Patents

Literature

53results about How to "Good skeleton" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Production method of ecotypic sintering ceramic colored permeable brick

InactiveCN105948707AEnsure porosityGood water permeabilityCeramic materials productionClaywaresBrickPrill

The invention belongs to the technical field of inorganic nonmetallic material, and relates to an ecotypic sintering ceramic colored permeable brick and a production method thereof. The method is characterized by including using the waste ceramic particles as a basic skeleton material, using the coarse particle size gradation as an internal layer skeleton material, using the fine particle size gradation as a surface layer skeleton material, adding proper amount of colorless and colored clear glaze fine powder, organic binder CMC, and water, and preparing the qualified ecotypic sintering ceramic colored permeable brick by performing the technologies such as preparation of materials, mixing, aging, secondary material distribution and pressing, drying, sintering and testing. The production method disclosed by the invention is suitable for industrial production of the permeable brick, and the prepared permeable brick has high water permeability, high compressive strength, rich colors, and good practical durability, and is widely used for ground laying of the outdoor public places such as large parking lot, square and city road, and artistic landscape.

Owner:宜兴友邦陶瓷有限公司

Method for matching asphalt suitable for different asphalt pavement

InactiveCN101241122AReasonable structureGood skeletonMaterial testing goodsHigh resistanceRoad surface

A method for matching asphalt mixture suitable for different asphalt road is provided which comprises of steps of: (1) aggregate test; (2) choosing of design aggregate; (3) choosing of dosage of asphalt; (4) Marshall test; (5) high temperature stability test of asphalt mixture at best oil amount; (6) water stability test of asphalt mixture at best oil amount; (7) low temperature bending test of small beam of asphalt mixture at best oil amount. The advantages of the present invention lies in: (1) can obtain high resistance friction to resist track and limit slightness granules to make the aggregate not easy to crash in the build process and traffic, and limit clay content and enhance bond force of aggregate and asphalt; (2) the structure of mixture is reasonable; (3) analysis process of asphalt volume is nicer; (4) asphalt road surface has high anti-track capability, at the same time has higher consistency of vibratory compaction; (5) the mixture prepared by the present invention has merits of less largest dimension granule diameter coarse aggregate and fine aggregate, and more medium aggregate, so the uniformity is good, and easy to press, and the mixture is tends to interlocked-denseness and the framework is good.

Owner:TIANJIN GUORUI ENG EXPERIMENT TESTING

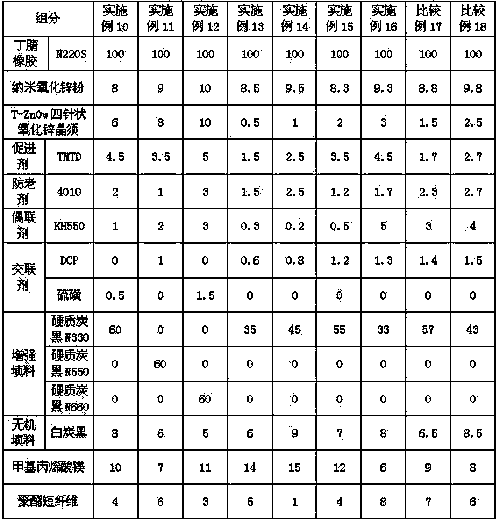

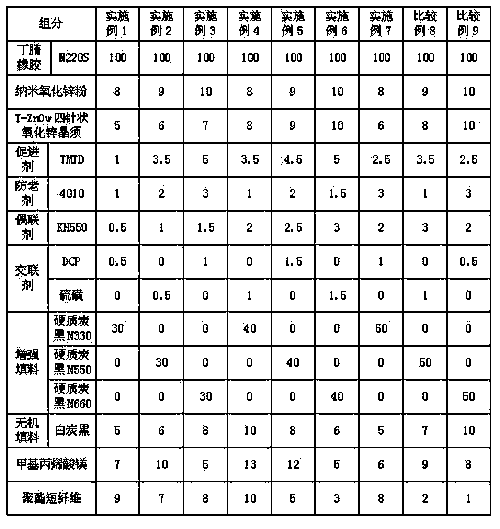

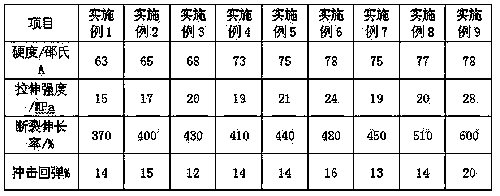

Nitrile rubber composite capable of improving mechanical property

The invention discloses a nitrile rubber composite capable of improving mechanical property. With the adoption of the composite, the nitrile rubber composite with better mechanical property can be obtained, and can be used for a blowout preventer rubber seal product. The composite adopts the technical scheme that the composite takes nitrile rubber as a main material. The composite adopts a T-ZnOw tetrapod-like zinc oxide whisker and utilizes high strength and high modulus of a complete structure of the composite to improve a high molecule; a three-dimensional crystal form structure of the composite is dispersed in a matrix, so that a skeleton effect is exerted; a unique three-dimensional space structure allows a gripping force between the composite and the matrix to be greater, so that an improvement effect is more significant, and the tensile strength is improved significantly; and transverse and longitudinal tensile strength values are basically same, so that the mechanical property of a matrix material is improved isotropically, and the strength and the processability of the matrix are improved significantly.

Owner:HEBEI BOLU TIANBAO PETROLEUM EQUIP MFG CO LTD

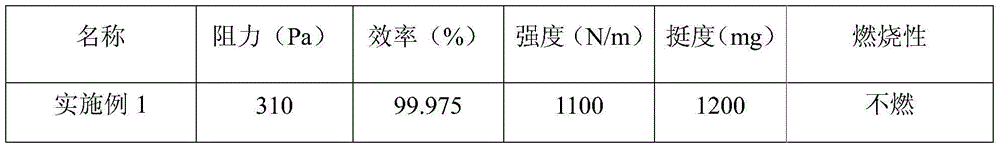

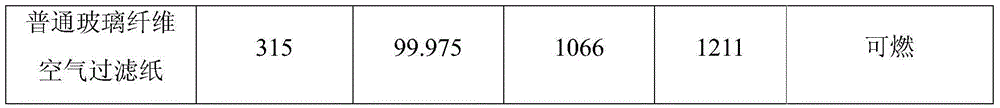

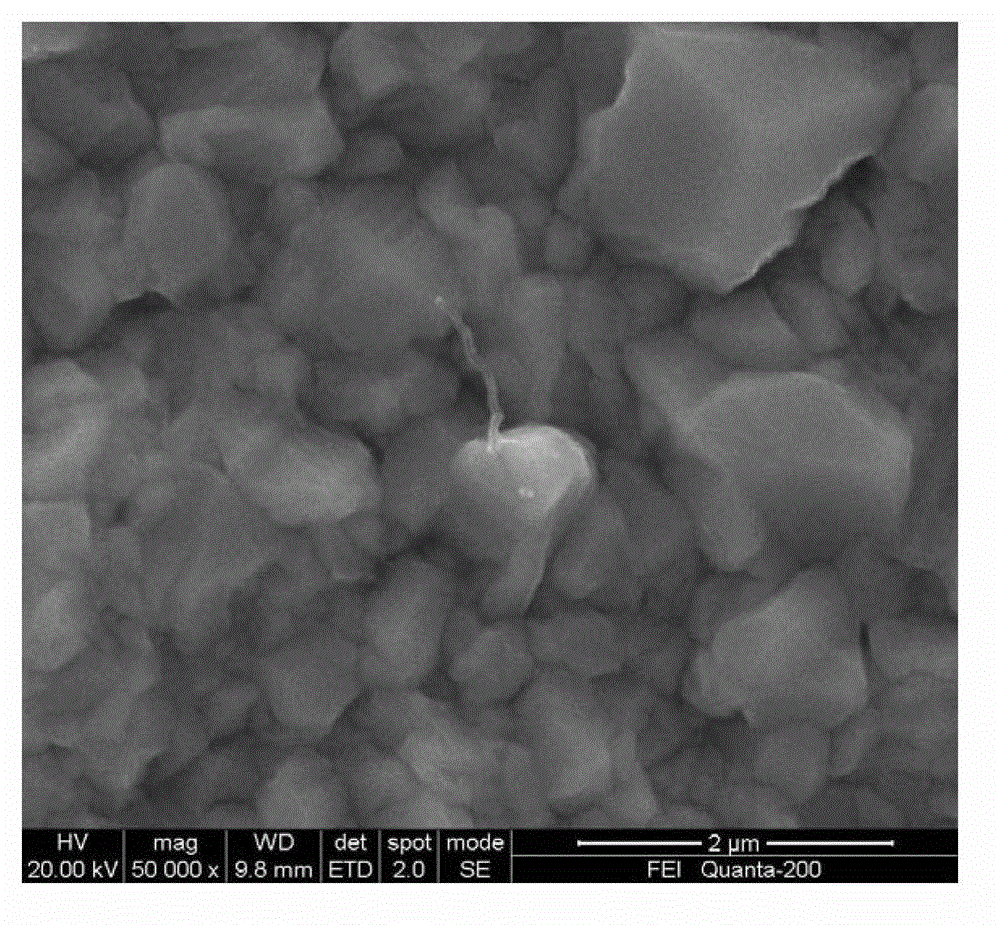

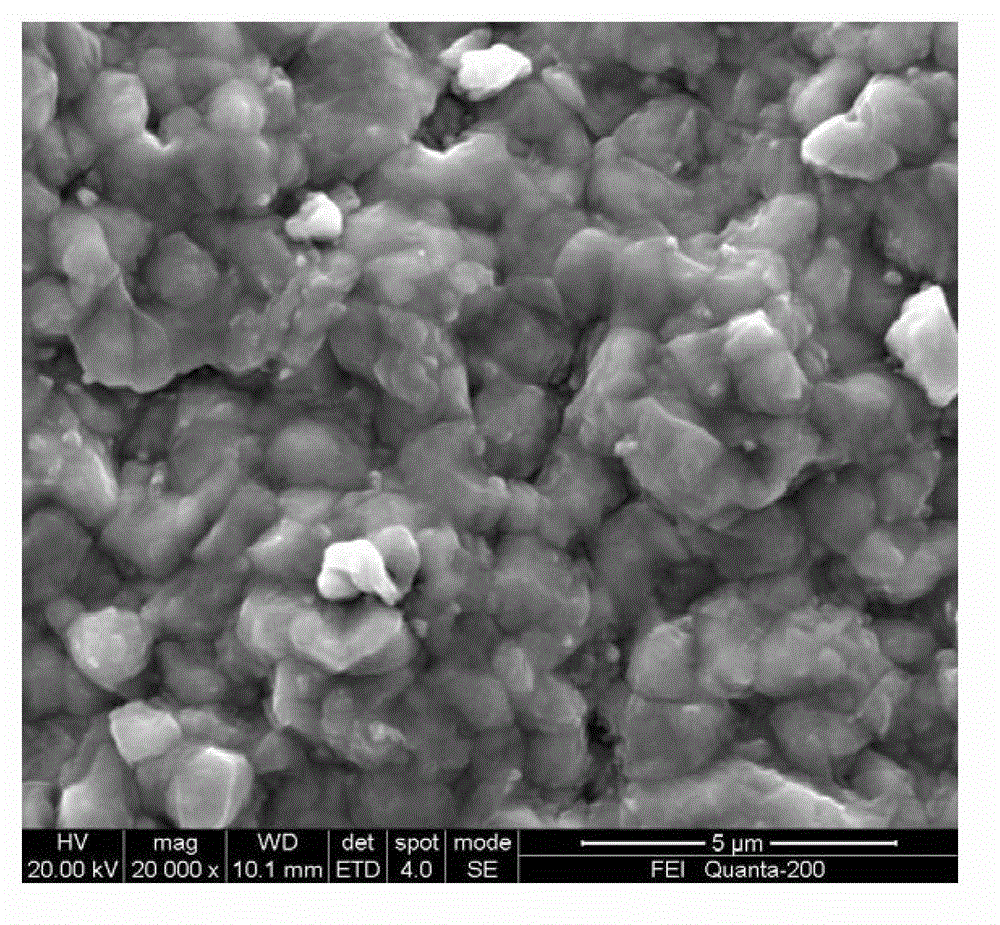

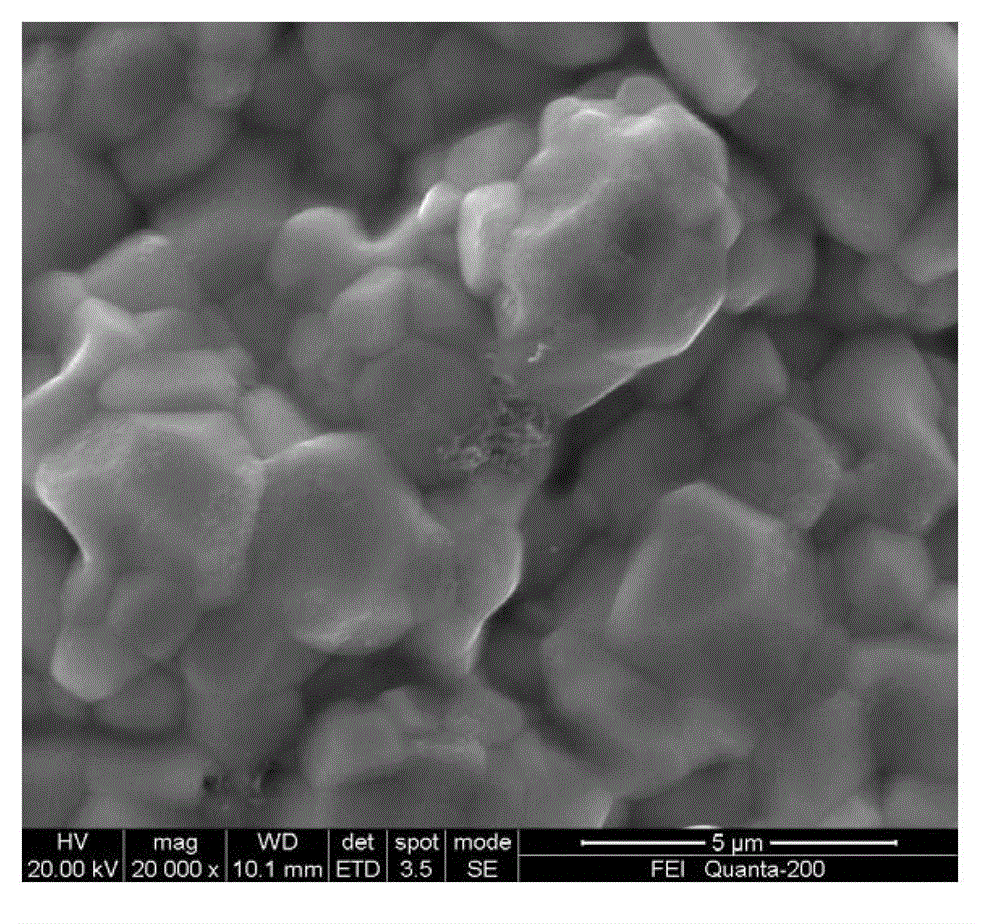

High flame retardancy glass fiber air filtering paper and preparation method thereof

ActiveCN103556544AThe mesh is tightly combinedThe gap is uniform and fineSynthetic cellulose/non-cellulose material pulp/paperFiltration separationEmulsionMicrometer

The invention discloses a piece of high flame retardancy glass fiber air filtering paper which is prepared from alkali-free glass fiber cotton with the diameter being 7-9 micrometers, alkali-free glass fiber cotton with the diameter being 0.3-0.4 micrometer, and a binding material, wherein the mass ratio of the alkali-free glass fiber cotton with the diameter being 7-9 micrometers to the alkali-free glass fiber cotton with the diameter being 0.3-0.4 micrometer is 1:(3.8-4.2); the binding material is a mixture of acrylic emulsion and a halogen-free organic phosphate fire retardant. The invention further discloses a preparation method of the high flame retardancy glass fiber air filtering paper. The preparation method comprises the following steps of firstly, pulping to disperse the raw materials so as to obtain pulp, subsequently gluing wet paper, removing moisture in the wet paper, and finally drying so as to obtain a product. The glass fiber air filtering paper is smooth and uniform in surface, and good in flame retardant property.

Owner:CHONGQING ZAISHENG TECH CORP

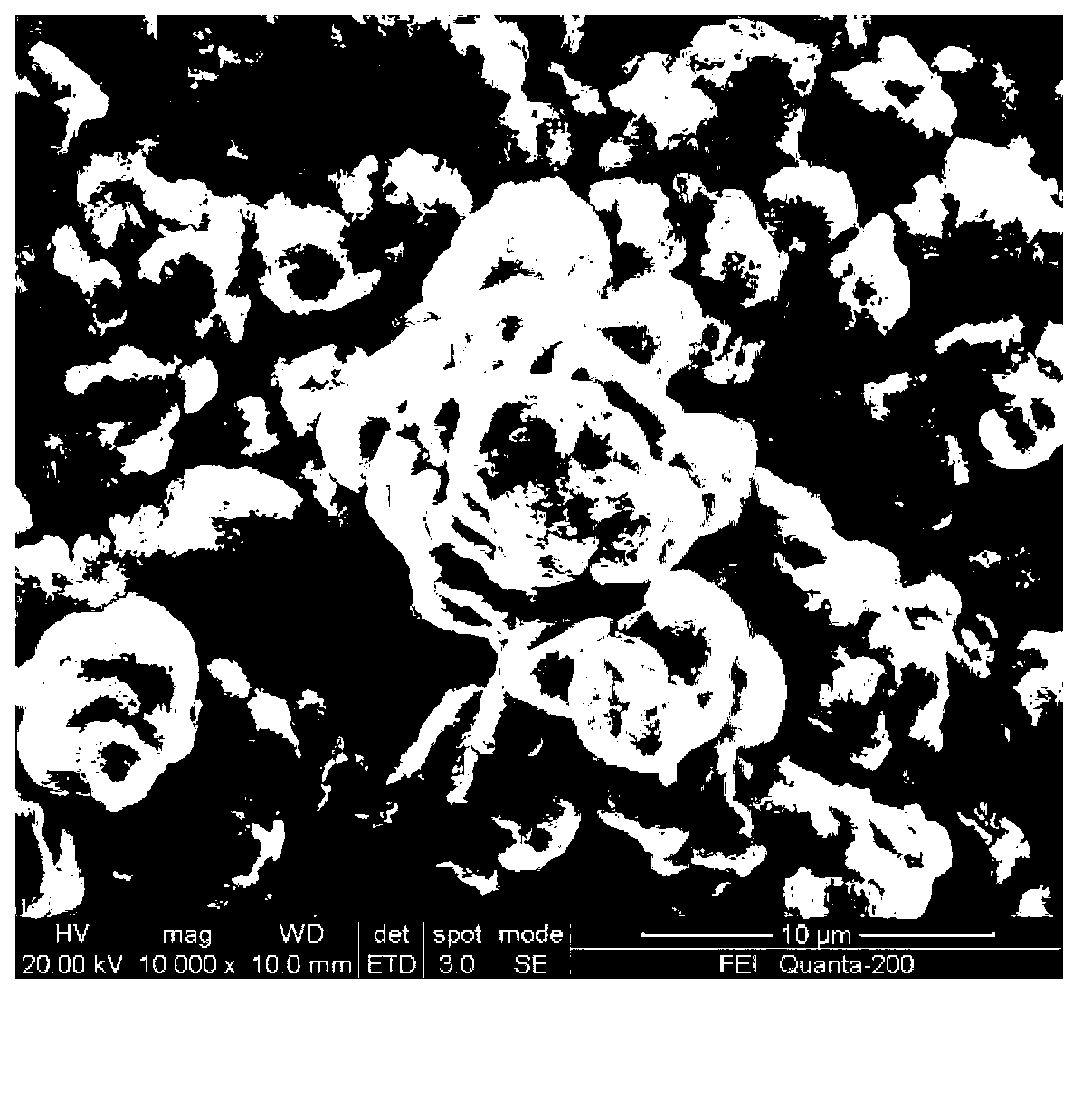

Carbon-Cu6Sn5 alloy negative electrode materials and preparation method thereof

InactiveCN103066252AReduce the likelihood of sheddingIncrease migration rateElectrolytic coatingsCell electrodesCarbon nanotubeAlloy

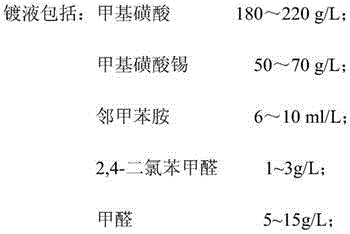

The invention discloses carbon-Cu6Sn5 alloy negative electrode materials and a preparation method thereof. The carbon-Cu6Sn5 alloy negative electrode materials and the preparation method thereof combine carbon nanometer tubes and graphene into electrodes and add a Cu-CNTs connecting layer between active materials and current collectors. Therefore, cyclic perforce of an alloy negative electrode is improved greatly. The carbon-Cu6Sn5 alloy negative electrode materials and the preparation method thereof use copper foils as the current collectors (electroplating substrates). The copper foils are plated by a Cu-CNTs composite plating and a composite plating of stannum-carbon nanometer tubes or stannum- graphene or stannum-carbon nanometer tubes- graphenes in sequence, wherein the thickness of the Cu-CNTs composite plating is 1-5 micrometers and the thickness of the composite plating of the stannum-carbon nanometer tubes or the stannum- graphene or the stannum-carbon nanometer tubes- graphene is 1-4 micrometers. The carbon-Cu6Sn5 alloy negative electrode materials can be obtained finally through thermal treatments. First specific discharge capacity of lithium ion battery alloy cathodes prepared by the method can achieve 613 m AH / g and specific capacity attenuation of the lithium ion battery alloy cathodes is only 4%-6% after 100 cycles. The carbon-Cu6Sn5 alloy negative electrode materials and the preparation method thereof are simple in technique, good in prepared alloy cathode performance and suitable for large-scale industrial production.

Owner:XIANGTAN UNIV

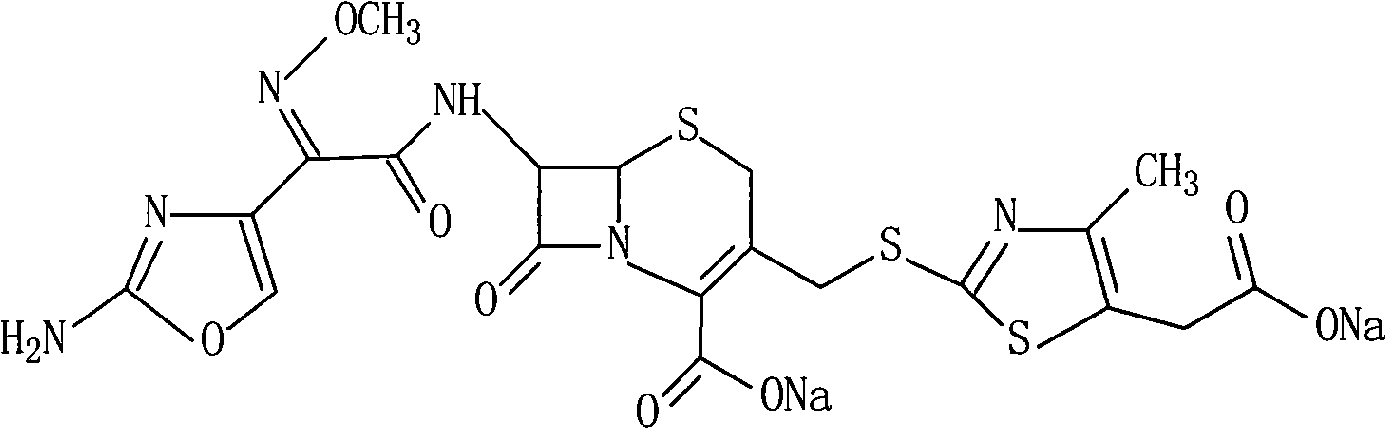

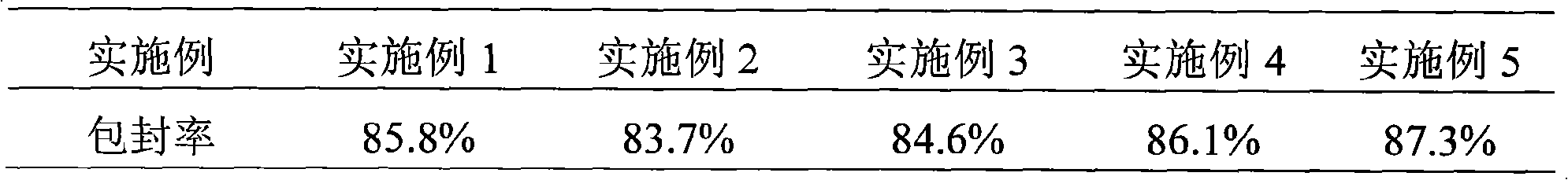

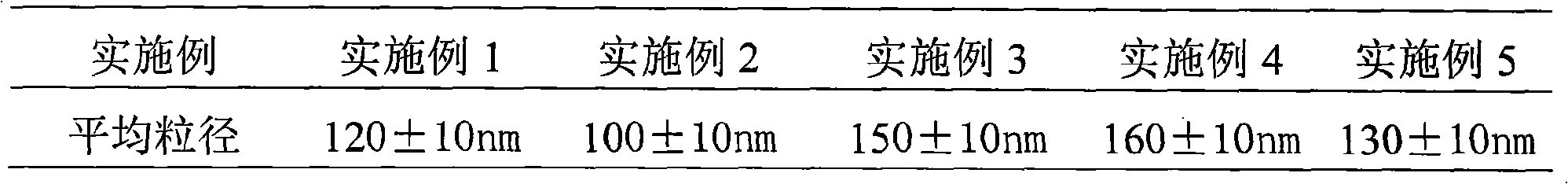

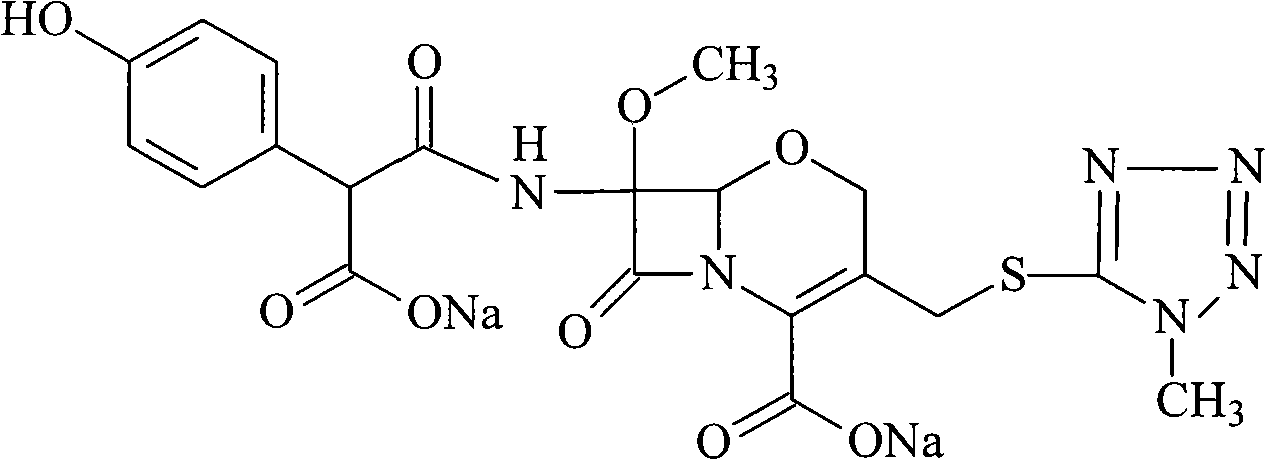

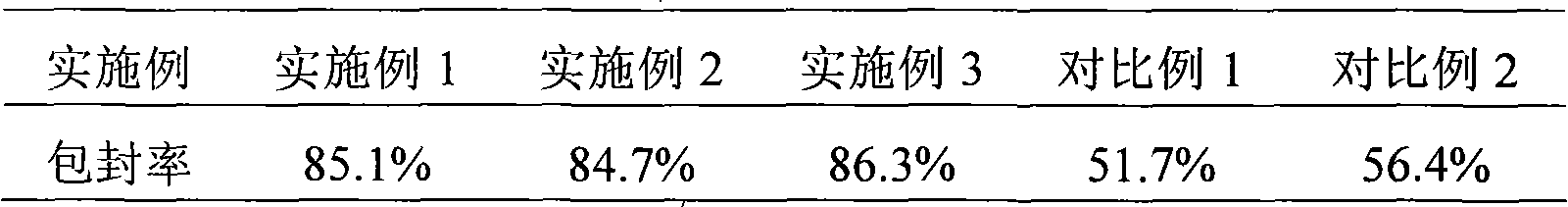

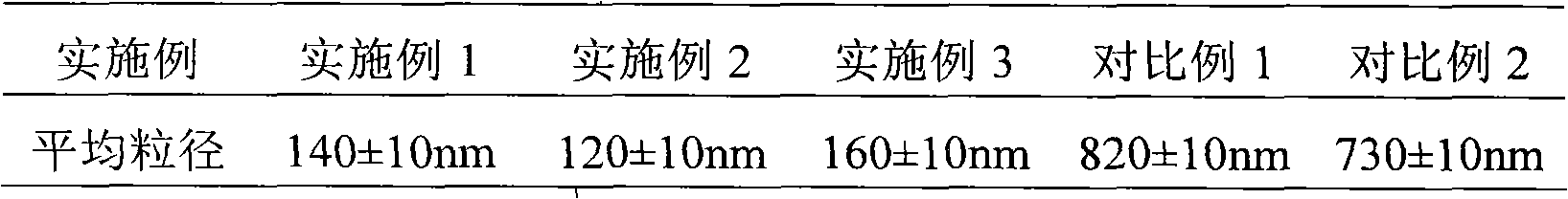

Cefodizime sodium proliposome preparation and preparation method thereof

InactiveCN101584664AUnexpected effectNo toxicityAntibacterial agentsOrganic active ingredientsCefodizime SodiumCholesterol

The invention relates to a cefodizime sodium proliposome preparation and a preparation method thereof. The proliposome preparation comprises cefodizime sodium, egg yolk lecithin, cholesterol, antioxidant and supporting agent, wherein the cefodizime sodium proliposome preparation comprises the following components by weight portion: 1 to 20 portions of the cefodizime sodium, 5 to 50 portions of the egg yolk lecithin, 3 to 30 portions of the cholesterol, 0.5 to 20 portions of the antioxidant and 3 to 50 portions of the supporting agent.

Owner:HAINAN LINGKANG PHARMA CO LTD

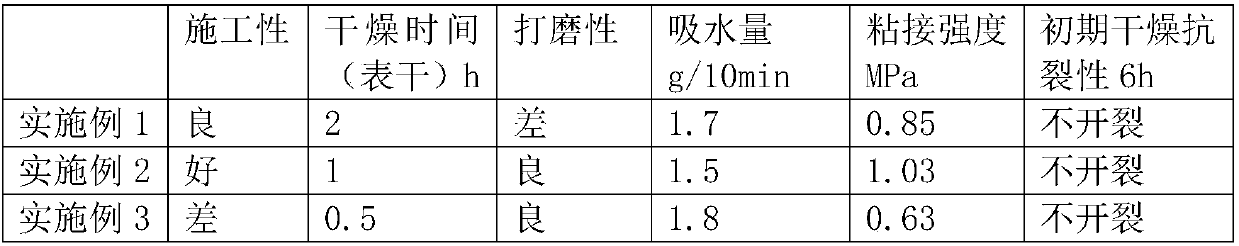

Putty for external wall spraying and preparation method of putty

The invention discloses putty for external wall spraying and a preparation method of putty. The putty contains the following raw materials in parts by weight: 260-320 parts of ash concrete, 250-300 parts of coarse whiting, 320-370 parts of snowflake white, 100-150 parts of talcum powder, 1-3 parts of lignocelluloses, 3-6 parts of cellulose ether, 6-10 parts of rubber powder, 2-4 parts of a water reducer, 2-4 parts of attapulgite and 2-4 parts of starch ether. The putty is prepared from multiple materials such as the rubber powder, the cement, a filler and an additive through compounding, is high in bonding strength and good flexibility and thixotropy, can adequately play roles of external wall leveling and decoration, has good thixotropy and flow resistance and does not flow, and the spraying construction can be realized.

Owner:HUBEI JIADE PUAN PAINT

Carbon nano tube-Sn-M alloy cathode material and preparation method thereof

InactiveCN103022449AComplete structureResidue reductionElectrolytic coatingsCell electrodesCarbon nanotubeAlloy

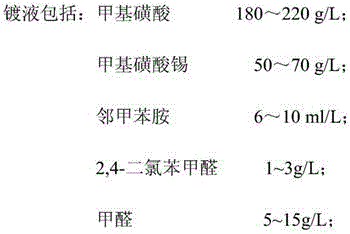

The invention discloses a carbon nano tube-Sn-M alloy cathode material and a preparation method of the carbon nano tube-Sn-M alloy cathode material. According to the invention, carbon nano tubes (CNTs) are composited into an electrode; a CNTs-Cu connection layer is added between the active material and a current collector; and the advantages of multicomponent alloy are combined, so that the circulation property of the alloy cathode is greatly improved. According to the invention, copper foil is used as a current collector (electroplate substrate) to composite and electroplate a CNTs-Cu composite coating with the thickness of 1-5 micro and a thin tin (or tin alloy) film with a thickness of 1-4 micro in sequence; and finally the CNTs-Sn-M alloy cathode material is obtained by heat treatment. The lithium ion battery alloy cathode prepared by adopting the method has a specific discharge capacity of 500-800 mAh / g for the first time, and the specific capacity is only decayed by 2-5 percent after 100 times of circulation. According to the invention, the process is simple, the performance of the prepared alloy cathode is good, and the alloy cathode is suitable for performing large-scale industrialized production.

Owner:XIANGTAN UNIV

Preparation method of multilayer structure battery cathode material containing C3N4 composite material

InactiveCN105789588ALarge specific surface areaEasy to captureCell electrodesSecondary cellsCarbon layerElectrical battery

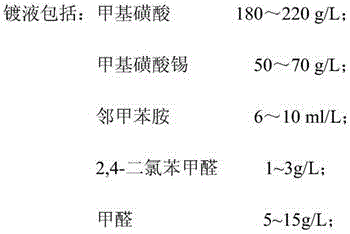

The invention discloses a preparation method of a multilayer structure battery cathode material containing a C3N4 composite material. By adopting the method, a complete carbon layer structure generates lots of defects and active sites which can better capture lithium ions so as to increase the lithium insertion quantity and improve the specific capacity of the cathode material; moreover, a rough-surface copper-plated aluminum foil is selected in structure and has the advantage of large specific surface area, and the relatively large specific surface area and a concave-convex structure can perfectly buffer the volume expansion in the charge / discharge process of tin; and meanwhile, the structure also can perfectly play a role of a skeleton, and the stress of volume expansion / shrinkage in the charge / discharge process is greatly buffered so as to improve the cycle performance of the aluminum / copper / tin / graphite multilayer structure cathode material.

Owner:SUZHOU SICHUANGYUANBO ELECTRONICS TECH CO LTD

Latamoxef sodium proliposome preparation

InactiveCN101642432AImprove stabilityHigh encapsulation efficiencyAntibacterial agentsOrganic active ingredientsLatamoxefSide effect

The invention provides a latamoxef sodium proliposome preparation which comprises 1-20 portions of latamoxef sodium, 5-40 portions of di-stearic acid phosphatidyl choline, 2-15 portions of cholesteroland 3-50 portions of support agent. The invention also provides a preparation method and application of the proliposome preparation. The proliposome preparation has the advantages of high stability and entrapment efficiency, uniform particle diameter, less side effect, and the like.

Owner:HAINAN MEIDA PHARMA

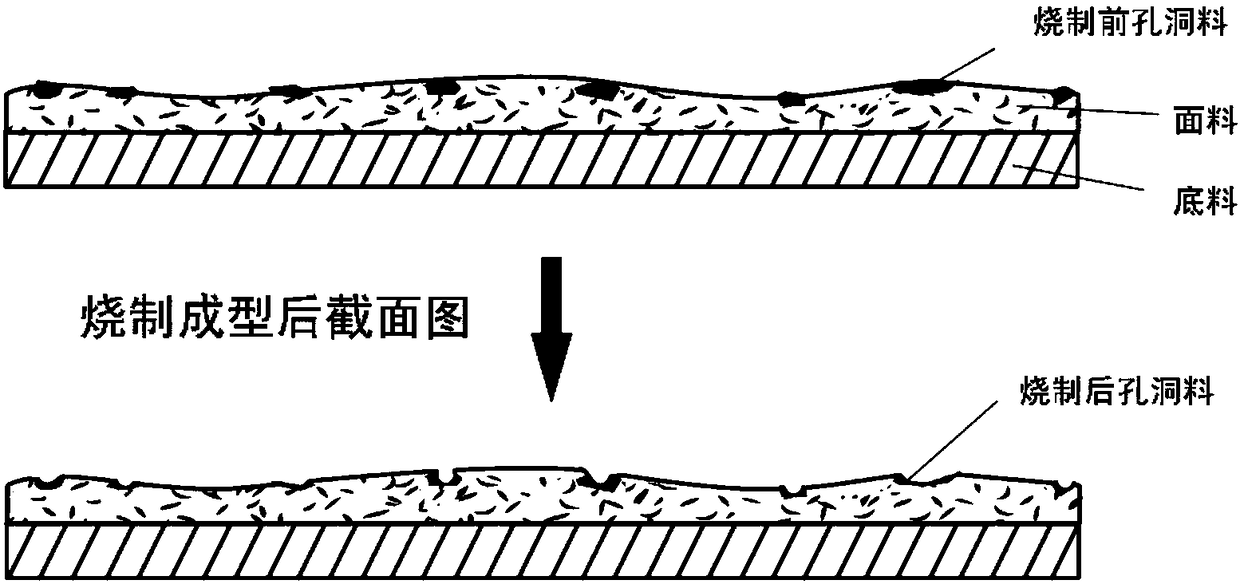

Preparation method of pore material, marble-imitated pore brick and preparation method thereof

ActiveCN108545999AVariety of textures and colorsImprove plasticityFeeding arrangmentsCeramicwareEpoxyBrick

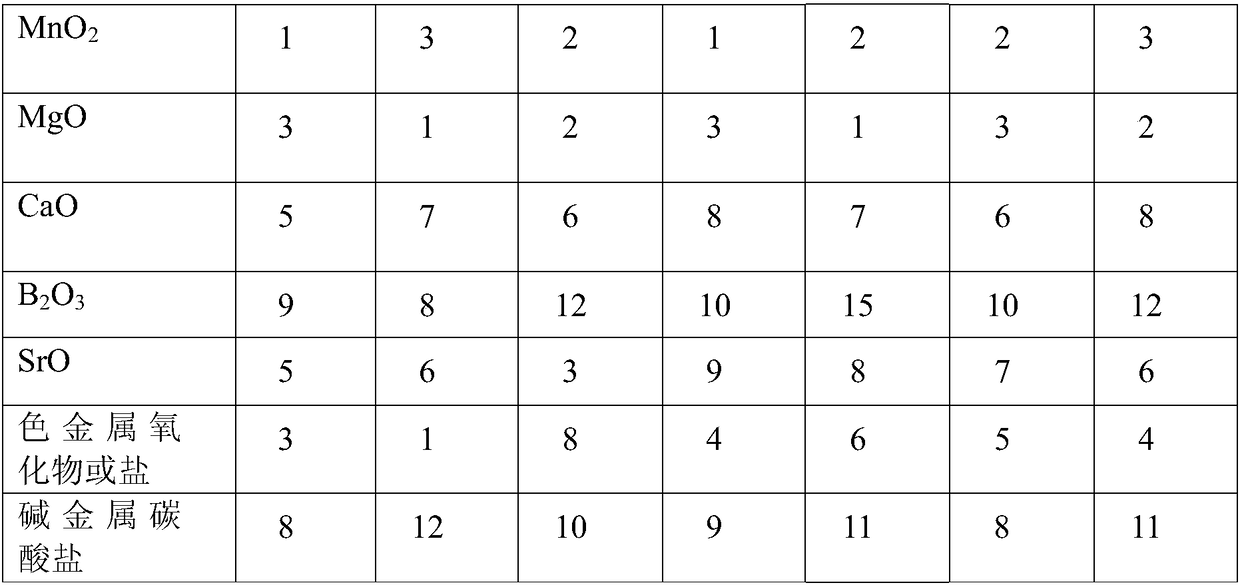

The invention discloses a preparation method of a pore material, a marble-imitated pore brick and a preparation method thereof; the preparation method of the pore material includes the following steps: a, mixing 45-55 parts by weight of SiO2, 3-7 parts by weight of Al2O3, 1-3 parts by weight of MnO2, 1-3 parts by weight of MgO, 5-8 parts by weight of CaO, 8-15 parts by weight of B2O3, 3-9 parts byweight of SrO, 1-8 parts by weight of coloring metal oxide or salt and 8-12 parts by weight of alkali metal carbonate, to prepare pore material frit, crushing to obtain pore material frit powder; b,mixing 20-40 wt% of the pore material frit powder, 20-30 wt% of epoxy resin, 30-50 wt% of a diluent and 1-5 wt% of a curing agent to form slurry; and c, after the slurry is cured, crushing to form irregular particles, and sieving to obtain the pore material. The pore material is used in the process of the marble-imitated pore brick, can form various and abundant geometric pore structure and has good skeleton feeling; moreover, a colored bright glossy effect is formed inside the pore material, and the pore decoration effect of the brick surface is greatly improved.

Owner:FOSHAN DONGHUA SHENGCHANG NEW MATERIAL CO LTD +3

Preparation method of multilayer anode with porous carbon composite material

InactiveCN105702935AHigh activityLarge specific surface areaCell electrodesSecondary cellsDischarge efficiencyRough surface

The invention discloses a preparation method of a multilayer anode with a porous carbon composite material. According to the method provided by the invention, the activity of the material can be increased by utilizing porous carbon spheres with relatively large specific surface areas; a copper plated aluminum foil with a rough surface is selected in structure; the copper plated aluminum foil has the advantage of large specific surface area; through adoption of the relatively large specific surface area and a concave-convex structure, volume expansion of tin in a charge-discharge process can be buffered well; moreover, the structure plays a framework role; the volume expansion and shrinkage stress in the charge-discharge process can be buffered greatly; the first time charge-discharge efficiency of the anode material is 76%; when the anode material discharges in 400mA / g, after the anode material cycles for 360 cycles, the capacity retention ratio is 79%; and when the anode material discharges in 600mA / g, after the anode material cycles for 480 cycles, the capacity retention ratio is 88%. The method provided by the invention is simple in technology and easy in control and is applicable to large scale production.

Owner:SUZHOU SICHUANGYUANBO ELECTRONICS TECH CO LTD

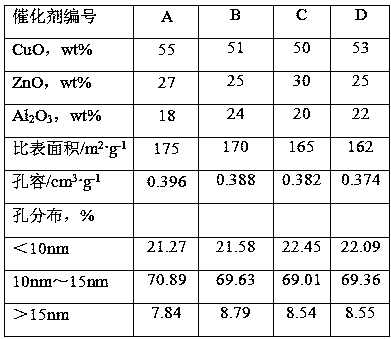

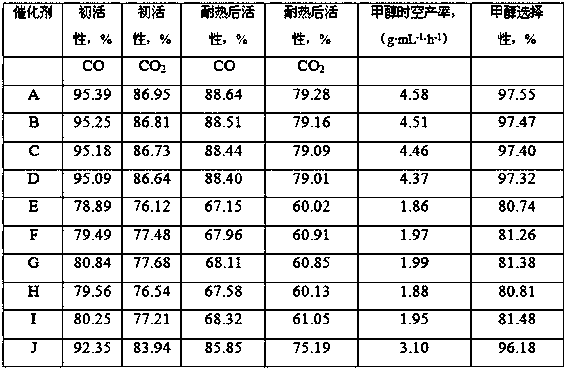

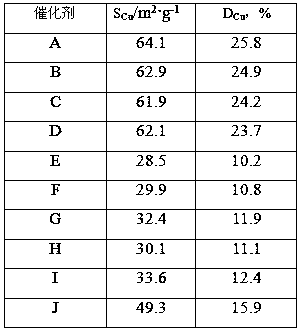

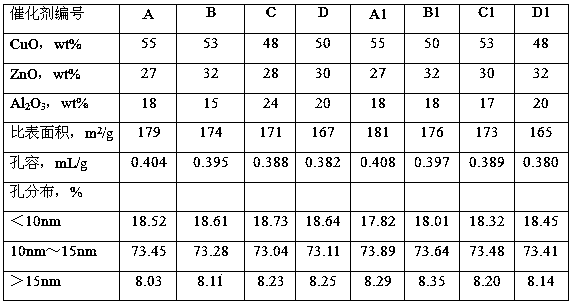

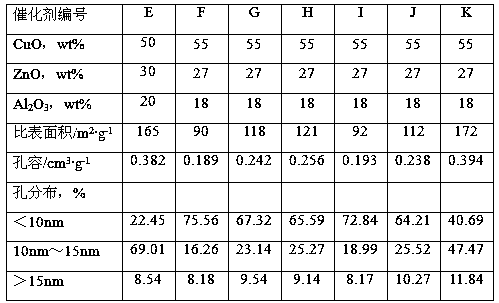

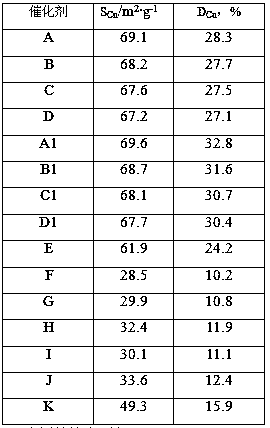

Preparation method of copper-containing catalyst

ActiveCN111686739AEvenly dispersedGood dispersionOrganic compound preparationHydroxy compound preparationPtru catalystSodium aluminate

The invention discloses a preparation method of a copper-containing catalyst, which comprises the following steps: (1) carrying out parallel flow gelatinization reaction on a mixed solution A and a sodium metaaluminate solution to obtain slurry I, and aging the slurry I; (2) dropwise adding the mixed solution B and a sodium carbonate solution into the aged slurry I obtained in the step (1) in a parallel flow manner, carrying out a gelling reaction to obtain slurry II, and aging the slurry II; and (3) carrying out solid-liquid separation on the material obtained in the step (2), and drying, roasting and molding the solid phase to obtain the catalyst, wherein a quaternary ammonium salt compound is added before the gelling reaction in the step (1), wherein the mixed solution A is an aqueous solution containing a soluble copper salt, a soluble zinc salt and an organic auxiliary agent, and the mixed solution B is an aqueous solution containing a soluble copper salt and a soluble aluminum salt. The catalyst has characteristics of uniform active metal copper distribution, good synergistic effect, large active metal active center number, catalyst activity improving, catalyst selectivity improving, catalyst thermal stability improving, and good application prospect.

Owner:CHINA PETROLEUM & CHEM CORP +1

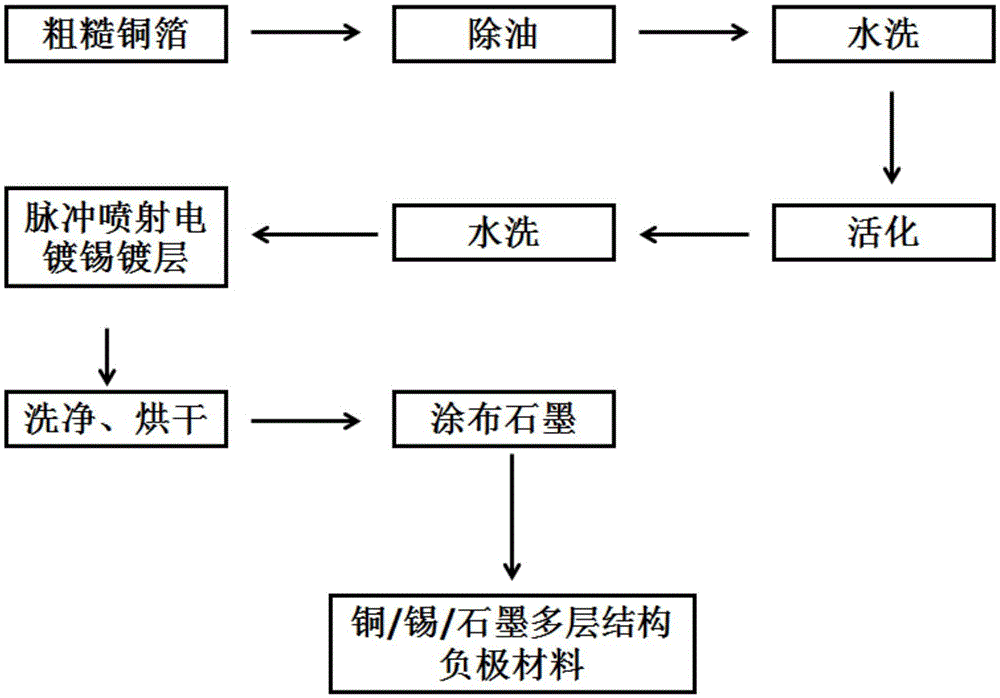

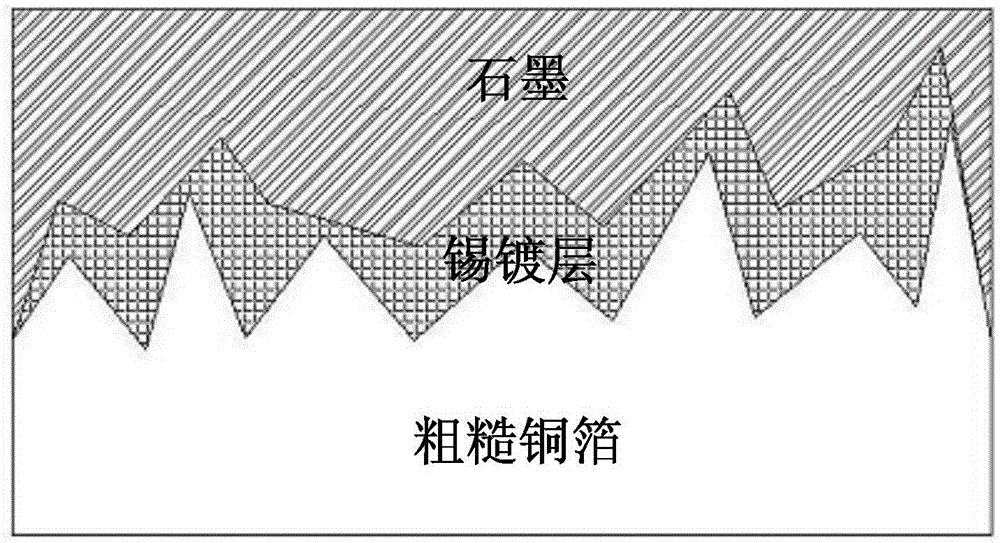

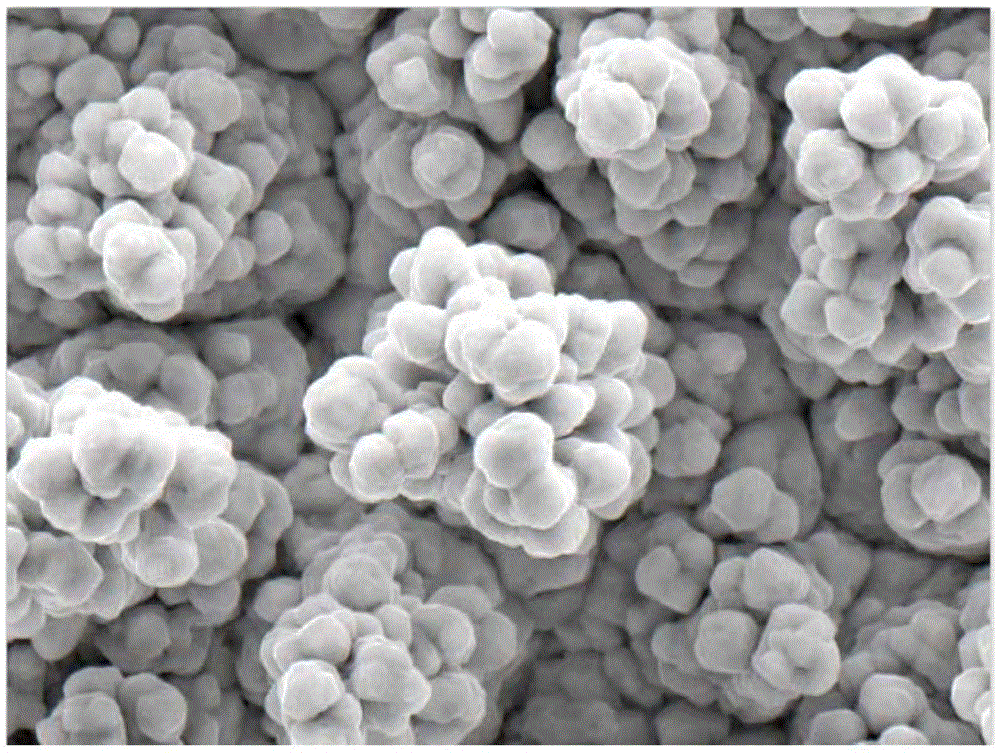

Copper/tin/graphite multi-layer structure anode material for lithium-ion battery and preparation method of copper/tin/graphite multi-layer structure anode material

InactiveCN105470487AImprove bindingIncrease migration rateCell electrodesSecondary cellsElectricityCopper foil

The invention discloses a copper / tin / graphite multi-layer structure anode material for a lithium-ion battery and a preparation method of the copper / tin / graphite multi-layer structure anode material, and belongs to the field of anode materials for lithium-ion batteries. The method comprises the following steps: with coarse copper foil or porous copper foil as a base, sequentially platingone surface with tin and further coating the surface with graphite to obtain a two-layer film structure; and after the copper foil is electrolyzed, unoiled and activated, preparing a tin coating by a pulse jet method, coating the tin coating with a layer of graphite, and carrying out thermal treatment at 80-150 DEG C, so as to prepare the copper / tin / graphite multi-layer structure anode material. Compared with the prior art, the copper / tin / graphite multi-layer structure anode material has better cycle performance than a tin anode material, and a higher specific capacity than a graphite anode material; and meanwhile, the technological process is simple. Therefore, the application prospect is very wide.

Owner:XIANGTAN UNIV

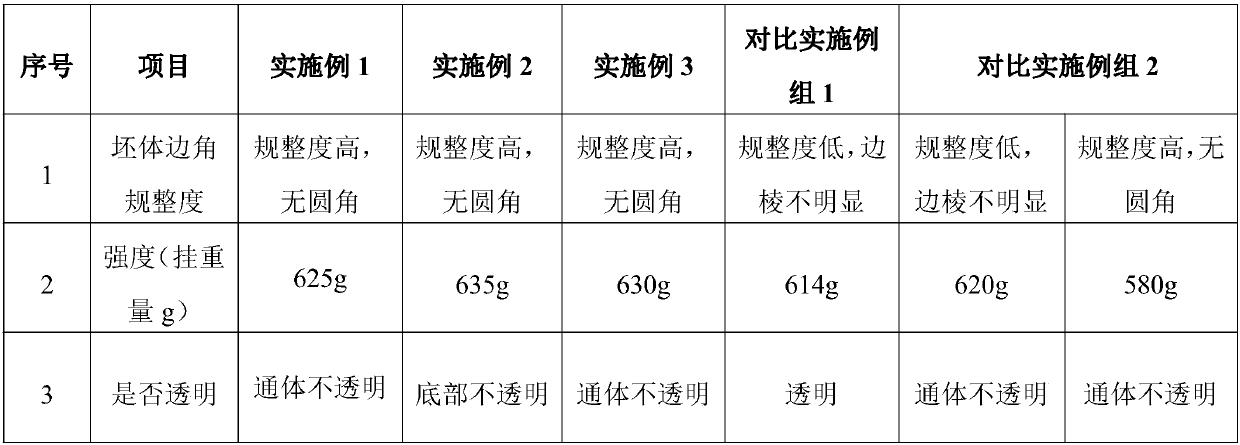

Technology for producing mosaic glass body

InactiveCN107827355AImprove the decorative effectAdd dimensionGlass shaping apparatusCompression moldingMetallurgy

A technology for producing a mosaic glass body comprises the following steps: 1, uniformly mixing 80-95 mass% of raw glass powder with 5-20 mass% of waste glass powder to obtain a mixture; 2, adding water to the mixture obtained in step 1, performing ball milling to obtain a slurry, and granulating and sieving the slurry to obtain a mixed body powder; and 3, adding the mixed body powder into a die, performing compression molding, and carrying out low-temperature sintering to obtain the mosaic glass body. The technology for producing the mosaic glass body has the advantages of realization of the effective recycling of the waste glass powder, and reduction of the production cost; and the prepared mosaic glass body has the advantages of high regularity, good skeleton feeling, structured and uniform laying, high strength and good non-transparent effect.

Owner:佛山市唯格建材有限公司 +1

Efficient energy-saving heat-insulation brick and method for preparing same

The invention provides an efficient energy-saving heat-insulation brick and a method for preparing the same. The efficient energy-saving heat-insulation brick is prepared from river channel sludge, coal gangue powder, palygorskite powder, brucite fibers, glass fibers, modified aluminum oxide, hydroxypropyl guar gum, glycol distearate, polycarboxylate water reducing agents, fire-resistant oxide, styrene, pore forming agents, composite additives and water. The efficient energy-saving heat-insulation brick and the method have the advantages that the efficient energy-saving heat-insulation brick prepared by the aid of the method is low in heat conductivity, excellent in heat-insulation performance and mechanical property and high in anti-erosion ability; the method is simple and is low in cost, the efficient energy-saving heat-insulation brick is mainly made from waste pollutants, and accordingly the efficient energy-saving heat-insulation brick and the method have certain energy conservation and environmental protection benefits.

Owner:HEFEI OAKS NEW BUILDING MATERIAL CO LTD

Piglet feed formula

The invention discloses a piglet feed formula. According to the piglet feed formula. The feed is composed of following raw materials in percentage by weight: 43% of corn, 12% of rice bran, 16% of soya bean meal, 5% of vinasse protein, 10% of wheat middling, 3% of corn germ meal, 4% of rice bran meal, 2.5% of cooked soybean flour, 4% of premix, 0.2% of zeolite powder and 0.3% of Cisuanbao. The piglet feed contains high-quality amino acids, mineral substances and other nutritional ingredients so as to be good for health and growth of pigs; meanwhile, the pigs have good skeletons and shapes; meanwhile, an environment-friendly formula is used so that the foul smell of excrement of the pigs can be effectively reduced and the environment protection is easy to realize; various small peptide and oligopeptide proteins are added so that the production performance of the pigs and the feed utilization rate are improved, and the diarrhea of the pigs and the morbidity of other diseases are effectively reduced.

Owner:漳州日高饲料有限公司

Highway concrete with thermal insulation effect and good durability

The invention discloses highway concrete with thermal insulation effect and good durability. Raw materials of the highway concrete comprise: Portland cement, gravel, ceramsite, pumice, expanded perlite, glazed hollow beads, fishbone dust, carbon fiber, polyimides fiber, a polychloroprene emulsion, epoxy resin, sulphur, sodium alkyl benzene sulfonate, a polycarboxylate superplasticizer and modifiedlignin fibre. The invention brings forward highway concrete with thermal insulation effect and good durability. The highway concrete with thermal insulation effect and good durability has a certain thermal insulation effect and good durability.

Owner:来安县塔鑫建材有限公司

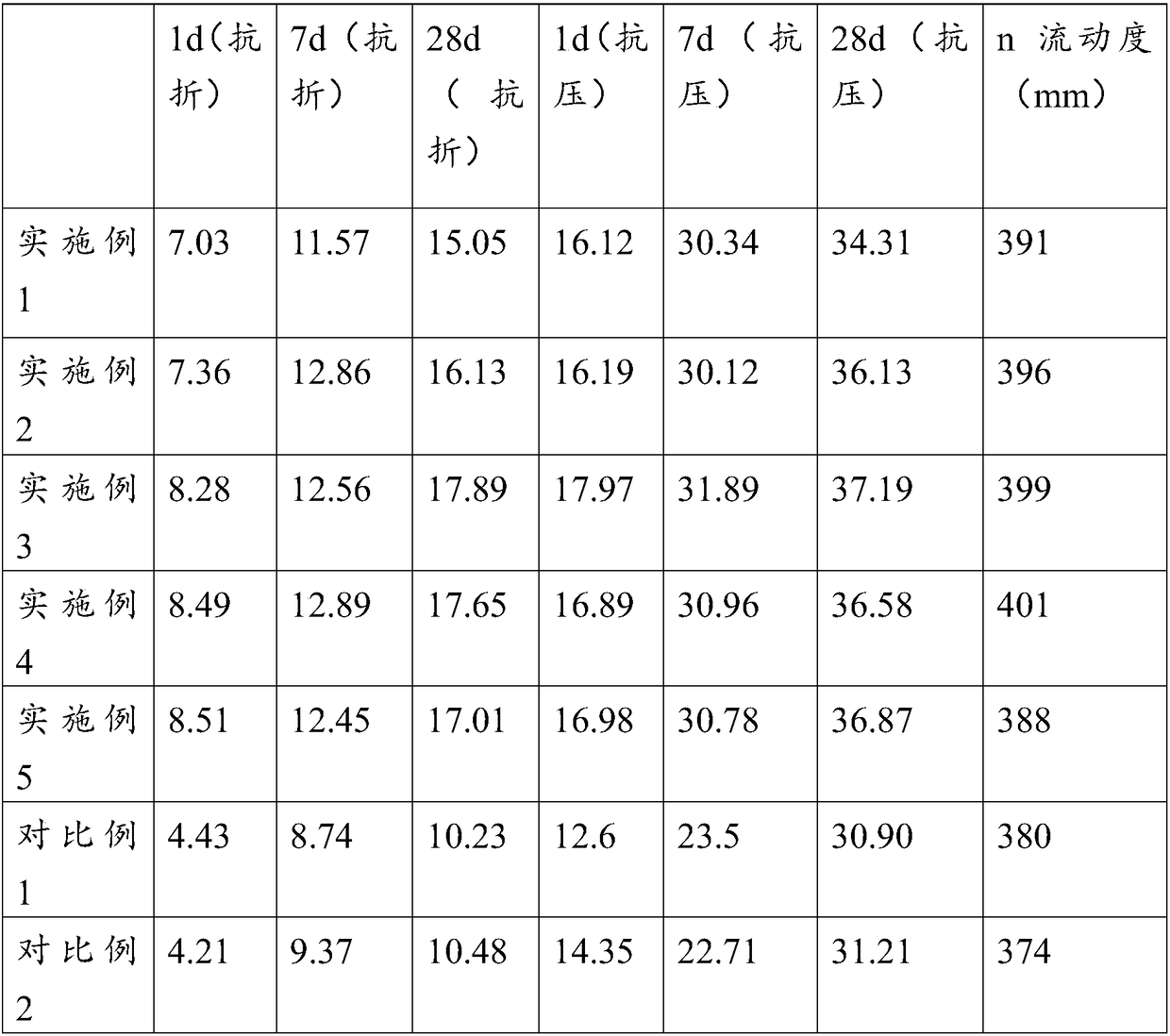

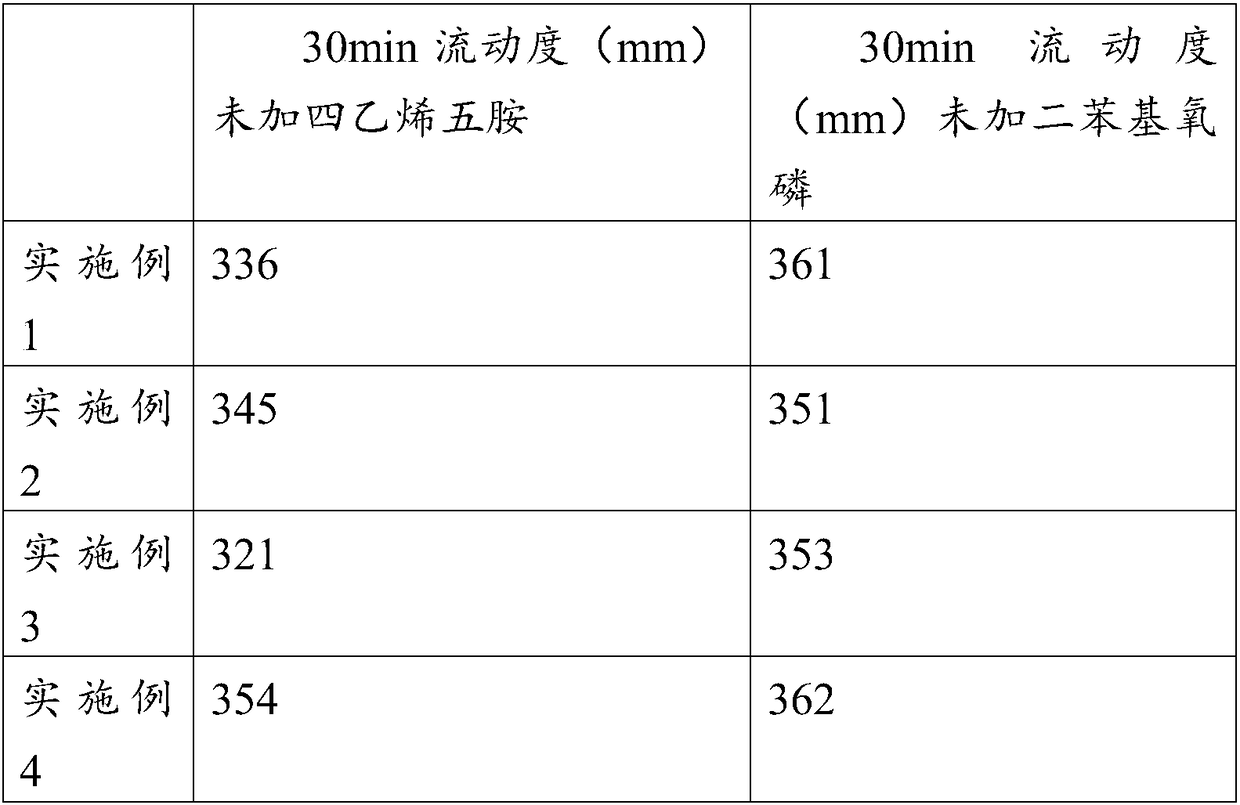

Building high-strength grouting material and preparation method thereof

The invention discloses a building high-strength grouting material. The building high-strength grouting material is prepared from, by weight, 44 parts of Portland cement, 33 parts of silver sand, 5 parts of fiber mixture, 4.5 parts of superfine slag powder, 2 parts of expanding agent, 1.5 parts of water reducing agent, 2 parts of defoaming agent, 3 parts of organic silicon microspheres, 4 parts ofglass beads and 1.2 parts of tetraethylenepentamine. The building high-strength grouting material is good in heat preservation and physical strength performance and high in compressive strength and breaking strength and has the high practical value and the good application prospect.

Owner:段宝荣

Non-sintered residual soil brick-making formula

The invention discloses a brick making method using non-sintered residual soil, adopting residual soil, cement, calcium oxide, calcium sulfate and fly ash as materials. Due to large sand content of residual soil and thick sand grain, the invention plays a good role as framework and effectively reduces drying shrinkage. The added fly ash can increase the silt content of the residual soil, so as to adjust the graduation of the residual soil. The calcium oxide can expand after hydrolysis for offsetting the volume shrinkage of the brick body during freezing, and then, is combined with carbon dioxide generating calcium carbonate for cementation. The activities of the fly ash, the calcium oxide and the silicon dioxide are stimulated by calcium sulphate, further improving the product strength. The calcium sulfate simulates the activities of the fly ash, the calcium oxide and the silicon dioxide, improving the strength of the product further. The invention has the advantages of utilizing building unproductive soil, protecting environment and saving energy due to the adoption of residual soil in the seaboard as materials.

Owner:王权民

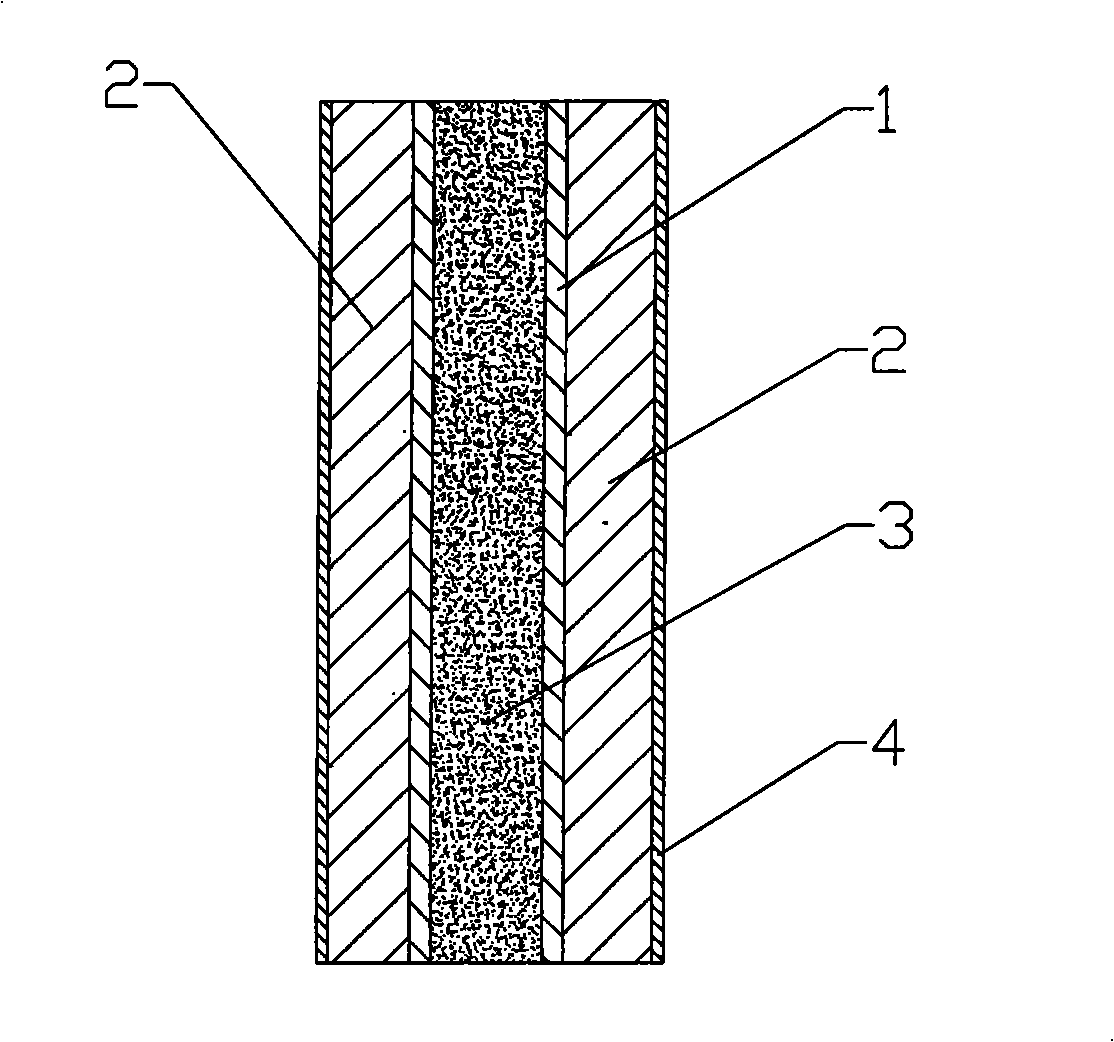

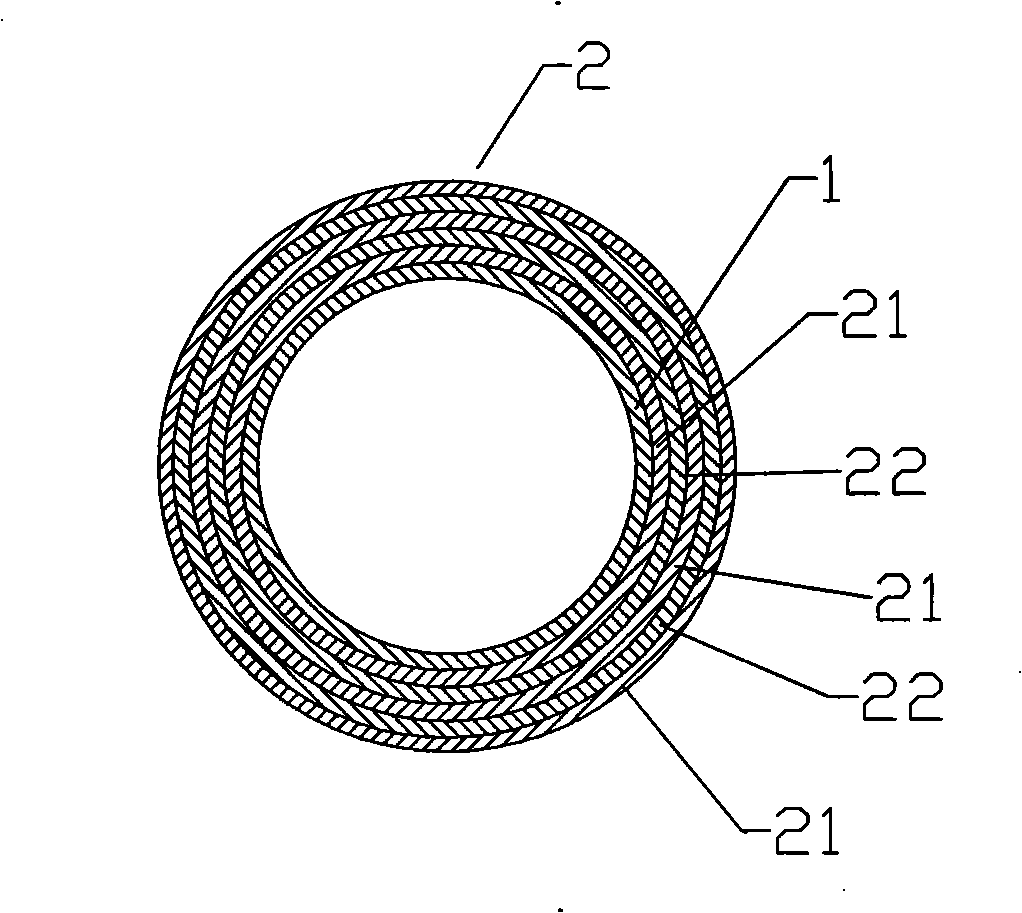

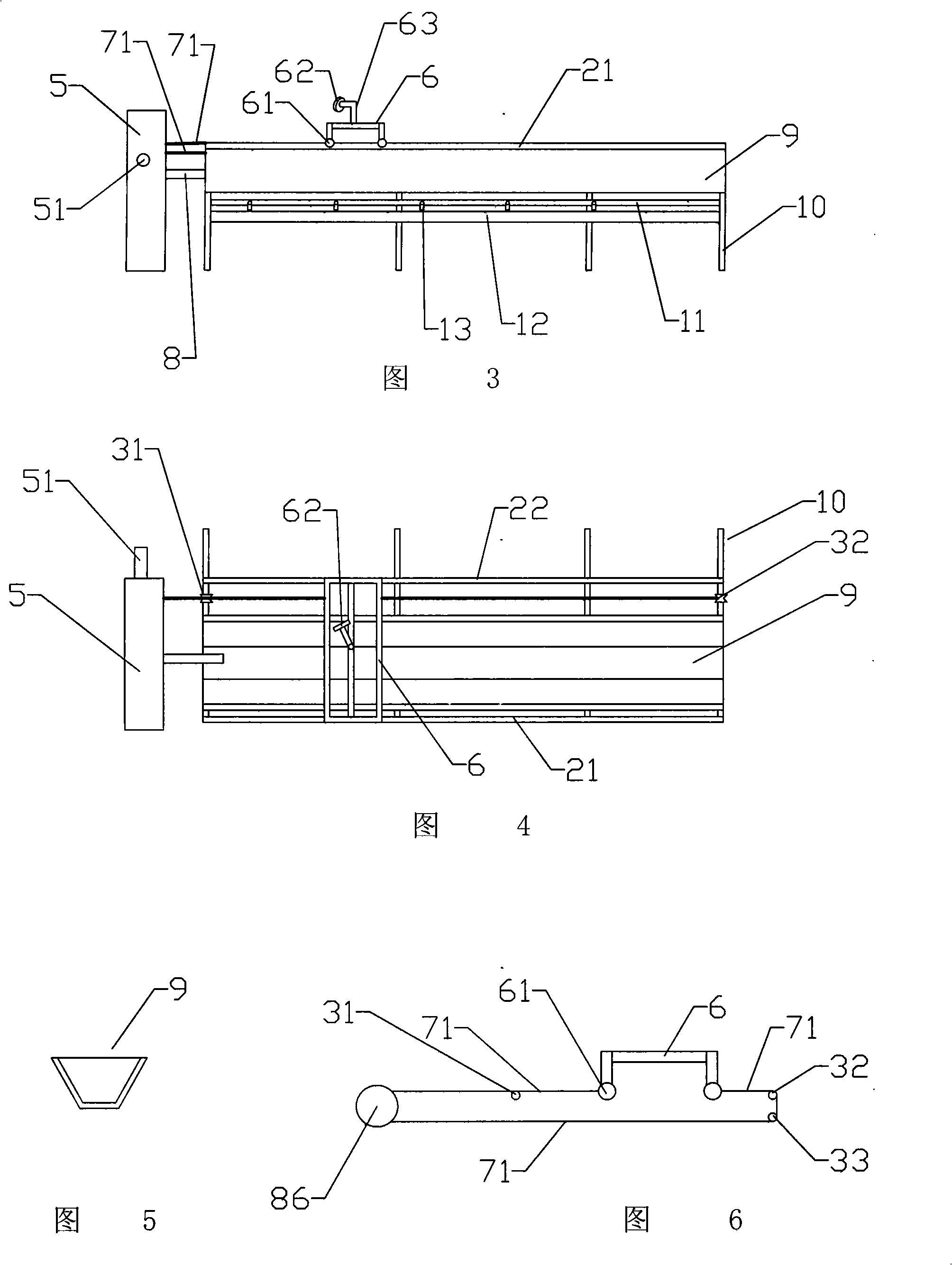

Support lever for greenhouse frame and processing equipment and preparation thereof

InactiveCN101322465AStable structureReduce weightClimate change adaptationFramesMetal frameworkEngineering

The invention relates to a knighthead for greenhouse frameworks and a processing device thereof and a preparation method, and the knighthead comprises a metal framework layer. The outer part of the metal framework layer is fixedly provided with a reinforced layer; the inner part of the metal framework layer is filled with a core body made of foamed material; the processing device comprises a stander, a power plant, the stander is provided with a stock tank, the power plant is provided with an output shaft, and the axis of the output shaft is positioned inside the stock tank. The preparation method is as follows: the metal framework layer is arranged inside the stock tank, sizing agent is poured inside the stock tank, glass fiber cloth is put inside the stock tank, the metal framework layer is rotated, the glass fiber cloth is coiled on the metal framework layer, a moving cart moves for coiling a PET film, scraps on the film are washed inside a water tank, the PET film is removed, a layer of unsaturated resin is coated on the outer layer so as to have more stable structure, lighter weight and more convenient installation. The winding way of the glass fiber cloth strengthens the intensity and toughness of the reinforced layer and has more corrosion resistance, and the surface resin and the reinforced layer do not easily scratch the film and have long service life.

Owner:张文

Concrete based on 3D printing, preparation method thereof and 3D printing column template

ActiveCN113372075AImprove stress resistanceImprove adsorption capacityAdditive manufacturing apparatusSolid waste managementCelluloseAluminate

The invention discloses concrete based on 3D printing, a preparation method thereof and a 3D printing column template, and relates to the field of constructional engineering, and the concrete is prepared from the following raw materials in parts by mass: 80-120 parts of ordinary Portland cement; 10-15 parts of silica fume; 4-7 parts of quick-setting and quick-hardening sulphoaluminate cement; 60-85 parts of quartz sand; 30-50 parts of water; 1-2 parts of a water reducing agent; 1-2 parts of an expanding agent; 0.4-0.6 part of a defoaming agent; 0.02-0.04 part of an air entraining agent; and 0.04-0.06 part of cellulose and the like. The method comprises the following steps: weighing the raw materials; uniformly mixing raw materials such as polyvinyl alcohol fiber and ordinary Portland cement to obtain a dry powder mixture; uniformly mixing the water and the water reducing agent, adding the mixture into the dry powder mixture, uniformly stirring, and discharging. The column template is formed by printing the concrete. The printing effect is good, the printed component has good compression resistance and bending resistance, the cracking rate is low, and application and popularization are easy.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

Preparation method of waste heat recycling concrete

InactiveCN109454745AIncrease internal temperatureImprove safety and qualityCeramic shaping apparatusTemperature differenceSlurry

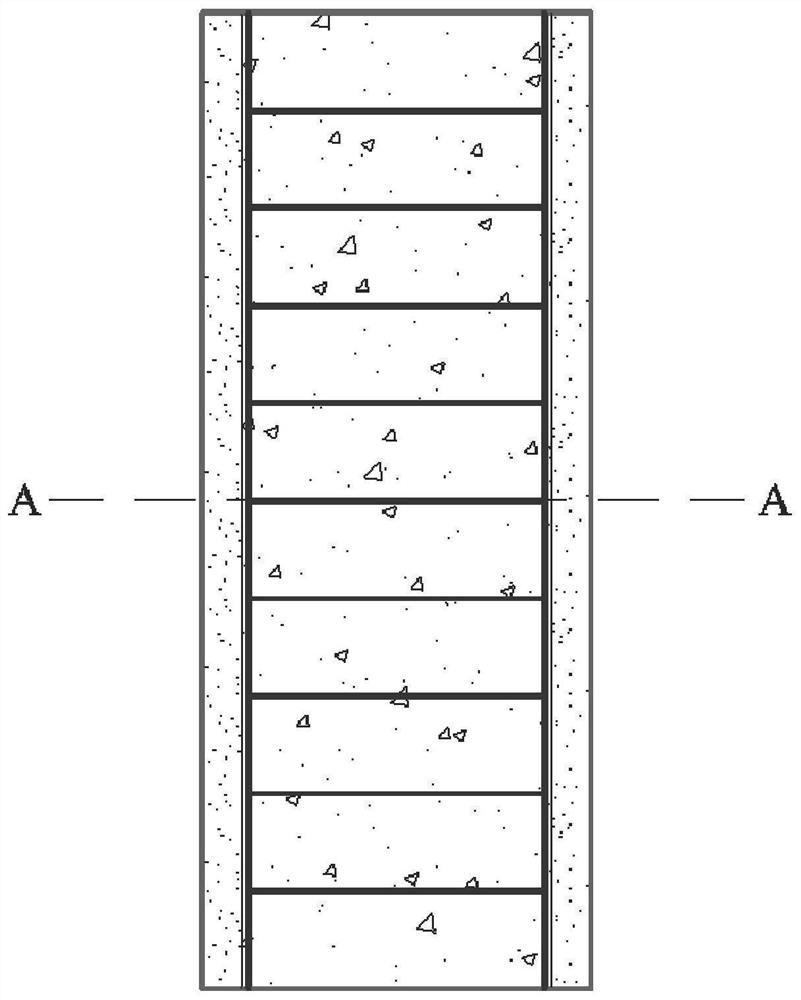

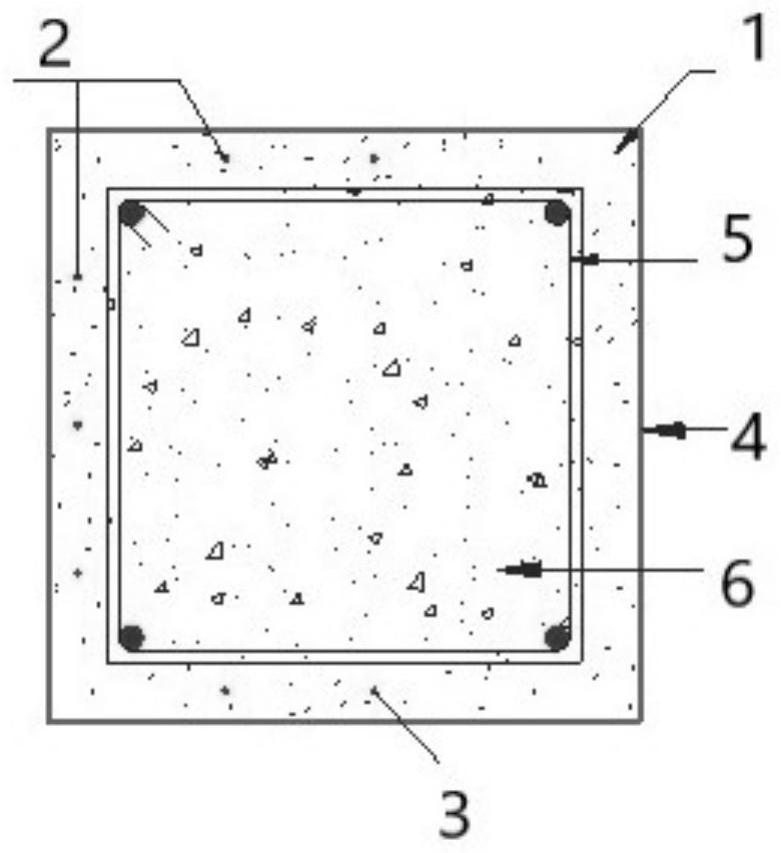

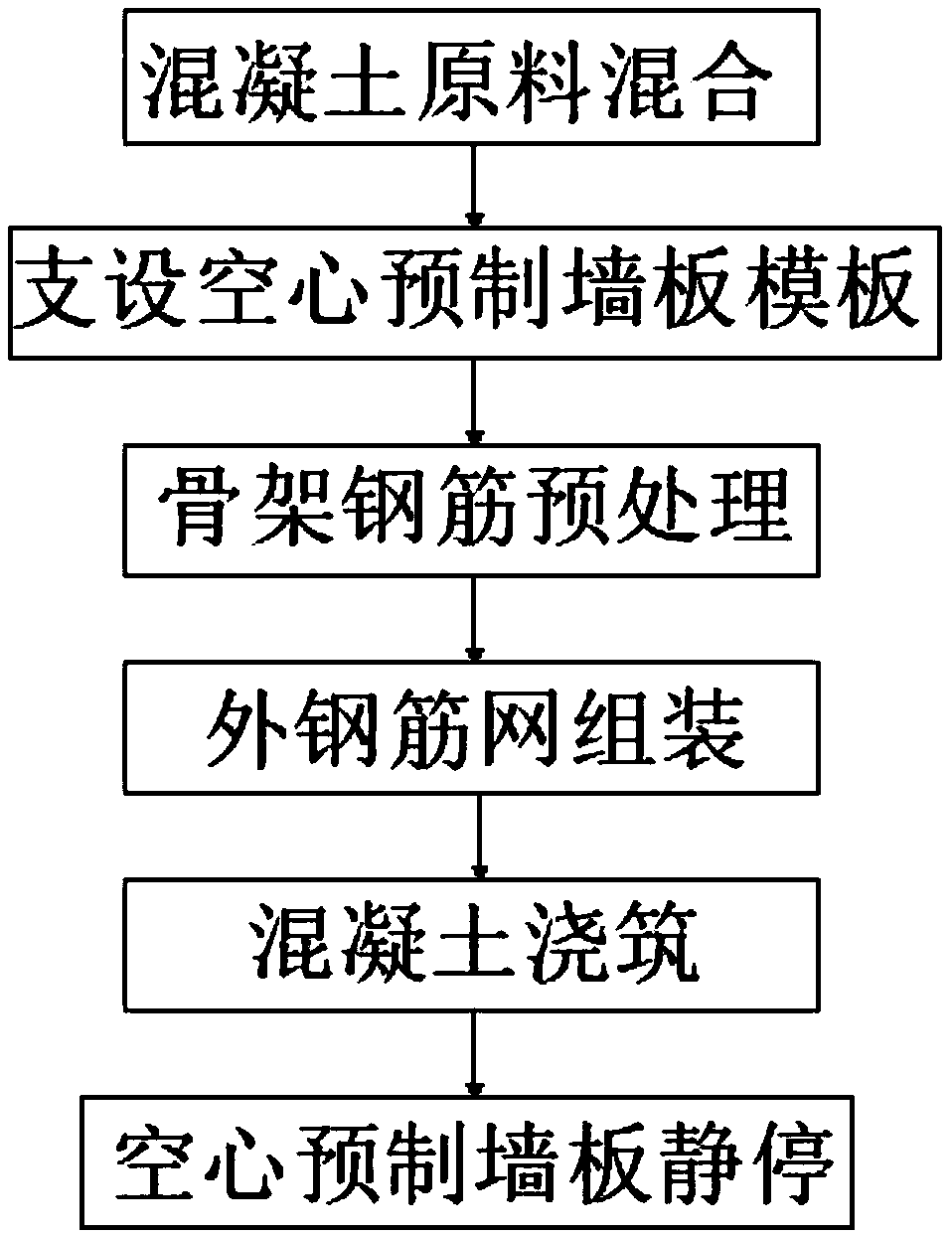

The present invention discloses a preparation method of a waste heat recycling concrete and belongs to the technical field of concrete production; the preparation method comprises the following stepsof: mixing concrete raw materials; erecting a hollow prefabricated wall formwork; pre-treating skeleton reinforcements; assembling outer reinforcement meshes; pouring the mixed concrete into the hollow prefabricated wall formwork, and controlling pouring velocity; and static placing the hollow prefabricated wall formwork for heat preservation at certain temperature after thickening and solidifyinga concrete slurry in the hollow prefabricated wall formwork; through the preparation method, in a process of static placing the poured concrete slurry, internal temperature of the hollow prefabricated wall formwork can be increased and internal and external temperature differences of the hollow prefabricated wall formwork can be reduced, thereby reducing internal and external stress differences of the hollow prefabricated wall formwork during concrete solidification and avoiding cracks in the hollow prefabricated wall formwork, and improving use safety and construction quality of the hollow prefabricated wall formwork.

Owner:罗永学

Straw filament and cow urine fermented material prepared nursery and culture substrate

InactiveCN106797821APromote fermentationReduce dosageBio-organic fraction processingExcrement fertilisersBiotechnologyFermentation

Disclosed is a straw filament and cow urine fermented material nursery and culture substrate. The straw filament and cow urine fermented material prepared nursery and culture substrate is prepared from the raw materials of, by weight percentage, 20-30% of cow urine, 8-20% of perlite or vermiculite or a mixture of perlite and vermiculite, 16-60% of straw filament and 10-20% of turf. The invention also relates to a preparation method of the straw filament and cow urine nursery and culture substrate. The method comprises rubbing straw filaments, fermenting the straw filaments and cow urine, and mixing the fermented materials with the perlite or vermiculite or the mixture of the perlite and the vermiculite as well as turf. The straw filament and cow urine fermented material nursery and culture substrate has the advantages that the rubbed straw filaments are large in specific surface area and high in absorbability to water and fertilizer and accordingly are beneficial to on-site cow urine cleaning and absorption of fermented fertilizer; application of bacteria can be reduced or even saved; rubbing treatment on straw can damage ash on the surface of the straw, so that the straw can turn easy to ferment, and the fermentation time can be shortened by more than 50%.

Owner:山东商道生物科技股份有限公司

Preparation method of methanol synthesis catalyst

ActiveCN110935456AGood dispersionOptimized areaOrganic compound preparationHeterogenous catalyst chemical elementsPtru catalystSodium aluminate

The invention discloses a preparation method of a methanol synthesis catalyst. The preparation method comprises the following steps: (1) carrying out a parallel flow gelling reaction on a mixed solution A and a sodium metaaluminate solution to obtain a slurry I, and aging; (2) adding a mixed solution B and a sodium carbonate solution into the aged slurry I obtained in the step (1) in a dropwise and parallel flow manner, carrying out a gelling reaction to obtain a slurry II, and aging; and (3) carrying out solid-liquid separation on the material obtained in the step (2), and drying, roasting and molding the solid phase to obtain the catalyst, wherein the mixed solution A is an aqueous solution containing a soluble copper salt and a soluble zinc salt, and the mixed solution B is an aqueous solution containing a soluble copper salt and a soluble aluminum salt. The catalyst prepared by the method has the advantages of uniform distribution of active metal copper and auxiliary agent zinc, good synergistic effect, large number of active metal active centers, improved activity, improved selectivity, improved thermal stability and prolonged service life.

Owner:CHINA PETROLEUM & CHEM CORP +1

Heat-resisting fast-drying printing ink

The invention discloses heat-resisting fast-drying printing ink. The printing ink is prepared from barium sulfate powder, acrylic resin, phenolic resin, isoamyl acetate, sunflower seed oil, propylene glycol, dipropylene glycol dimethyl ether, rosin resin, nanosilicon dioxide, nano bentonite, titanium dioxide, pigment, linalool, titanate and water. The printing ink prepared through the synergistic effect of all components is high in drying speed, the drying time of the printing ink is shortened by over a half compared with that of traditional printing ink, and the phenomena that the traditional printing ink often causes smearing on the paperback and paper adhesion are avoided; the printing ink is high in adhesive force, uniform in printing effect, free of deinking, high in printing quality, good in heat resistance and capable of suitable for requirements of many occasions.

Owner:BENGBU WEIGUANG PLASTIC PRODS

Preparation method of copper-zinc catalyst

ActiveCN110935457AHigh activityGood synergyOrganic compound preparationHeterogenous catalyst chemical elementsPtru catalystSodium aluminate

The invention discloses a preparation method of a copper-zinc catalyst. The preparation method comprises the following steps: (1) carrying out a parallel flow gelling reaction on a mixed solution A and a sodium metaaluminate solution to obtain a slurry I, and aging; (2) adding a mixed solution B and a sodium carbonate solution into the aged slurry I obtained in the step (1) in a dropwise and parallel flow manner, carrying out a gelling reaction to obtain a slurry II, and aging; and (3) carrying out solid-liquid separation on the material obtained in the step (2), and drying, roasting and molding the solid phase to obtain the catalyst, wherein the mixed solution A is an aqueous solution containing a soluble copper salt, a soluble zinc salt and an organic auxiliary agent, and the mixed solution B is an aqueous solution containing a soluble copper salt and a soluble aluminum salt. The catalyst prepared by the method has the advantages of uniform distribution of active metal copper, good synergistic effect, large number of active metal active centers, improved activity, improved selectivity, improved thermal stability and prolonged service life.

Owner:CHINA PETROLEUM & CHEM CORP +1

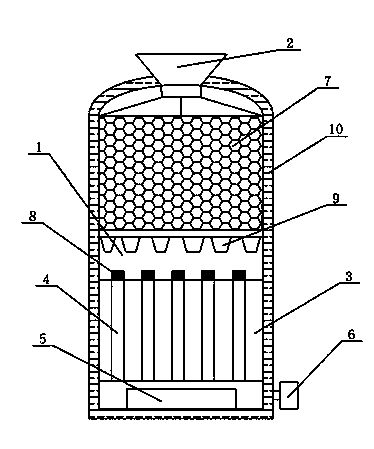

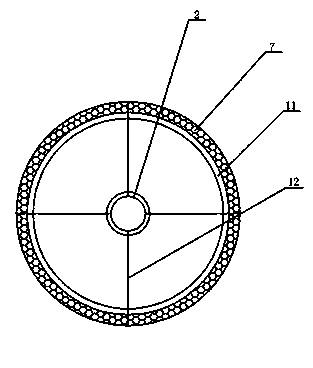

Anticorrosive unhusked rice drying device

InactiveCN103704335AEasy to dropAvoid pollutionSeed preservation by dryingRice grainMaterials science

The invention relates to a drying device, and particularly relates to an anticorrosive unhusked rice drying device, comprising a shell, a drying chamber, a preheating chamber and an electric heating chamber, wherein a funnel feeding hole is formed in the top of the preheating chamber; the electric heating chamber can generate warm air; an anticorrosive layer is arranged on the inner wall of the shell; a columnar steel mesh with openings in the top and bottom is connected to the lower side of the feeding hole; absorbent cloth is sleeved with the columnar steel mesh; a plurality of material spray ports are formed below the columnar steel mesh. Due to the adoption of the technical scheme, the anticorrosive rice drying device disclosed by the invention is not easy to corrode, and unhusked rice pollution is prevented.

Owner:CHONGQING YUNSEN FOOD & BEVERAGE

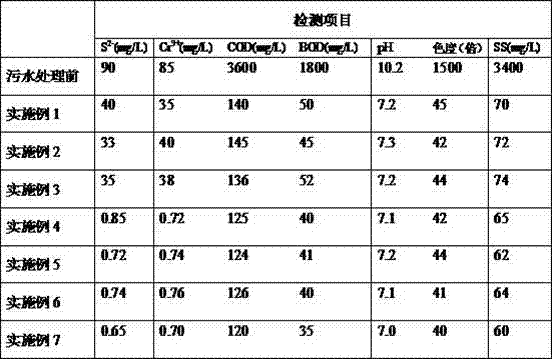

Leather sewage treatment agent

ActiveCN106966475ASpeed up filteringLow compressibilityFatty/oily/floating substances removal devicesWater contaminantsMedicineSludge

The invention discloses lather sewage treatment agent which comprises the following raw materials in parts by weight: 15-20 parts of coal ash, 10-15 parts of attapulgite hybrids, 20-25 parts of 4A zeolite, 20-25 parts of lime and 10-15 parts of clay. The flocculant disclosed by the invention is a special treatment agent for leather sewage, according to different properties of different treatment agents, various impurities in sewage can be settled in multiple directions and multiple angles, due to addition of the 4A zeolite, a very good framework function can be achieved in the treatment agent, sludge floc aggregate can be kept porous when being dehydrated, collapse of the floc aggregate is prevented, the compressibility of the impurities in sewage can be degraded, and due to cooperation of different components, surface charges and interface activity of sludge granules can be effectively improved, and the filtering speed of the sludge can be greatly increased.

Owner:韩培利

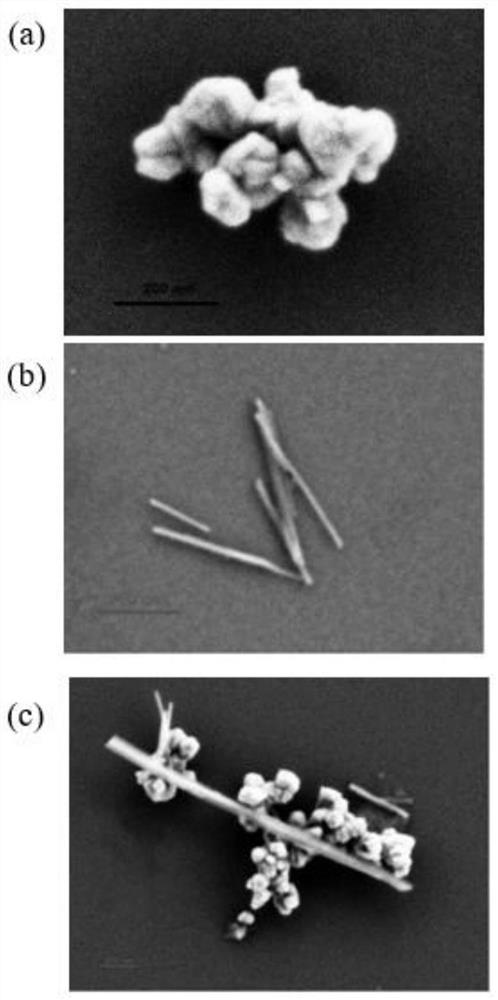

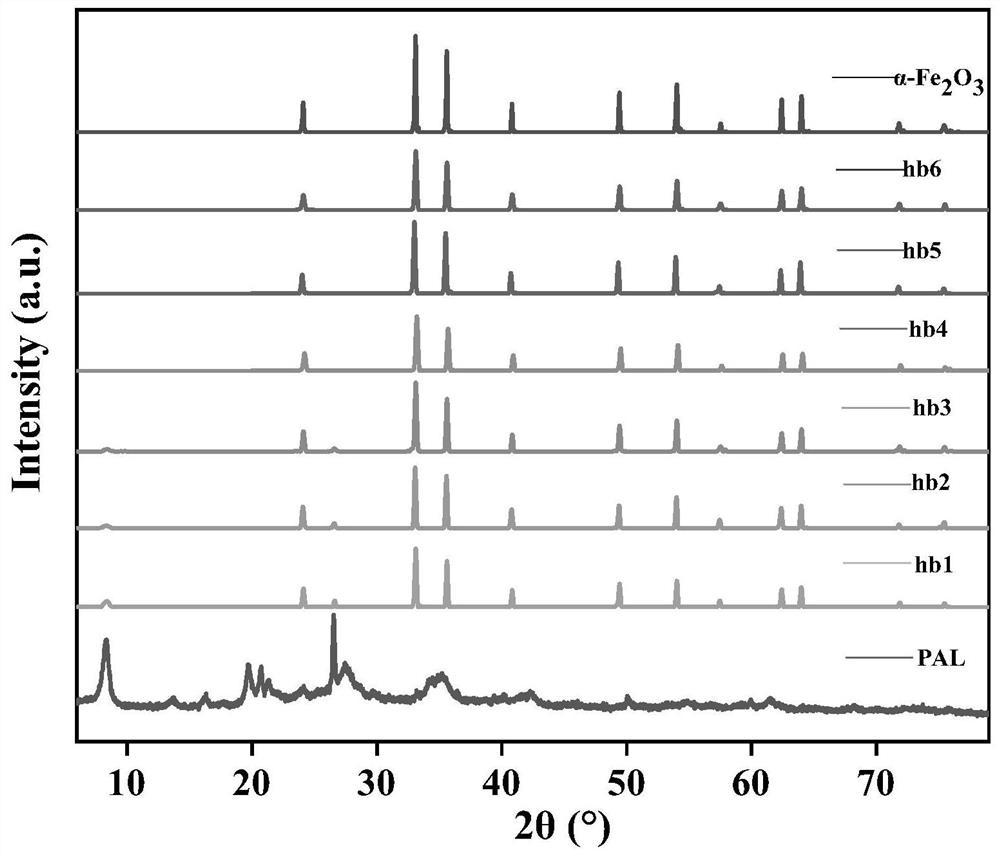

Attapulgite-based iron oxide red composite pigment and preparation method thereof

The invention discloses an attapulgite-based iron oxide red composite pigment and a preparation method thereof, wherein the attapulgite-based iron oxide red composite pigment comprises the following raw materials in percentage by mass: 0.02%-0.4% of a dispersant, 0.2%-1% of an antifoaming agent, 5%-10% of iron oxide red, 0.5%-10% of attapulgite, and the balance being deionized water. The pigment with better color performance and stability is obtained by controlling the ratio of the attapulgite to the iron oxide red, the content of the dispersant, the dispersing and grinding rate and other conditions. The preparation method of the composite pigment provided by the invention can effectively improve the dispersity and uniformity of the iron oxide red pigment, has the advantages of excellent pigment performance, simple method, simple operation and the like, and provides a more efficient, environment-friendly and convenient method for producing the iron oxide red composite pigment.

Owner:SOUTHEAST UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com