Preparation method of waste heat recycling concrete

A technology of concrete and waste heat, applied in manufacturing tools, ceramic molding machines, etc., can solve problems affecting the safety and construction quality of hollow prefabricated wall panels, and cracks in hollow prefabricated wall panels, so as to improve the use safety and construction quality, and increase the temperature , to avoid the effect of cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

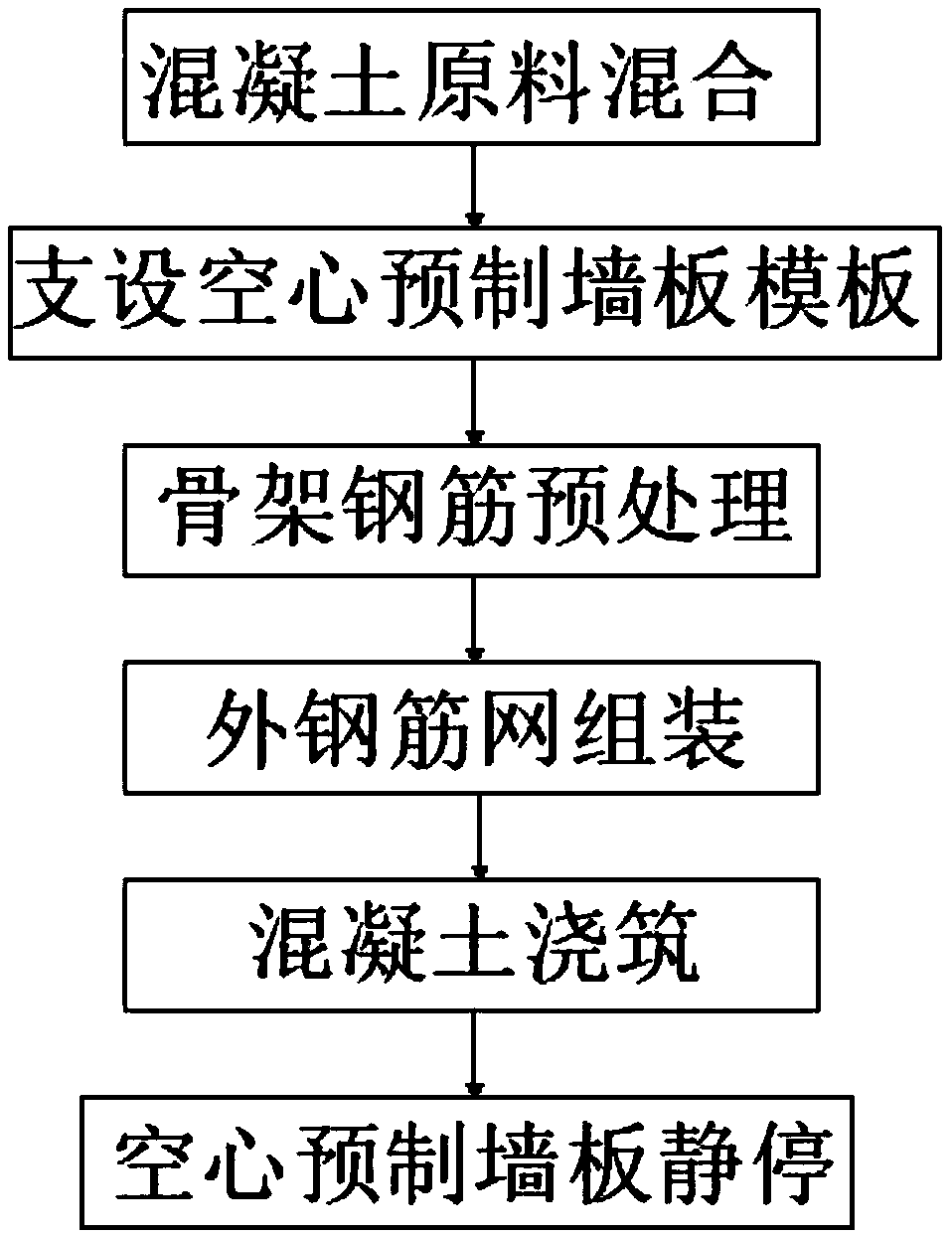

[0036] see figure 1 , a method for preparing concrete with waste heat reuse, the preparation method comprising the following steps: step 1, mixing concrete raw materials, mixing concrete raw materials cement, gypsum, lime, fly ash, fine aggregate, coarse aggregate, waste heat recovery insulation balls, Mix water and aluminum powder admixture, fully stir and mix in the mixer;

[0037] Step 2, support the hollow prefabricated wall formwork, use the combined steel formwork to build the prefabricated wall formwork, fix it with lead wires, install the side formwork and the bottom side formwork on the steel formwork frame respectively, and complete the construction of the hollow prefabricated wall formwork;

[0038] Step 3: Pretreatment of the skeleton steel bars, derusting the skeleton steel bars, straightening the skeleton steel bars after derusting, dividing them according to requirements, welding them to the shape matching the hollow prefabricated wall formwork, and then putting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com