Patents

Literature

49results about How to "Unexpected effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Use of leukotriene receptor antagonist for treatment of scarring

InactiveUS20030162828A1Alleviate and eliminate scarAlleviate and eliminate and capsular contractureBiocideAnimal repellantsPsychiatryLeukotriene Receptor Antagonists

A method of preventing or treating either scarring or capsular contractures in subjects in need of such treatment comprising the administration of leukotriene receptor antagonists to said subject in need of treatment.

Owner:SCHLESINGER FAMILY PARTNERS A HAWAII

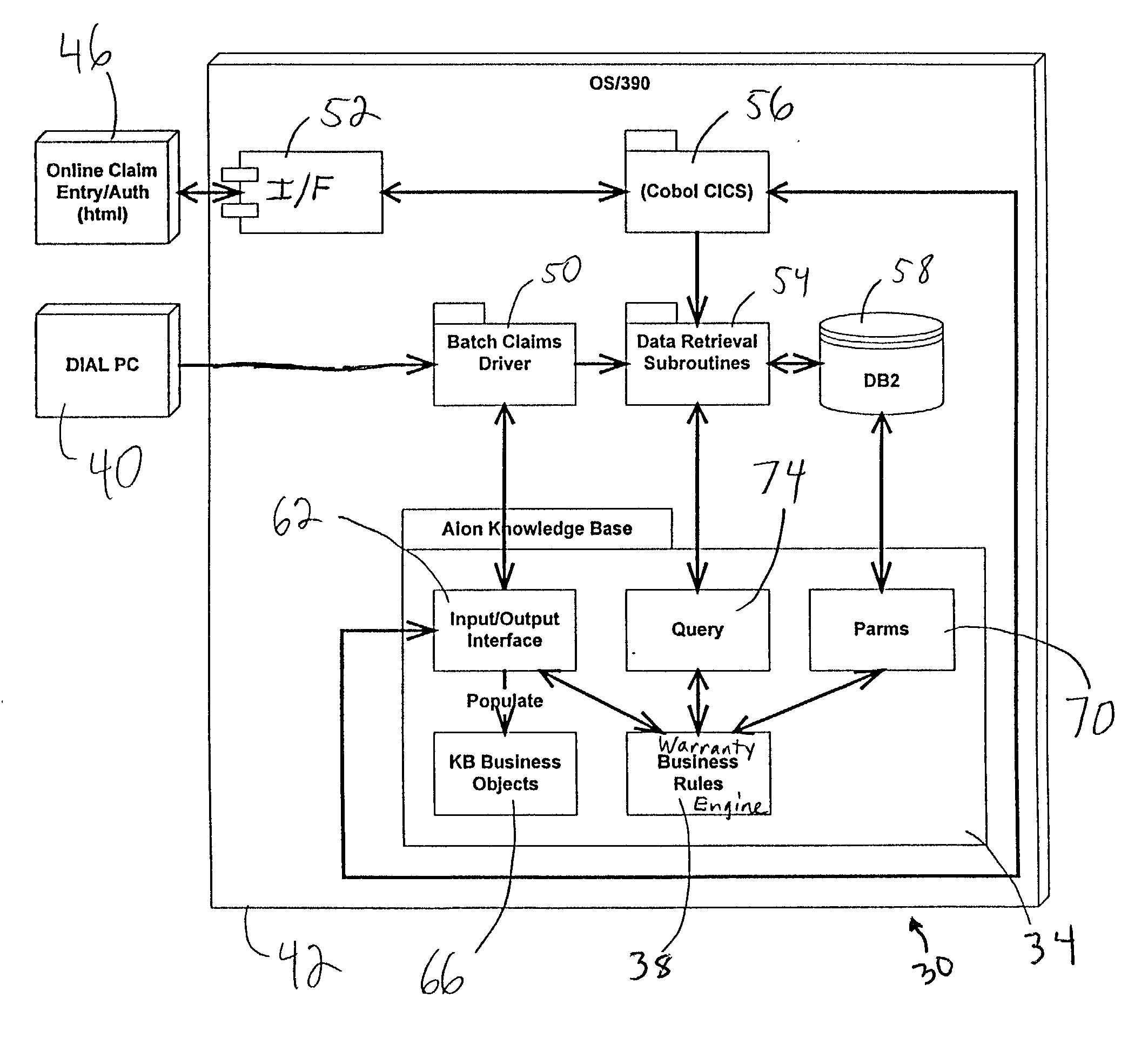

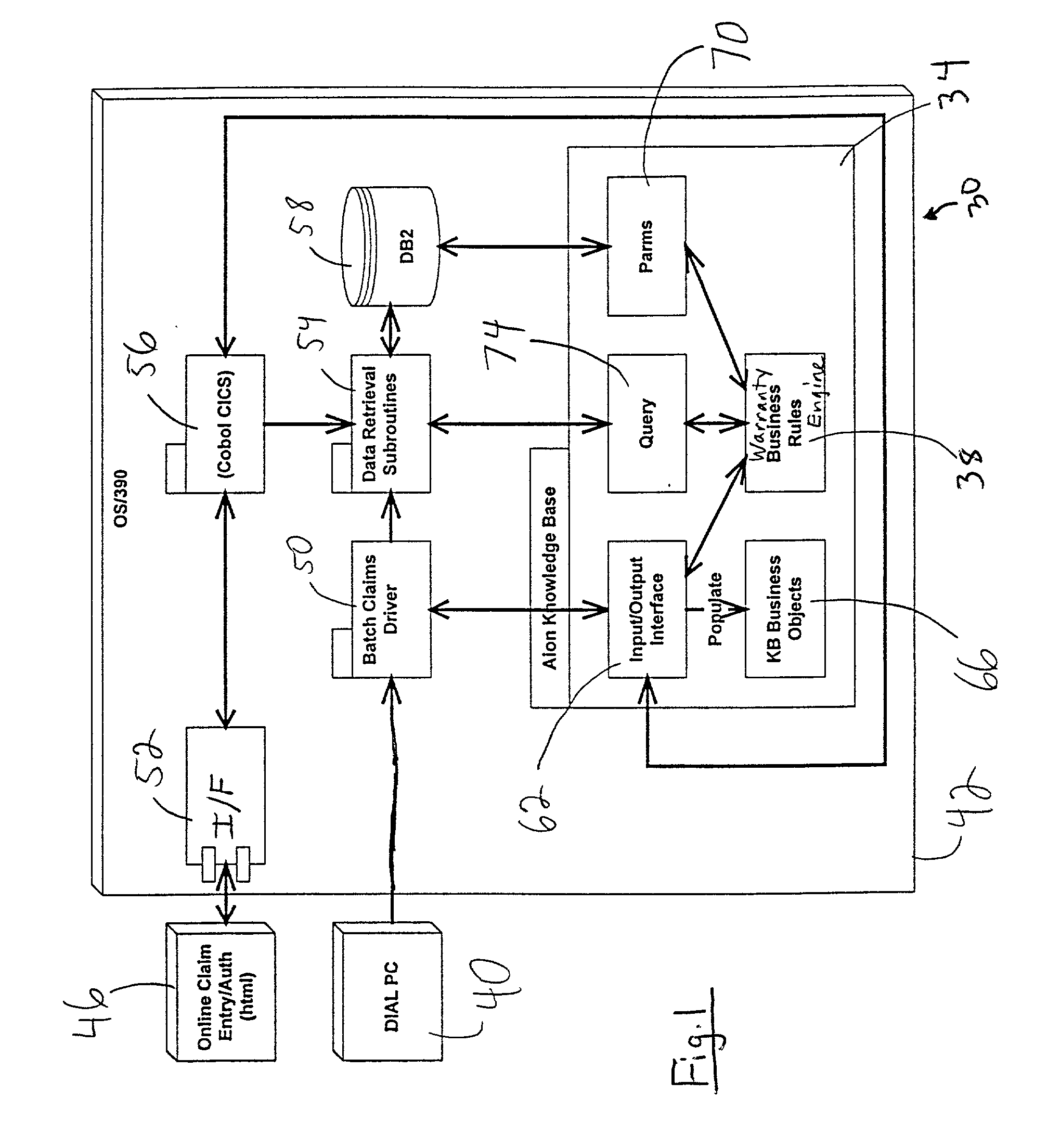

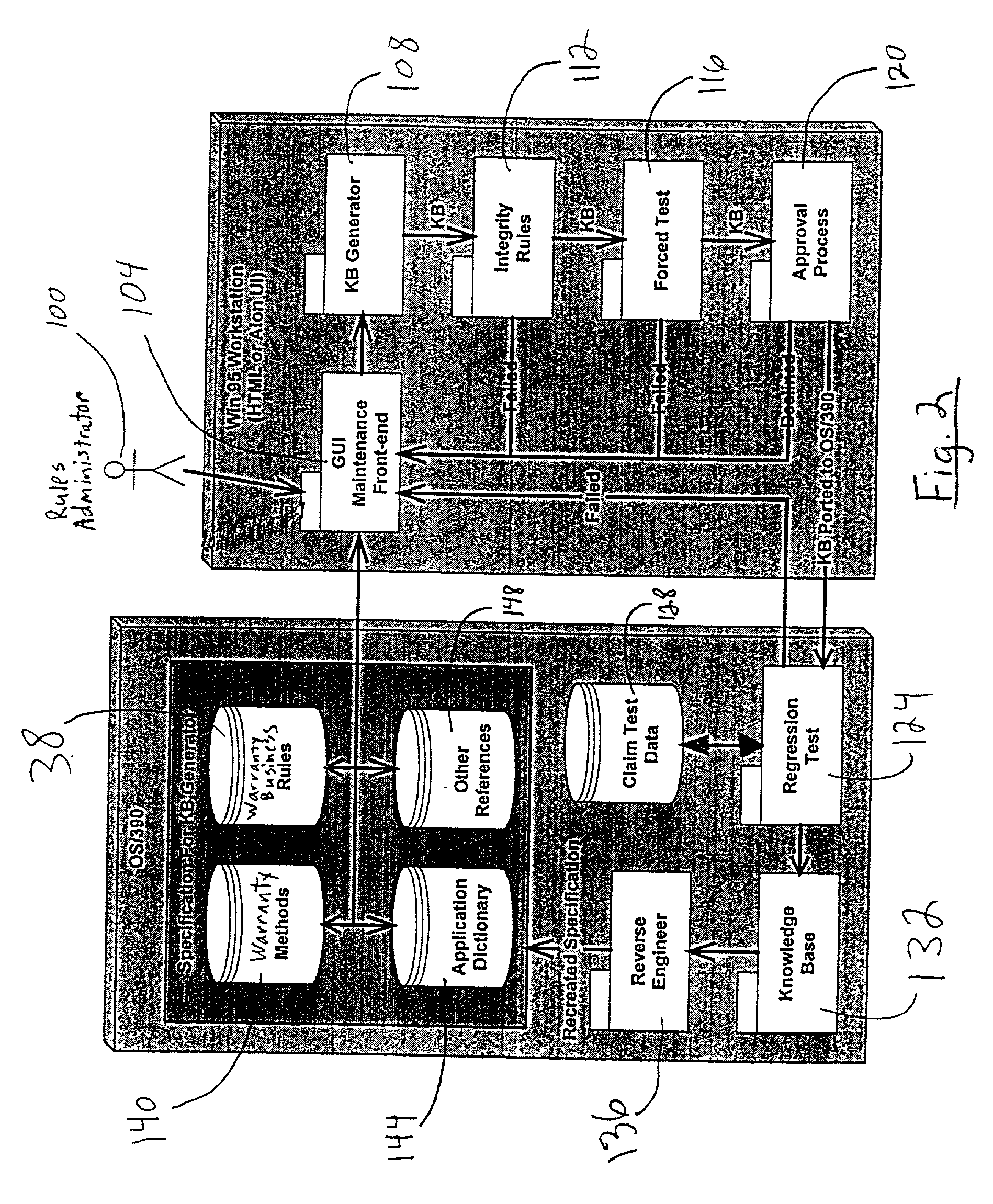

Computer-implemented vehicle repair claims processing system

InactiveUS20020128876A1Unexpected effectEasy to useFinanceKnowledge representationHandling systemReliability engineering

A computer-implemented vehicle repair claim processing method and apparatus. Repair data is received related to repair of a vehicle. Repair claim expert rules determine at least one response to the input repair claim data based upon the received input repair claim data. The repair claim expert rules include repair claim-related premises and repair claim-related actions. At least one of the repair claim-related premises uses the received repair claim data to determine whether a preselected repair claim-related action should be executed. The preselected repair claim-related action is used to generate a repair claim-related response. The expert rules are accessible by an user in a high level computer expression format.

Owner:CHRYSLER GROUP LLC

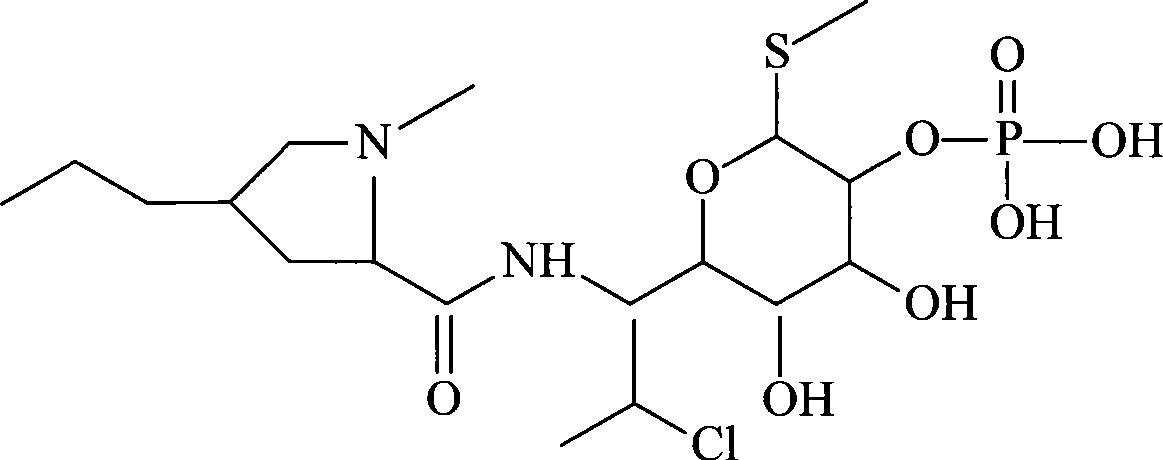

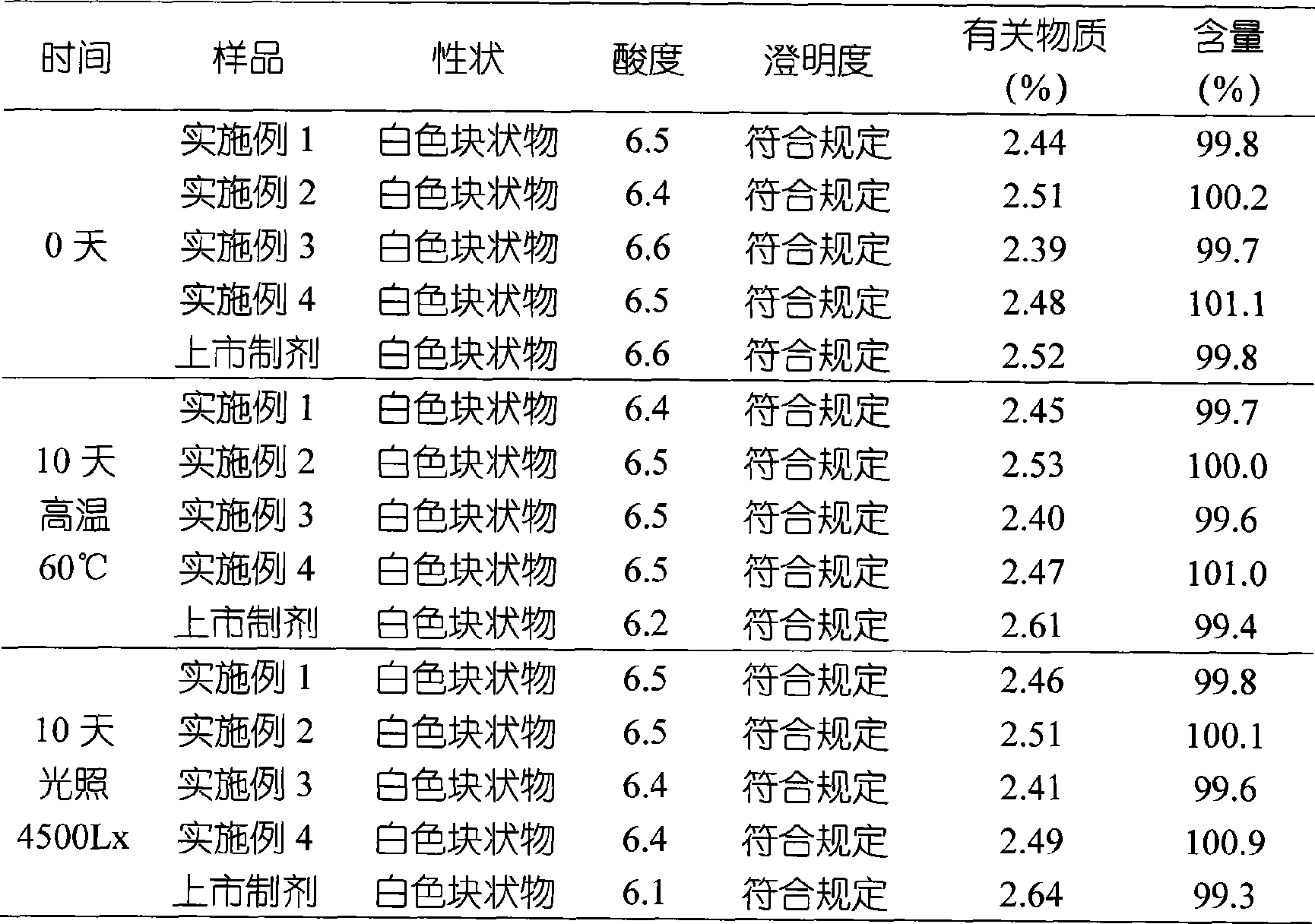

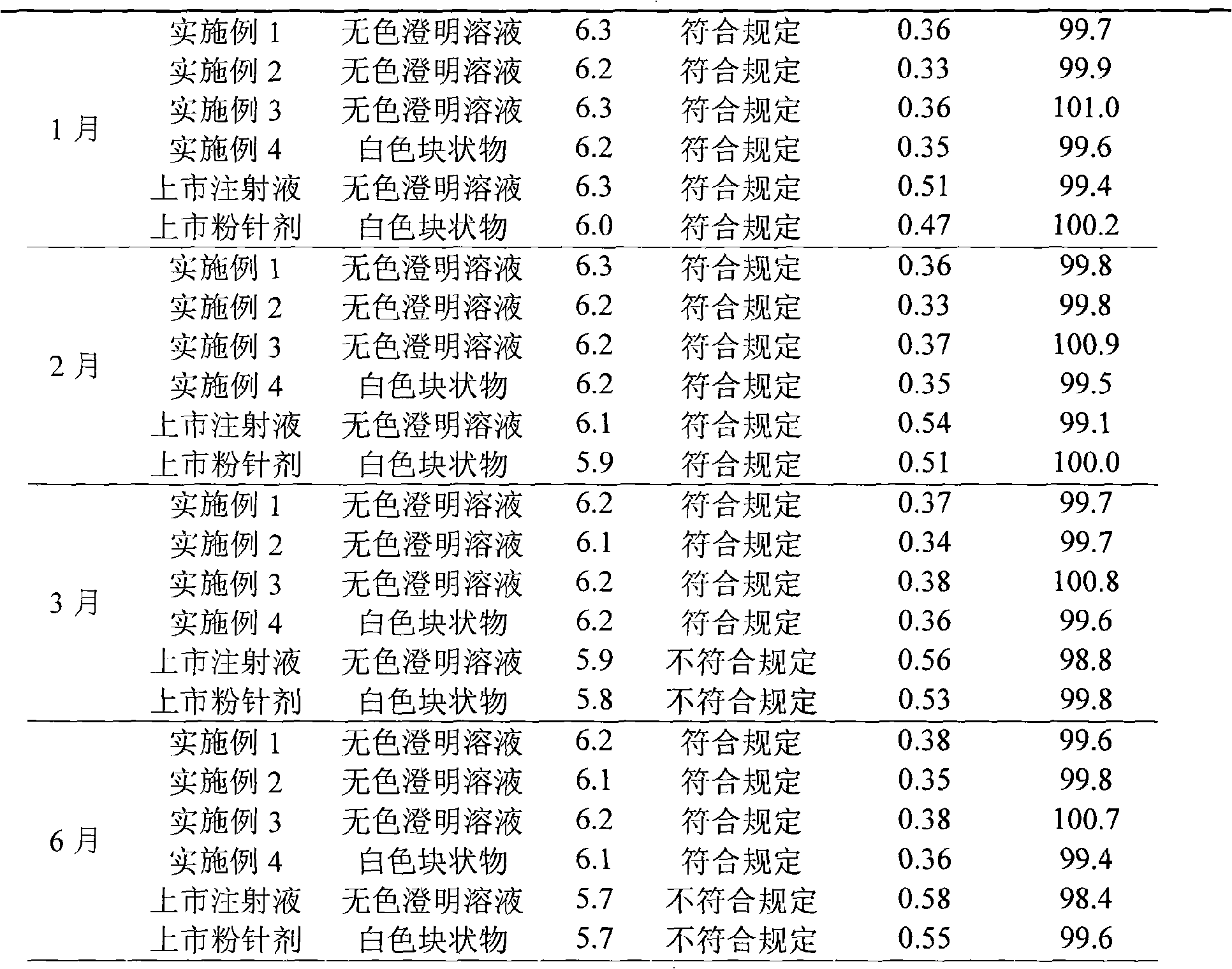

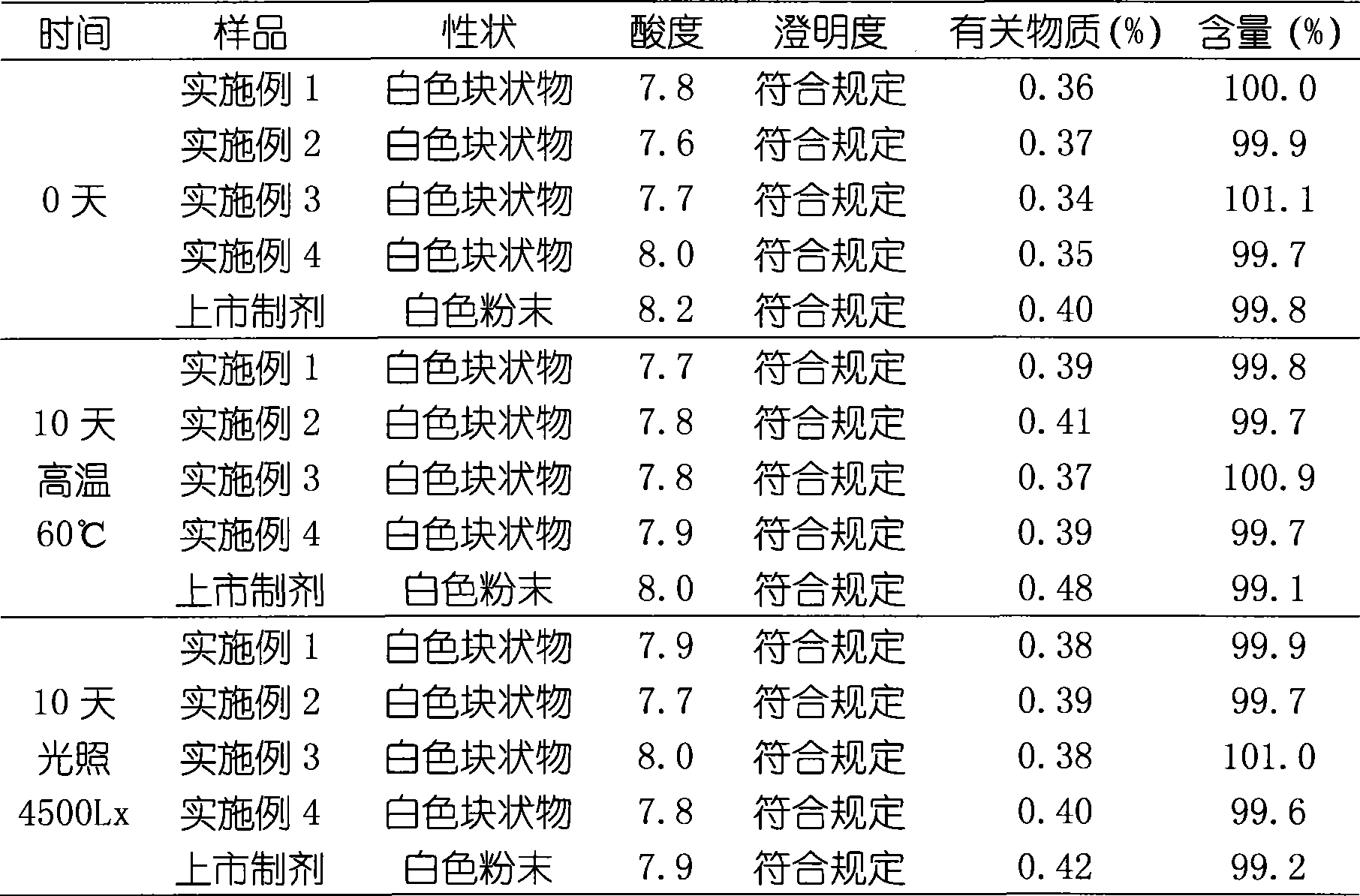

Clindamycin phosphate lipidosome freeze-dried preparation and preparation method thereof

InactiveCN101530393AAchieve vitrificationAvoid damageAntibacterial agentsOrganic active ingredientsFreeze-dryingCholesterol

The invention relates to a clindamycin phosphate lipidosome freeze-dried preparation and a preparation method thereof. The clindamycin phosphate lipidosome freeze-dried preparation is characterized by comprising the following components in portion by weight: 15 to 25 portions of clindamycin phosphate, 10 to 40 portions of dimyristyl acid lecithin, 1 to 10 portions of cholesterol, 1 to 5 portions of antioxidant, and 5 to 25 portions of cryoprotectant.

Owner:HAINAN LINGKANG PHARMA CO LTD

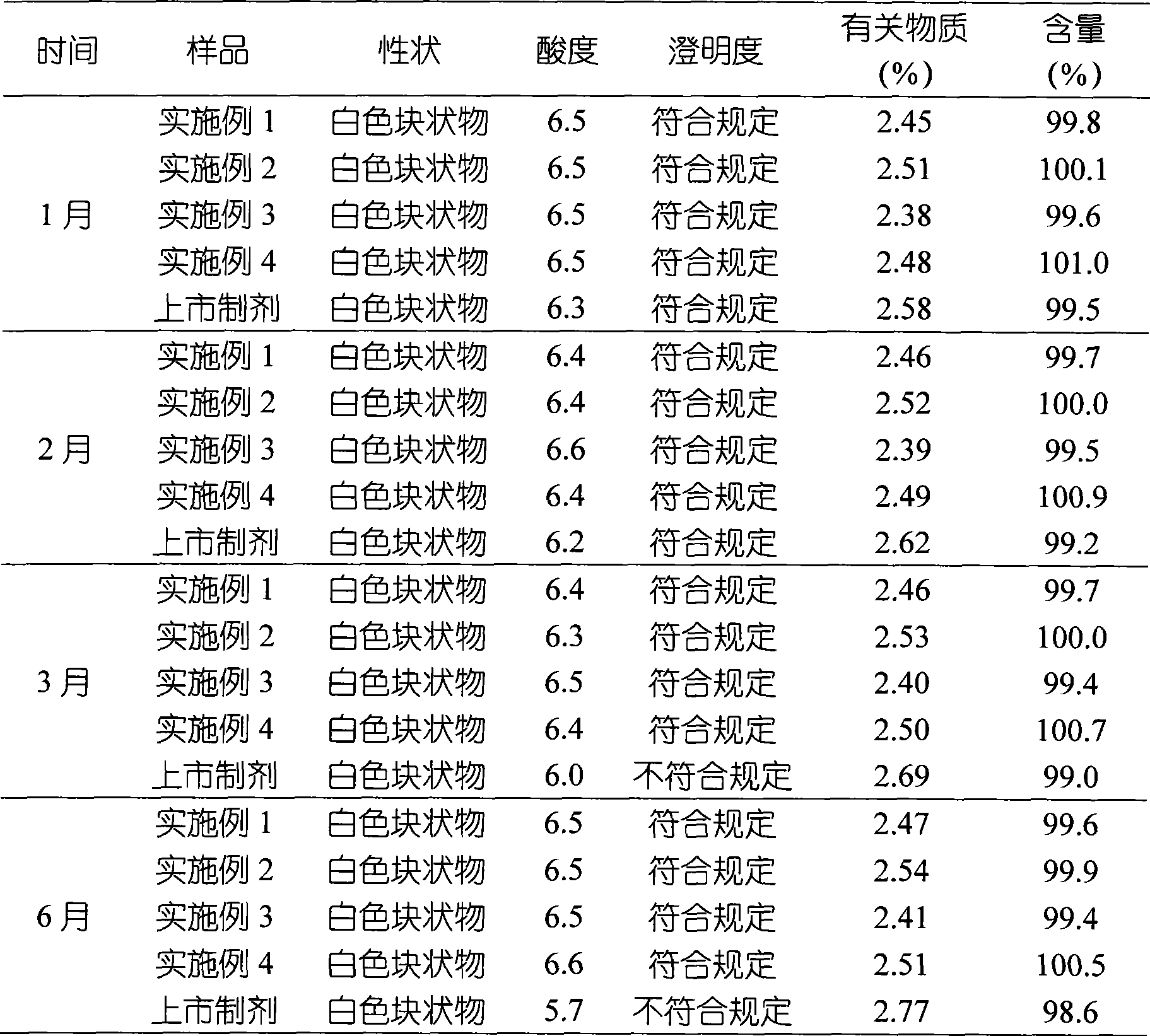

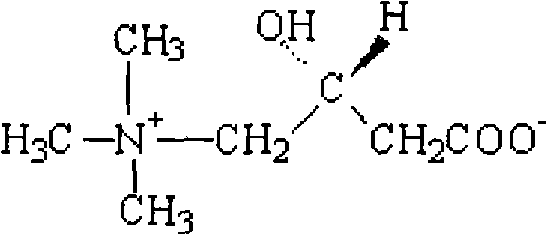

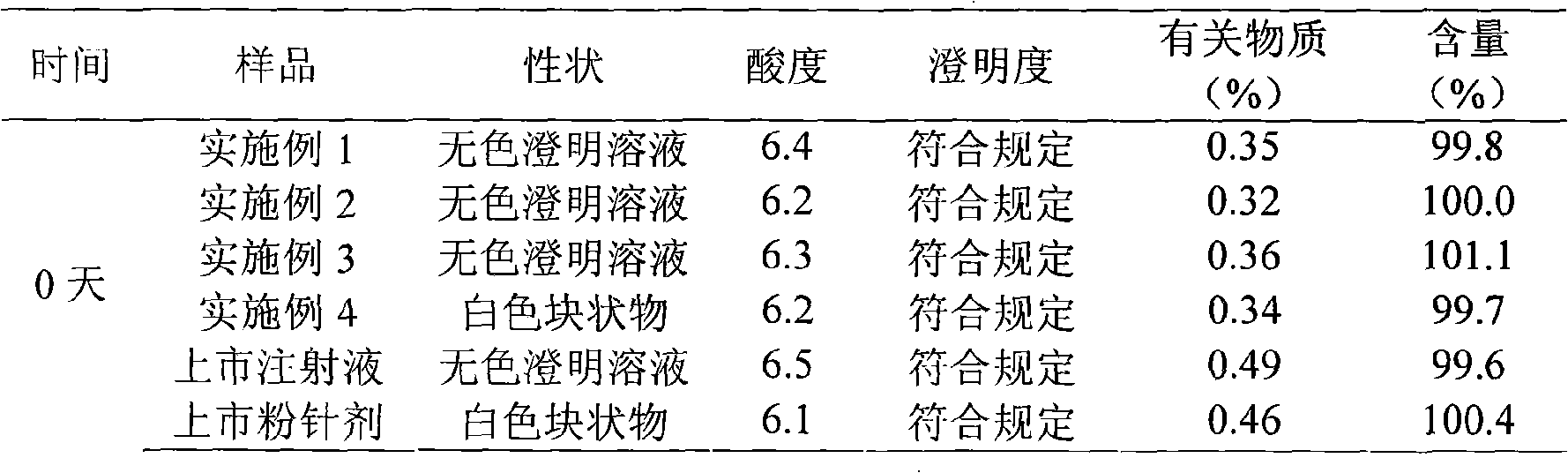

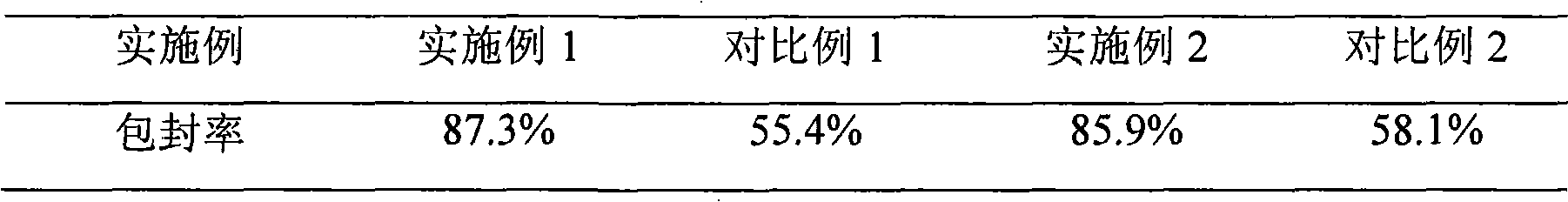

Levocarnitine liposomes injection

InactiveCN101637450AUnexpected effectImprove stabilityOrganic active ingredientsMetabolism disorderAcute toxicity testingCholesterol

The invention discloses levocarnitine liposomes injection, which is characterized by comprising the following active ingredients in parts by weight: 1 part of levocarnitine, 3-15 parts of soybean lecithin, 0.4-7.5 parts of cholesterol and 0.02-1 part of antioxidant, and a pharmaceutically acceptable carrier, wherein, the antioxidant is one or more of L-cysteine, thiourea, vitamin E and butylated hydroxyanisole and is most preferably the vitamin E. The invention also discloses a preferable preparation method of the levocarnitine liposomes injection, namely ammonium sulphate pH gradient method.The invention provides levocarnitine liposomes injection which has excellent stability, high entrapment rate and low leakage rate in the process of long-term storage. The acute toxicity tests, unusualtoxicity tests and heat source tests adopting the levocarnitine liposomes injection all conform to the specifications and are applicable to industrialized production.

Owner:HAINAN YONGTIAN PHARMA INST

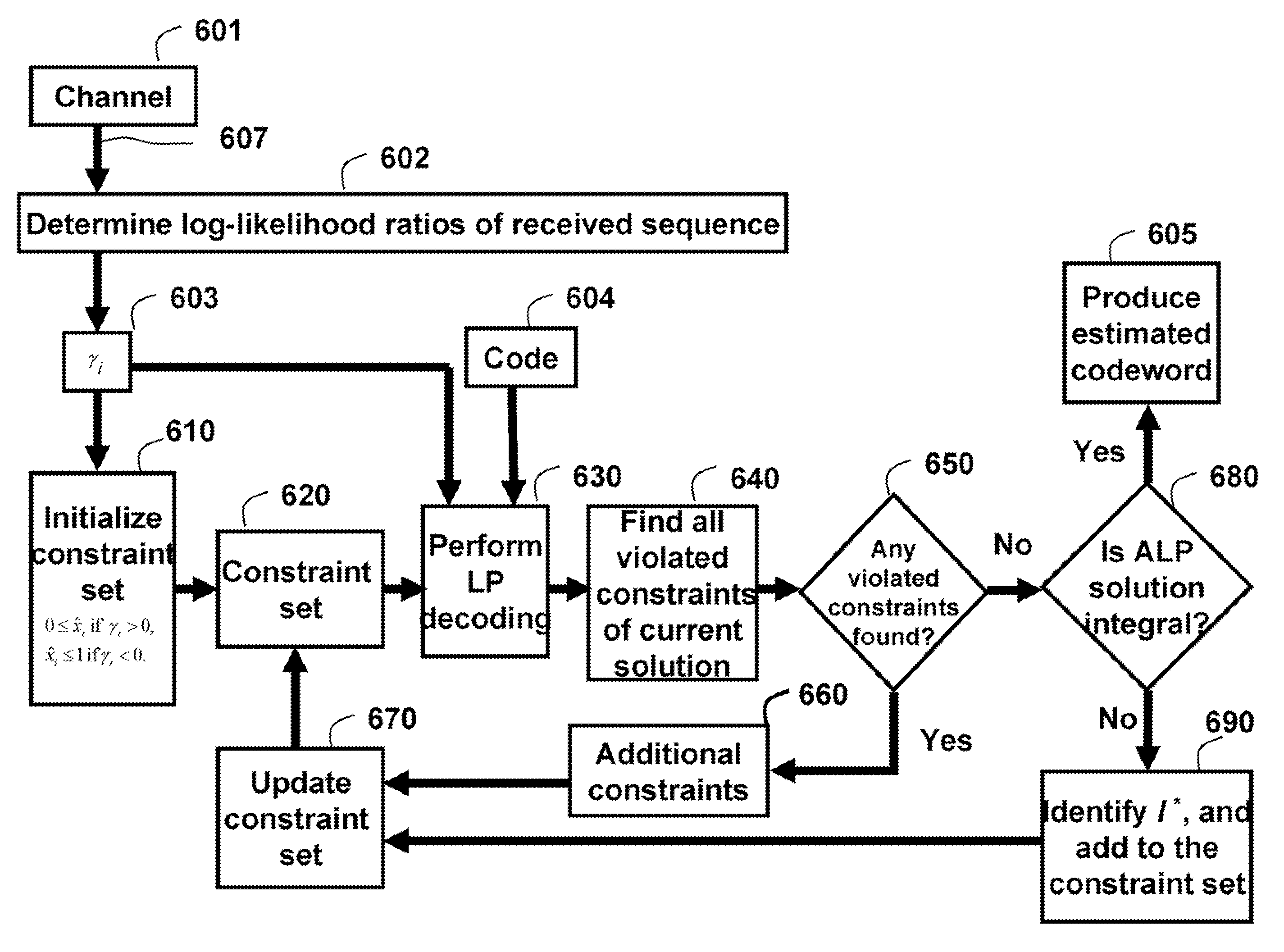

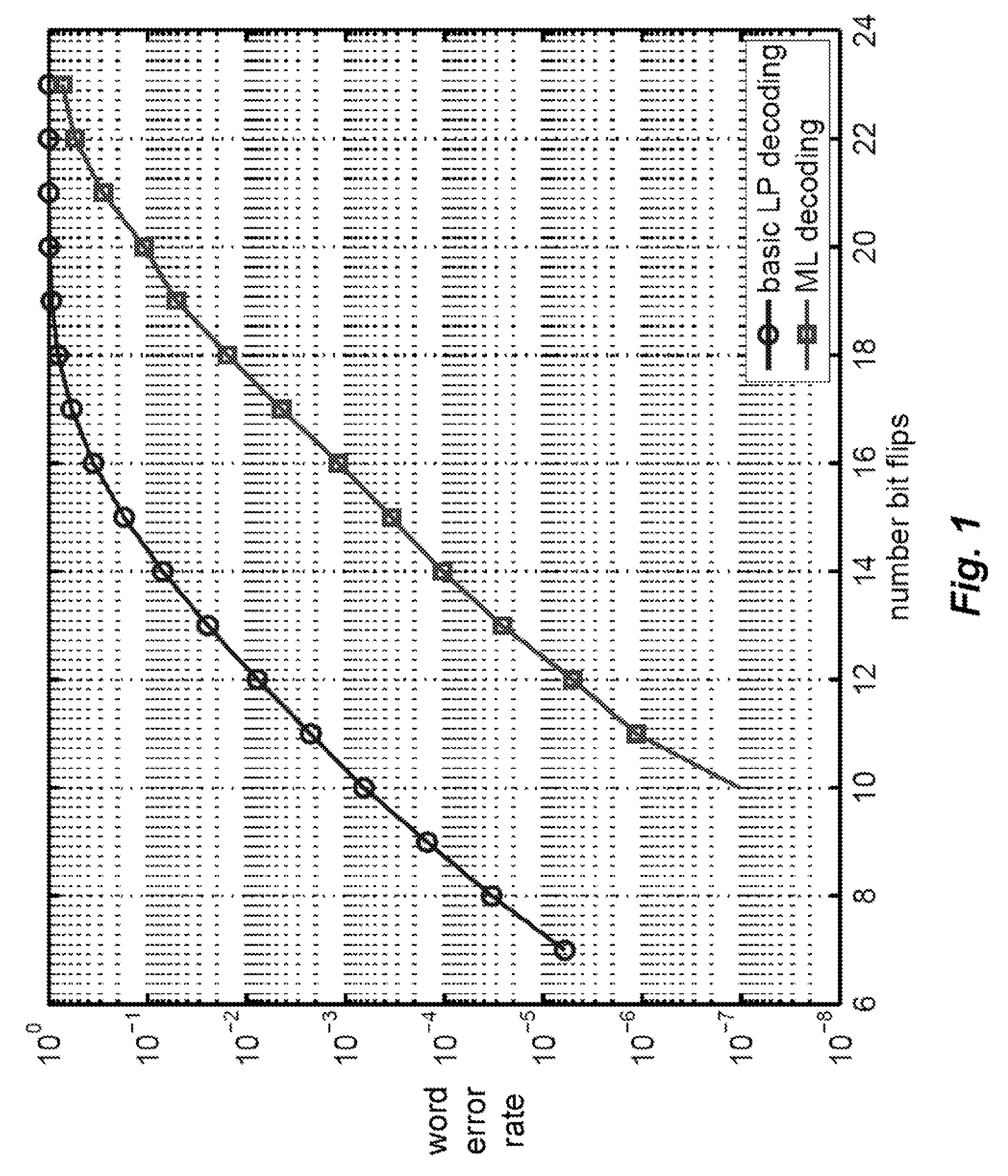

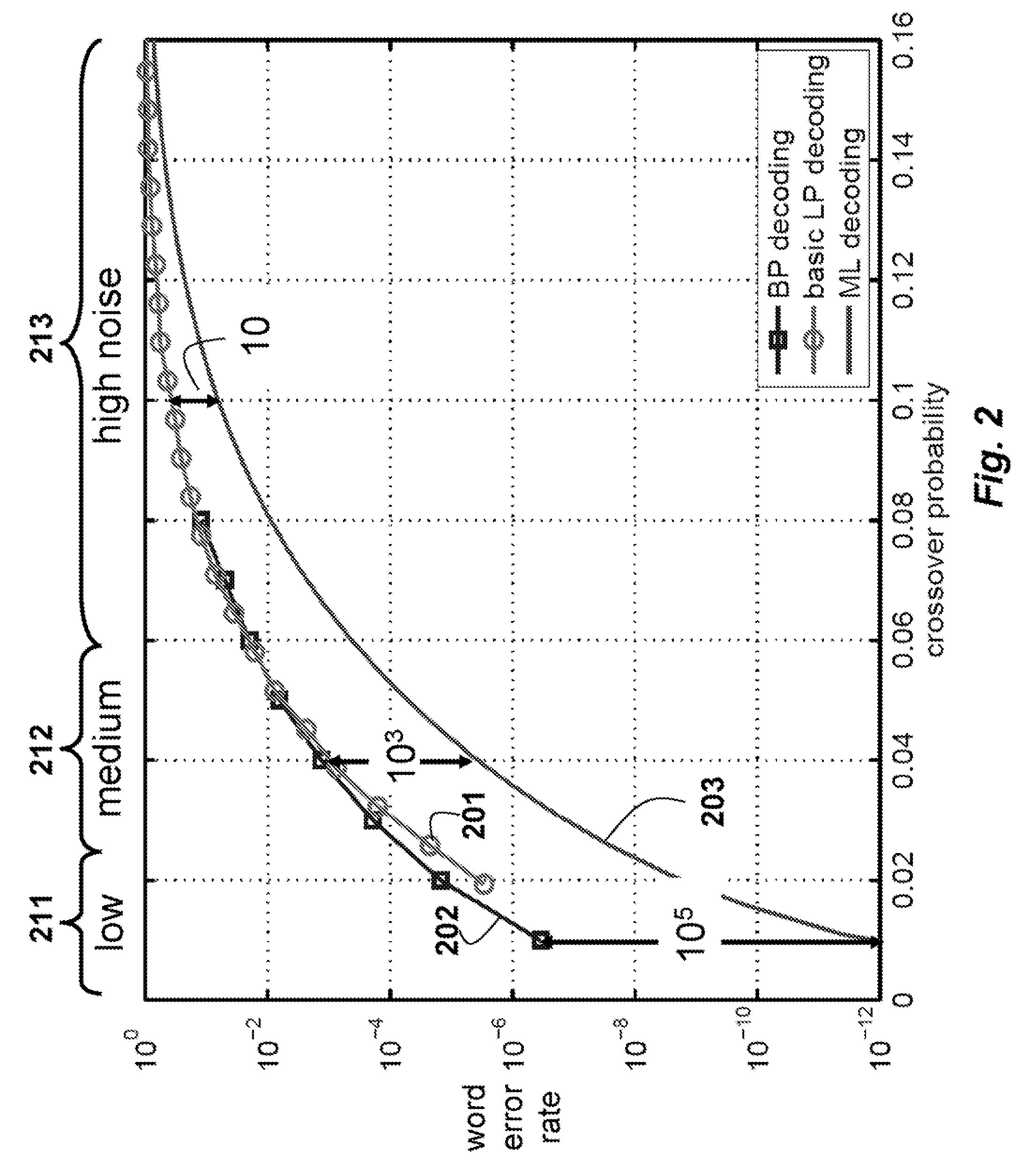

Maximum Likelihood Decoding via Mixed-Integer Adaptive Linear Programming

InactiveUS20080316069A1Extension of timeReduce error rateData representation error detection/correctionOther decoding techniquesLikelihood-ratio testLog likelihood

A method and system decodes a sequence of symbols received via a channel to a codeword of an error-correcting code. Log-likelihood ratios are determined from a sequence of symbols received via a channel. A set of constraints is initialized according to the log-likelihood ratios. An adaptive linear programming decoder is applied to the set of constraints and the log-likelihood ratios according to an error-correcting code to produce an estimate of the codeword and an updated set of constraints. If the estimate of the codeword is a non-integer pseudo codeword, further update the set of updated constraints with a set of integer constraints if the estimate of the codeword is the non-integer pseudo codeword, and proceeding with the applying step, and otherwise producing the estimate of the codeword as the final codeword.

Owner:MITSUBISHI ELECTRIC RES LAB INC

Glycerol fructose liposome drug combination injection and preparation method thereof

InactiveCN101632681AUnexpected effectImprove stabilityHydroxy compound active ingredientsPharmaceutical non-active ingredientsDrugLiposome

Owner:灵康药业集团股份有限公司

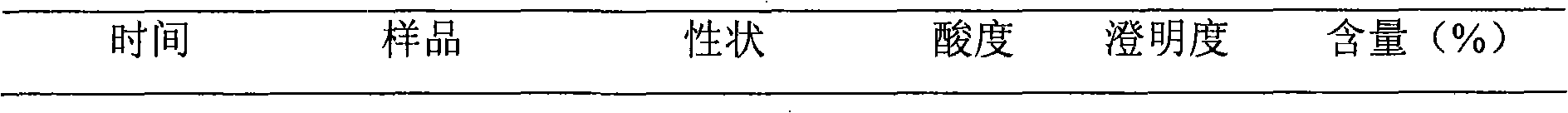

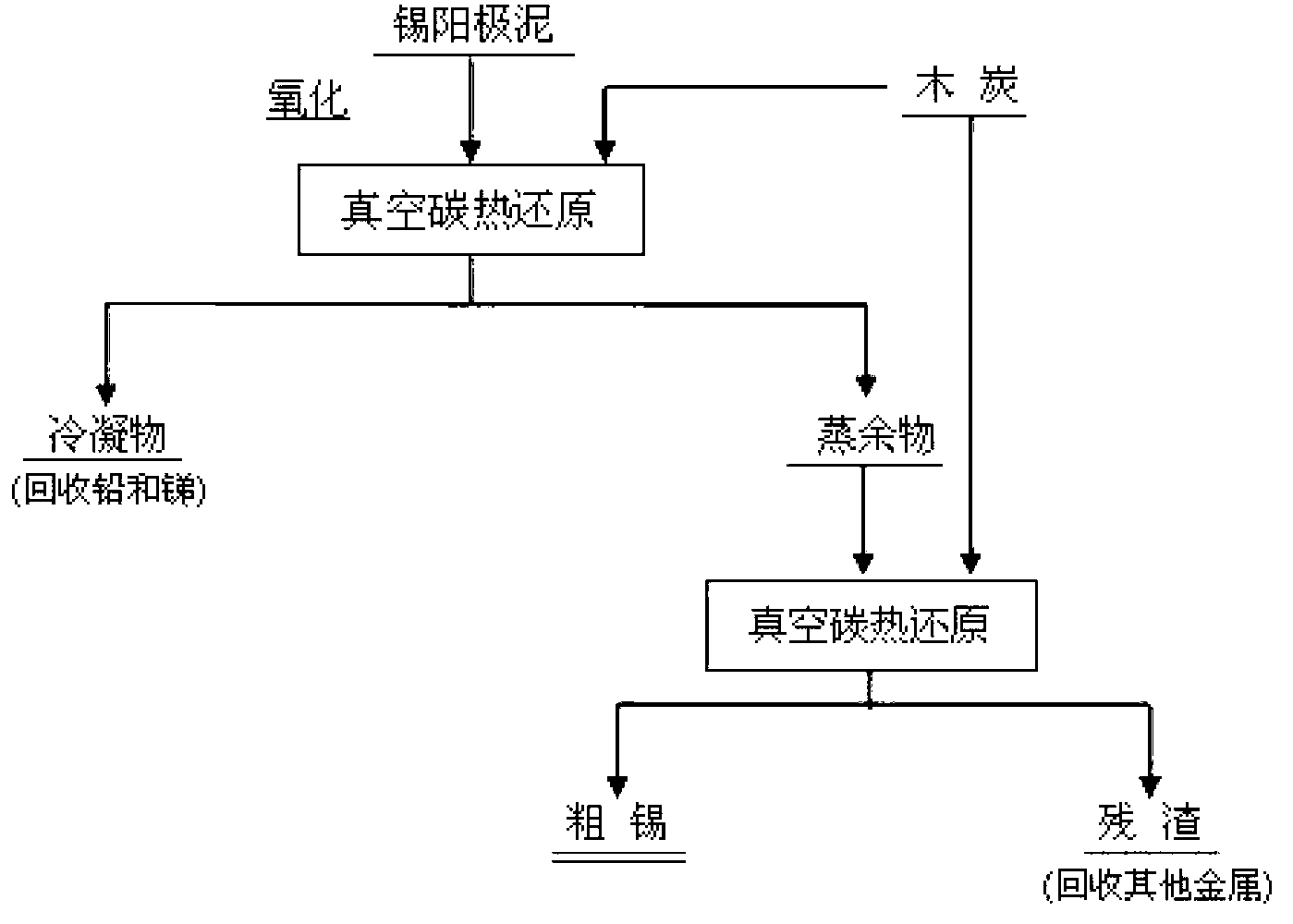

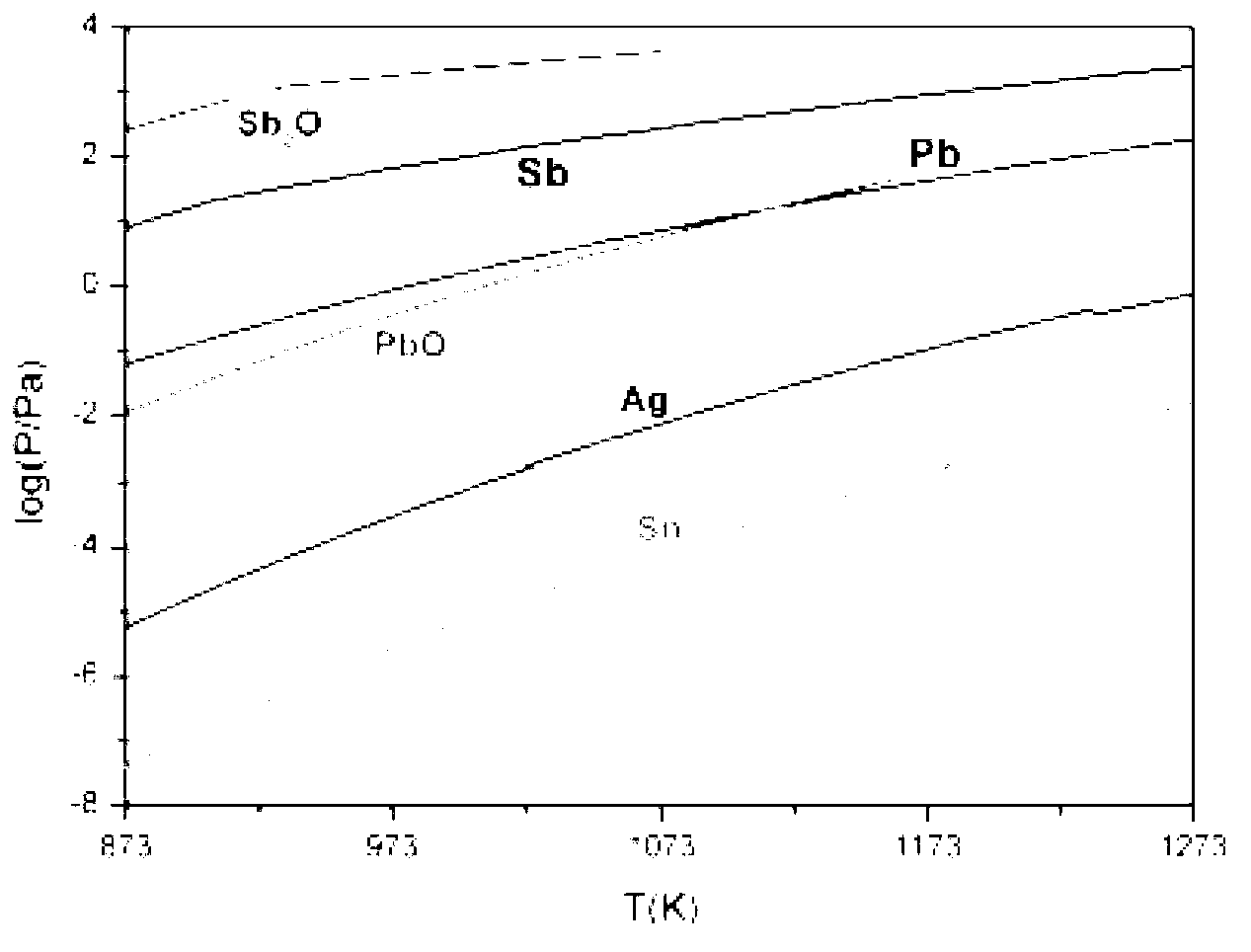

Treatment method of tin anode slurry

InactiveCN103255297AUnexpected effectImprove removal effectProcess efficiency improvementTin dioxideNonferrous metal

The invention relates to a treatment method of tin anode slurry, which belongs to the technical field of vacuum metallurgy of non-ferrous metals. The treatment method of the tin anode slurry comprises the following steps of: reducing and decomposing lead-antimony composite compound carbon in the tin anode slurry into lead oxide and antimony oxide by using naturally stacked oxidized tin anode slurry as the material through two-step vacuum melting, quickly evaporating to remove the lead oxide and the antimony oxide to obtain residuum; and reducing the residuum, so that tin dioxide in the residuum is reduced to obtain crude tin. According to the treatment method of the tin anode slurry, the lead removing rate of the tin anode slurry is not lower than 99%, the antimony removing rate is not lower than 92%, the direct tin yield is not lower than 94% and the tin content in the crude tin is not less than 94wt%. The treatment method of the tin anode slurry disclosed by the invention can be used for simultaneously removing the lead and the antimony by one step, simplifying the treatment process of the tin anode slurry and lowering the production cost. Compared with the existing tin anode slurry treatment process, the treatment method of the tin anode slurry disclosed by the invention has the advantages of being simple in process, low in energy consumption, small in smoke gas pollution and the like.

Owner:CENT SOUTH UNIV

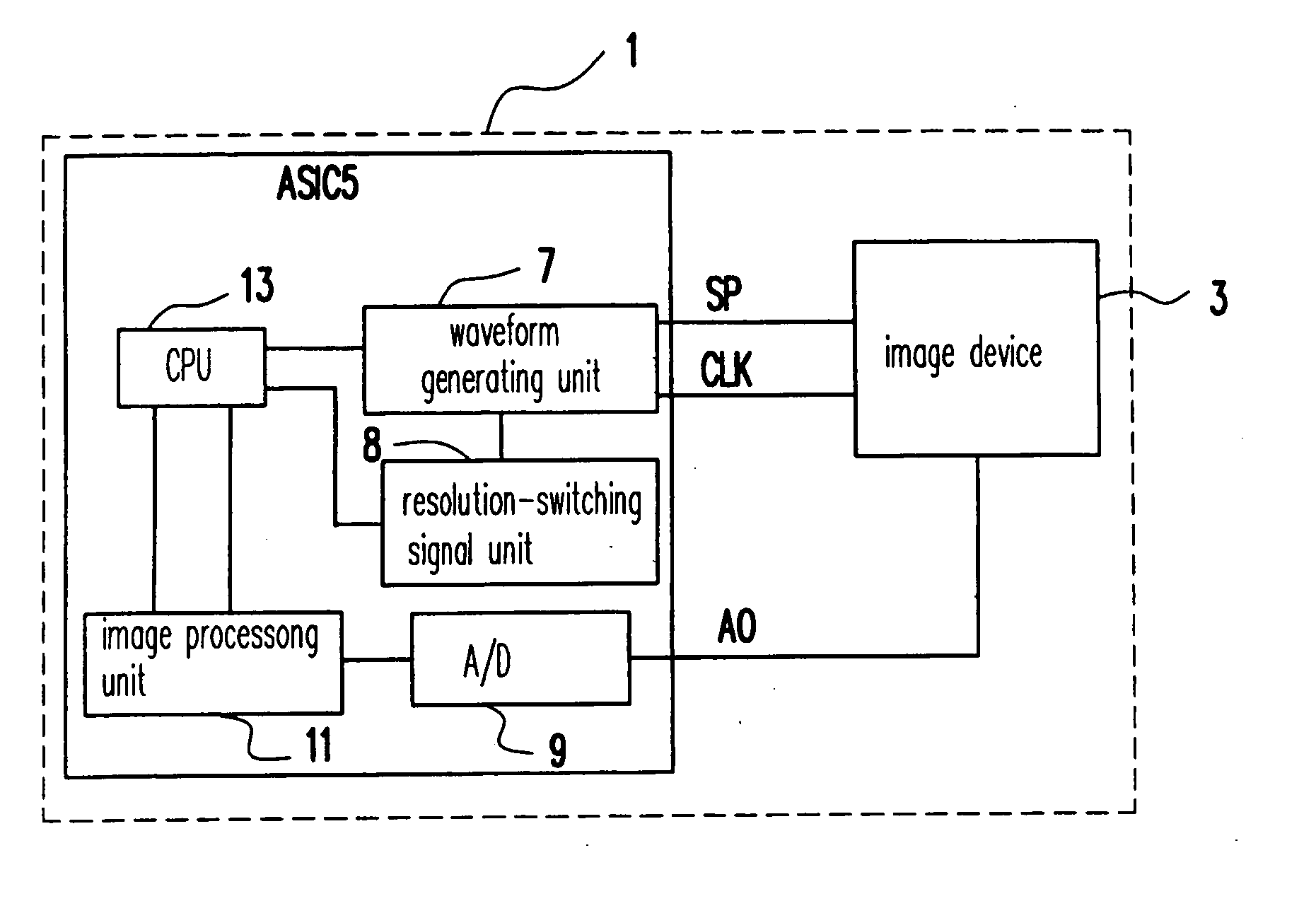

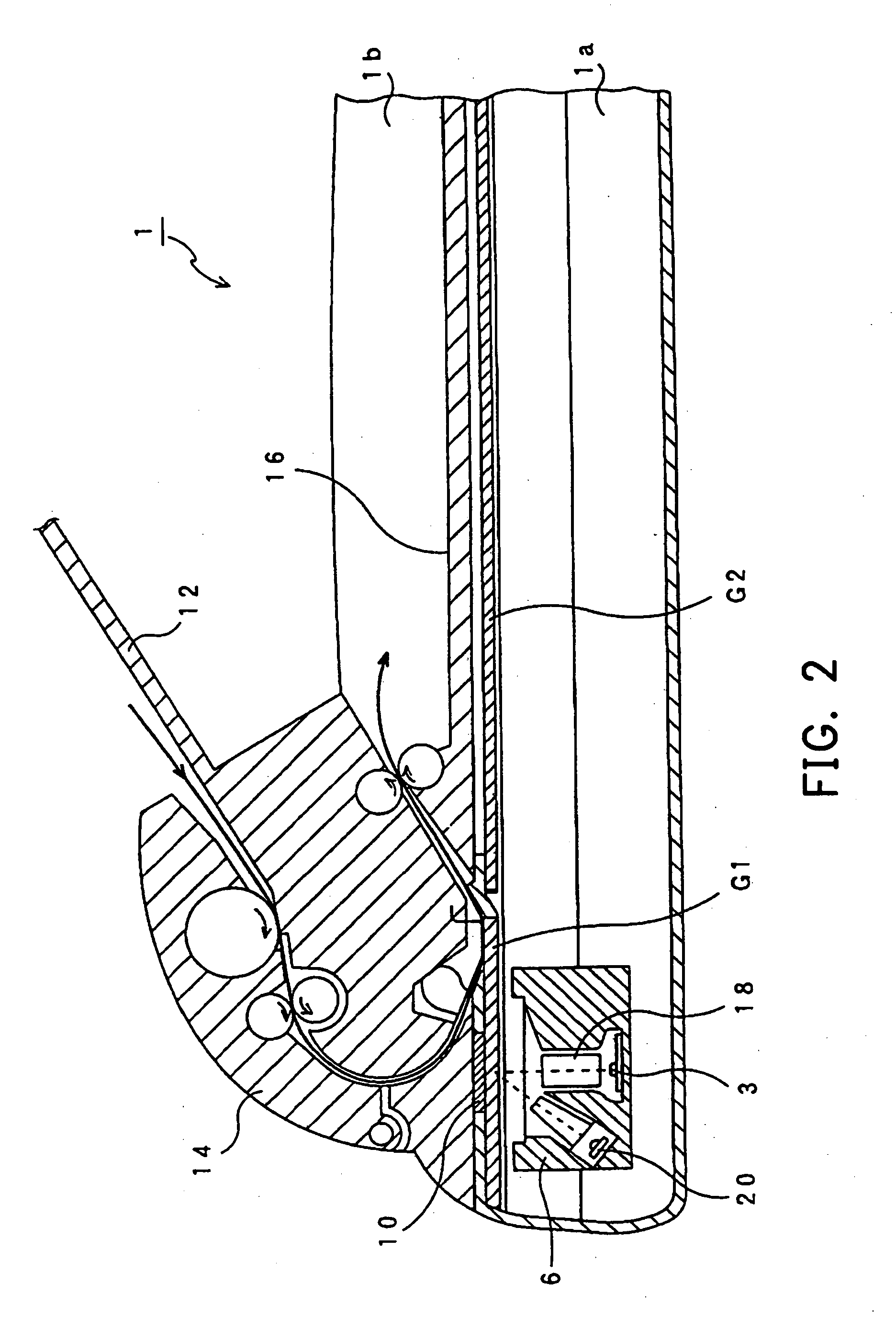

Image sensor, reading device and method for setting particular mode

ActiveUS20050002071A1Control costUnexpected effectTelevision system detailsColor television detailsStart signalImage sensor

An image sensor, a reading device and a method for setting a particular mode are provided. The image sensor comprises a plurality of photoelectric converting elements, for converting optical signals to electric signals; a group of channel select switches, each channel select switch arranged between a charge output unit of each channel select switch and a signal line corresponding to each photoelectric converting element, wherein the group of the channel select switches can be turned on and off sequentially synchronizing with an externally supplied clock pulse signal; and particular mode setting means, wherein when a clock pulse signal and a start signal with a fixed width are input, the particular mode setting means sets a particular mode under a specific combination pattern of the clock pulse signal and the start signal.

Owner:BROTHER KOGYO KK

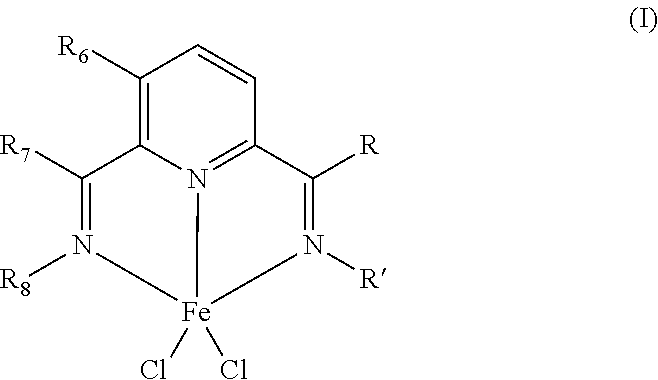

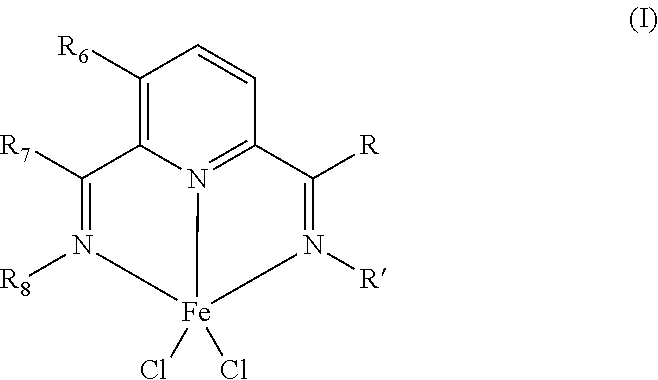

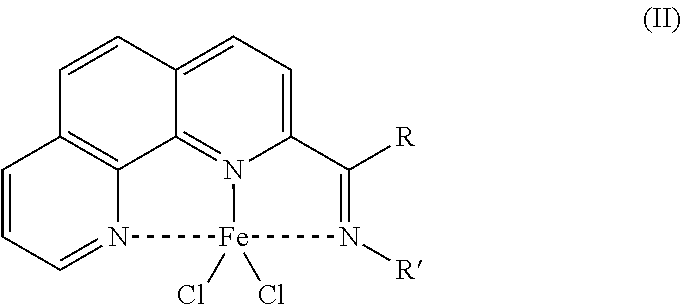

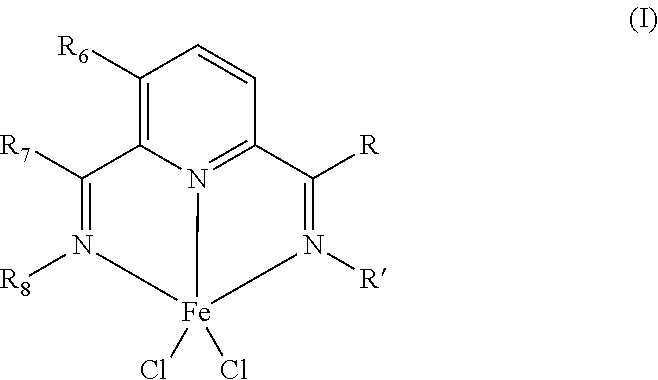

Catalyst composition and process for ethylene oligomerization

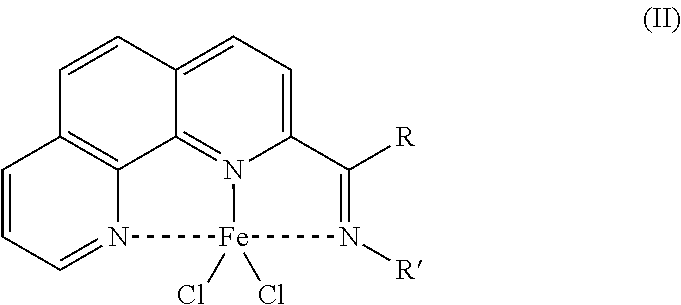

ActiveUS20140316087A1High oligomerization activityStart fastOrganic-compounds/hydrides/coordination-complexes catalystsIron group organic compounds without C-metal linkagesOrganic solventReaction temperature

The present disclosure provides a catalyst composition for ethylene oligomerization including an imino ferrous complex shown in Formula (I) as the main catalyst, an aluminum-containing cocatalyst, water, and an organic solvent:According to the present disclosure, a higher oligomerization activity can be obtained with the catalyst composition than with a catalyst composition system in the prior art which contains no water. Moreover, when the catalyst composition according to the present disclosure is used, a high selectivity of α-olefins is obtainable. Besides, the catalyst composition according to the present disclosure can enable rapid initiation, stable operation, and good repeatability of the oligomerization reaction. According to the present disclosure, a high oligomerization activity can be obtained even at a rather low ratio of Al / Fe, or at a low reaction temperature.

Owner:CHINA PETROCHEMICAL CORP +1

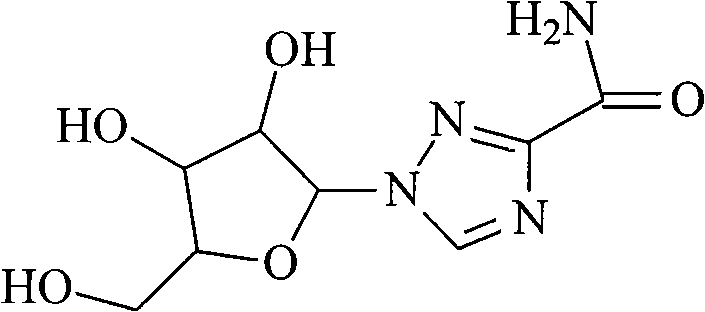

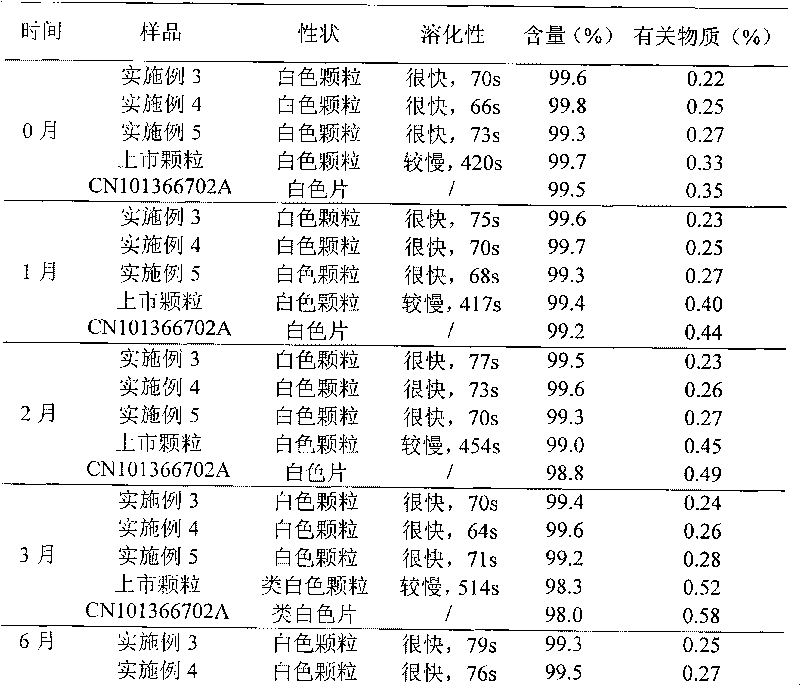

Ribavirin lipid microsphere effervescent granules

InactiveCN101703481AUnexpected effectNon-immunogenicOrganic active ingredientsAntiviralsYolkLipid formation

The invention relates to ribavirin lipid microspheres of a targeting drug delivery system and a method for preparing the same, in particular to ribavirin lipid microsphere effervescent granules and a method for preparing the same. The method comprises the steps of: adopting film dispersion technology to obtain the ribavirin lipid microspheres by combining a certain amount of yolk lecithin, cholesterol and deoxysodium cholate with an active component, namely ribavirin, and then mixing the ribavirin lipid microspheres with certain excipient to obtain the effervescent granules. The effervescent granules have the advantages of quick response, high bioavailability, and less toxic and side effects, so that the satisfactory technical effect is achieved.

Owner:HAINAN LINGKANG PHARMA CO LTD

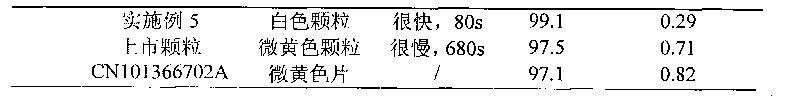

Creatine phosphate sodium lipidosome freeze-dried preparation and preparation method thereof

InactiveCN101530391ASafety proofUnexpected effectOrganic active ingredientsPharmaceutical non-active ingredientsAntioxidantPhosphate

The invention relates to a creatine phosphate sodium lipidosome freeze-dried preparation and a preparation method thereof. The creatine phosphate sodium lipidosome freeze-dried preparation is characterized by comprising the following components in portion by weight: 10 to 20 portions of creatine phosphate sodium, 10 to 40 portions of phospholipids, 0 to 10 portions of cholesterol, 1 to 10 portions of antioxidant, and 5 to 20 portions of cryoprotectant.

Owner:HAINAN LINGKANG PHARMA CO LTD

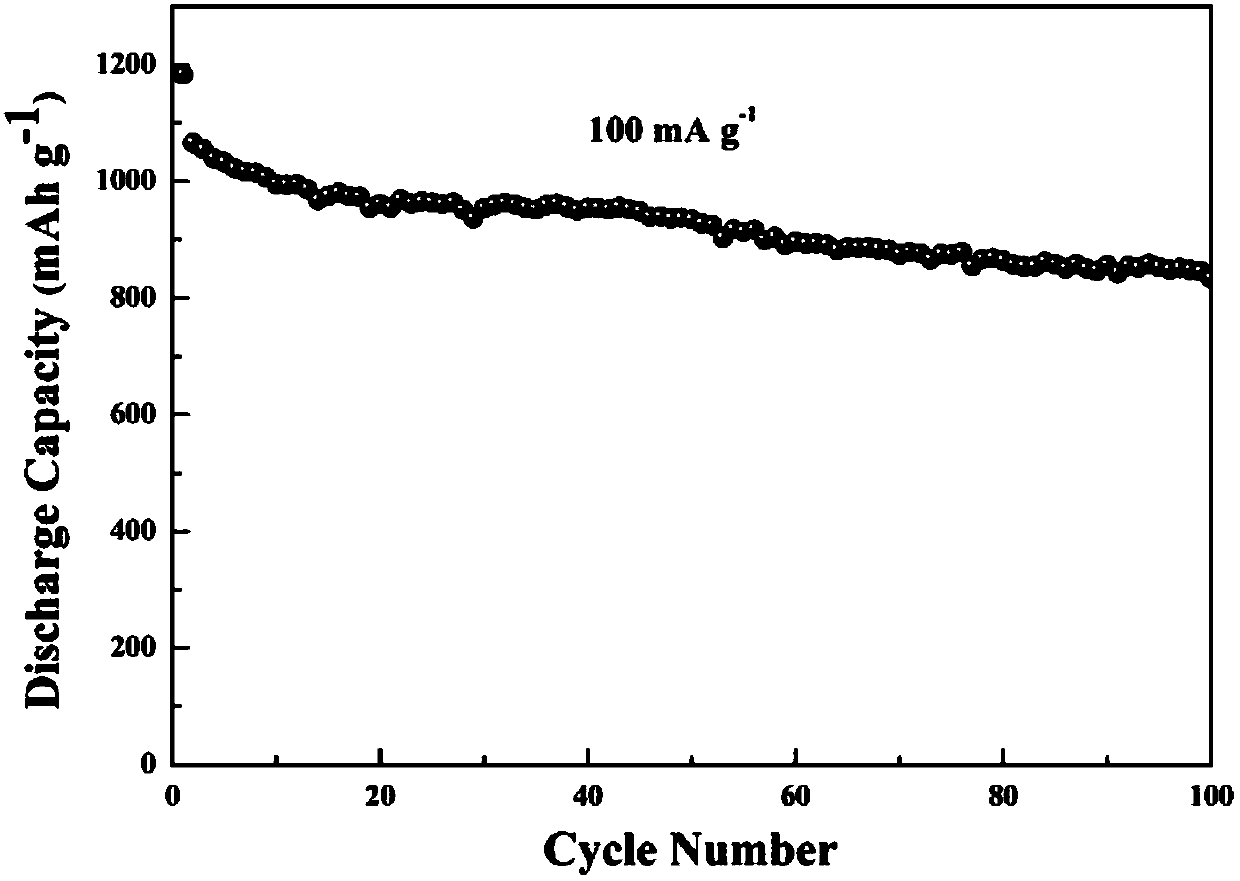

Method for preparing lithium ion carbon negative electrode material from mixed mushroom residue waste

ActiveCN107732209AUnexpected effectWide variety of sourcesCell electrodesSecondary cellsMetal impuritiesHierarchical porous

The invention relates to a method for preparing multi-element doped hierarchical porous carbon with mixed mushroom residue waste as a raw material and application of the multi-element doped hierarchical porous carbon in a lithium battery negative electrode material. The method includes the steps that after being dried and ball-milled, the mixed mushroom residue waste is mixed with metal salt and inorganic base, and high-temperature calcination treatment is conducted; then metal impurities are removed by using inorganic acid, and the multi-element doped hierarchical porous carbon is obtained. The hierarchical porous carbon prepared through the preparation method is doped with multiple elements, is rich in micropore, mesopore and macropore, and is especially suitable for being applied to a lithium ion negative electrode material. Raw materials are wide in source, the process is simple, operation is convenient, the cost is low, the obtained product is excellent in performance, and expanded production is easy.

Owner:大理宸宇储能新材料有限公司

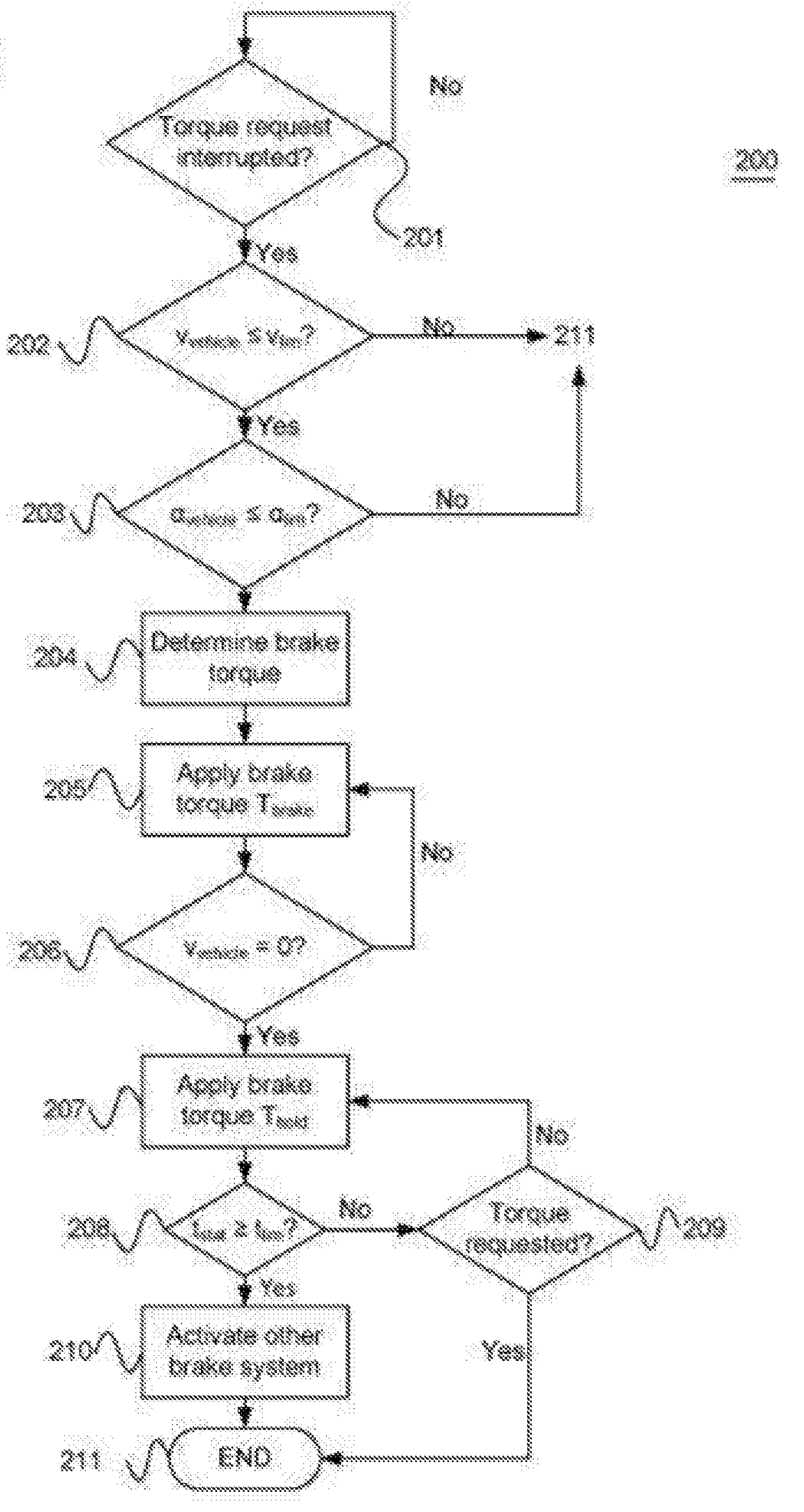

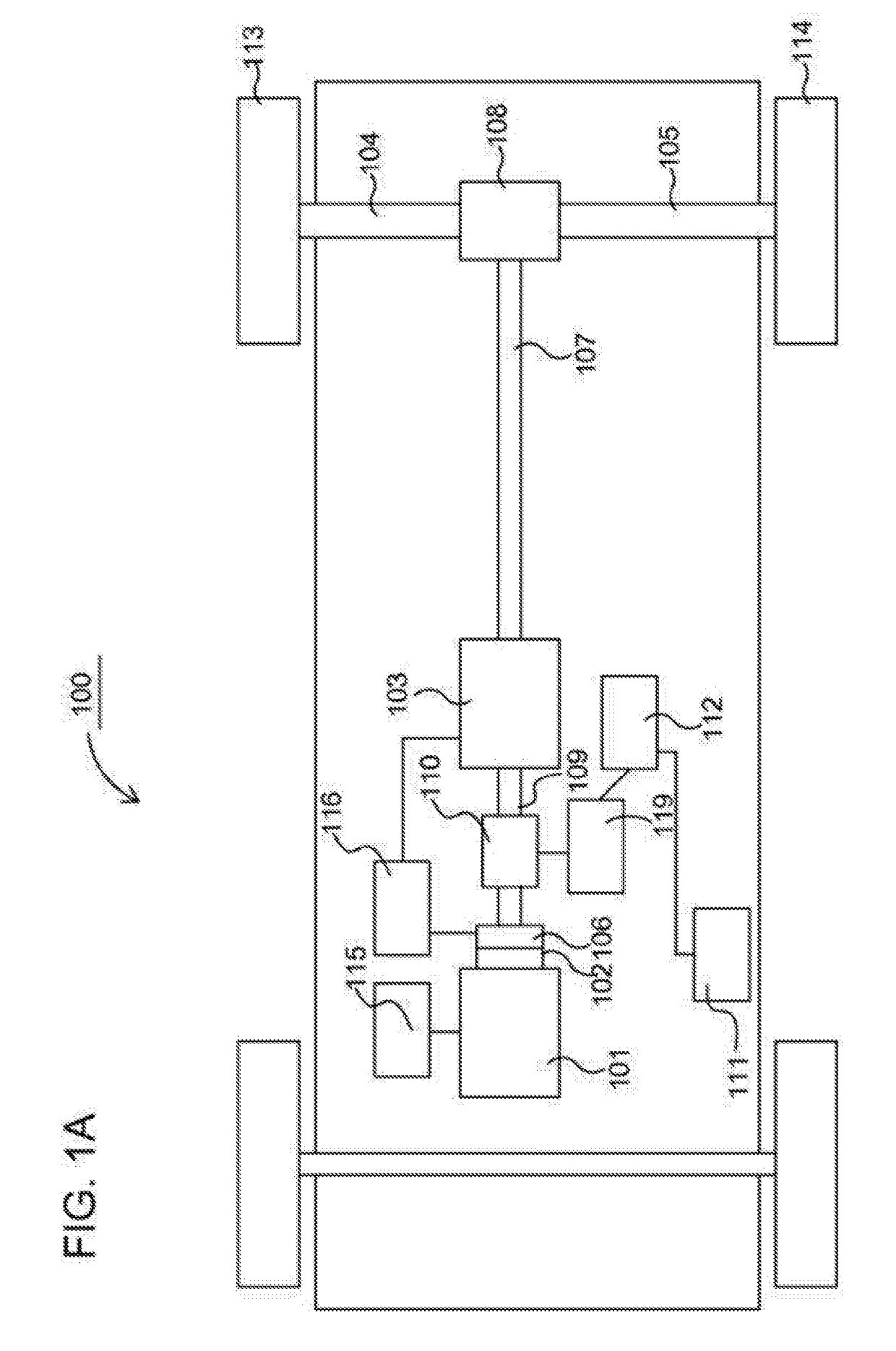

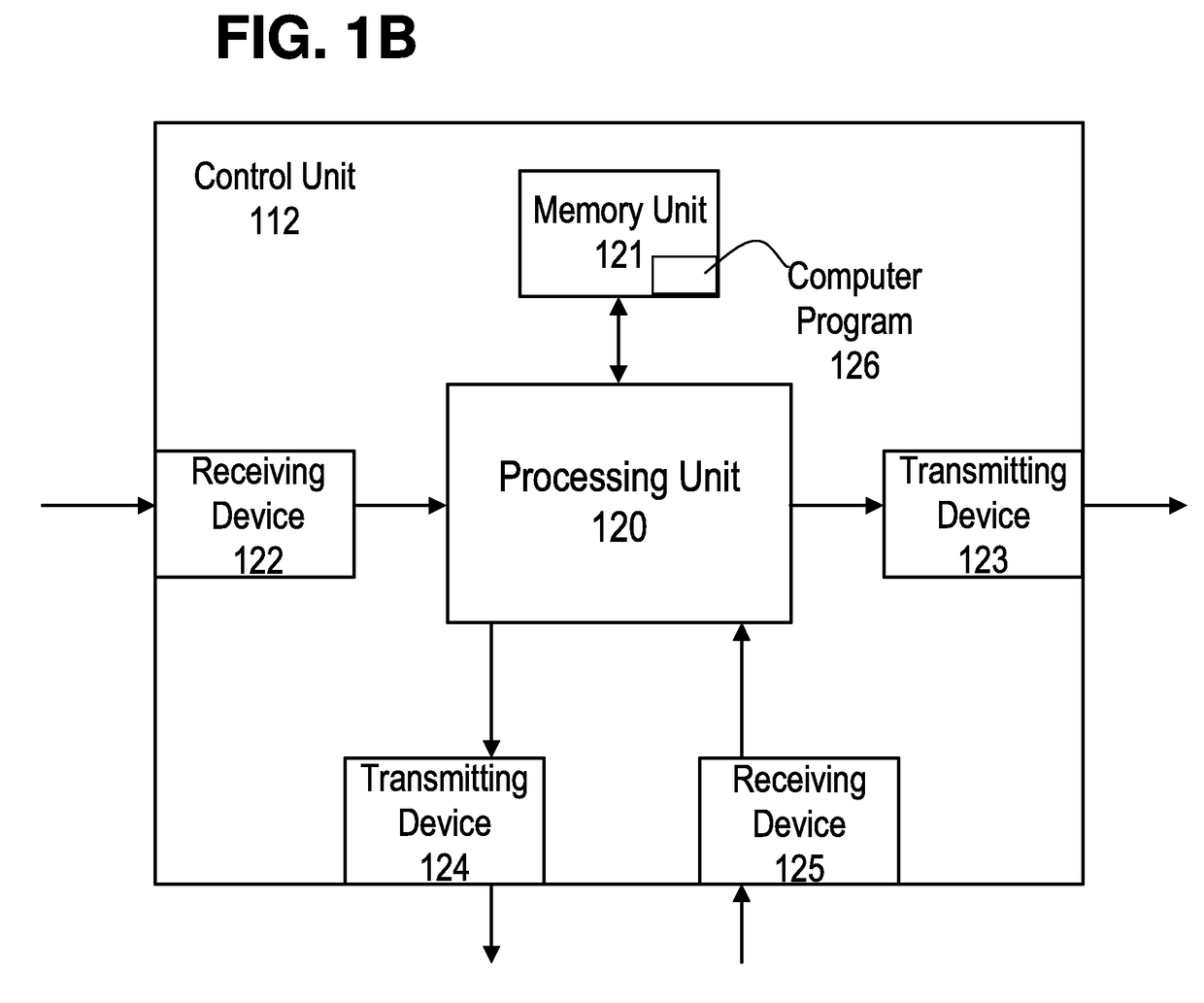

Method and system for decelerating a vehicle

ActiveUS20170297558A1Facilitate maneuveringFacilitates higher accuracy maneuveringHybrid vehiclesSpeed controllerBrake torqueDrive wheel

The present invention relates to a method for decelerating a vehicle comprising an electrical machine being arranged to provide a controllable torque to at least one drive wheel, said vehicle including driver controllable means for actively requesting a torque for propelling the vehicle. The method includes, when a driver request for a propelling torque is reduced at least to a first extent: applying a first brake torque by means of said electrical machine, by means of said first brake torque, decelerate said vehicle to a stationary state, and by means of said electrical machine, when said vehicle has been decelerated to said stationary state, continue applying a torque by means of said electrical machine to keep said vehicle in said stationary state.

Owner:SCANIA CV AB

Diet cellulose health product for preventing and treating astriction and its preparing method

The present invention relates to a dietary cellulose health-care food for preventing and curing constipation and its preparation method. It is made up by using wheat, soybean, lentinus edodes, dried fungus, jujube, white granulated sugar and corn through a special preparation process. Said invention also provides the concrete steps of said preparation process.

Owner:TONGKANG ECONOMIC & TRADE JILIN PROV

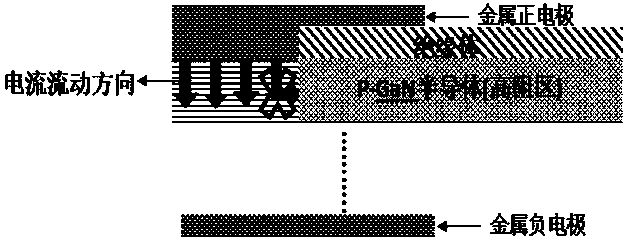

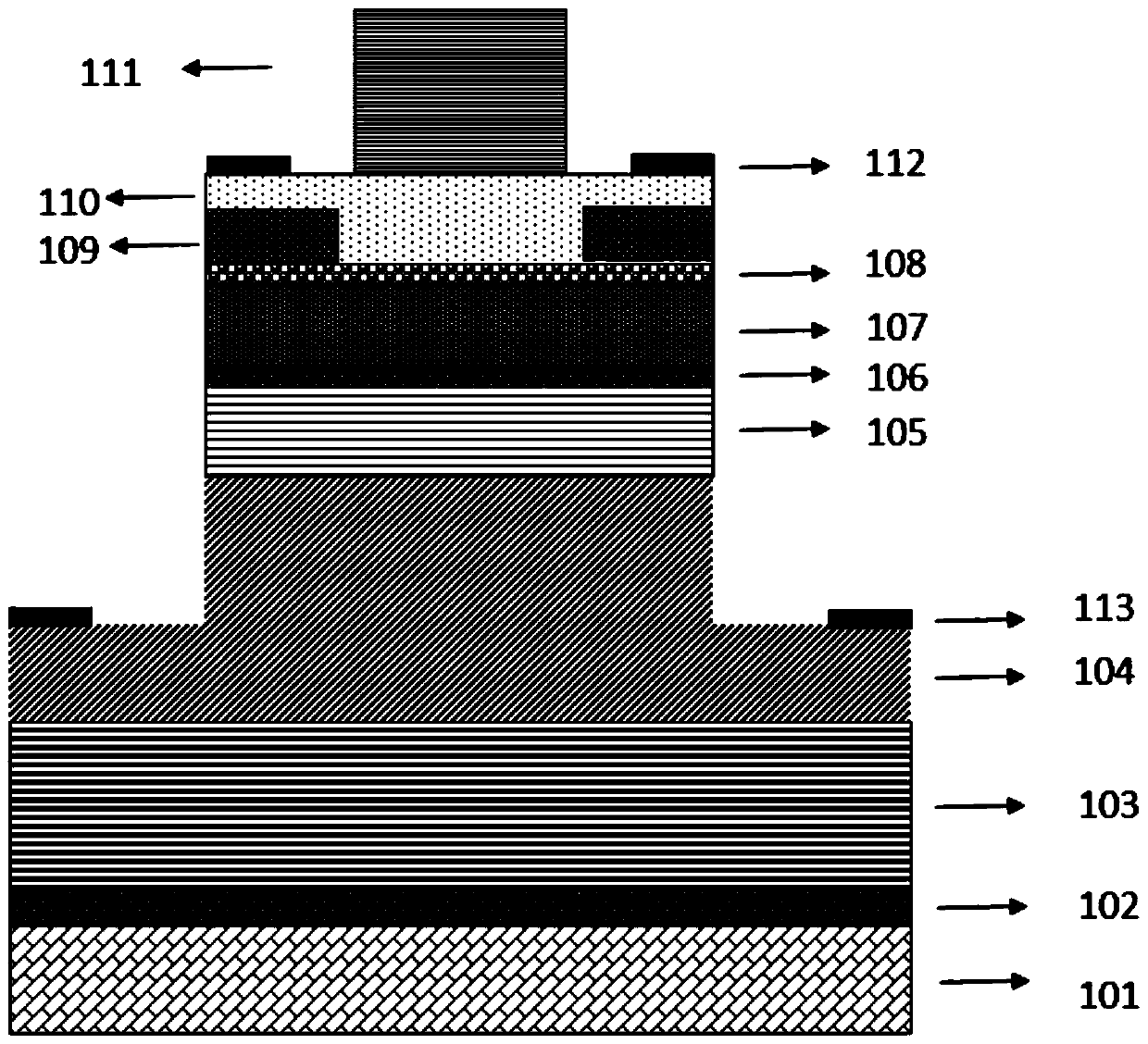

VCSEL device with high-dielectric-constant limiting hole and preparation method thereof

PendingCN110277732AUnexpected effectReduce lateral spreadLaser detailsSemiconductor lasersEngineeringNitride

The invention discloses a VCSEL device with a high-dielectric-constant current limiting hole and a preparation method thereof. An epitaxial structure of the device sequentially comprises a substrate, a buffer layer, a nitride epitaxial DBR and an N-type semiconductor transmission layer in the epitaxial growth direction. The N-type semiconductor transmission layer is divided into two parts, wehrein the lower layer completely covers the nitride epitaxy DBR. A multi-quantum well layer, a P-type current blocking layer and a P-type semiconductor transmission layer are sequentially arranged on the N-type semiconductor transmission layer; a P-type heavily-doped semiconductor transmission layer; and the outer side of the upper surface of the P-type heavily-doped semiconductor transmission layer is provided with an annular high-dielectric-constant insulating layer which is made of non-doped HfO2 or Ta2O5. Compared with a device with a tunneling junction, the device with the high-dielectric-constant current limiting hole has the advantages that the process time can be reduced by nearly 40%, the light-emitting threshold value can be reduced by about 0.5 mA, and the output power at the temperature of 80 mA is improved by 14.3% compared with that of a conventional device.

Owner:HEBEI UNIV OF TECH

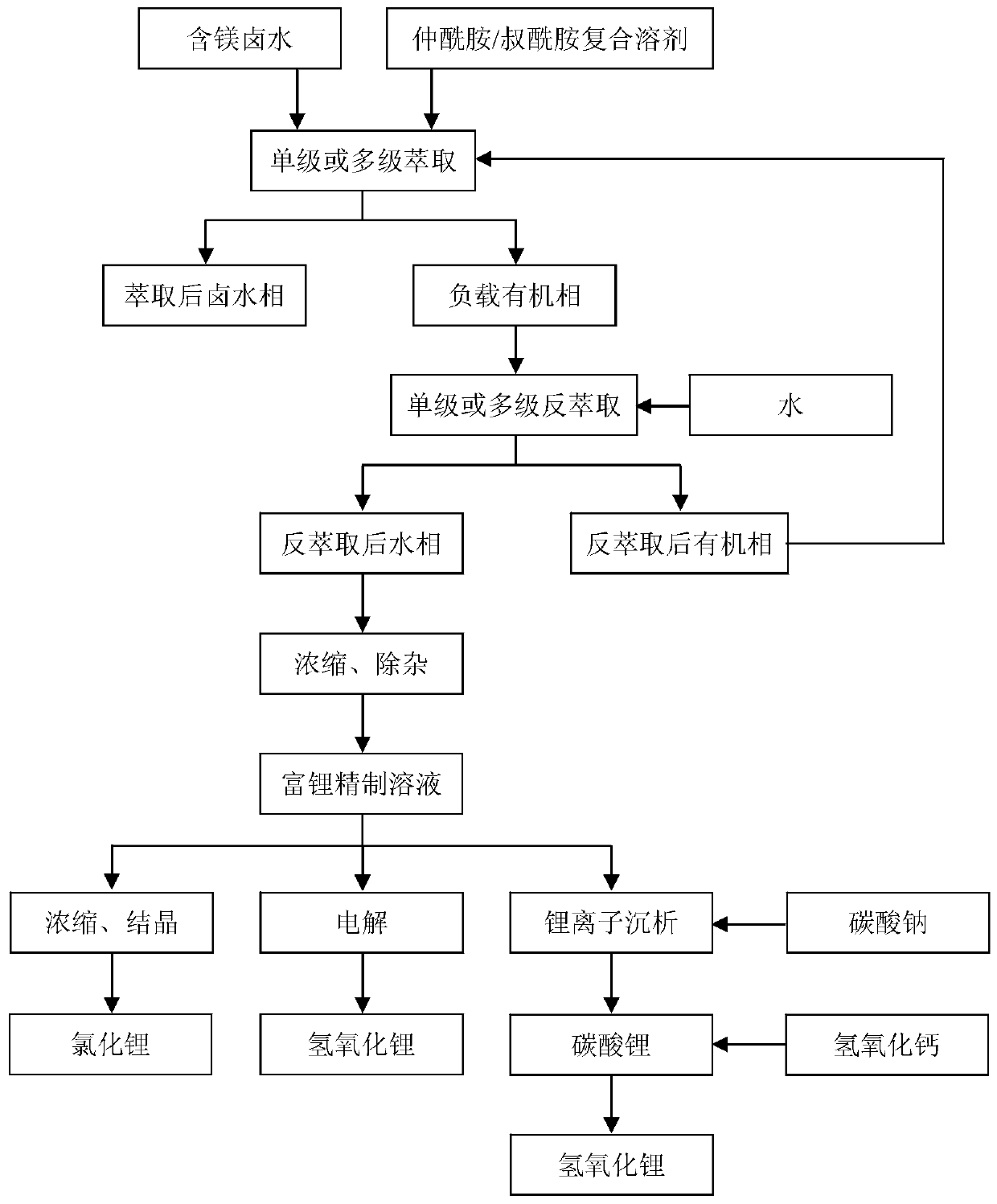

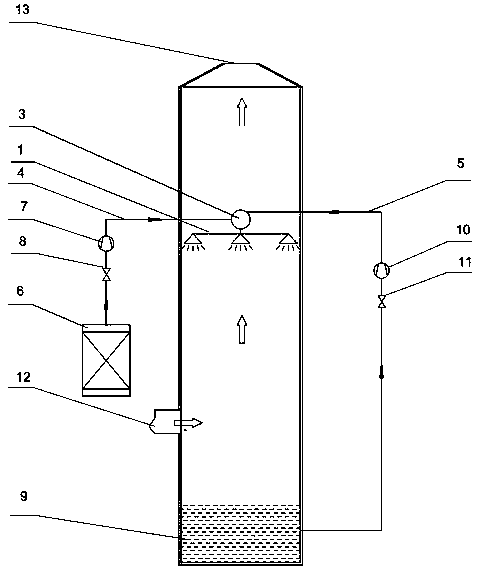

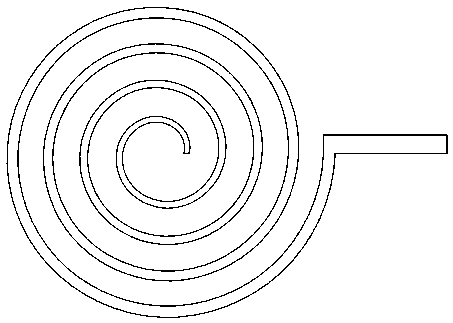

Extraction system and method for separating magnesium and extracting lithium from magnesium containing brine with secondary amide/tertiary amide complex solvent and application of extraction method

ActiveCN110643833AUnexpected effectSimple structureElectrolysis componentsLithium halidesLithium chlorideLithium hydroxide

The invention discloses an extraction system and method for separating magnesium and extracting lithium from magnesium containing brine with a secondary amide / tertiary amide complex solvent and application of the extraction method. The extraction system contains secondary amide and tertiary amide, and each of the secondary amide and the tertiary amide is composed of a single compound or a mixtureof two or more compounds. The total number of carbon atoms in a molecule of the secondary amide ranges from 12 to 18, the total number of carbon atoms in a molecule of the tertiary amide ranges from 18 to 32, and the solidifying point of the extraction system is lower than 0 DEG C. Single-stage or multi-stage counter-current extraction is carried out under the condition that the volume ratio of anorganic phase to a brine phase is (1-10):1, the density of the brine is 1.25-1.38 g / cm<3>, and the temperature ranges from 0 DEG C to 50 DEG C; and a water phase low in magnesium-lithium ratio is obtained through reextraction, and lithium chloride, lithium carbonate and lithium hydroxide products are obtained through concentration, purification and preparation. The extraction system and method for separating magnesium and extracting lithium from the magnesium containing brine with the secondary amide / tertiary amide composite solvent and the application of the extraction method have the excellent effects that a secondary amide extraction agent is simple in molecular structure and easy to produce, and the viscosity and other physical characters of the complex solvent are improved through the tertiary amide; the multi-stage extraction rate of Li+ is high, the magnesium-lithium separation coefficient is large, water is used for reextraction, and acid-base consumption is greatly reduced; and the extraction separation technological process is short, the extraction system is small in dissolution loss, and high industrial application value is achieved.

Owner:XIANGTAN UNIV

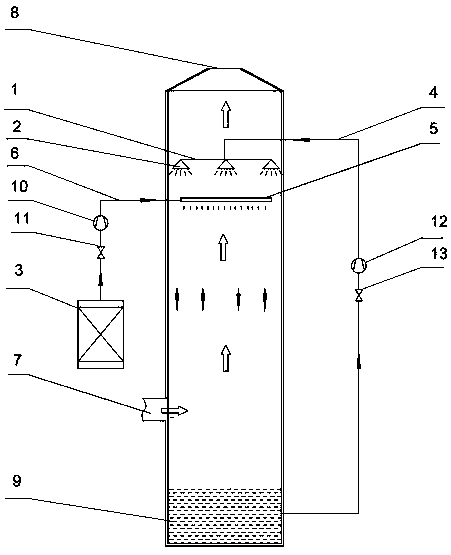

Method of using chlorine dioxide containing liquid to carry out denitration

PendingCN111229006AObvious cost advantageLow costGas treatmentDispersed particle separationChlorine dioxideFlue gas

The invention provides a method of using chlorine dioxide containing liquid to carry out denitration. The method comprises the following steps: (1) preparing a chlorine dioxide containing liquid; (2)mixing nitric acid with the chlorine dioxide containing liquid to form a mixed solution; (3) contacting the mixed solution with flue gas, oxidizing NO in the flue gas into high-valence NOx by chlorinedioxide in the mixed solution, and absorbing the high-valence NOx by nitric acid in the mixed solution; (4) separating the flue gas from the mixed solution. Nitric acid is used as an absorbent, and the technical problems of poor denitration effect of chlorine dioxide and high cost in the prior art are solved.

Owner:SHANDONG NORMAL UNIV

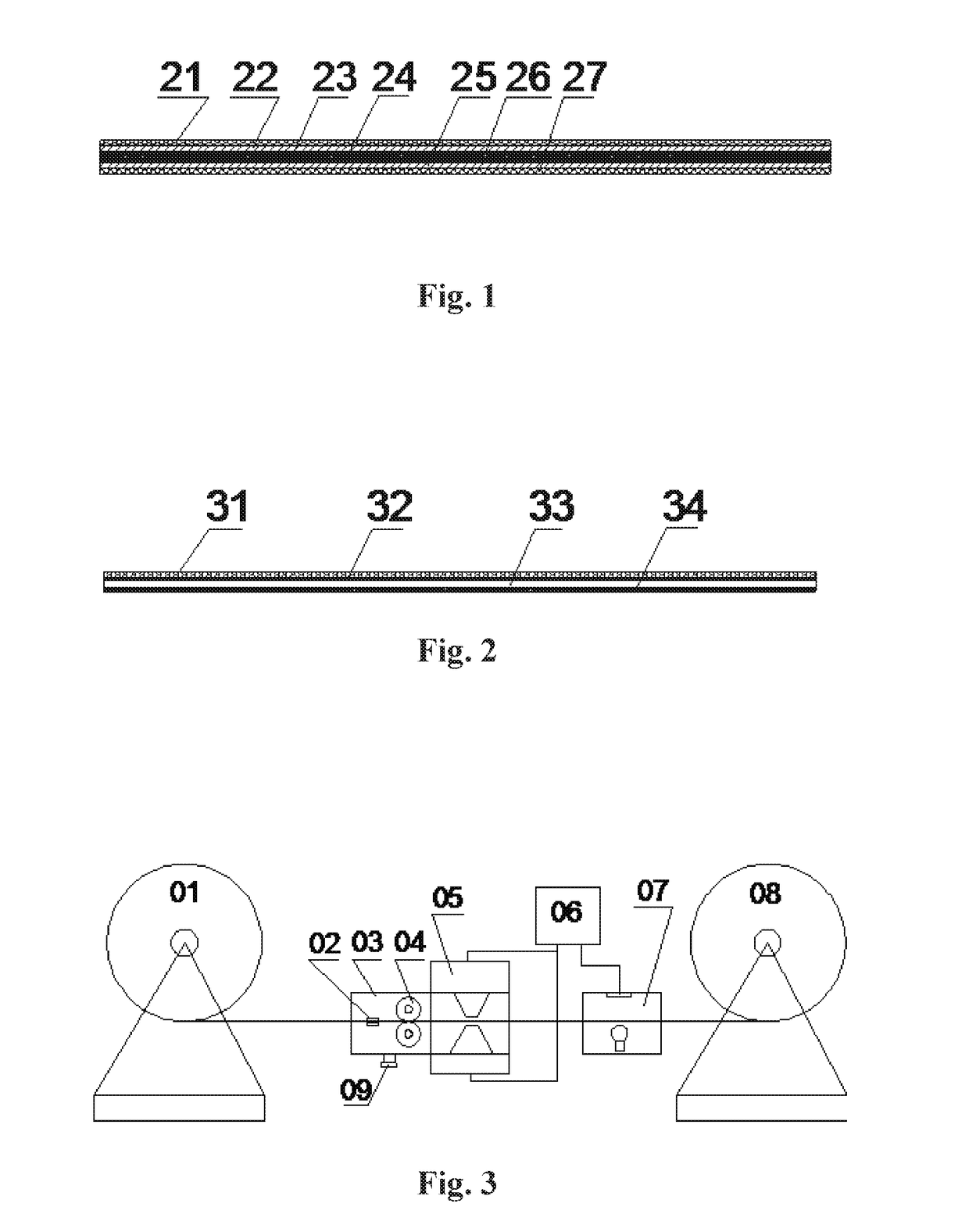

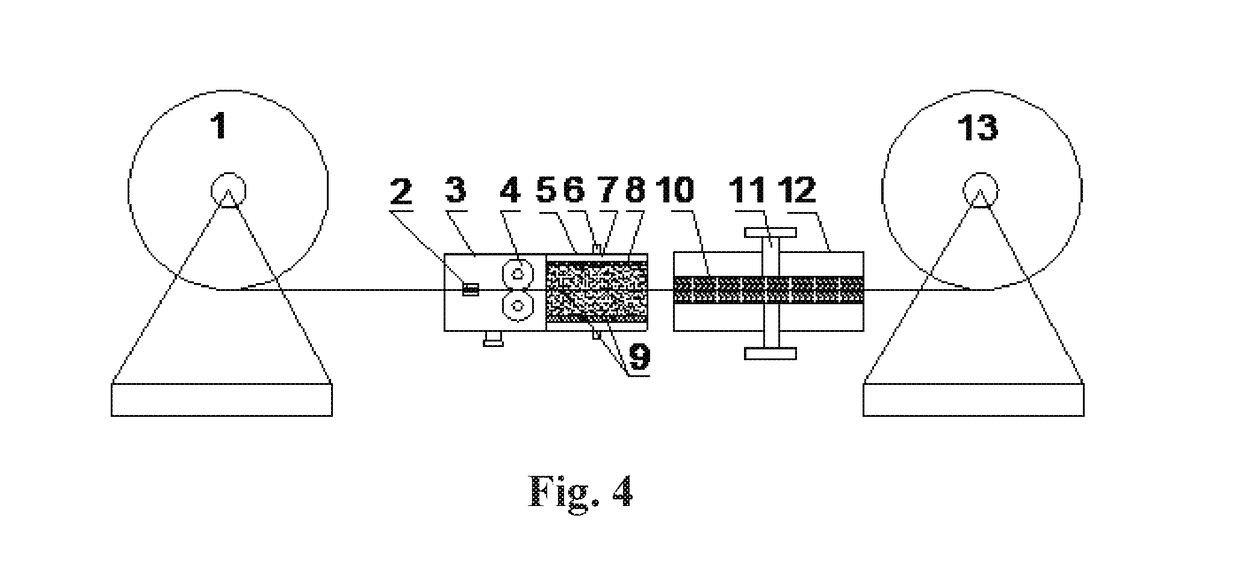

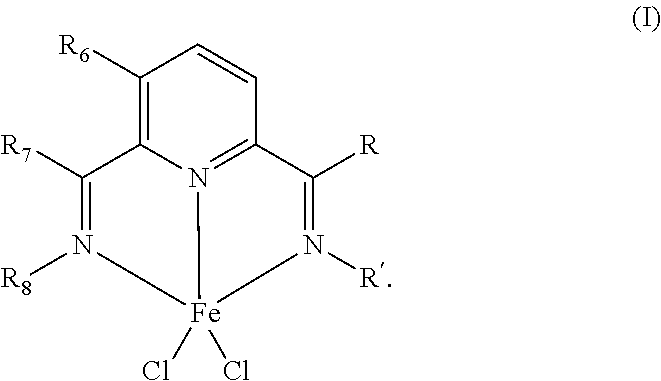

Macro-molecular leakage-free self-adhering aluminum foil and manufacturing method thereof

ActiveUS20190339469A1Improve fatigueIncrease resistanceSynthetic resin layered productsLaminationLower gradeLow graded

Owner:HANGZHOU JULI INSULATION

Macro-molecular leakage-free self-adhering aluminum foil and manufacturing method thereof

InactiveUS20180003909A1Improve fatigueIncrease resistanceSynthetic resin layered productsLaminationAl powderThin membrane

A macro-molecular leakage-free self-adhering aluminum foil has two layers of aluminum foil compounded using a PET film, and the other surfaces of each layer coated with a modified PE adhesive layer respectively; or air gaps in one surface or two surfaces are filled with nano-aluminum to form a permeable air gap-free surface. The foil has advantages: 1, high folding resistance, fatigue resistance and strength 2, wrapping self-adhering performance is good, and stripping strength formed after adhesion is several times as high as that of the prior art; 3, air gaps in the surface of the aluminum foil filled with nano-aluminum powder result in improved compactness; manufacture from low-grade aluminum foil, and so that rolling precision requirements are lowered, and manufacturing cost reduced; 4, insulating strength is high, shielding effect is good, the return loss phenomenon is avoided, and tensile strength is good.

Owner:HANGZHOU JULI INSULATION

Catalyst composition and process for ethylene oligomerization

ActiveUS9266983B2Start fastHigh activityOrganic-compounds/hydrides/coordination-complexes catalystsIron group organic compounds without C-metal linkagesOrganic solventReaction temperature

The present disclosure provides a catalyst composition for ethylene oligomerization including an imino ferrous complex shown in Formula (I) as the main catalyst, an aluminum-containing cocatalyst, water, and an organic solvent:According to the present disclosure, a higher oligomerization activity can be obtained with the catalyst composition than with a catalyst composition system in the prior art which contains no water. Moreover, when the catalyst composition according to the present disclosure is used, a high selectivity of α-olefins is obtainable. Besides, the catalyst composition according to the present disclosure can enable rapid initiation, stable operation, and good repeatability of the oligomerization reaction. According to the present disclosure, a high oligomerization activity can be obtained even at a rather low ratio of Al / Fe, or at a low reaction temperature.

Owner:CHINA PETROCHEMICAL CORP +1

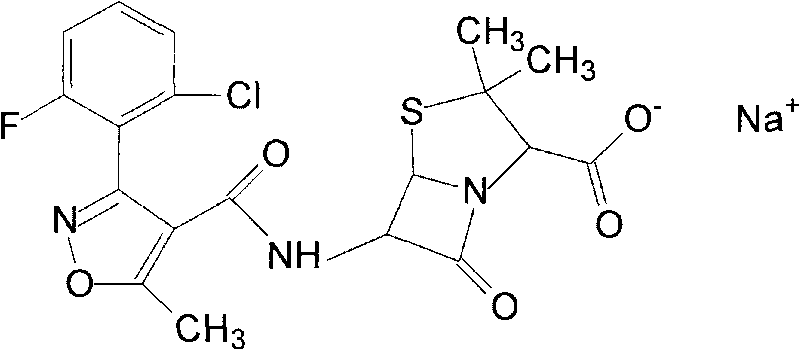

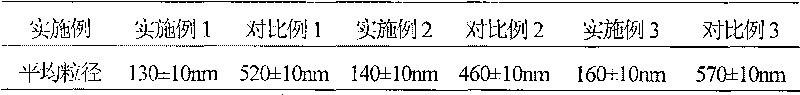

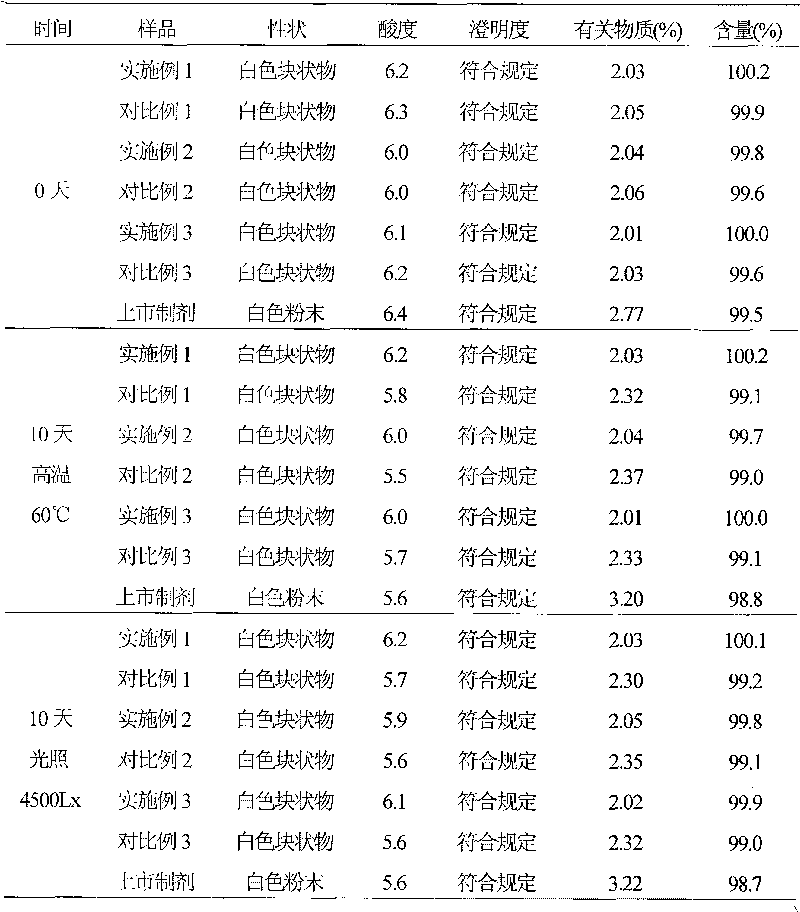

Flucloxacillin sodium suspension and new application thereof

InactiveCN101700234AEasy to storeEasy to transportPowder deliveryAntimycoticsFreeze-dryingFlucloxacillin sodium

The invention relates to a flucloxacillin sodium suspension and a new application thereof. The invention provides the flucloxacillin sodium suspension containing 1 part by weight of flucloxacillin sodium, 3-14 parts by weight of surfactant and 2-20 parts by weight of freeze-drying support agent. The invention further discloses the new application of the flucloxacillin sodium suspension in the preparation of drugs for treating pityrosporum folliculitis.

Owner:HAINAN MEILAN SMITH KLINE PHARMA

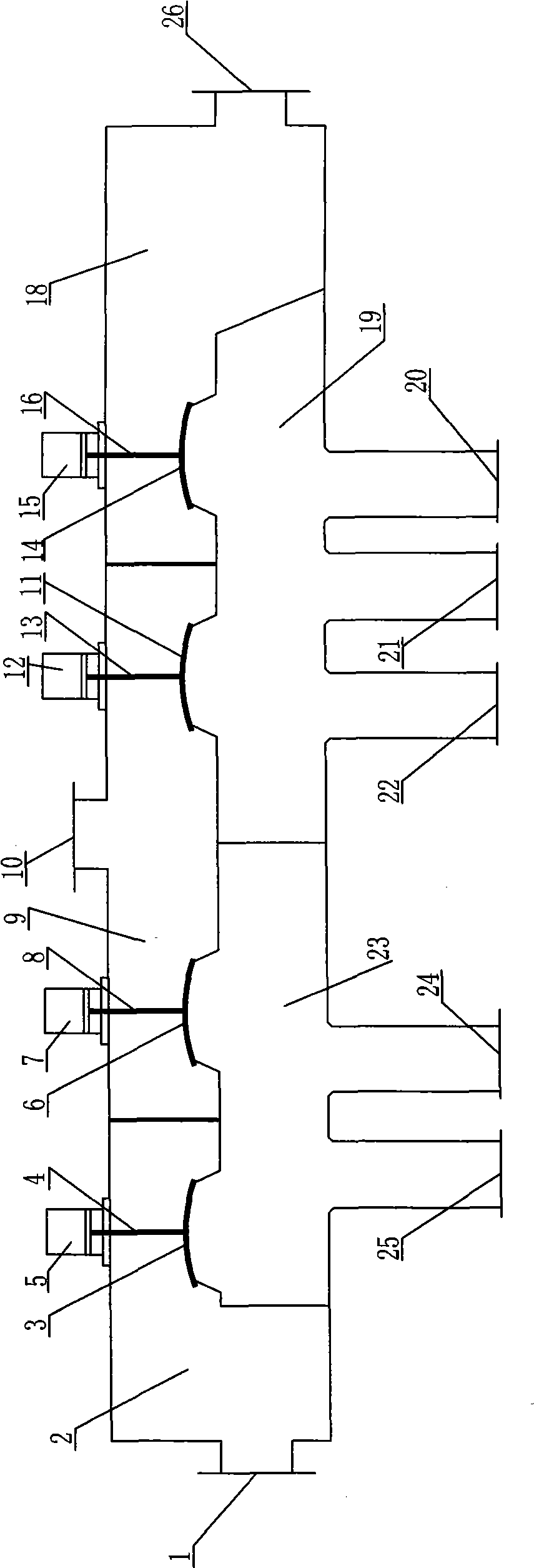

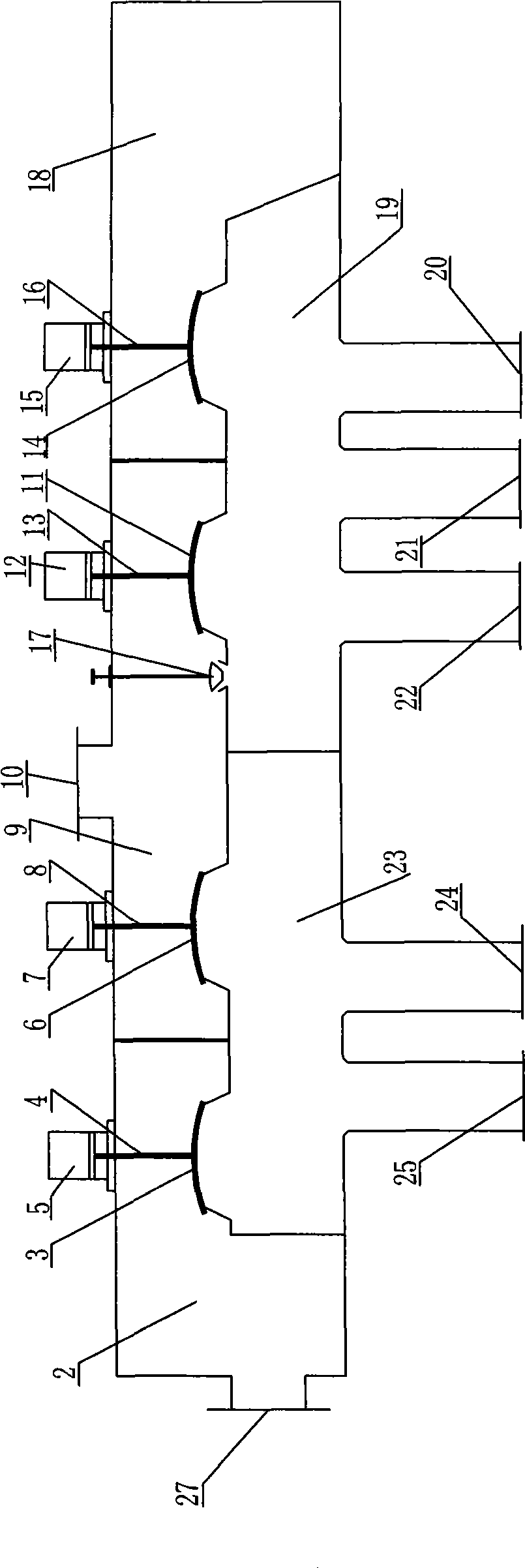

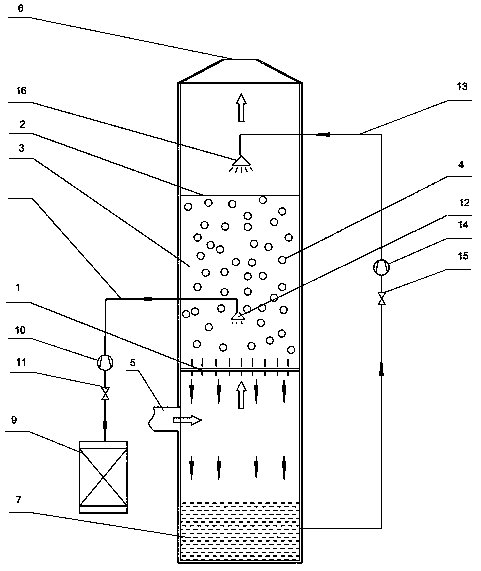

Multistage multi-pressure jigging machine and coal preparation method thereof

InactiveCN101543801AImprove sorting efficiencyHigh recovery rateWet separationGranularityVolumetric Mass Density

The present invention discloses a multistage multi-pressure jigging machine and a coal preparation method thereof, a jigging machine comprising two to four separating segments and a coal preparation method thereof. The invention adopts low wind pressures which are independent in each separating segment and are most appropriate for the material separated in the separating segment. The low wind pressures adopted in different separating segments in one machine are different and have remarkable difference. According to the multistage multi-pressure jigging machine adopting the structure and the coal preparation method, the jig beds of different separating segment can provide most appropriate shatter value for the separated material. In the actual technique of jigging separation which has larger difference between the average densities and granularities of separated material on segments, the layering effect of each segment can obtain an optimal state thereby greatly increasing the separation efficiency of device, increasing the recovery rate of product, reducing the effect of product loss and obtaining the separation effect which can not obtained by prior jigging machine.

Owner:JINYITONG SCI ANDTECH BEIJING CO LTD

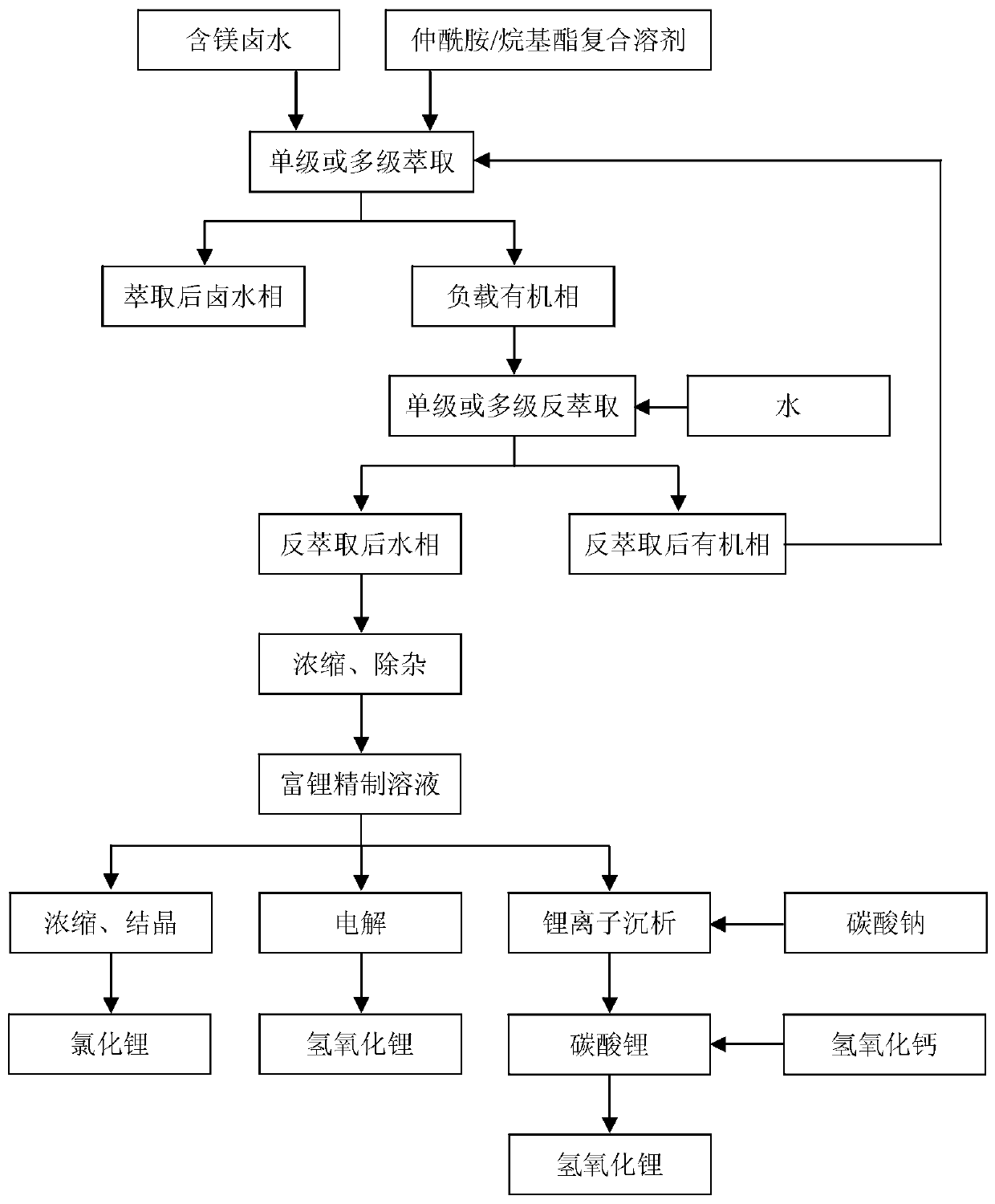

Extraction system and extraction method for extracting lithium from magnesium-containing brine by using secondary amide/alkyl ester complex solvent, and application thereof

ActiveCN110643836AUnexpected effectSimple structureElectrolysis componentsLithium halidesLithium chlorideLithium hydroxide

The invention discloses an extraction system and an extraction method for extracting lithium from magnesium-containing brine by using a secondary amide / alkyl ester complex solvent, and application thereof. The extraction system contains secondary amide and alkyl ester which are respectively prepared from a single compound or a mixture of more than two compounds; in the molecules, the totals of carbon atoms are respectively 12 to 18 and 8 to 20; and the freezing point of the extraction system is smaller than 0 DEG C. The extraction method comprises the steps of carrying out single-stage or multi-stage counter-current extraction under the conditions that the volume ratio of an organic phase and a brine phase is 1 to 10:1, the brine density is 1.25 to 1.38g / cm<3> and the temperature is 0 to 50 DEG C, carrying out back-extraction to obtain a low-magnesium-lithium-ratio water phase, and obtaining lithium chloride, lithium carbonate and lithium hydroxide products through concentration, purification and preparation. The extraction system and the extraction method for extracting the lithium from the magnesium-containing brine by using the secondary amide / alkyl ester complex solvent, and the application thereof provided by the invention have the excellent effects that a secondary amide extraction agent is simple in molecular structure and easy to produce, the physical properties such asviscosity of the complex solvent is improved through alkyl ester, the Li+ multistage extraction rate is high, the lithium-magnesium separation coefficient is large, and the acid-alkali consumption isgreatly reduced due to back-extraction by water; and the extraction separation process flow is short, and the extraction system is low in solution loss and has a favorable industrial application value.

Owner:XIANGTAN UNIV

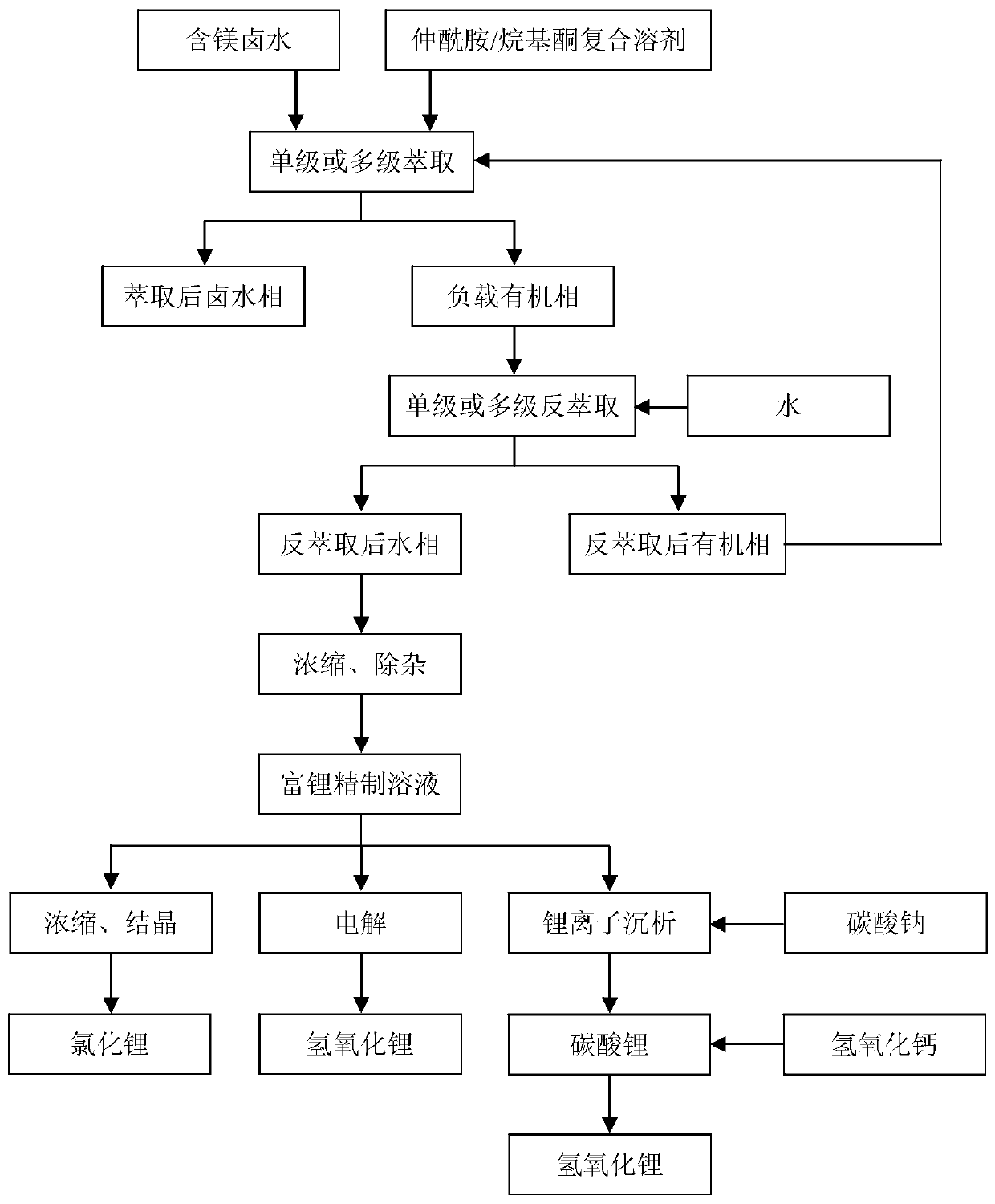

Extraction system and extraction method for separating magnesium and extracting lithium from magnesium-containing brine with secondary amide/alkyl ketone complex solvent and application of extraction method

ActiveCN110669938AUnexpected effectSimple structureElectrolysis componentsLithium halidesLithium chlorideLithium carbonate

The invention discloses an extraction system and an extraction method for separating magnesium and extracting lithium from magnesium-containing brine with a secondary amide / alkyl ketone complex solvent and application of the extraction method. The extraction system contains secondary amide and alkyl ketone each of which consists of a single compound or more than two mixtures; the total number of carbon atoms in a molecule of the secondary amide and the total number of carbon atoms in a molecule of the alkyl ketone are 12-18 and 8-12 respectively; and the solidifying point of the extraction system is lower than 0 DEG C. Single-stage or multistage counter-current extraction and back extraction are performed under the conditions that the volume ratio of an organic phase to a brine phase is (1-10) : 1, the density of the brine is 1.25-1.38 g / cm<3> and the temperature is 0-50 DEG C to obtain an aqueous phase low in magnesium and lithium ratio, and concentration, impurity removal and preparation are performed to obtain a lithium chloride product, a lithium carbonate product and a lithium hydrate product. The extraction system and the extraction method have the excellent effects a secondary amide extraction agent is simple in molecular structure and easy to produce, and the alkyl ketone improves physical properties, such as the viscosity of the complex solvent, and the like; the multistage extraction rate of Li<+> is high; the magnesium and lithium separation coefficient is big; back extraction is performed with water, so that acid and alkali consumption is greatly reduced; the extraction and separation process flow is short; the extraction system has small solvent loss; and the extraction system and the extraction method have high industrial application value.

Owner:XIANGTAN UNIV

Method for denitrifying flue gas by using chlorine dioxide

PendingCN111282417AObvious cost advantageLow costGas treatmentDispersed particle separationEnvironmental chemistryNitric Oxide / Nitrogen

The invention provides a method for denitrifying flue gas by using chlorine dioxide. The method comprises the steps: (1) preparing chlorine dioxide; (2) in a nitric acid environment, making chlorine dioxide contact with flue gas, and oxidizing nitric oxide in the flue gas into high-valence nitric oxide by the chlorine dioxide; and meanwhile, absorbing high-valence nitric oxide with nitric acid; and (3) separating the flue gas from a liquid. According to the invention, nitric acid is used as an absorbent, and the technical problems of poor denitration effect and high cost of chlorine dioxide inthe prior art can be solved.

Owner:SHANDONG NORMAL UNIV

Application of aliphatic acid salt solution as rubber page rolling release agent and rubber page rolling method

The invention discloses application of an aliphatic acid salt solution as a rubber page rolling release agent and a rubber page rolling method. Found by the researches of the inventors, through enabling a page-rolled rubber sheet to pass through the aliphatic acid salt solution, the surface of the rubber sheet can be uniformly covered with the aliphatic acid salt solution, so that the wound rubber sheet can not be adhered together; by using the aliphatic acid salt solution, particularly the aliphatic acid salt solution with the mass percentage concentration of over 10%, as the rubber page rolling release agent, an unexpected effect is obtained.

Owner:广东华声电器实业有限公司

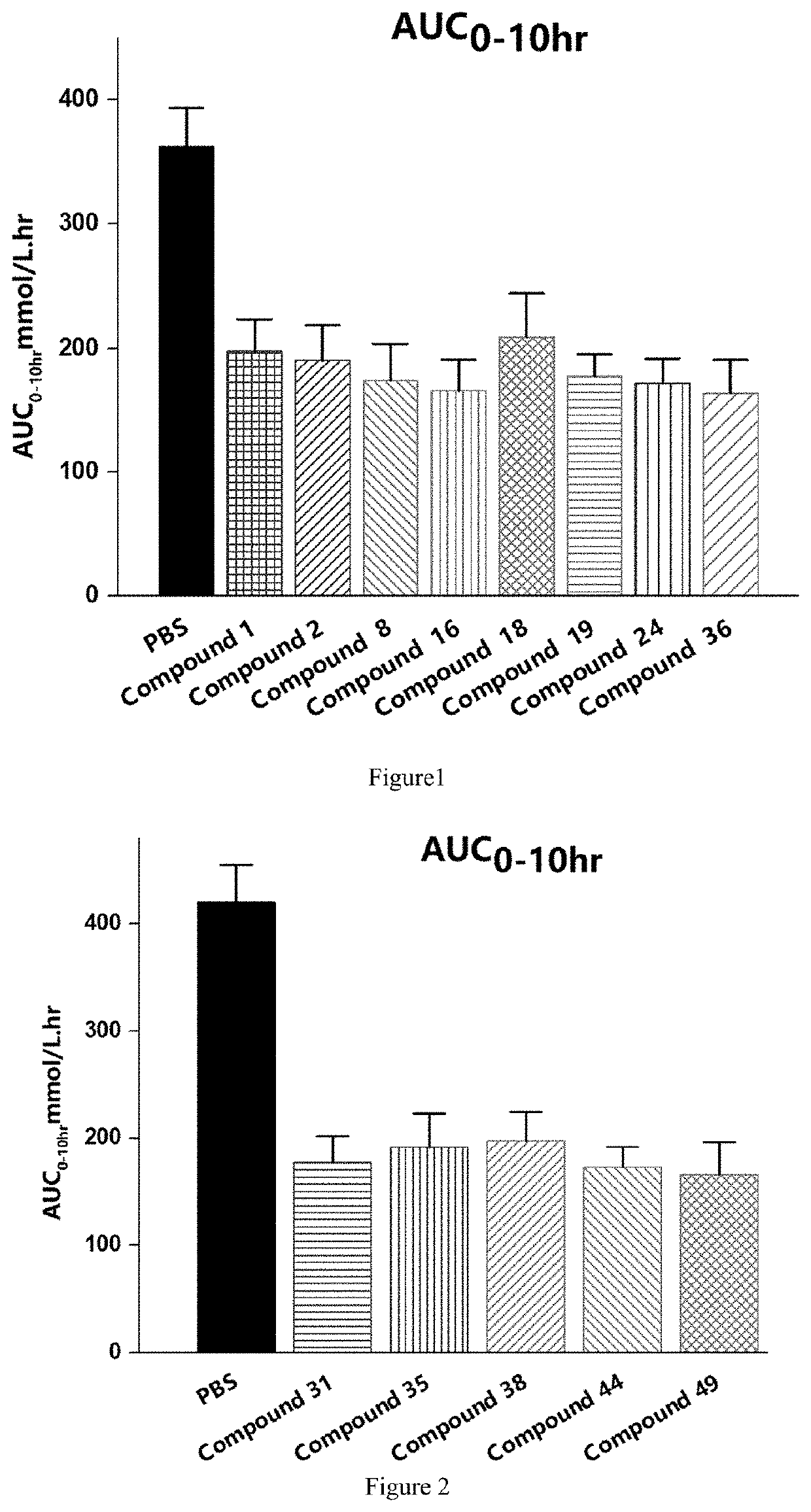

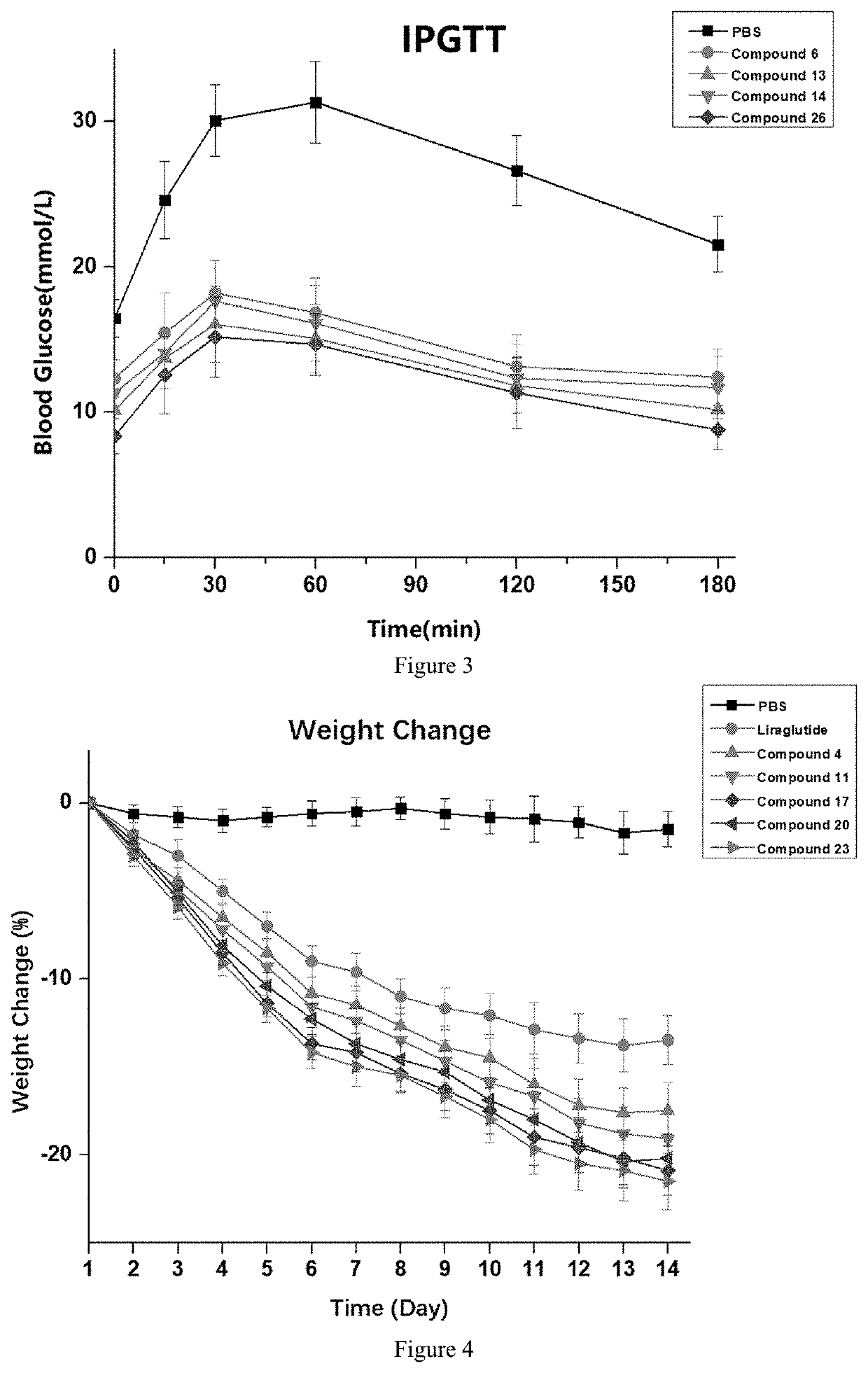

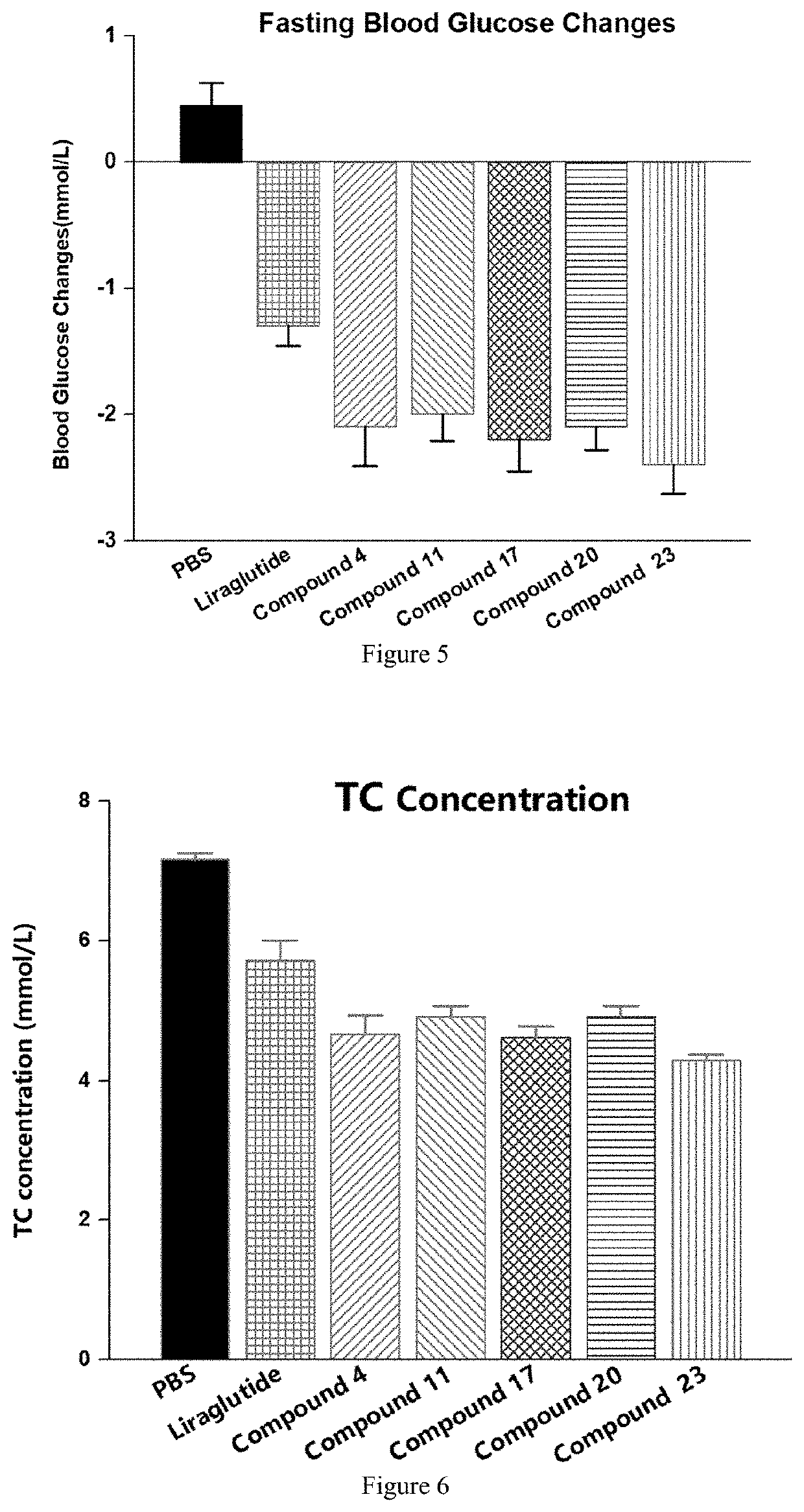

Novel polypeptide and therapeutic uses thereof

PendingUS20220127323A1Unexpected effectInhibit progressPeptide-nucleic acidsPeptide/protein ingredientsPeptide chemistryBiochemistry

The invention relates to the field of peptide chemistry, in particular, the invention relates to a peptide compound and its use in medical treatment.

Owner:VITALIXIR BEIJING CO LTD

New method for medium-carbon ferrochrome production

The invention relates to a new method for medium-carbon ferrochrome production, and belongs to the technical field of ferrous metal smelting. The new method disclosed by the invention comprises the following steps: preparing 350-360kg of Cr2O3 and 85-95kg of silica according to per ton of liquid high-carbon ferrochrome, wherein the Cr2O3 is supplied by chrome ores; and stacking the prepared material chrome ores and silica at the bottom of a furnace, and smelting at 1500-1800 DEG C in a manner of bottom heating to obtain medium-carbon ferrochrome. The new method disclosed by the invention is simple in process, low in energy consumption, low in requirement on equipment, and convenient for large-scale industrialized application.

Owner:五矿(湖南)铁合金有限责任公司

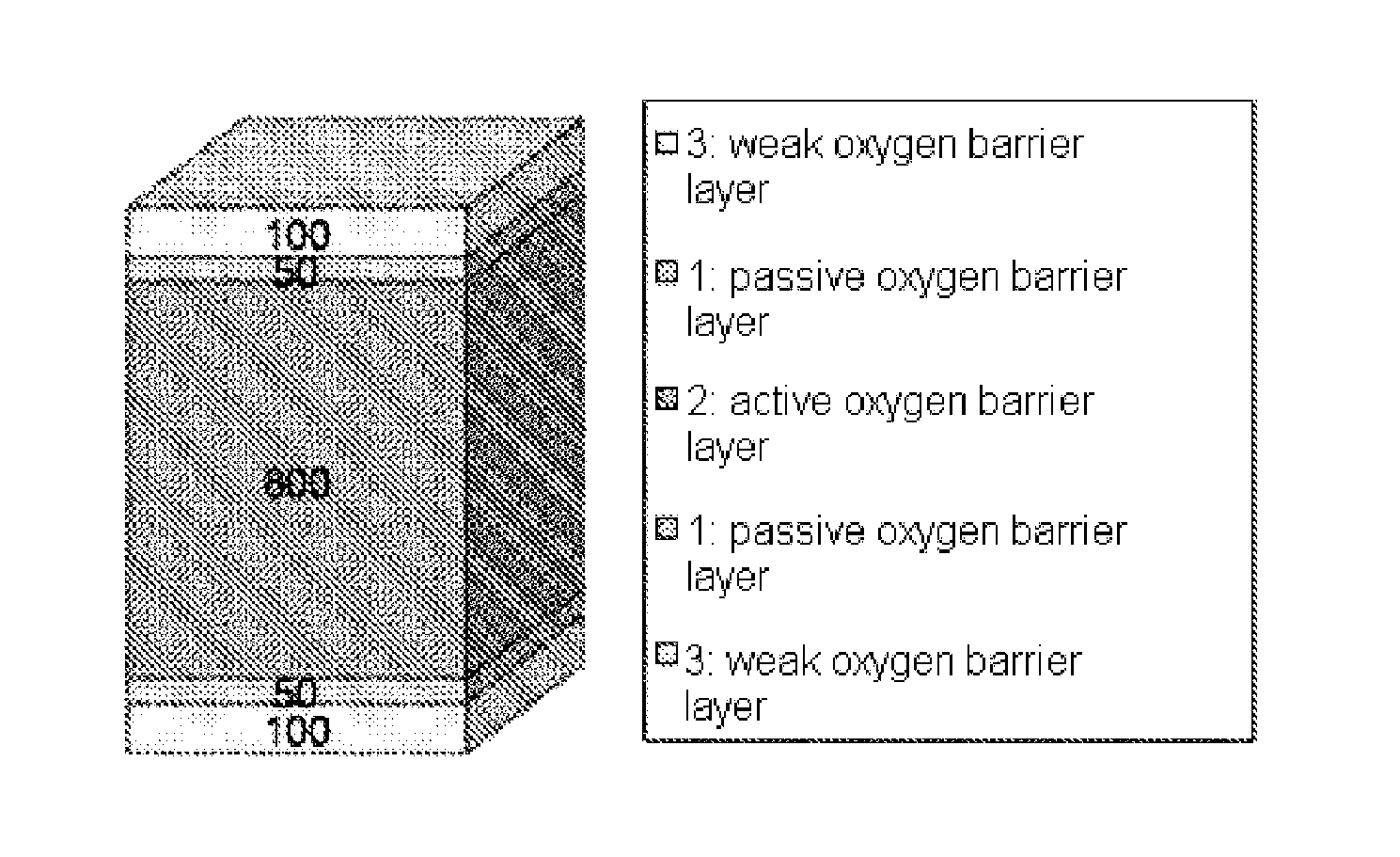

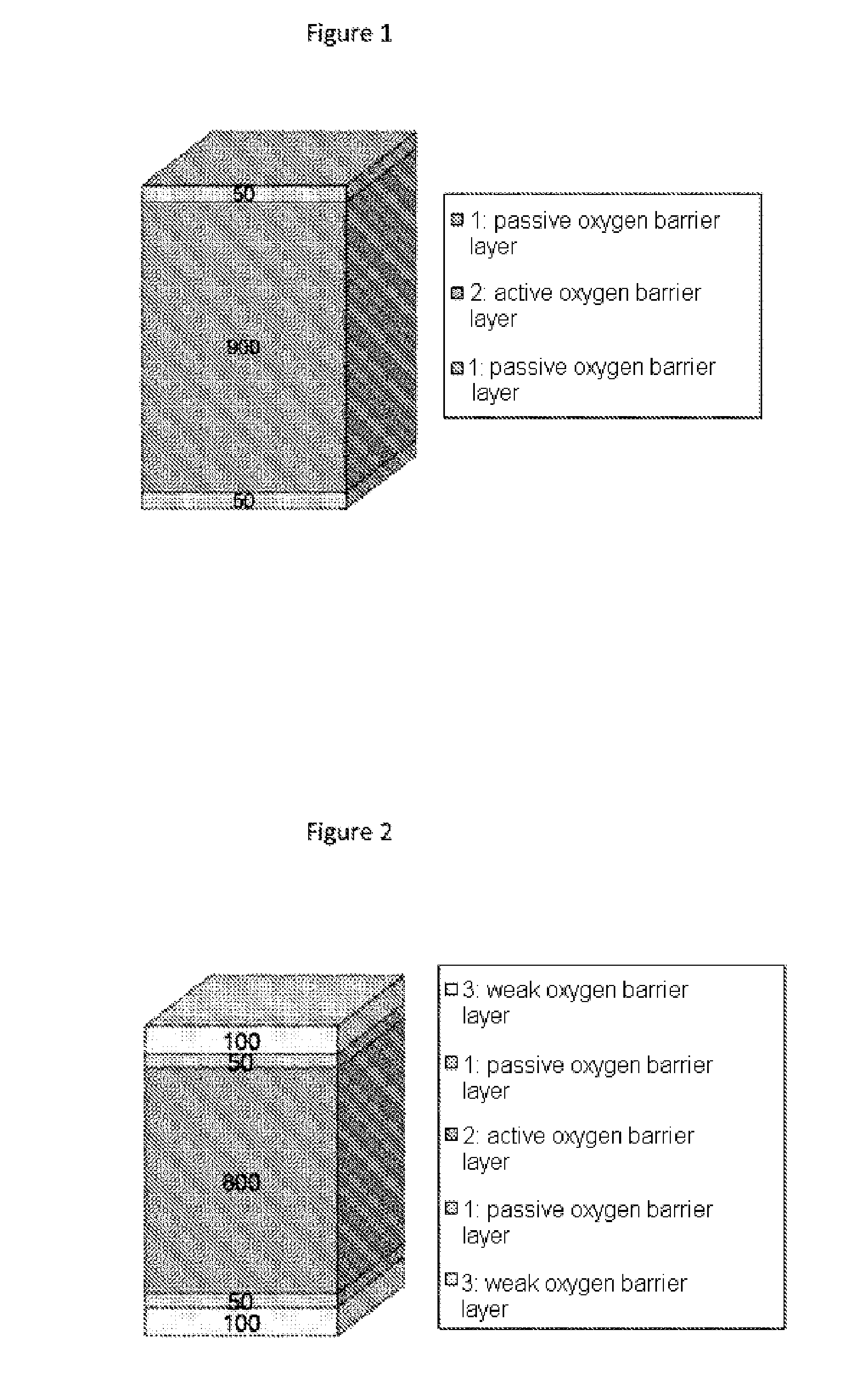

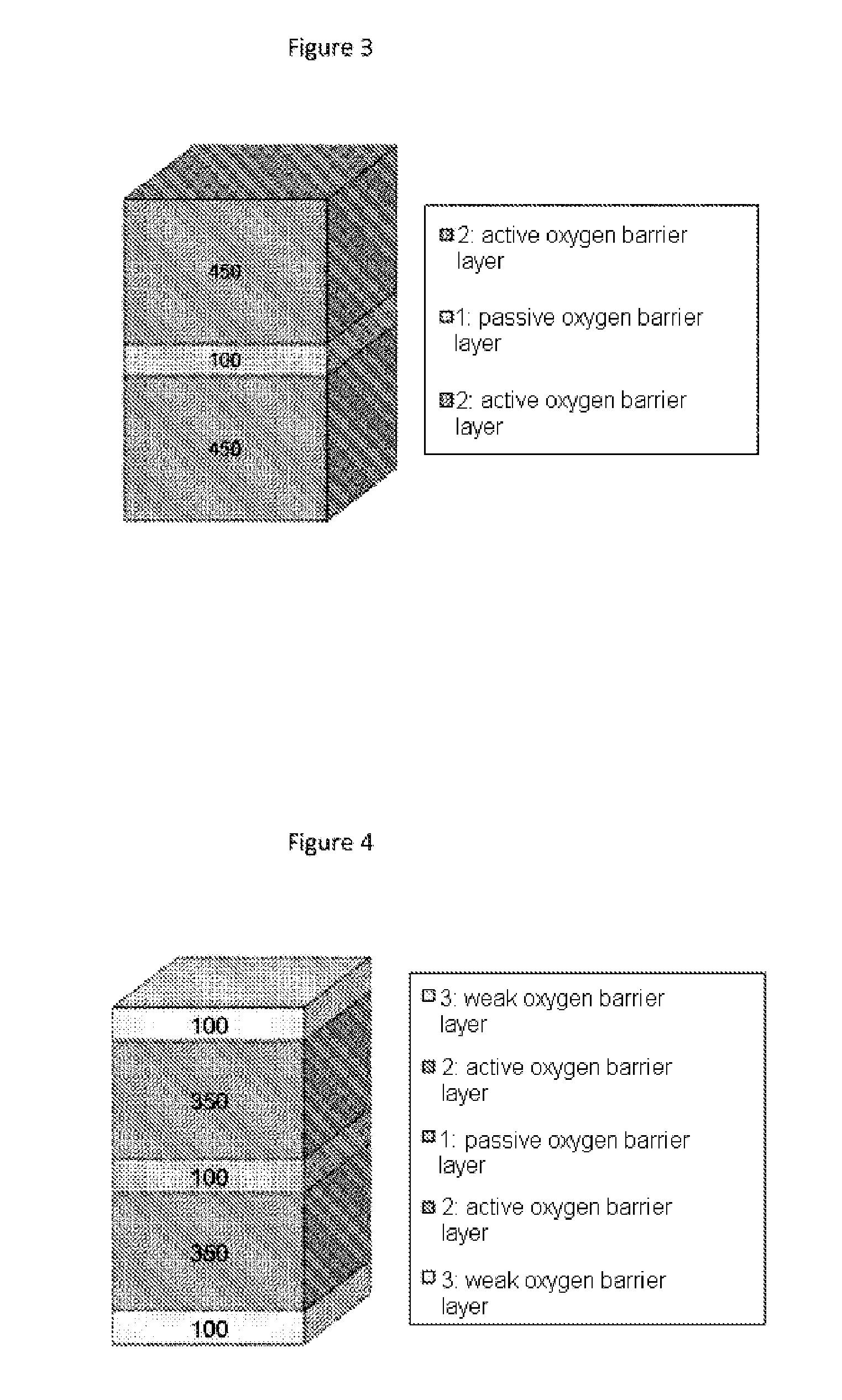

Multilayer packaging structure

InactiveUS20140305939A1Easy to understandUnexpected effectFlexible coversWrappersShell moldingOxygen

The invention relates to a multilayer structure produced by moulding and intended to form at least one part of the packaging wall, said structure comprising an oxygen barrier layer, referred to as a “passive layer”, composed of a resin that is a barrier to oxygen, and another layer, referred to as to an “active layer”, composed of at least one resin that is permeable to oxygen and in which oxygen absorbers are dispersed. The invention also relates to packaging comprising said multilayer structure.

Owner:AISAPACK HLDG SA

A New Method for Production of Medium Carbon Ferrochrome

The invention relates to a new method for medium-carbon ferrochrome production, and belongs to the technical field of ferrous metal smelting. The new method disclosed by the invention comprises the following steps: preparing 350-360kg of Cr2O3 and 85-95kg of silica according to per ton of liquid high-carbon ferrochrome, wherein the Cr2O3 is supplied by chrome ores; and stacking the prepared material chrome ores and silica at the bottom of a furnace, and smelting at 1500-1800 DEG C in a manner of bottom heating to obtain medium-carbon ferrochrome. The new method disclosed by the invention is simple in process, low in energy consumption, low in requirement on equipment, and convenient for large-scale industrialized application.

Owner:五矿(湖南)铁合金有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com