Building high-strength grouting material and preparation method thereof

A high-strength, grouting material technology, applied in the field of grouting materials, can solve the problems of poor grout strength and fluidity, and achieve the effect of increasing the connection effect, improving the physical strength performance, and suppressing the generation of foam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

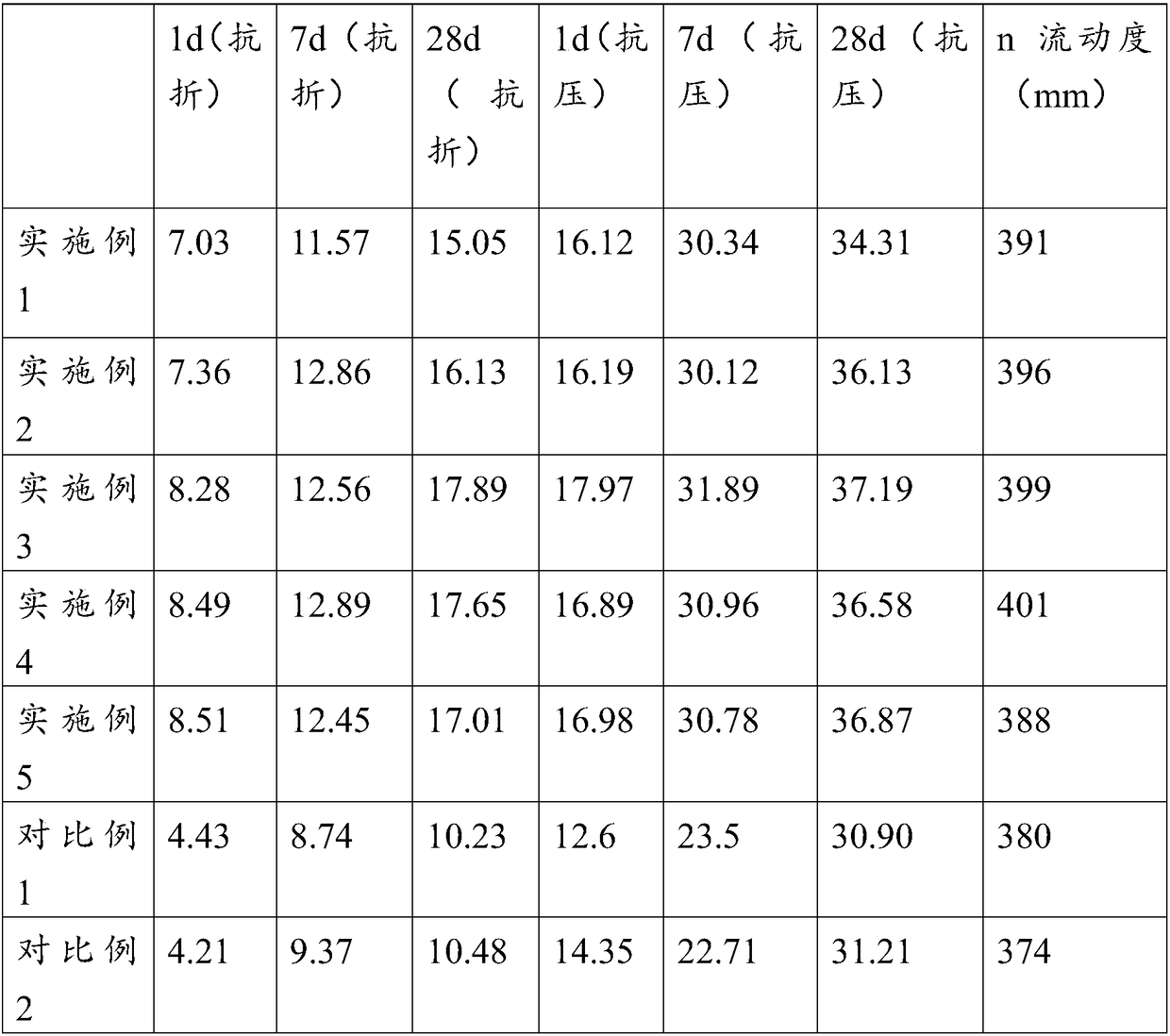

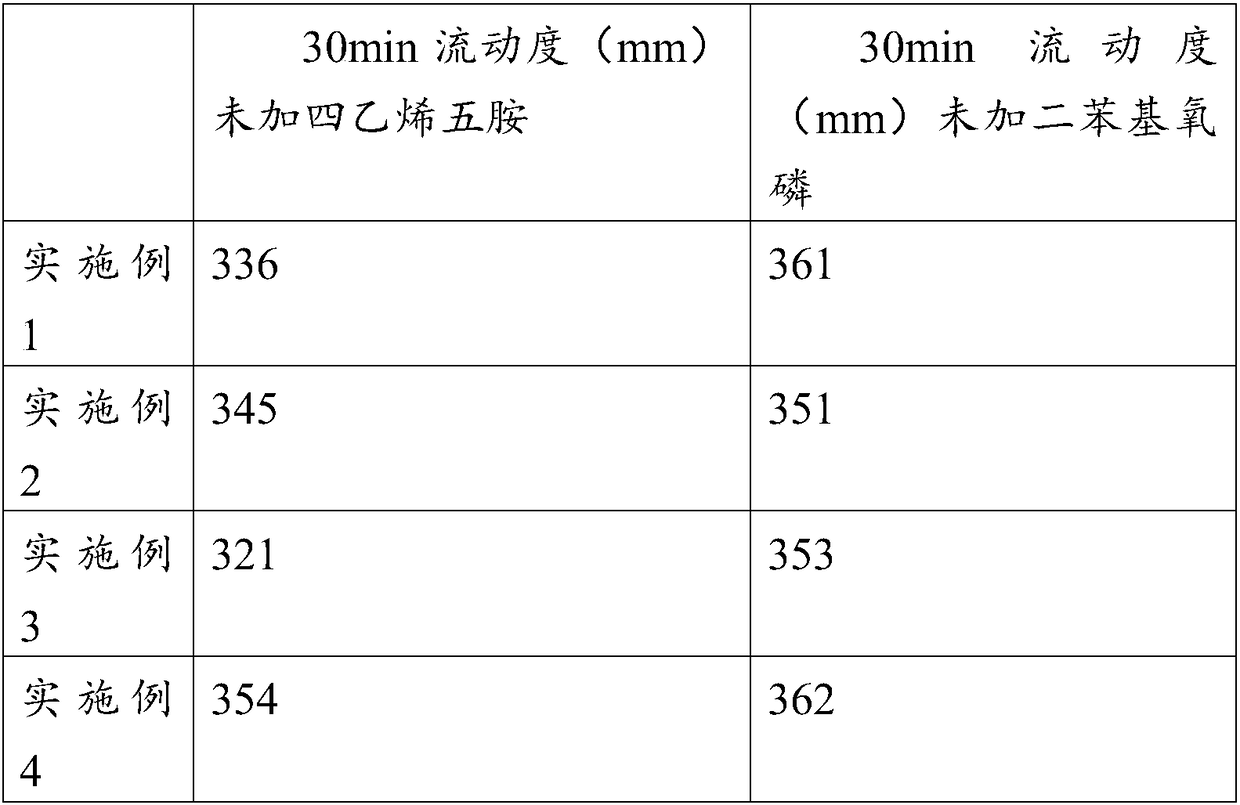

Examples

example 1

[0023] A high-strength grouting material, characterized in that the composition of the high-strength grouting material includes the following raw materials in parts by weight:

[0024] 44 parts of Portland cement, 33 parts of fine sand, 5 parts of fiber mixture, 4.5 parts of slag powder, 2 parts of expansion agent, 1.5 parts of water reducing agent, 2 parts of defoamer, 3 parts of silicone microspheres, vitrified microspheres 4 parts and 1.2 parts of tetraethylenepentamine, the fine sand is the river sand of 0.3mm, the river sand of 0.5mm, according to the mixture of 2:1 composition by weight, and described fiber mixture is glass fiber, steel fiber, carbon fiber, According to the mixture composed of 11:8:4.5 by weight, the specific surface area of the slag fine powder is 450m 2 / Kg, the particle size is 4um, and the particle size of the vitrified microbeads is 2um.

[0025] Expanding agent is CSA expanding agent

[0026] The water reducer comprises the following raw materi...

example 2

[0035] A high-strength grouting material, characterized in that the composition of the high-strength grouting material includes the following raw materials in parts by weight:

[0036] 44 parts of Portland cement, 33 parts of fine sand, 5 parts of fiber mixture, 4.5 parts of slag powder, 2 parts of expansion agent, 1.5 parts of water reducing agent, 2 parts of defoamer, 3 parts of silicone microspheres, vitrified microspheres 4 parts and 1.2 parts of tetraethylene pentamine, described fine sand is the river sand of 0.3mm, the river sand of 0.5mm, according to the mixture of 2:1 composition by weight, described fiber mixture is glass fiber, steel fiber, carbon fiber, According to the mixture composed of 11:8:4.5 by weight, the specific surface area of the slag fine powder is 450m 2 / Kg, the particle size is 4um, and the particle size of the vitrified microbeads is 2um.

[0037] The expansion agent is AUA concrete expansion agent (Jiangmen Zhongjian Technology Development Co....

example 3

[0046] A high-strength grouting material, characterized in that the composition of the high-strength grouting material includes the following raw materials in parts by weight:

[0047] 44 parts of Portland cement, 33 parts of fine sand, 5 parts of fiber mixture, 4.5 parts of slag powder, 2 parts of expansion agent, 1.5 parts of water reducing agent, 2 parts of defoamer, 3 parts of silicone microspheres, vitrified microspheres 4 parts and 1.2 parts of tetraethylene pentamine, described fine sand is the river sand of 0.3mm, the river sand of 0.5mm, according to the mixture of 2:1 composition by weight, described fiber mixture is glass fiber, steel fiber, carbon fiber, According to the mixture composed of 11:8:4.5 by weight, the specific surface area of the slag fine powder is 450m 2 / Kg, the particle size is 4um, and the particle size of the vitrified microbeads is 2um.

[0048] The expansion agent is expansion agent A; expansion agent A: consists of 15 parts of calcium sulfo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com