Method for denitrifying flue gas by using chlorine dioxide

A chlorine dioxide and chlorine dioxide oxidation technology, applied in the field of flue gas denitrification, can solve the problems of high cost and poor denitrification effect of chlorine dioxide, and achieve the effect of obvious cost advantage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

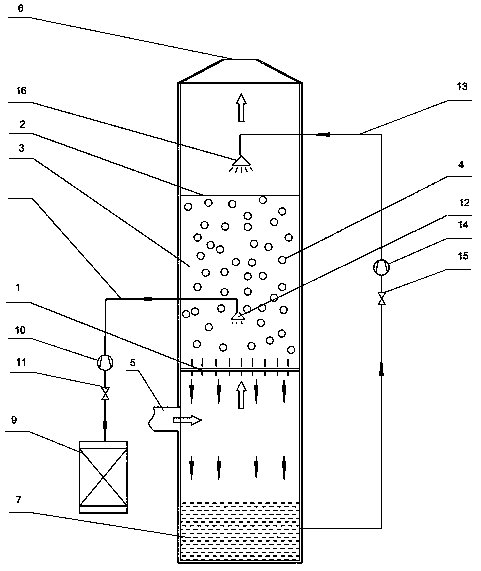

[0080] combined with figure 1 , the present invention is described:

[0081] A turbulent ball tower, a cylinder with a diameter of 0.8m, a tower height of 5m, and a wall thickness of 8mm, made of 304L stainless steel. It consists of a tower shell, a support plate 1, a turbulent ball 4, a retaining net 2, and a demister 15. The support plate 1 is installed at a position 2 meters away from the bottom of the tower shell. The support plate 1 is a circular grating structure with a gap spacing of 15 mm, a porosity of 0.3, and a material of 304 stainless steel. There is a retaining net 2 at 1.5m above the supporting plate 1, and the hole diameter of the retaining net 2 is 20mm. The space between the supporting plate 1 and the retaining net 2 is the turbulent ball area 3, and the turbulent ball 4 is placed in the turbulent ball area 3, and the turbulent ball 4 is a 34mm hollow PE ball, and the accumulation height of the turbulent ball is about 0.4m when it is empty. The flue gas i...

Embodiment 2

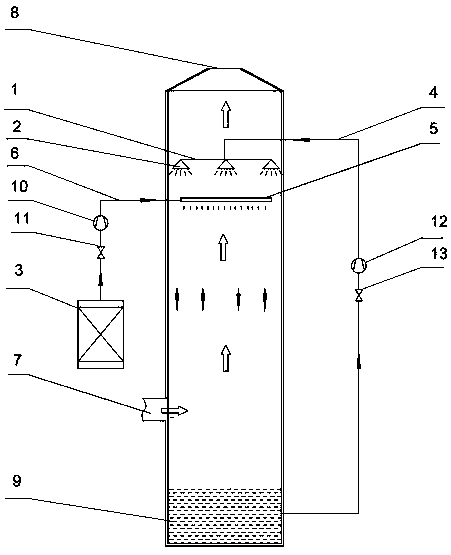

[0086] combined with figure 2 , attached image 3 , the present invention is described:

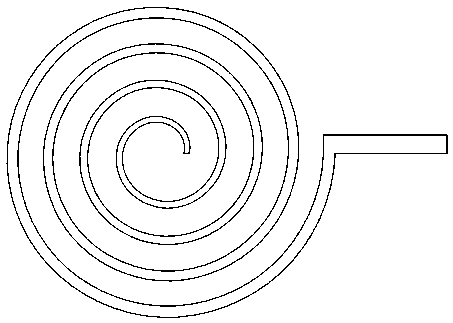

[0087] A spray tower, a cylinder with a diameter of 0.8m, a tower height of 5m, a wall thickness of 8mm, made of 304L stainless steel. A sprinkler 1 is installed at a position 1 meter away from the top of the tower, and the sprinkler 1 is composed of three 90° conical solid nozzles 2, which are evenly arranged in a cross section. Sprinkler 1 is connected to nitric acid inlet pipe 4; chlorine dioxide distributor 5 is located 0.8m below sprinkler 1, chlorine dioxide distributor 5 is a plane spiral tube, the lower part of the tube is facing the flue gas A number of small holes of 1 mm are evenly opened in the direction. The chlorine dioxide distributor 5 is connected to the intake pipe 6 of chlorine dioxide. At a position 1.5m away from the bottom of the tower, the spray tower is provided with a flue gas inlet 7, and a flue gas outlet 8 is set at the top. The bottom of the spray tower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com