Multistage multi-pressure jigging machine and coal preparation method thereof

A technology of jigging and jigging, applied in chemical instruments and methods, wet separation, solid separation, etc., can solve the problems of not being able to achieve the most ideal state, difficulty in adjustment, and failure to maximize the effect of the whole machine.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

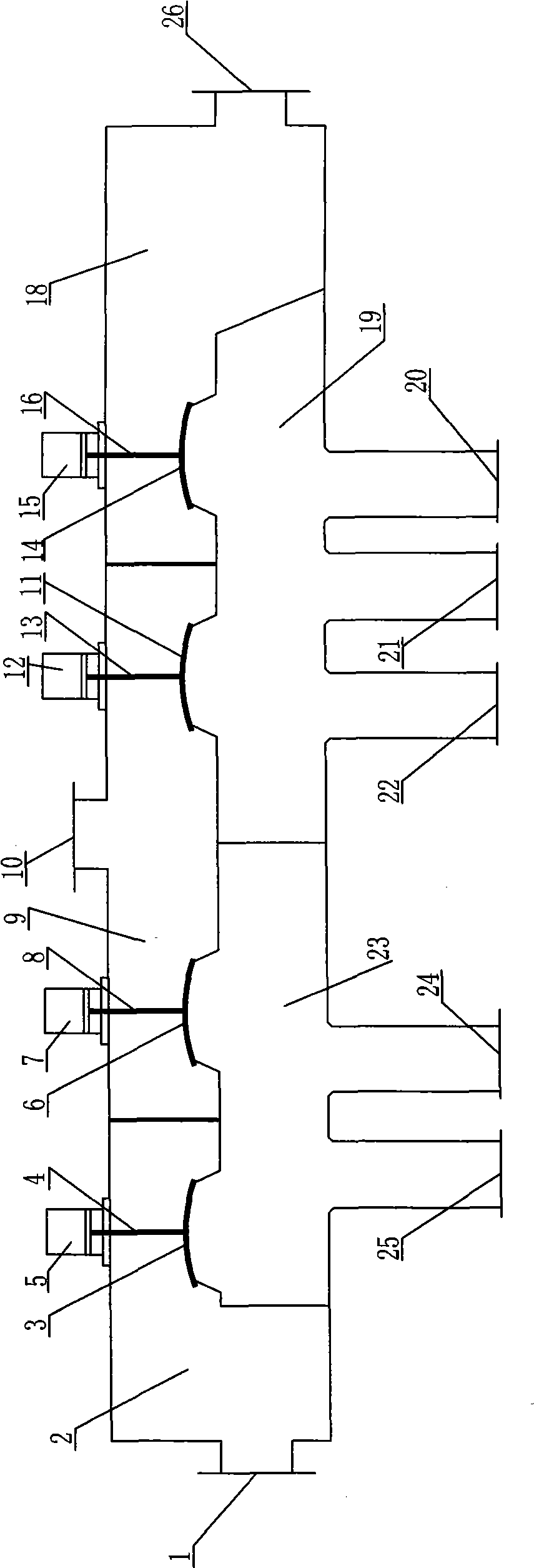

Embodiment 1

[0034] Embodiment 1, an air pulsation jig with multi-chambers shared air chambers for coal preparation will be described as an example below. A multi-chamber shared air chamber air pulsation multi-pressure jig machine, the machine is realized on the existing multi-chamber shared air chamber air pulsation jig machine, the body structure of the machine (including jig chamber, air chamber, air valve , sieve plate, etc.), all hardware such as feeding and discharging systems, control systems and other auxiliary systems are existing technologies. It is also equipped with its own air inlet and air supply system with different air supply pressures to realize the independent operation or control of each section of wind supply, and the air supply pressure of this section can be adjusted during the jig work as required to realize the air supply of each section. The jigging work under mutually independent air supply pressure constitutes a multi-chamber shared air chamber air pulsation mul...

Embodiment 2

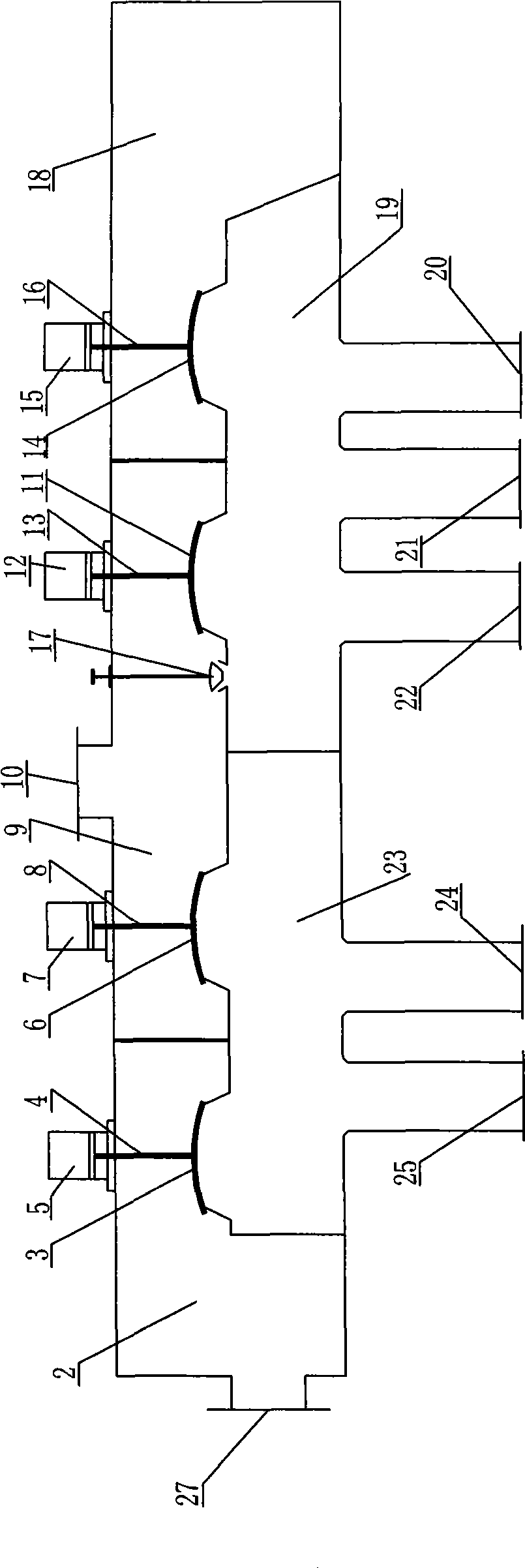

[0037] Embodiment 2, an air pulsation jig with multiple chambers sharing an air chamber for coal preparation will be described below as an example. Another multi-chamber shared air chamber air pulsation multi-pressure jig machine, this machine is also realized on the existing multi-chamber shared air chamber air pulsation jig machine, the body structure of this machine (comprising jig chamber, air chamber, wind Valves, sieve plates, etc.), feeding and discharging systems, control systems and other auxiliary systems, etc., are all existing technologies, and are characterized by passing through the other sections except the first section in the air box of the existing air chamber air pulsation jig An adjustable pressure relief valve is connected in parallel next to each exhaust valve to realize independent manipulation or control of the low-pressure air pressure supplied to the bed by each section, and it is also possible to adjust the relief valve of this section during the jig ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com