(NO 3 ) 2 ·3H 2 O and AlCl 3 ·6H 2 Dissolve O in deionized water, add dimethyl ammonium chloride and mix evenly to form a mixed solution B, Cu 2+ Concentration is 1.8mol / L, Al 3+ The concentration is 2.0mol / L, and the weight concentration of dimethyl ammonium chloride is 23g / L. Add deionized water in the reaction tank, sodium metaaluminate solution (containing Al 2 o 3 42g / L) and the mixed solution A were added into the reaction tank concurrently, the gelling temperature was 60°C, the gelling pH was 7.5, and the gelling time was 0.9 hours to obtain slurry I. The slurry I was aged under stirring, the stirring speed was 220 rpm, the aging temperature was 75° C., the pH val...

Embodiment 2

[0037] According to the method for embodiment 1, by the component content ratio of catalyst B in table 1, Cu(NO 3 ) 2 ·3H 2 O, Zn(NO 3 ) 2 ·6H 2 O was dissolved in deionized water, added diisooctyl sodium sulfosuccinate and mixed evenly to prepare a mixed solution A (wherein the weight concentration of diisooctyl sodium sulfosuccinate was 70g / L), and Cu(NO 3 ) 2 ·3H 2 O and Al 2 (SO 4 ) 3 18H 2 Dissolve O in deionized water, add chlorinated methylaniline and mix evenly to prepare mixed solution B (the weight concentration of chlorinated methylaniline is 18g / L). Add deionized water in the reaction tank, sodium metaaluminate solution (containing Al 2 o 3 36g / L) and the mixed solution A were added into the reaction tank in parallel, the gelling temperature was 55°C, the gelling pH was 7.6, and the gelling time was 0.8 hours to obtain slurry I. The slurry I was aged under stirring, the stirring speed was 225 rpm, the aging temperature was 76° C., the aging pH value wa...

Embodiment 3

[0039] According to the method for embodiment 1, by the component content ratio of catalyst C in table 1, Cu(NO 3 ) 2 ·3H 2 O, Zn(NO 3 ) 2 ·6H 2 0, add sodium cetylbenzene sulfonate and mix evenly, be mixed with mixed solution A and dissolve in deionized water to make mixed solution A (wherein the weight concentration of sodium cetylbenzene sulfonate is 62g / L), the Cu (NO 3 ) 2 ·3H 2 O and Al(NO 3 ) 3 9H 2Dissolve O in deionized water, add dimethylaniline chloride and mix evenly to form a mixed solution B (the weight concentration of dimethylaniline chloride is 20g / L). Add deionized water in the reaction tank, sodium metaaluminate solution (containing Al 2 o 3 54g / L) and the mixed solution A were added into the reaction tank concurrently, the gelation temperature was 52°C, the pH value was 7.5, and the gelation time was 1.1 hours to obtain the slurry I. The slurry I was aged under stirring, the stirring speed was 170 rpm, the aging temperature was 72° C., the agin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com