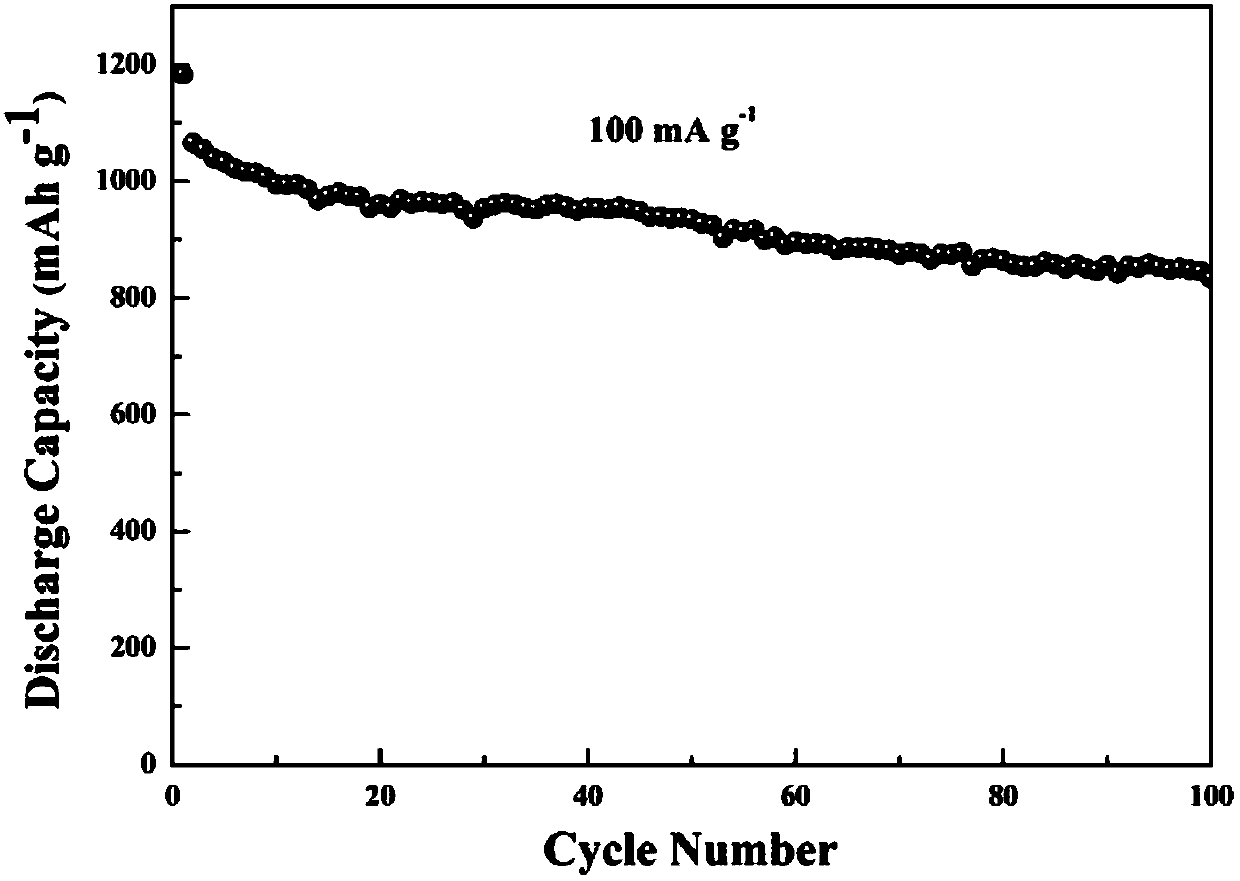

Method for preparing lithium ion carbon negative electrode material from mixed mushroom residue waste

A technology of carbon negative material and mixed bacteria, which is applied in the field of lithium-ion batteries to achieve the effects of increasing reversible specific capacity, improving comprehensive electrochemical performance, and high economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] 1) Mix oxytetracycline slag and Penicillium slag powder at a mass ratio of 1:1, bake in a vacuum oven at 100°C for 24 hours, remove moisture, and then ball mill the obtained dried slag waste for 6 hours, Obtain a fungus residue powder with an average particle size of about 25 μm;

[0045] (2) Take a certain amount of mixed bacteria residue of oxytetracycline and penicillin obtained in step (1) and nickel chloride and sodium hydroxide are mixed in aqueous solution according to the ratio of mass ratio 29:5:15, and at 80 DEG C Continue to stir until the water is evaporated to dryness to obtain a uniform mixture of nickel chloride, nickel hydroxide, sodium hydroxide and bacterium residue;

[0046] (3) the homogeneous mixture of nickel chloride, nickel hydroxide, sodium hydroxide and mixed bacterium slag that step (2) obtains is under nitrogen atmosphere, with the air velocity of 1L / min, the rate of temperature rise of 5 ℃ / min rises to 1000°C high temperature, heat preserva...

Embodiment 2

[0051] 1) Mix oxytetracycline slag and cephalosporin slag at a mass ratio of 1:1, place in a vacuum oven at 100°C and bake for 24 hours to remove moisture, and then ball mill the obtained dried slag waste for 6 hours to obtain Mushroom residue powder with an average particle size of about 25 μm;

[0052] (2) Take a certain amount of mixed bacteria residue obtained in step (1), mix it with nickel chloride and sodium hydroxide in an aqueous solution at a mass ratio of 29:5:15, and keep stirring at 80°C until the water evaporates to dryness , obtain the homogeneous mixture of nickel chloride, nickel hydroxide, sodium hydroxide and bacterium residue;

[0053] (3) The homogeneous mixture of nickel chloride, nickel hydroxide, sodium hydroxide and bacterium slag that step (2) obtains is under nitrogen atmosphere, with the air velocity of 1L / min, the rate of temperature rise of 5 ℃ / min rises to 1000 ℃ high temperature, heat preservation for 2 hours, to obtain a mixture containing nic...

Embodiment 3

[0058] 1) Mix cephalosporin residues and penicillin residues at a mass ratio of 1:1, bake in a vacuum oven at 100°C for 24 hours to remove moisture, and then ball mill the obtained dried residues for 6 hours. Obtain the fungus residue powder with an average particle size of about 20 μm;

[0059] (2) Take a certain amount of oxytetracycline slag obtained in step (1), mix it with nickel chloride and sodium hydroxide in an aqueous solution at a mass ratio of 12:2:7, and keep stirring at 80°C until the water content Evaporate to dryness to obtain a homogeneous mixture of nickel chloride, nickel hydroxide, sodium hydroxide and bacterium residue;

[0060] (3) The homogeneous mixture of nickel chloride, nickel hydroxide, sodium hydroxide and bacterium slag that step (2) obtains is under nitrogen atmosphere, with the air velocity of 1L / min, the rate of temperature rise of 5 ℃ / min rises to 1000 ℃ high temperature, heat preservation for 2 hours, to obtain a mixture containing nickel, s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com