Treatment method of tin anode slurry

A technology of tin anode slime and treatment method, which is applied in the direction of improving the process efficiency, can solve the problems of high operation intensity, long process time, long process flow, etc., so as to reduce the production cost, strengthen the removal effect, and simplify the treatment process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

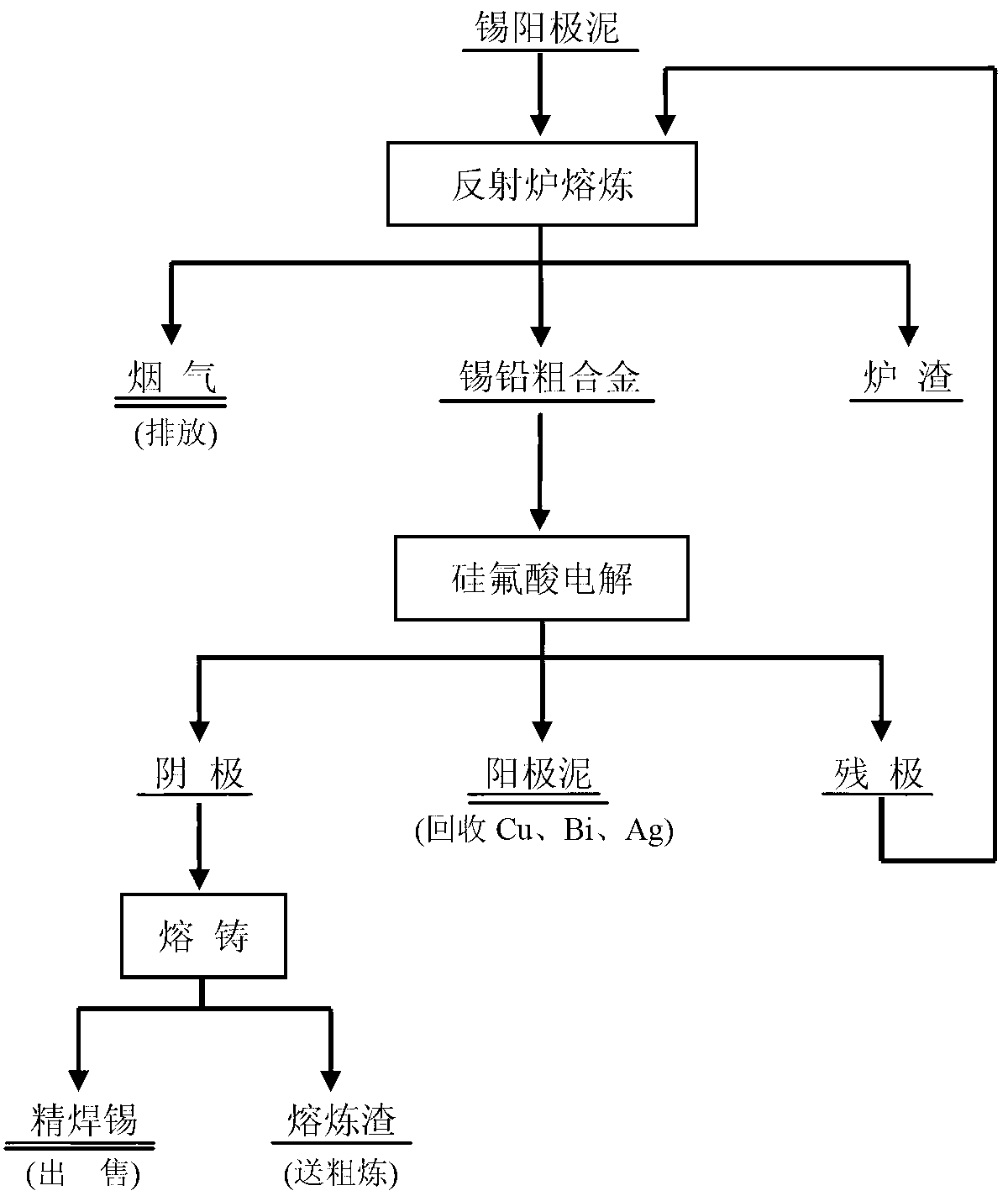

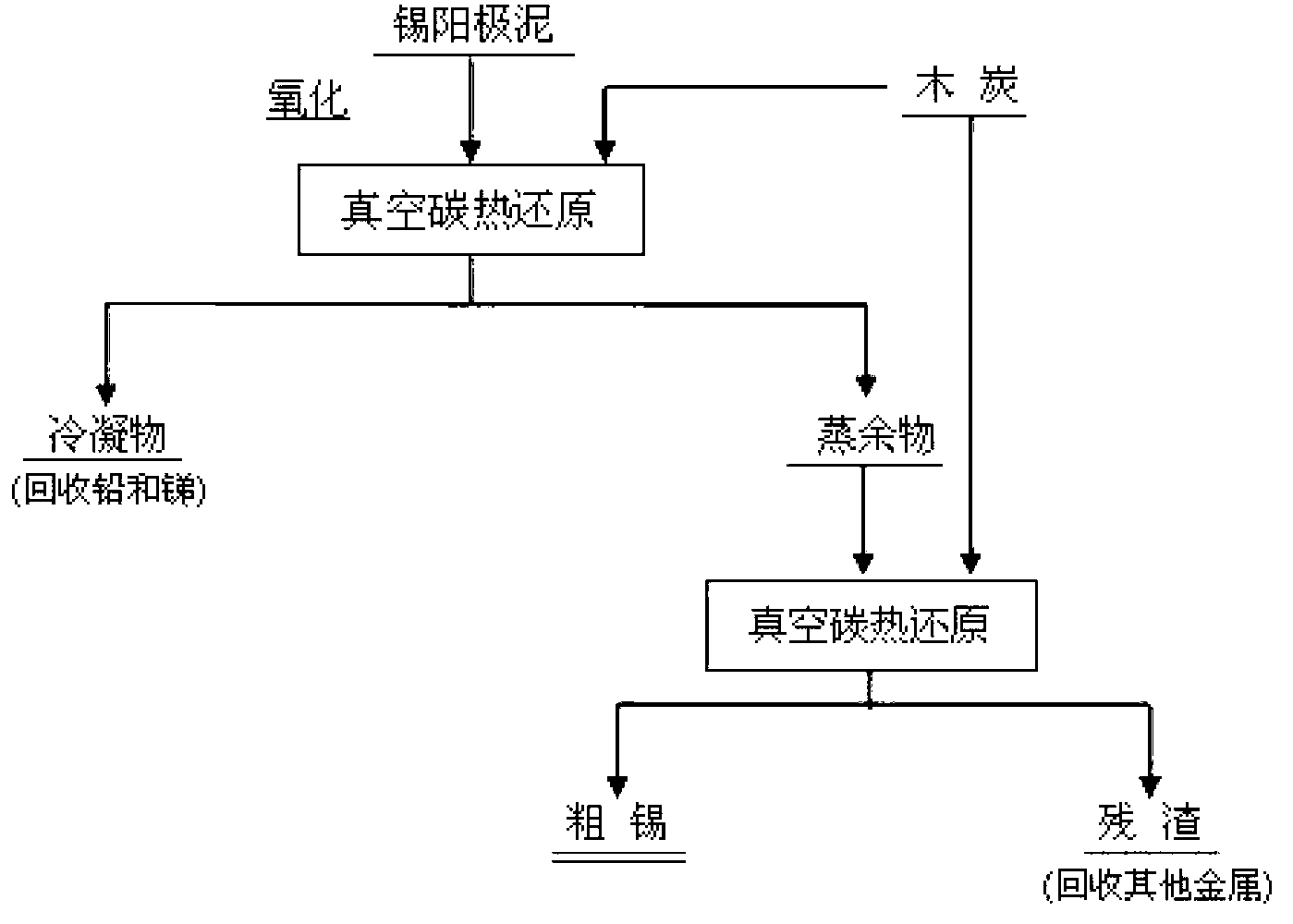

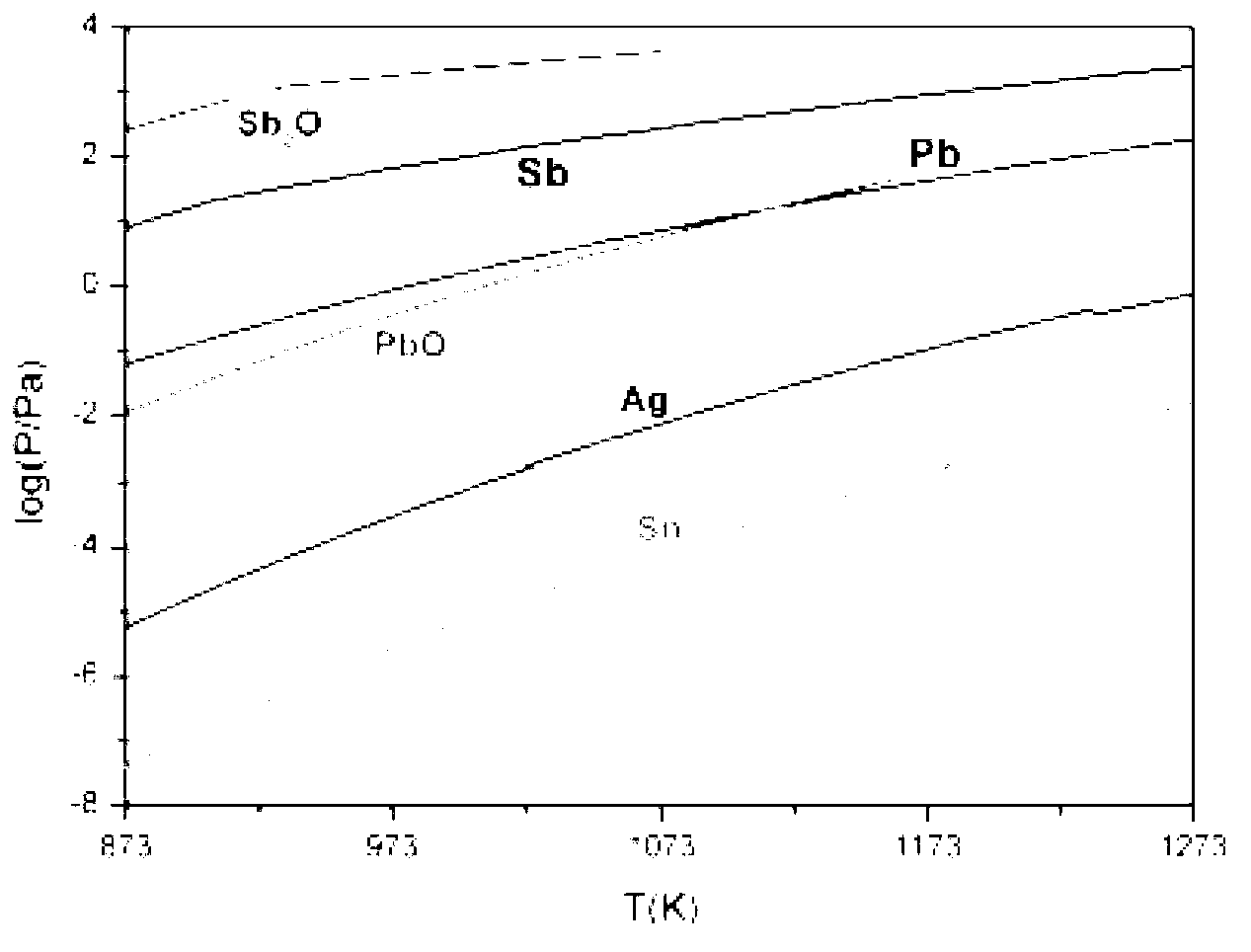

Method used

Image

Examples

Embodiment 1

[0045] A compound compound containing lead and antimony (molecular formula: Pb 2 Sb 2 o 7 ) tin anode slime as raw material (the stacking days are 300 days), the chemical composition analysis results show that the slime mainly contains Sn31.27wt%, Pb13.63wt%, Sb19.85wt%, Ag0.098wt%. First, take 8g of the anode slime and mix it evenly with 4% charcoal powder, put it into a material boat and place it in a vacuum reaction furnace for vacuum carbothermal reduction reaction. The reduction temperature is 850° C., the reduction time is 60 minutes, the vacuum degree of the system is about 100 Pa, and the air flow rate is about 400 ml / min. After the reaction was completed, 3.77 g of distillate was collected from the boat, and the evaporation rate was 52.9%. According to chemical composition analysis, the residue mainly contains Sn63.71wt%, Pb0.12wt%, Sb3.00wt%, Ag0.203wt%. Calculated according to the residue, the removal rate of lead and antimony in the vacuum carbothermal reductio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com