Furnace for thermal regulation of preforms and control method of an air cooling device fitted to such a furnace

A technology for cooling devices and preforms, which is applied in the direction of furnaces, furnace components, and the treatment of discharged materials. It can solve problems that are difficult to control, and achieve the effects of reducing energy consumption, improving efficiency, and optimizing heat treatment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

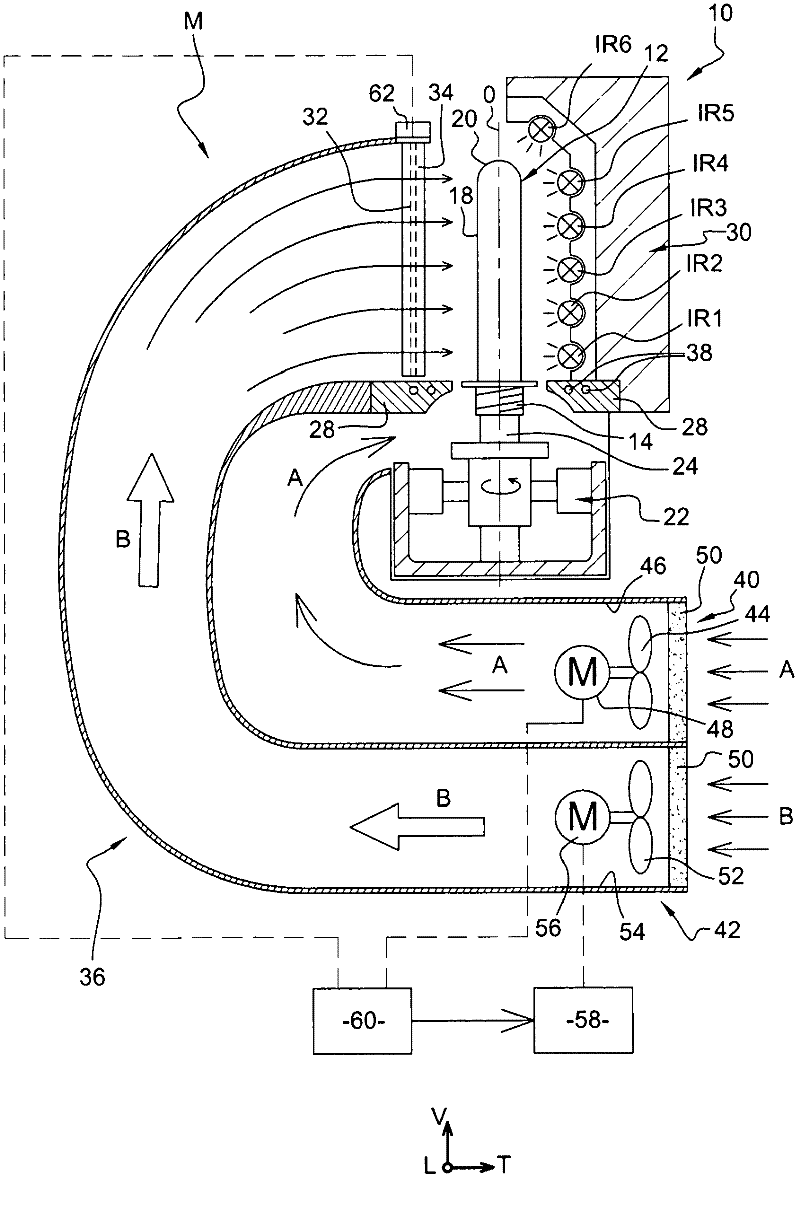

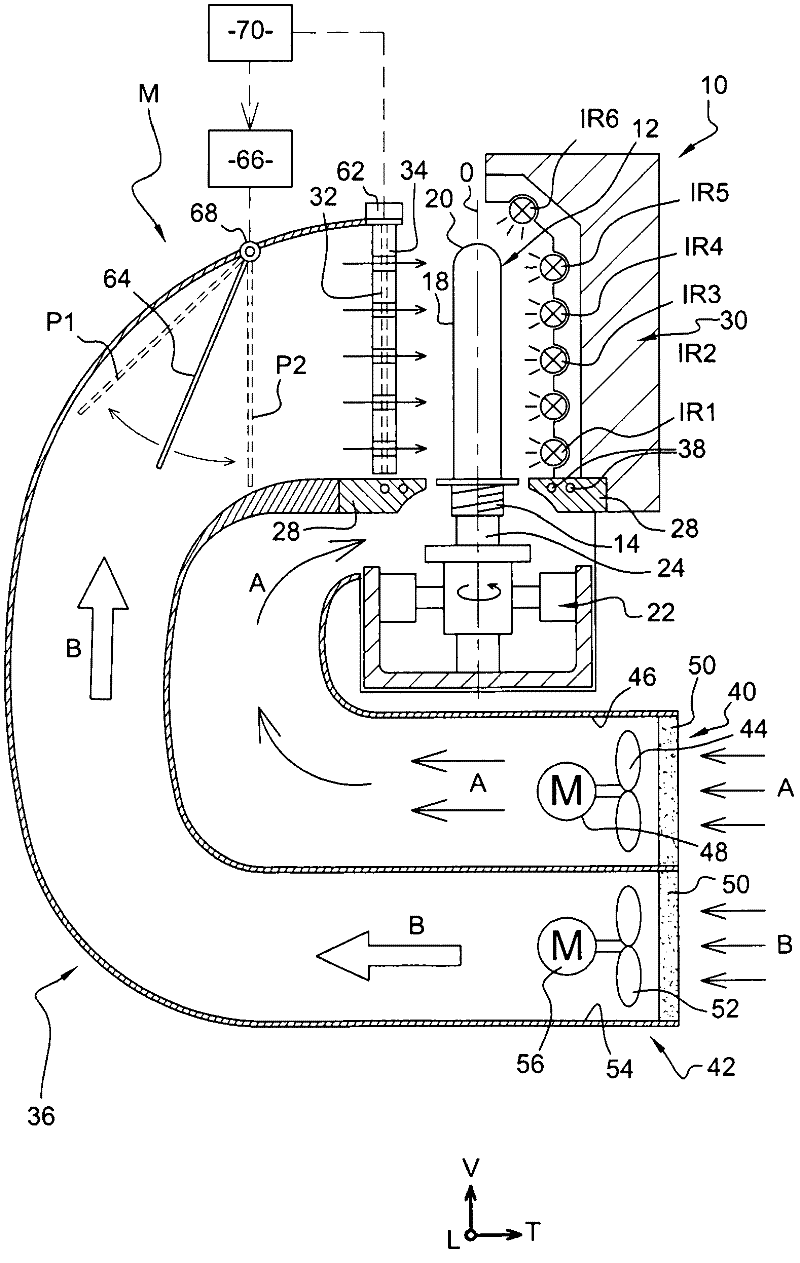

[0080] In the following description and claims, the non-limiting use of "longitudinal", "vertical" and "transverse" orientations is used according to the definitions given in the description and relative to the illustrations shown The three-sided reference system (L, V, T) indicates the components separately.

[0081] Conventionally, the terms "upper" and "lower" will be used to define the vertical orientation of the element relative to the three-sided reference system (L, V, T), which does not refer to the gravity field of the earth.

[0082] Similarly, the terms "upstream" and "downstream" will be used with reference to the direction in which the preform travels along the heating path, or alternatively, to the direction in which the cooling air flows through the furnace.

[0083] The same, similar or similar elements of the present invention are represented by the same numeral signs.

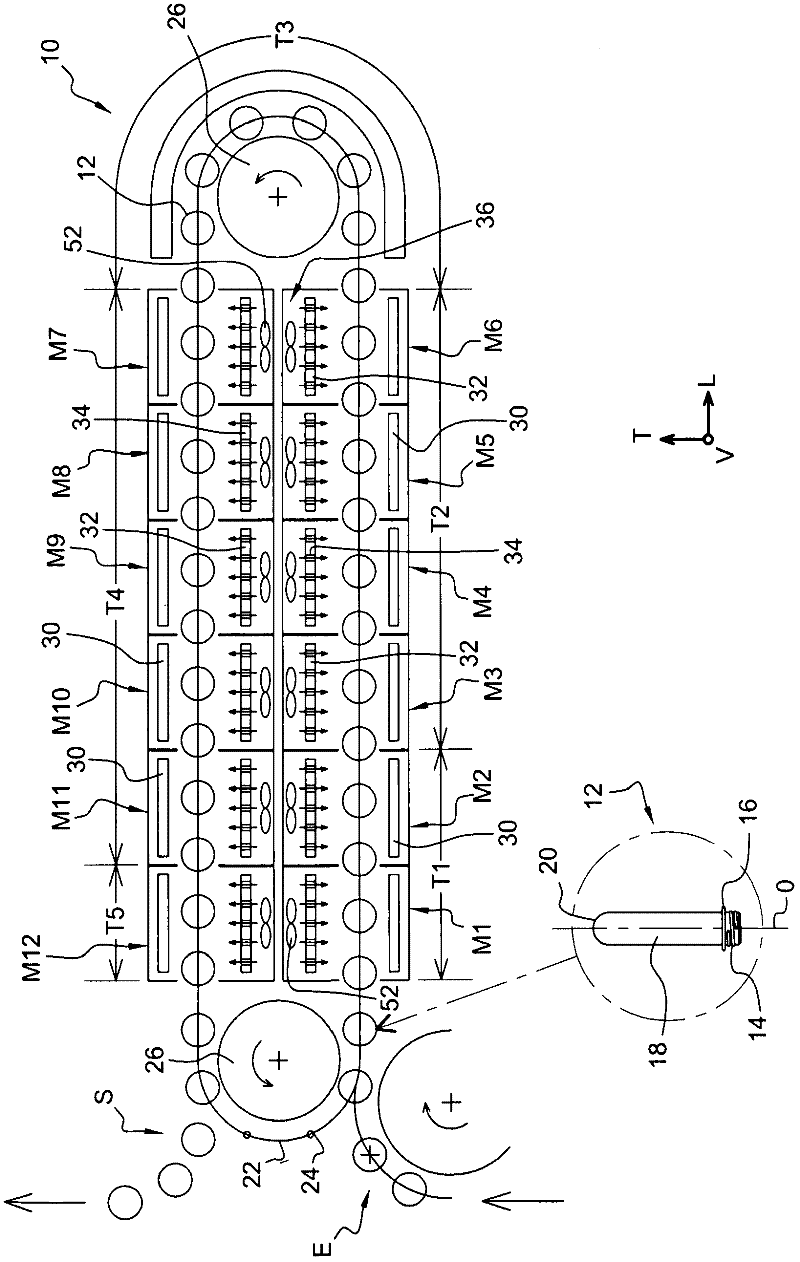

[0084] figure 1 An embodiment of the furnace 10 for heat-treating the thermoplastic preform 12 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com