N-C-Cr-V-RE multi-element co-diffusion material for 45 steel surface strengthening

A n-c-cr-v-re, surface strengthening technology, applied in metal material coating process, coating, solid-state diffusion coating, etc., can solve the problem of affecting the service life of plastic molds and mechanical parts, poor corrosion resistance, and surface hardness Low-level problems, to achieve the effect of dense permeable layer structure, strong corrosion resistance, and short surface treatment cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

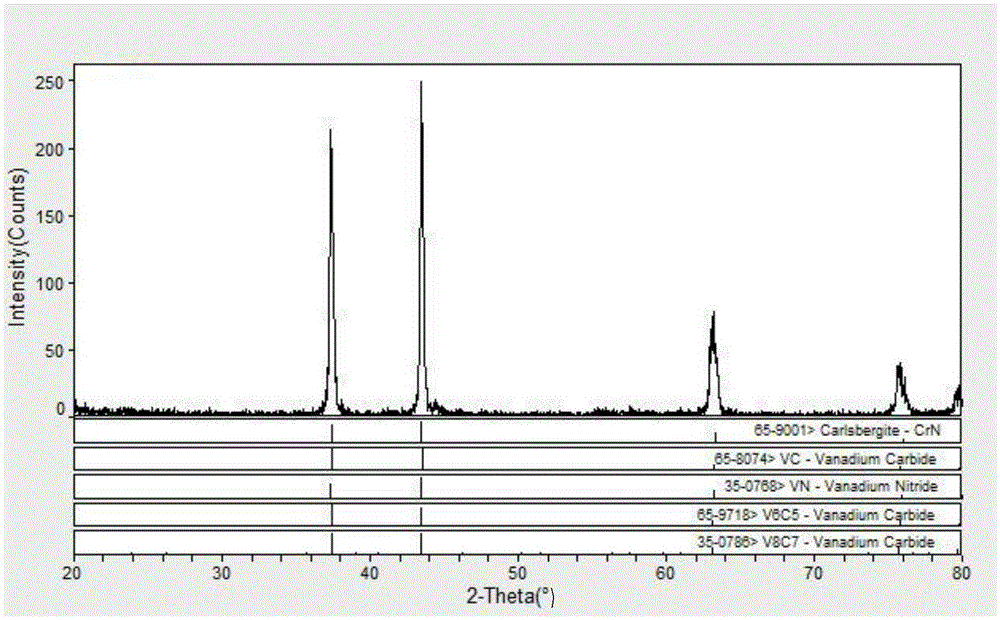

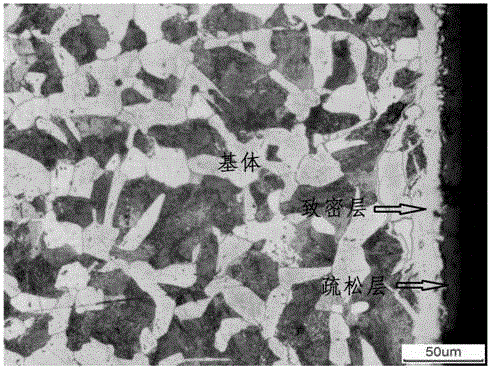

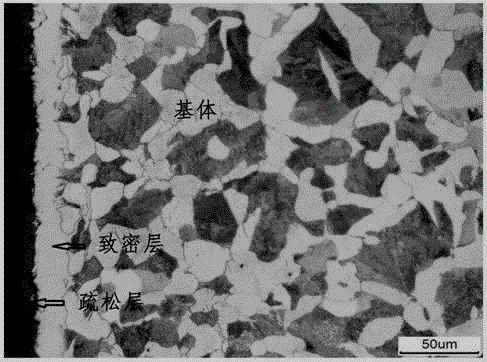

[0025] First, use 500#, 1000#, 2000#, 3000# sandpaper to polish the 45 steel sample in sequence, and then wash off the sample with acetone, alcohol and water in sequence. Use J-2 type base salt pre-infiltration N-C, the process is 570°C×3h, the process is 570°C×4h, the process is 570°C×5h, oil cooling. The pre-infiltration N-C time is 3h, 4h and 5h respectively, and the infiltration layer tissue under different pre-infiltration time is as follows: figure 1 , figure 2 and image 3 shown.

Embodiment 2

[0028] The N-C-Cr-V-RE multi-component co-infiltration material used for strengthening the surface of 45 steel, the Cr-V-RE co-infiltration material is made of the following raw materials in weight fractions: 52 parts of borax, 6 parts of NaF, K 2 CO 3 7 copies, V2 o 5 6 parts, Cr 2 o 3 2 parts, 4 parts of aluminum powder, 3 parts of RE.

[0029] N-C pre-infiltration: First, use 500#, 1000#, 2000#, 3000# sandpaper to polish the 45 steel sample in sequence, and then wash off the sample with acetone, alcohol and water in sequence. Use J-2 type base salt to pre-infiltrate N-C on 45 steel, the process is: 570℃×4h, oil cooling. Throw away the loose layer of the pre-infiltrated N-C sample, and then wash off the pre-infiltrated sample with acetone, alcohol and water in sequence.

[0030] Cr-V-RE co-infiltration: raise the temperature of the resistance furnace to 850 ° C, start adding borax; add NaF and K at intervals of 10 minutes 2 CO 3 Mix and add borax to adjust the fluidit...

Embodiment 3

[0034] The N-C-Cr-V-RE multi-component co-infiltration material used for strengthening the surface of 45 steel, the Cr-V-RE co-infiltration material is made of the following raw materials in weight fractions: 58 parts of borax, 9 parts of NaF, K 2 CO 3 10 copies, V 2 o 5 9 parts, Cr 2 o 3 3 parts, 6.5 parts of aluminum powder, 4.5 parts of RE.

[0035] N-C pre-infiltration: use 500#, 1000#, 2000#, 3000# sandpaper to polish the 45 steel sample in sequence, and then wash off the sample with acetone, alcohol and water in sequence. Use J-2 type base salt to pre-infiltrate N-C on 45 steel, the process is: 570℃×4h, oil cooling. Throw away the loose layer of the pre-infiltrated N-C sample, and then wash off the pre-infiltrated sample with acetone, alcohol and water in sequence.

[0036] Cr-V-RE co-infiltration: raise the temperature of the resistance furnace to 850 ° C, start adding borax; add NaF and K at intervals of 10 minutes 2 CO 3 Mix and add borax to adjust the fluidit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com