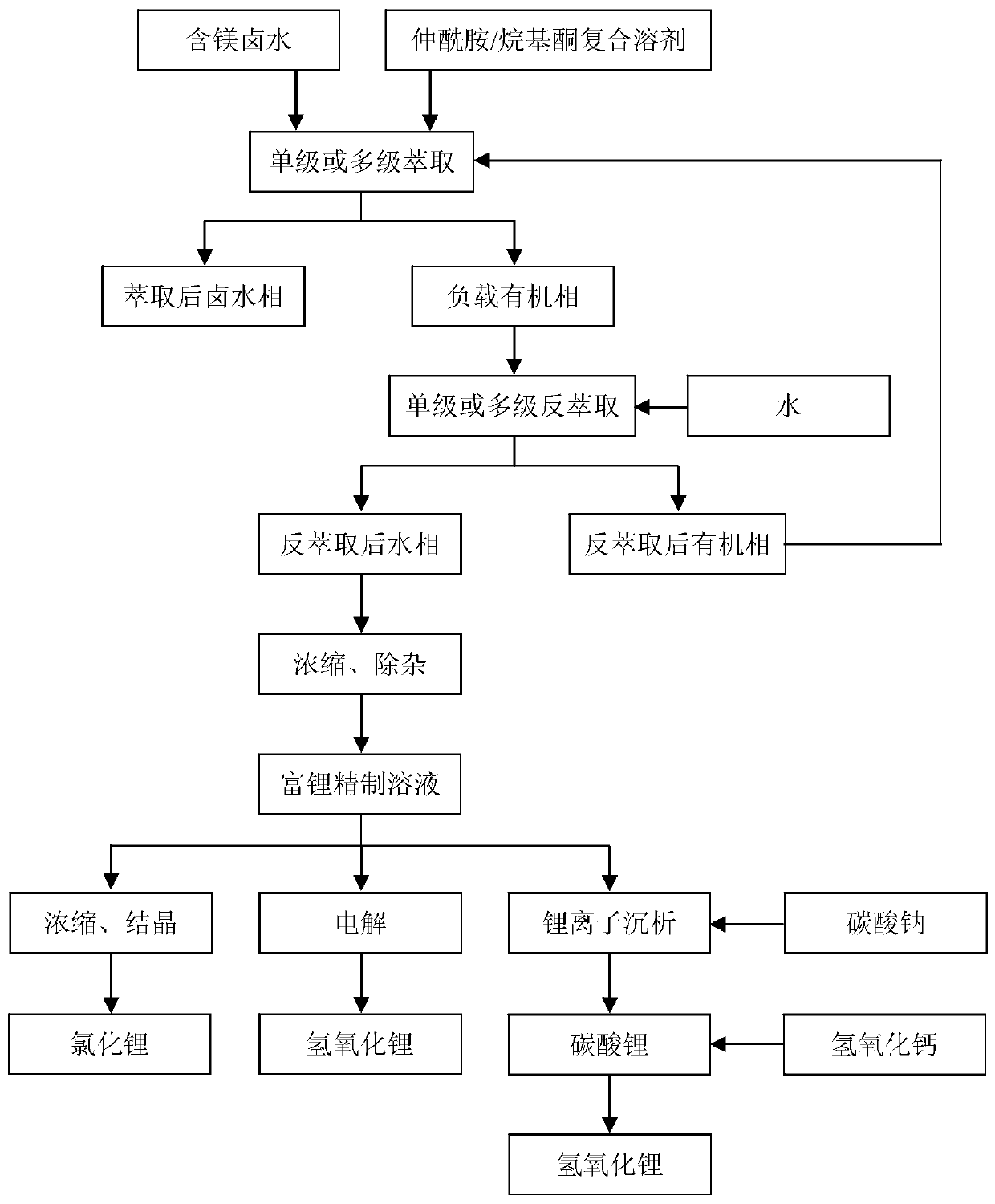

Extraction system and extraction method for separating magnesium and extracting lithium from magnesium-containing brine with secondary amide/alkyl ketone complex solvent and application of extraction method

A composite solvent and secondary amide technology are applied in the field of extraction systems for separating magnesium from magnesium-containing brines and extracting lithium from composite solvents, which can solve problems such as failure to complete the large-scale test verification and screening of extractants, and failure to find extraction systems, and achieve Reduce acid-base consumption, simple structure, and achieve the effect of two-way balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Li in brine of a salt lake in Qaidam Basin, Qinghai + and Mg 2+ The contents are 2.01g / L and 113.43g / L respectively, the mass ratio of magnesium to lithium is 56.43:1, of which Na + , K + , Cl - , and B 2 O 3 The contents are 3.83, 1.60, 325.98, 44.00 and 8.14g / L respectively, and the brine density is 1.34g / cm 3 , the pH value of brine is 4.3. Take 6mL of this brine into a 100mL ground conical flask, and then add 27mL of N-isooctylbutanamide extractant and 3mL of diisobutyl ketone co-extractant, the co-extractant accounts for 10% of the organic phase volume, and the organic The volume ratio of phase to salt lake brine is 5:1. Put the magnet in the conical flask, insert the matching air condenser tube into the bottle mouth to prevent the liquid from splashing, put it in the DF-101S type heat-collecting constant temperature heating magnetic stirrer, mix and stir at 20℃, and extract for 20min. Then the mixed liquid was transferred to a 100mL plastic test tube, an...

Embodiment 2

[0058] Take 27mL N-isoamyl octanamide extractant and 3mL 2,6,8-trimethyl-4-nonanone co-extractant in a 100mL ground conical flask, the co-extractant accounts for 10% of the organic phase volume, Then, 10 mL of the salt lake brine in Example 1 was added therein, and the volume ratio of the organic phase to the salt lake brine was 3:1. Put the magnet in the conical flask, insert the matching air condenser tube into the bottle mouth to prevent the liquid from splashing, put it in the DF-101S type heat-collecting constant temperature heating magnetic stirrer, mix and stir at 20℃, and extract for 20min. Then the mixed liquid was transferred to a 250mL plastic test tube, and centrifuged at 4000r / min for 10min in an LD5-10 desktop centrifuge. The two-phase interface was clear. + , Mg 2+ organic phase. Transfer the loaded organic phase to another 100mL ground-mouth conical flask, add deionized water in a volume ratio of 1:3 to the organic phase, and place it in a DF-101S collector t...

Embodiment 3

[0064] Take 24mL of N-amylisononamide extractant and 6mL of dipentyl ketone co-extractant in a 100mL ground conical flask, the co-extractant accounts for 20% of the organic phase volume, and then add 3mL of Example 1 to it. The volume ratio of organic phase to salt lake brine is 10:1. Put the magnet in the conical flask, insert the matching air condenser tube into the bottle mouth to prevent the liquid from splashing, put it in the DF-101S type heat collecting type constant temperature heating magnetic stirrer, mix and stir at 0 ℃ and extract for 20min. Then the mixed liquid was transferred to a 100mL plastic test tube, and centrifuged at 4000r / min for 8min in an LD5-10 desktop centrifuge. The two-phase interface was clear. + , Mg 2+ organic phase. Transfer the loaded organic phase to another 100mL ground-mouth conical flask, add deionized water in a volume ratio of 1:10 to the organic phase, and place it in a DF-101S collector type constant temperature heating magnetic stir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| freezing point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com