Patents

Literature

47 results about "Co diffusion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

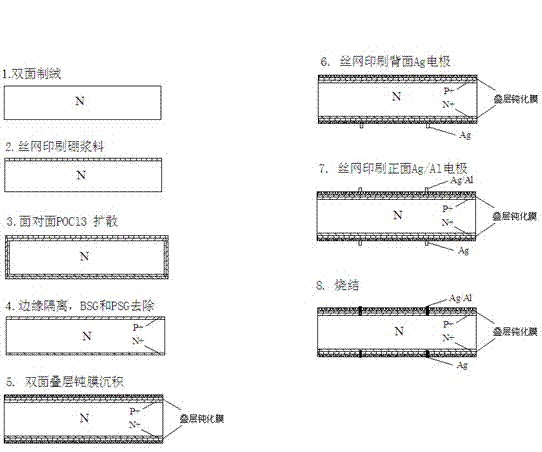

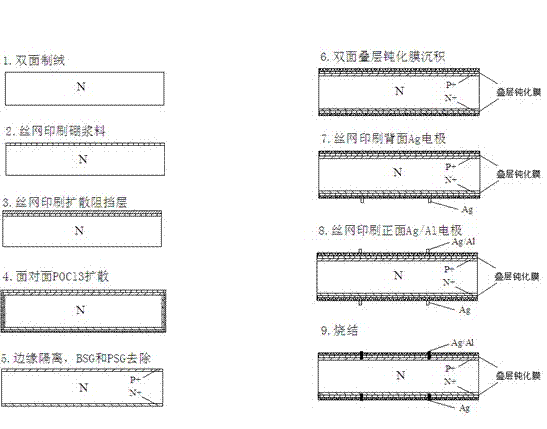

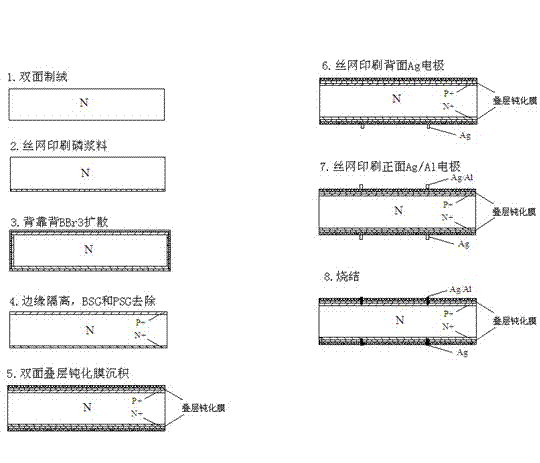

A process for preparing n-type solar cells by co-diffusion of boron and phosphorus

InactiveCN102263159ASimple manufacturing processReduce manufacturing costFinal product manufactureOther printing apparatusScreen printingSlurry

The invention discloses a process for preparing an n-type solar cell by co-diffusion of boron and phosphorus, which comprises the following steps: making surface texture; screen-printing boron slurry or phosphorus slurry on the surface of a silicon chip, and drying at 100-500°C Dry for 5~30 minutes; according to the self-blocking and out-diffusion characteristics of boron slurry or phosphorus slurry at high temperature, you can choose whether to screen print a layer of barrier layer slurry on it; the active layer is back-to-back for high-temperature boron and phosphorus diffusion; for For n-type silicon wafers printed with boron paste, first diffuse at 880-1100°C for 10-60 minutes, then cool down to 800-950°C, and then inject POCl3 source for phosphorus diffusion for 10-60 minutes; for n-type silicon wafers printed with phosphorous paste BBr3 source was passed into the wafer at a temperature of 880-1100°C for boron-phosphorus co-diffusion for 10-60 minutes; edge isolation and removal of BSG, PSG and barrier layers; double-sided passivation; preparation of electrodes.

Owner:JIANGYIN XINHUI SOLAR ENERGY

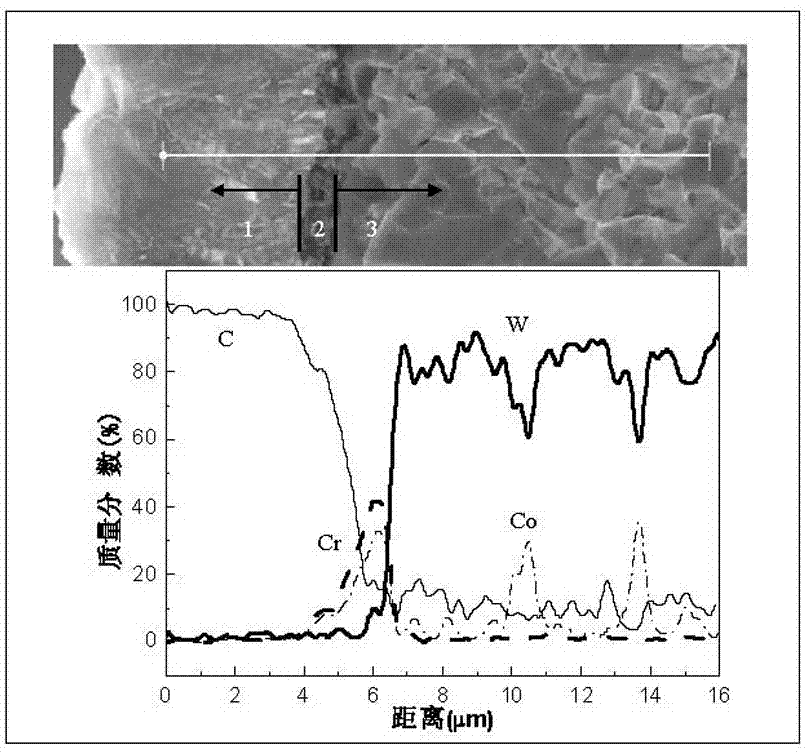

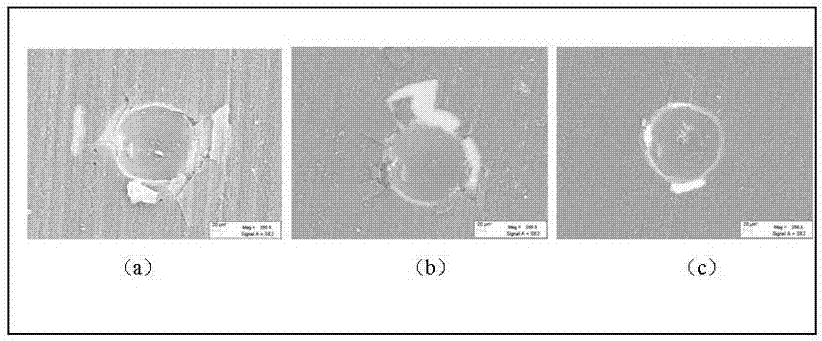

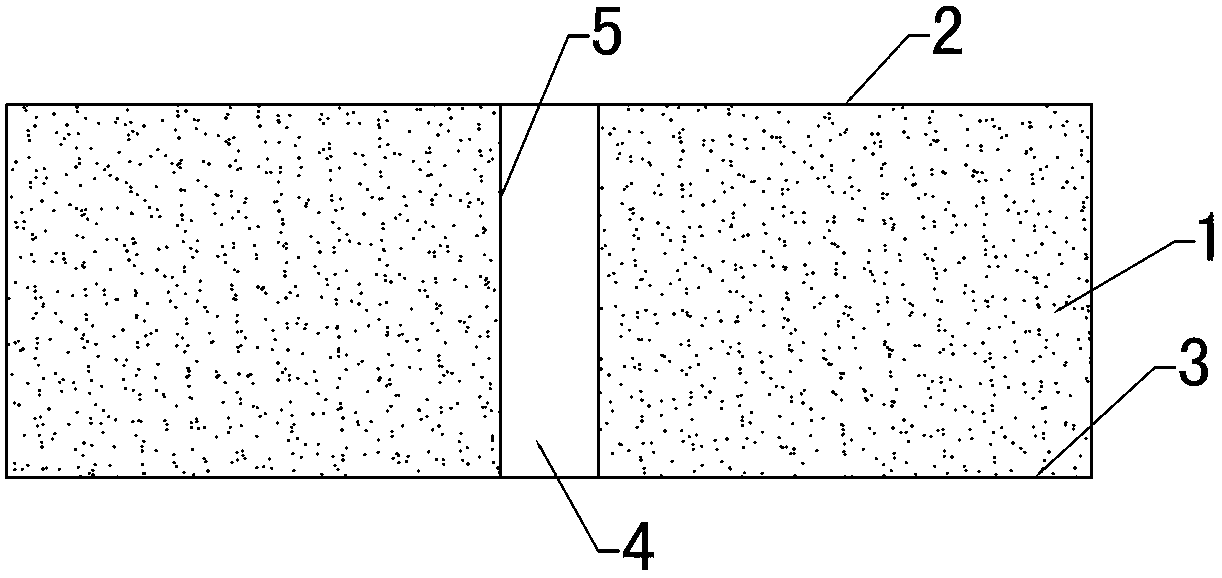

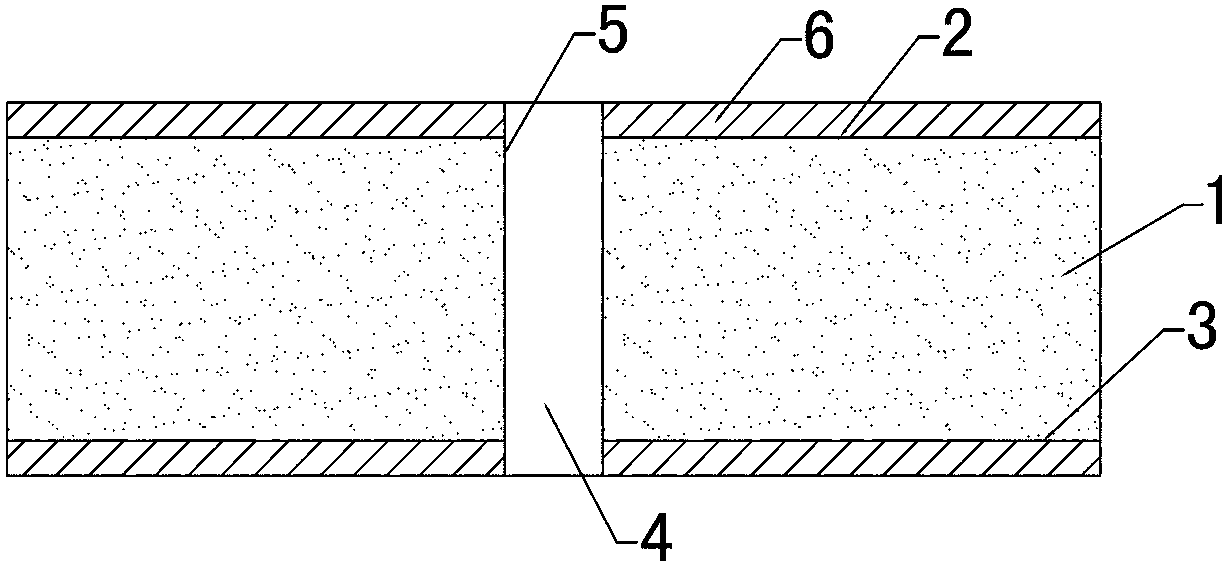

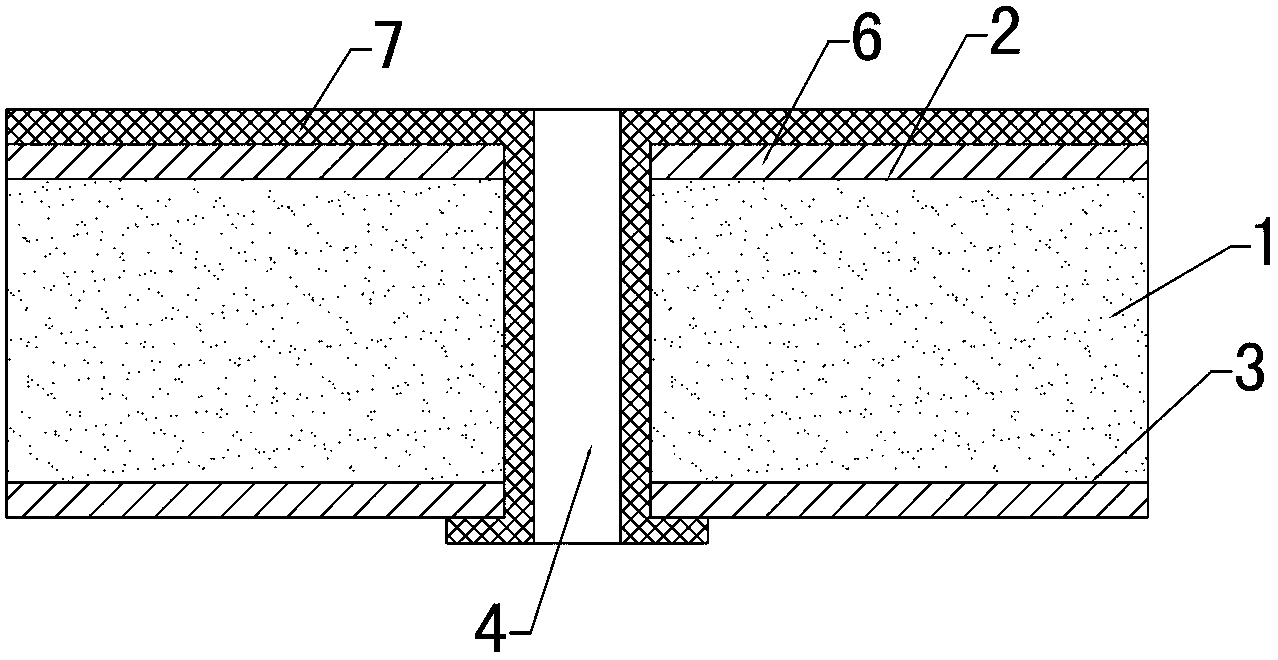

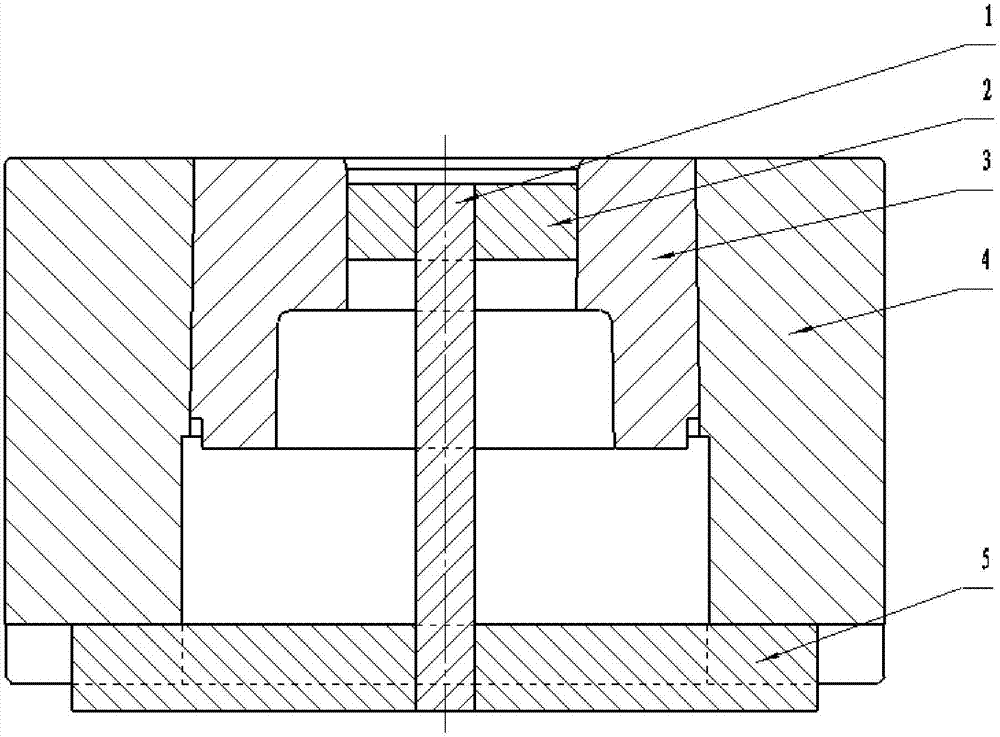

Preparation method of diamond coated cutting tool

InactiveCN107267984AExtended service lifePromote nucleationVacuum evaporation coatingSputtering coatingSurface layerAlloy

The invention discloses a preparation method of a diamond coated cutting tool. The preparation method comprises the following steps: (1) corroding a cutting tool base body; (2) depositing a Cr / CrN transition layer; and (3) depositing a diamond coating. With adoption of the preparation method, the binding force between the diamond coating and a hard alloy base is effectively improved, Co diffusion is also restrained, and nucleation and growth of the diamond coating are facilitated to form the diamond coating with high adhesive force; after depositing the diamond coating, contents of Co on the surface layer and the interior of the hard alloy are basically kept consistent, so that Co deficiency on the surface layer does not cause strength reduction of the cutting tool, and the Cr / CrN transition layer facilitates keeping of keenness of the cutting edge of the cutting tool.

Owner:ZHUZHOU CEMENTED CARBIDE CUTTING TOOLS CO LTD

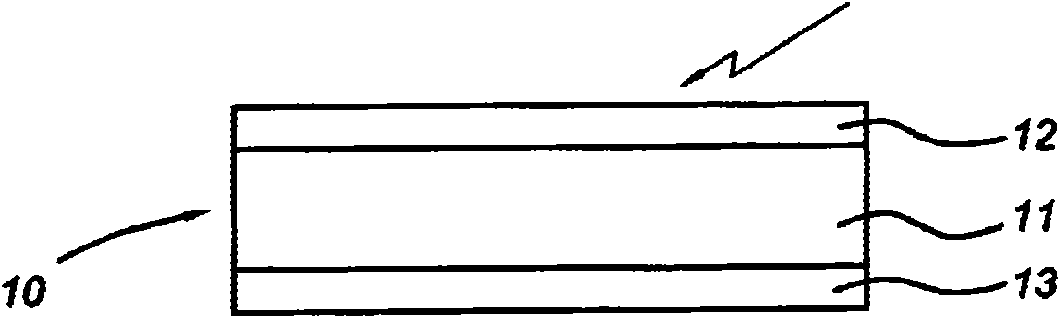

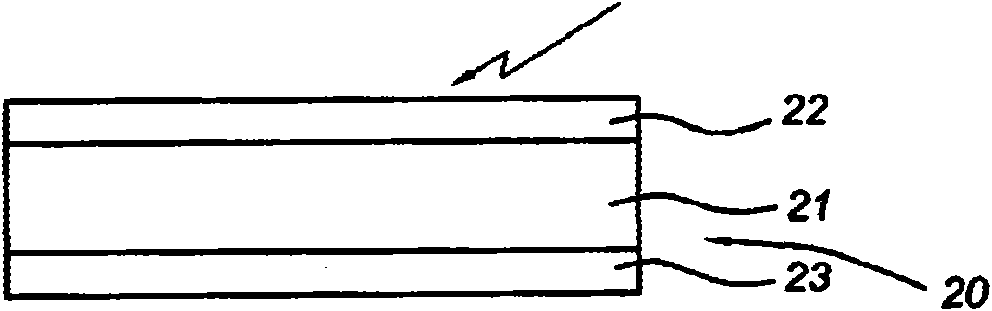

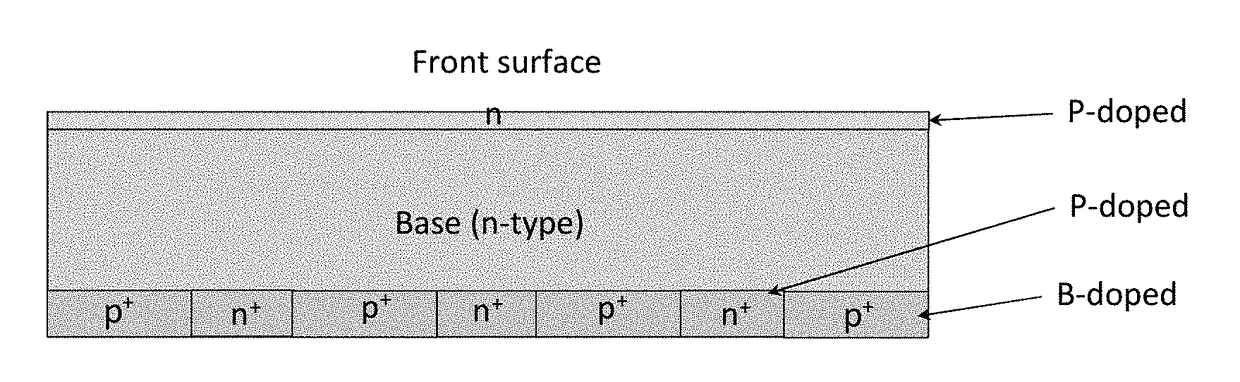

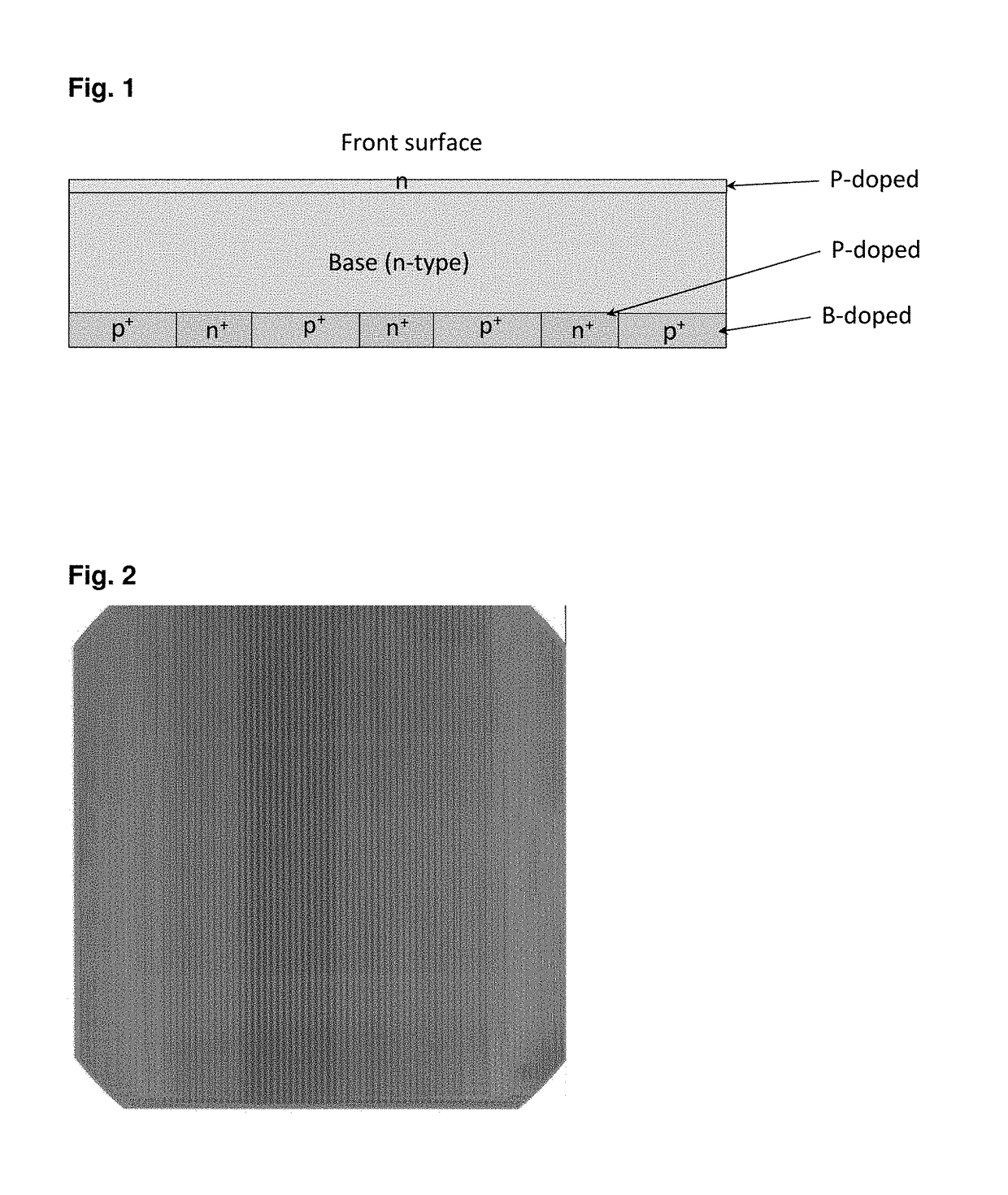

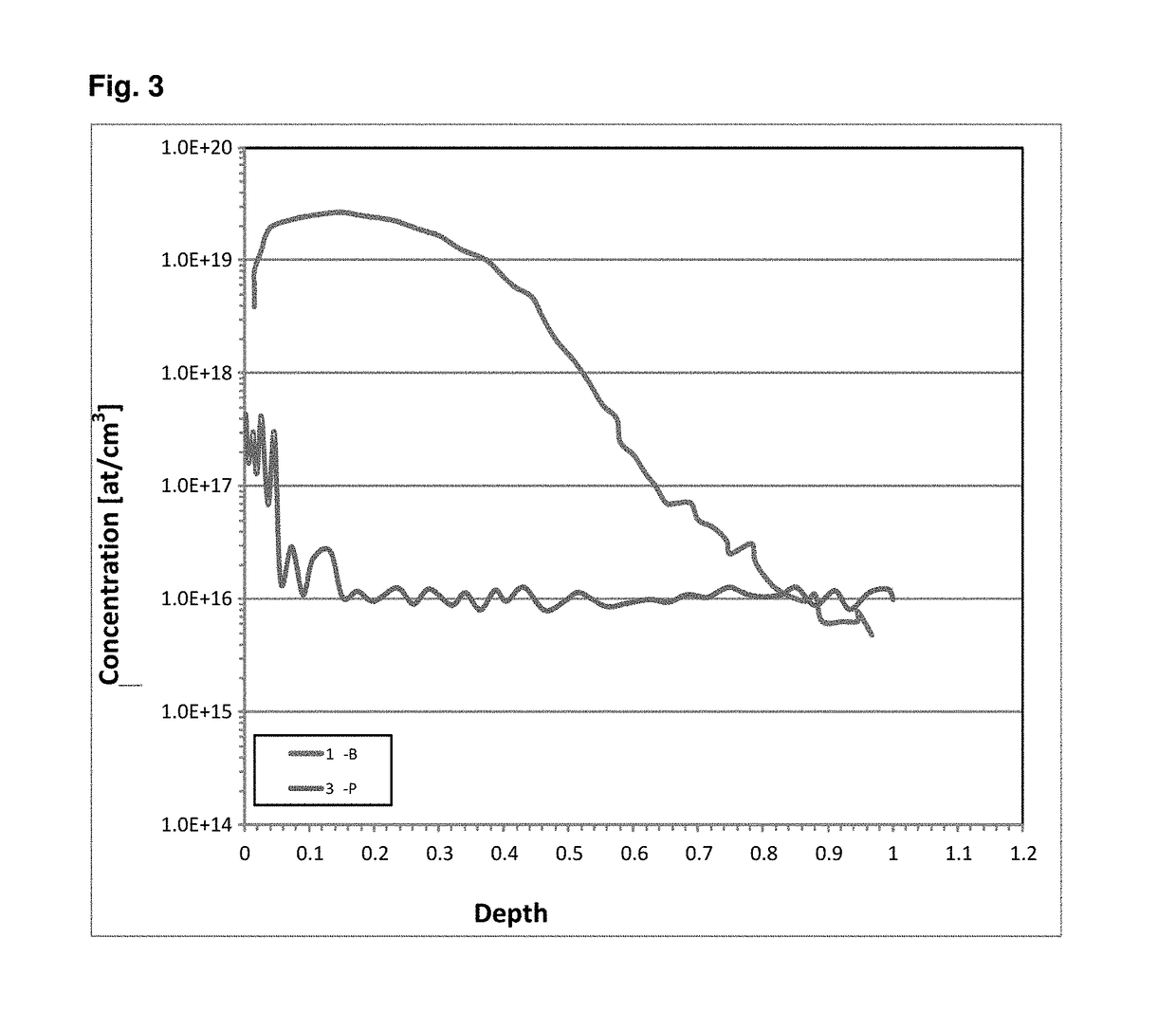

Method of manufacturing crystalline silicon solar cells using co diffusion of boron and phosphorus

ActiveCN101919070AReduce overflowImprove qualityFinal product manufacturePhotovoltaic energy generationCrystalline siliconCo diffusion

The present invention provides a method of manufacturing a crystalline silicon solar cell, subsequently comprising: providing a crystalline silicon substrate having a first side and a second side opposite the first side; pre-diffusing Phosphorus into a first side of the substrate to render a Phosphorus diffused layer having an initial depth; blocking the first side of the substrate; - exposing a second side of the substrate to a Boron diffusion source; heating the substrate for a certain period of time and to a certain temperature so as to diffuse Boron into the second side of the substrate and to simultaneously diffuse the Phosphorus further into the substrate.

Owner:NEDERLANDSE ORG VOOR TOEGEPAST-NATUURWETENSCHAPPELIJK ONDERZOEK (TNO)

Preparation method for cast iron cylinder liner based on inner surface coating

ActiveCN107619990AImprove yieldImprove wear resistanceCylinder headsFoundry mouldsHydrogenSand blasting

The invention discloses a preparation method for a cast iron cylinder liner based on an inner surface coating. The coating is formed by coating the inner wall of a mold with a paint with an optimizedformula, a casting is cast through a centrifugal casting mode and then subjected to ultrasonic treatment through a hydrogen ethanol solution, then the inner wall of the casting is subjected to roughening through a high-speed sand blasting mode, and finally a co-diffusion coating is formed through co-diffusion with a co-diffusion agent. The yield of the cast iron cylinder liner is up to 96.3-97.2%,compared with traditional cylinder liners of the type on the market, the abrasion resistance of the cast iron cylinder liner is improved by 33.9-35.1%, and thus the service life of the cast iron cylinder liner can be effectively prolonged.

Owner:ZYNP GRP ANHUI CO LTD

Preparation method of N-type double-sided solar cell

ActiveCN105609594AAvoid accessSimple production processFinal product manufactureSemiconductor devicesSlurryCo diffusion

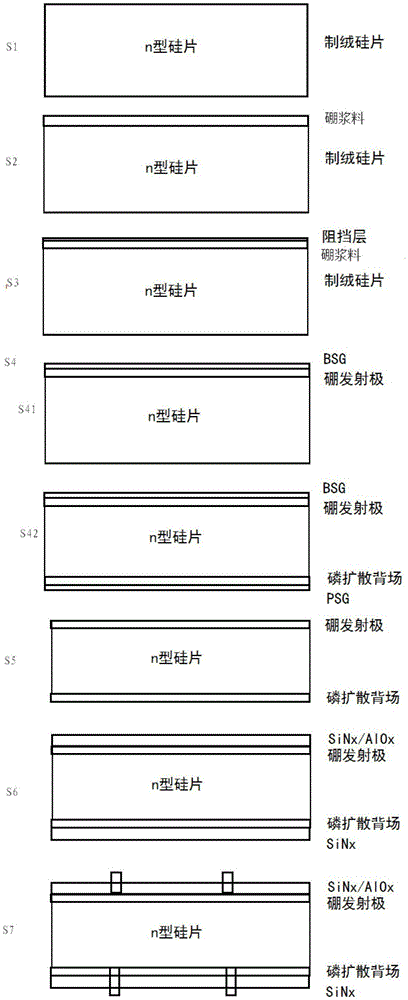

The invention provides a preparation method of an N-type double-sided solar cell. A mask is not needed, and a production technology of the N-type double-sided solar cell is simplified. The preparation method of the N-type double-sided solar cell sequentially comprises the following steps: (S1) carrying out texturing on the surface of an N-type silicon wafer to form suede; (S2) coating the front surface of the textured silicon wafer with boron slurry; (S3) carrying out drying and sintering, and forming a borosilicate glass layer on the front surface of the silicon wafer as a barrier layer; (S4) carrying out annealing co-diffusion; (S5) carrying out acid pickling, and washing off borosilicate glass on the front surface of the silicon wafer and phosphorosilicate glass on the back surface of the silicon wafer; (S6) coating the surface of the silicon wafer with a passivation film; and (S7) printing an electrode and sintering the electrode. The step (S4) further comprises the following steps: (S41) boron diffusion, namely forming a boron emitter on the front surface of the silicon wafer, and (S42) phosphorus diffusion, namely forming a phosphorous diffusion back field on the back surface of the silicon wafer.

Owner:SUZHOU TALESUN SOLAR TECH CO LTD

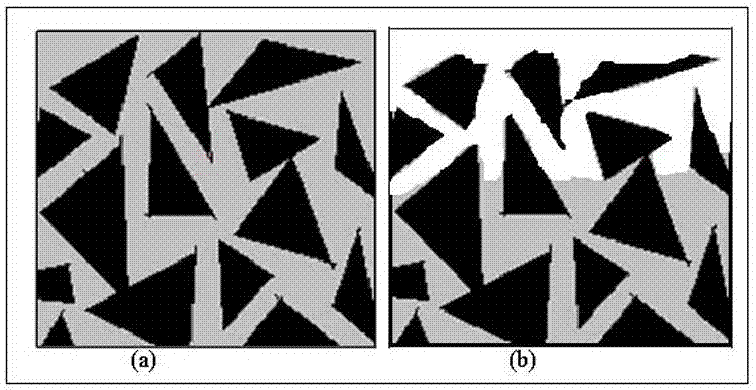

Manufacturing method for black silicon double-face cell

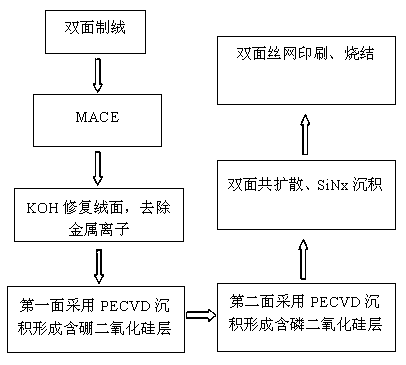

InactiveCN105576081AReduce reflectivityPromote absorptionFinal product manufacturePhotovoltaic energy generationSolar cellSilicon dioxide

The invention discloses a manufacturing method for a black silicon double-face cell. The method comprises steps that (1) double-face texturing for a silicon chip is carried out; (2), black silicon structures are made at two faces of the silicon chip by employing auxiliary metal chemical corrosion; (3), after KOH nanometer suede-like face restoration, metal ions are removed through utilizing acid; (4), PECVD deposition is employed for the first face to form a boron-contained silicon dioxide layer; (5), PECVD deposition is employed for the second face to form a phosphorus-contained silicon dioxide layer; (6), double-face co-diffusion is carried out, and double-face SiNx deposition is carried out; and (7), through double-face screen printing and sintering, the black silicon double-face solar cell is formed. According to the method, doping concentration of the cell surface after diffusion can be improved, and the open-circuit voltage, the short-circuit current and conversion efficiency can be further improved.

Owner:JIANGXI UNIEX NEW ENERGY CO LTD

Preparation method for vacuum mechanical energy aided diffusing zinc-aluminum-chromium alloy layer

InactiveCN107058942AImprove antioxidant capacityImprove corrosion resistanceSolid state diffusion coatingOrganizational growthMechanical energy

The invention belongs to the field of mechanical energy aided diffusing, and particularly relates to a vacuum mechanical energy aided diffusing zinc-aluminum-chromium alloy layer and a preparation method thereof. By adding chromium into co-diffusion agent, the organizational structure of an existing mechanical energy aided diffusing zinc-aluminum co-diffusion layer is changed. Chromium is an element which has a great effect on the organizational structure of steel, because of the existence of the chromium, the organizational growth of a zinc-aluminum layer is changed, and the mechanical energy aided diffusing zinc-aluminum co-diffusion layer which is similar to a mechanical energy aided diffusing zinc layer in organization is changed to a multi-layer co-diffusion layer organization; and the combination is closer and firmer, and the oxidation resistance and the corrosion resistance of materials are improved prominently. Chromium exists in a diffusion layer in a solid solution manner, and plays a role of solid-solution strengthening.

Owner:CHANGZHOU UNIV

Too surface treatment method

InactiveCN102409313AHigh strengthChange physical and chemical propertiesVacuum evaporation coatingSputtering coatingAluminum IonMaterials science

The invention relates to a surface treatment method for a tool. The method comprises the following steps of: pretreating the tool; and compounding a diffusion layer on the tool, wherein the compound diffusion layer is a metal ion layer into which titanium ions or aluminum ions are injected, and can be a carbon diffusion layer, a nitrogen diffusion layer or a carbon-nitrogen co-diffusion layer. Layer diffusion treatment is performed on the tool, so that the physical and chemical performance of the surface is changed, the strength of the tool is enhanced remarkably under the condition of not lowering other performance, and excellent comprehensive performance is ensured.

Owner:WUJIANG WUHUA HARDWARE PROD

Preparation method of multilayer composite modified layer with strong toughness on titanium alloy surface

InactiveCN101851744AHigh bonding strengthImprove bindingVacuum evaporation coatingSputtering coatingNitrogen gasTitanium alloy

The invention relates to a preparation method of a multilayer composite modified layer with strong toughness on a titanium alloy surface, belonging to the technical field of surface modification and strengthening of metal materials. The invention is characterized by being a technical scheme that unit diffusion of Mo and co-diffusion of Mo / N are alternately and cyclically carried out on the surface of a titanium alloy substrate to prepare the Mo / MoN multilayer composite modified layer with strong toughness. The preparation method comprises the following steps: firstly, coating a Mo bottom layer with the thickness of 4-6 mu m by diffusion on the surface of a workpiece; then simultaneously introducing argon and nitrogen and coating a MoN layer with the thickness of 2-4 mu m by diffusion on the surface of the workpiece; cutting off the nitrogen supply, only introducing argon into a vacuum chamber, and continuing to coating a Mo layer with the thickness of 2-4 mu m by diffusion on the surface of the workpiece; by turning on and cutting off the nitrogen supply, continuing to alternately and cyclically coating MoN layers and Mo layers by diffusion on the surface of the workpiece, and enabling the most superficial layer of the multilayer composite layer to be the MoN layer to prepare the Mo / MoN multilayer composite layer with the modulation period of 2-4 mu m and the total thickness of 10-50 mu m; and taking out the workpiece after the workpiece cools in a furnace to the room temperature. The prepared Mo / MoN multilayer composite modified layer obviously improves the wear resistance of the titanium alloy under the high contact load condition.

Owner:TAIYUAN UNIV OF TECH

Method for preparing double-faced back contact solar cell

ActiveCN102709389AExcellent process matchingExcellent electrical performanceFinal product manufactureSemiconductor devicesDopantPhosphor

The invention discloses a method for preparing a double-faced back contact solar cell, comprising following steps: (1) holing; (2) washing, and texturizing the front face and the back face of a silicon wafer; (3) arranging a first doping agent on the front face and in the hole of the silicon wafer, and arranging the first doping agent in the surrounding area of the hole in the back face of the silicon wafer, wherein the doping type of the first doping agent is opposite to that of the silicon wafer; (4) arranging a second doping agent in the non-hole surrounding area on the back face of the silicon wafer, wherein the doping type of the second doping agent is the same as that of the silicon wafer; (5) growing barrier layers on the front face and the back face of the silicon wafer; (6) annealing the silicon wafer at the temperature of 800 to 1000 DEG C, diffusing and making junctions; (7) etching peripheral junctions; (8) washing and removing the barrier layers; (9) arranging passivation anti-reflection films on the front face and the back face of the silicon wafer; and (10) arranging a porous metal electrode in the hole, printing and sintering. Adopting a method for arranging the doping agents, i.e. adopting the various type doping agents on two faces of the silicon wafer, the double-faced back contact solar cell realizes the co-diffusion of boron-phosphor in the presence of the barrier layers, thereby greatly simplifying process flows and reducing the production cost.

Owner:CSI CELLS CO LTD +1

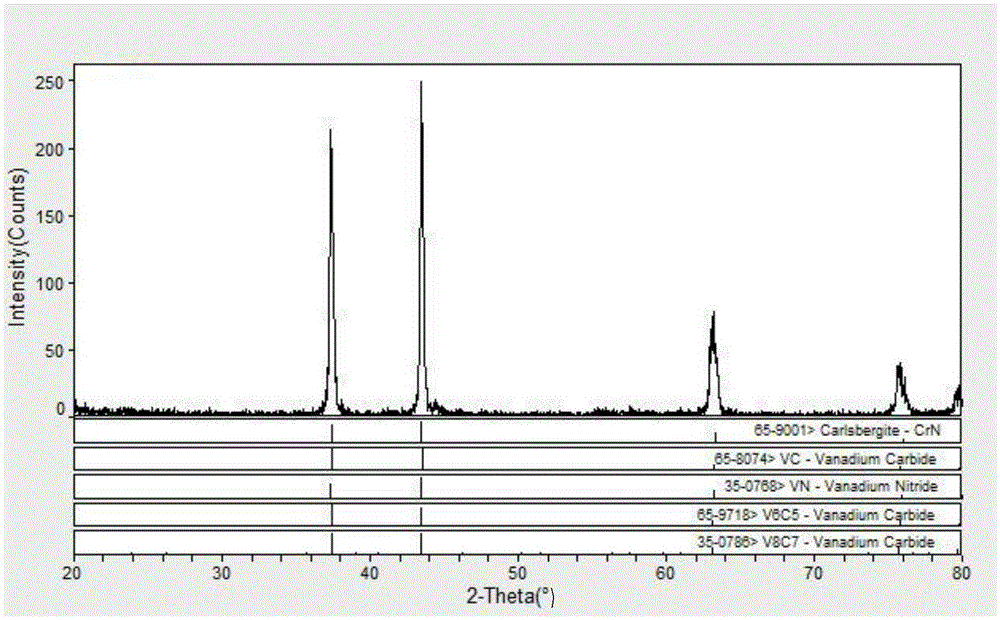

N-C-Cr-V-RE multi-element co-diffusion material for 45 steel surface strengthening

ActiveCN105331926AShort processing cycleImprove corrosion resistanceSolid state diffusion coatingMechanical componentsHardness

The invention discloses an N-C-Cr-V-RE multi-element co-diffusion material for 45 steel surface strengthening. The co-diffusion material comprises the following two parts including a J-2 base salt material and a Cr-V-RE co-diffusion material, wherein the Cr-V-RE co-diffusion material is prepared from borax, NaF, K2CO3, V2O5, Cr2O3, aluminum powder and RE. After being subjected to 570 DEG C*4h N-C pre nitrocarburizing, 950 DEG C*6h Cr-V-RE co-diffusion and 550 DEG C*2h tempering, the diffusion layer structure of 45 steel is compact and continuous and high in corrosion resistance and hardness, and surface strengthening properties of corrosion resistance and abrasion resistance of plastic molds and various mechanical parts are guaranteed. The process is simple; the operation is convenient; the heat treatment period is short; the controllability is high; the property defects of unit diffusion metal or nonmetal are overcome; the application prospects are quite wide.

Owner:GUANGXI UNIV

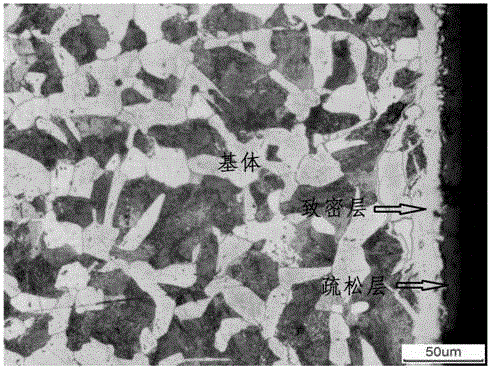

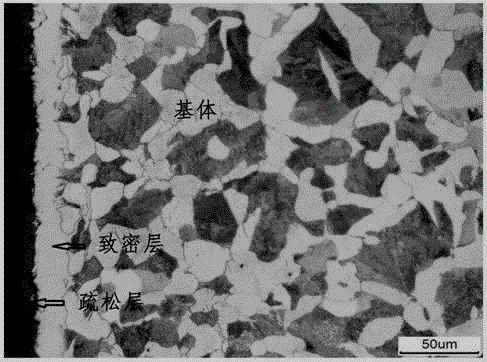

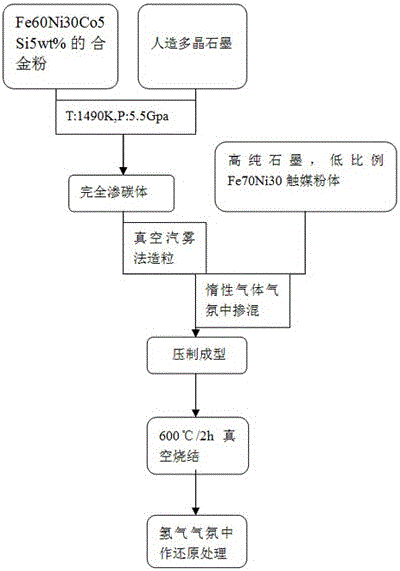

Preparation method of artificial diamond synthesis graphite core column

ActiveCN106270484AReduce manufacturing costTo achieve the purpose of growth controllabilityTurbinesOther manufacturing equipments/toolsCarbonizationAlloy

The invention discloses a preparation method of an artificial diamond synthesis graphite core column. The preparation method is characterized by comprising the steps that cementite is firstly prepared, and then the prepared cementite is implanted into graphite alloy accelerant powder to prepare the graphite core column. The cementite is implanted into the powder accelerant core column, in the external environment that under the conditions of the high temperature and the high pressure, crystallization and nucleation are preferentially achieved in the cementite, and co-solution and co-diffusion are achieved at the same time, due to the density potential and the chemical potential, carbon atoms and a metal accelerant are enriched towards the periphery of the cementite, and the growth continuity of diamond crystals in the cementite is guaranteed; and in addition, the implanting proportion of the cementite is controlled, and therefore diamond crystallization and nucleation are controlled, then the grain size is controlled, and the aim of diamond growth controllability is achieved. According to the method, the problem of diamond carbonization and the impurity discharge problem existing in the seeding method are avoided, meanwhile, a high-quality accelerant alloy is used in cementite preparation, and therefore the content of precious metal in the graphite accelerant powder can be reduced correspondingly, and the production cost can be reduced.

Owner:ZHONGNAN DIAMOND CO LTD

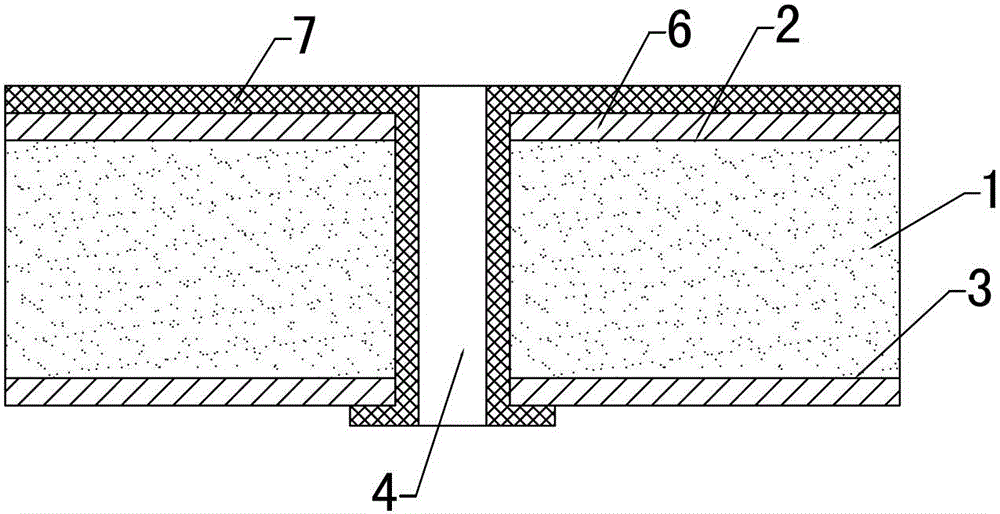

Corrosion-resistant and alkali-resistant treatment method for pipe piece connecting piece of metro

InactiveCN102409286AGuaranteed conductivity requirementsDoes not affect coordination resistanceSolid state diffusion coatingSpecial surfacesAlkaline waterRunning economy

The invention relates to a corrosion-resistant and alkali-resistant treatment method for a pipe piece connecting piece of a metro. The method is characterized by comprising the following steps of: performing multi-metal co-diffusion treatment on the pipe piece connecting piece to endow the pipe piece connecting piece with corrosion resistance and electrical conductivity; and performing different alkali-resistant treatment on special parts which may contact alkaline water after the pipe piece connecting piece is assembled, wherein the special parts comprise polished rod parts and middle threads of bolts in the pipe piece connecting piece, five thread parts and end faces at the two ends of each bolt, and exposed parts after nuts and gaskets are assembled. By the corrosion-resistant and alkali-resistant treatment method for the pipe piece connecting piece of the metro, the technical requirements of corrosion resistance, alkali resistance, electrical conductivity and the like of the pipe piece connecting piece of the metro are met, the maintenance and replacement frequency of components and parts in the running of the metro is greatly decreased at the same time, and the running economy of the metro is improved.

Owner:SHANGHAI DACROMET SURFACE TREATMENT

Anti-corrosive paint for steel materials of ships and preparation method of anti-corrosive paint

InactiveCN105623405ALow costExtended service lifeCarboxyl rubber coatingsAnti-corrosive paintsFiberPolyester

Owner:YANGZHONG HUYANG SHIPPING CO LTD

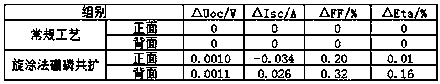

Preparation method of N-type double-sided battery

ActiveCN108110090AReduce manufacturing costReduce the risk of contaminationFinal product manufacturePhotovoltaic energy generationScreen printingEngineering

The invention relates to a preparation method of an N-type double-sided battery. The method comprises the following steps of (1) texturing; (2) boron and phosphorus co-diffusion at front and back sides of a textured silicon wafer by adopting a spin-coating method; (3) HF cleaning; (4) PECVD of AlOx and a passivation film at the front side; (5) the passivation film is deposited at the back side bymeans of PECVD; (6) screen printing and sintering; (7) laser edge isolation; and (8) light-heat treatment of the battery. According to the preparation method, the problem of boron and phosphorus diffusion at present is solved, the technological process is effectively simplified, cross contamination of boron and phosphorus elements is avoided and the conversion efficiency of the battery is improved.

Owner:江苏顺风新能源科技有限公司

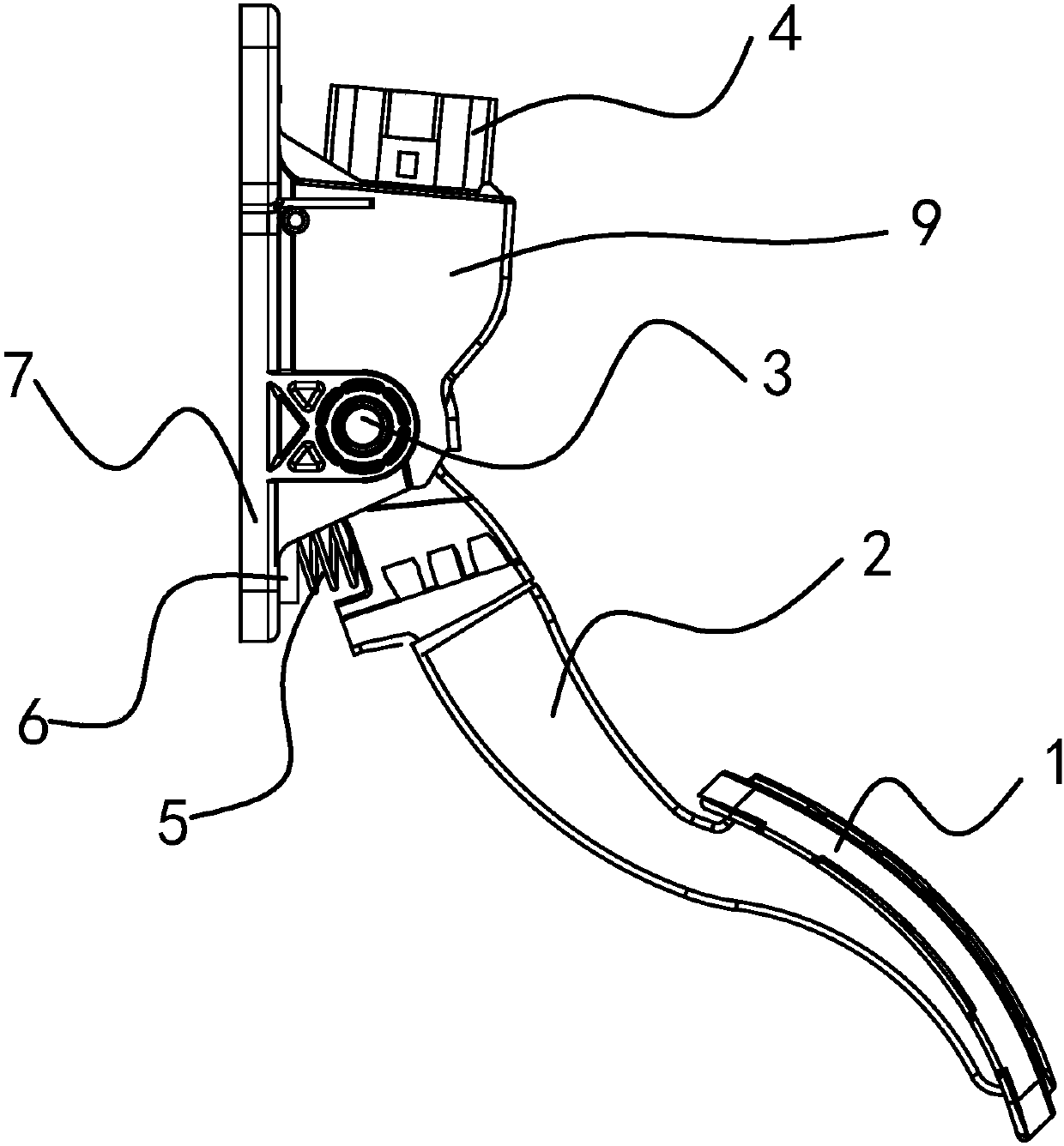

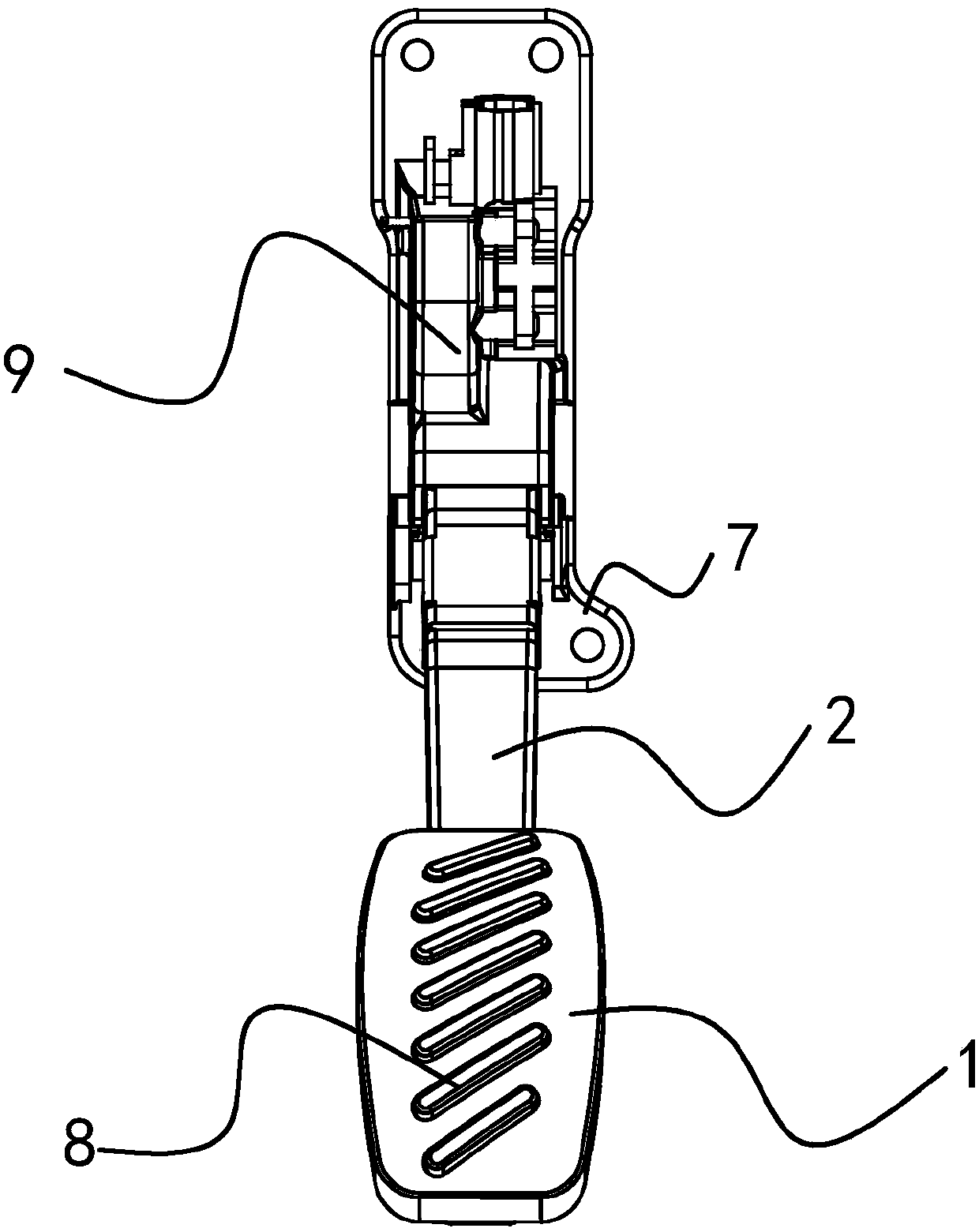

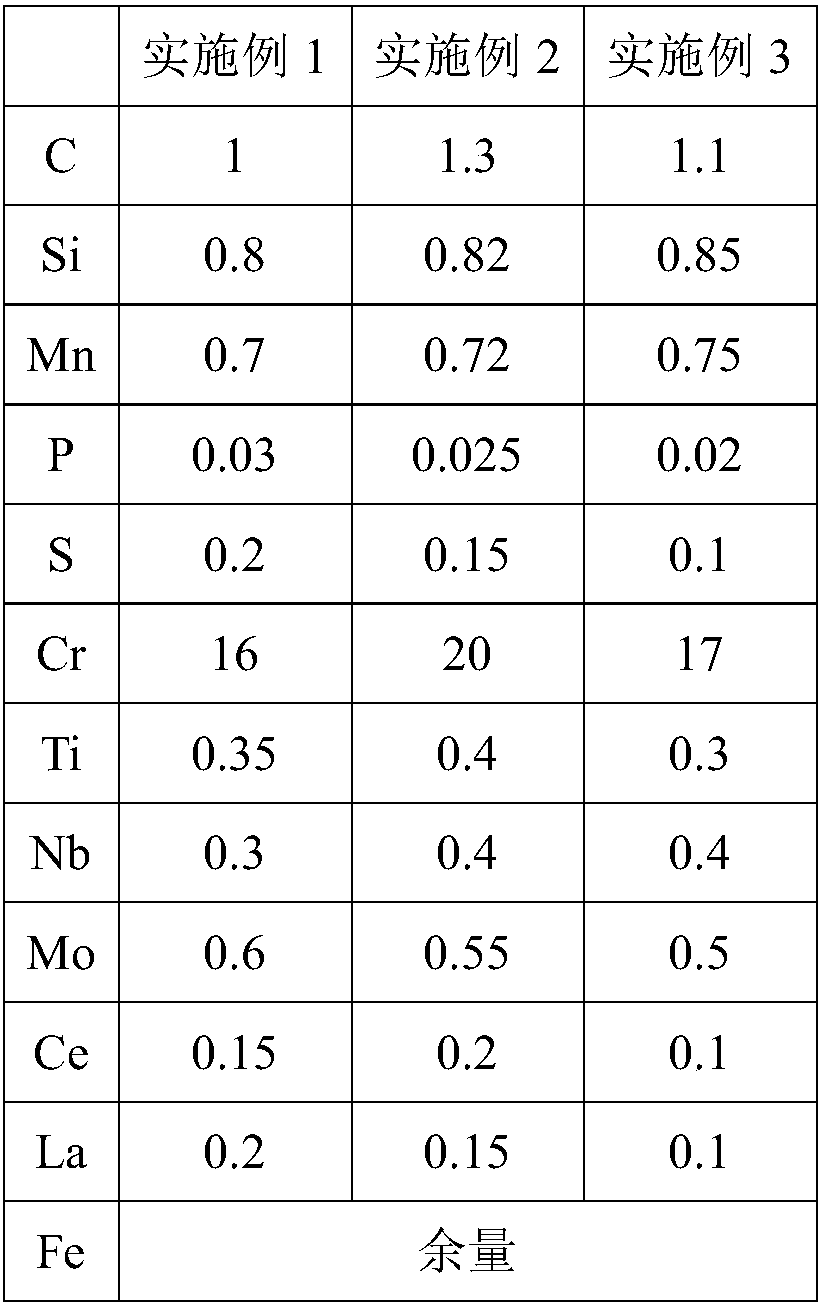

Electronic accelerator pedal assembly

ActiveCN107554292AReduce precipitationImprove stabilitySolid state diffusion coatingPropulsion unit arrangementsEngineeringMechanical engineering

The invention provides an electronic accelerator pedal assembly and belongs to the technical field of car parts. According to the electronic accelerator pedal assembly, the problems that an existing electronic accelerator pedal assembly is complex in structure, not resistant to abrasion, poor in transmission effect and low in sensitivity are solved. The electronic accelerator pedal assembly comprises a base, and the base is composed of the components of, by weight, 1-1.3% of C, 0.8-1% of Si, 0.7-0.8% of Mn, 0.02-0.03% of P, 0.1-0.2% of S, 16-20% of Cr, 0.3-0.4% of Ti, 0.3-0.5% of Nb, 0.5-0.6%of Mo, 0.1-0.2% of Ce, 0.1-0.2% of La and the balance Fe. The base further comprises a co-diffusion coating, is internally provided with an electronic induction part and is further provided with a pedal shaft. The pedal shaft is sleeved with a rotary shaft sleeve, a pedal is assembled on the rotary shaft sleeve, and the base comprises a bottom plate. A cylindrical spring seat is arranged on the bottom plate, a reset spring is fixedly mounted in the spring seat, the reset spring is arranged perpendicular to the bottom plate, and the other end of the reset spring is fixed to the rotary shaft sleeve. The electronic accelerator pedal assembly has the advantages of being simple in structure and high in sensitivity.

Owner:NINGBO GAOFA AUTOMOTIVE CONTROL SYSTEM CO LTD

Chromium-titanium-nitrogen-carbon multicomponent diffusion medium and co-diffusion method thereof

ActiveCN105039904AImprove high temperature resistanceAccelerated corrosionSolid state diffusion coatingTemperature resistanceSodium cyanate

The invention discloses a chromium-titanium-nitrogen-carbon multicomponent diffusion medium which is composed of sodium carbonate, a chromium-titanium supply agent, a catalyst, sodium chloride, sodium hydroxide and sodium cyanate. On the basis of an improved nitrocarburizing salt bath diffusion medium, metal elements of chromium and titanium are creatively added, and through chromium-titanium-sulfur-nitrogen-carbon multicomponent medium-temperature salt bath co-diffusion, a workpiece can have the better high-temperature resistance, fatigue resistance and corrosion resistance and higher hardness. Compared with the conventional thermal treatment technology, medium-temperature salt bath co-diffusion is adopted in the medium, the treatment temperature is low, temperature keeping time is short, and energy can be saved to a great extent; and compared with carburizing and quenching, energy can be saved by more than 50%. The diffusion medium and a co-diffusion method are wide in application range and suitable for surface treatment of carbon structural steel, die steel and stainless steel.

Owner:深圳华悦鑫材科技有限公司

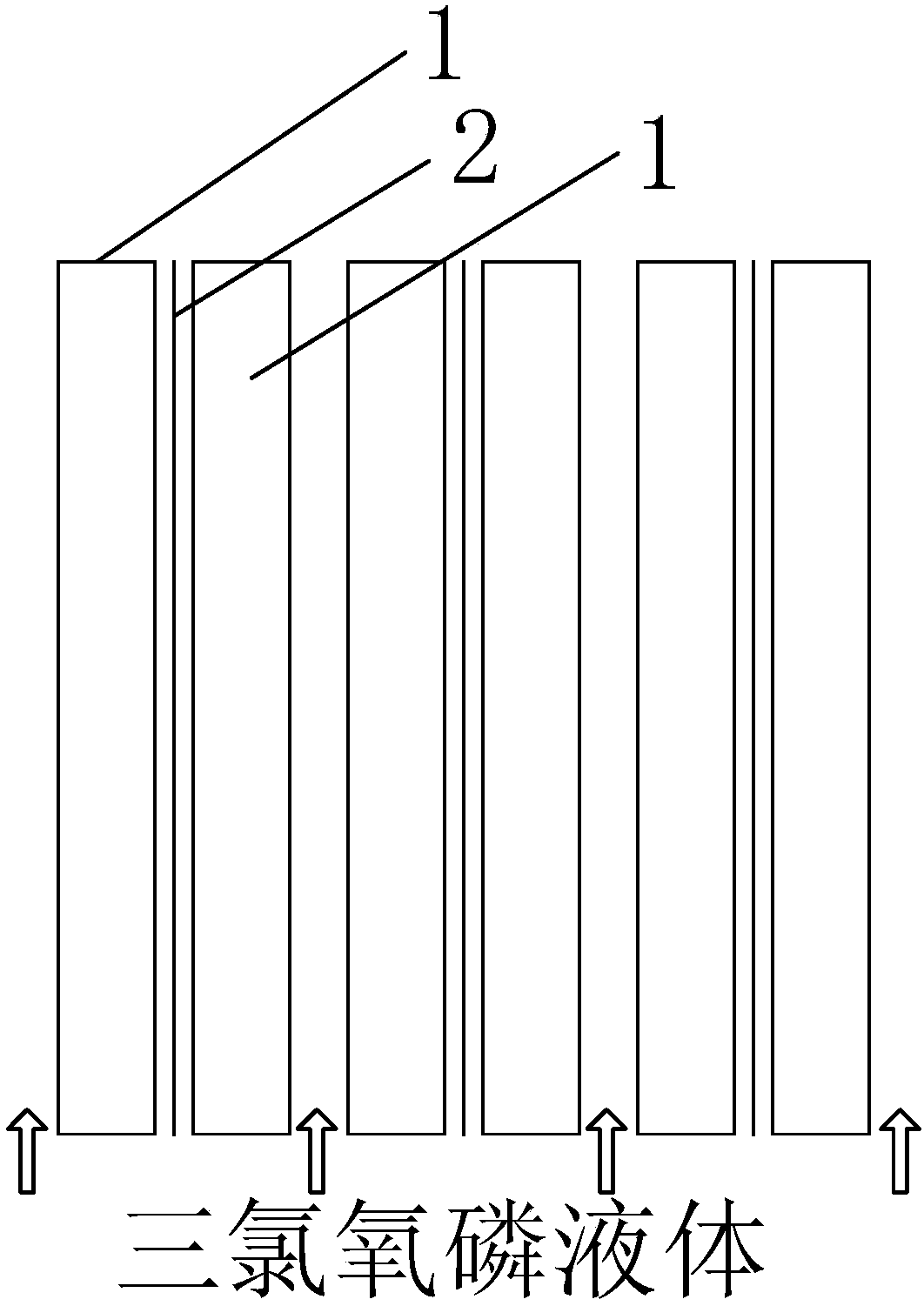

Manufacturing method of PERT crystalline silicon solar cell using novel doping mode

InactiveCN107706268AReduce processLow costFinal product manufacturePhotovoltaic energy generationCrystalline siliconCo diffusion

The invention discloses a manufacturing method of a PERT crystalline silicon solar cell using a novel doping mode. Silicon wafers adopt a B and P co-diffusion process, including the front side P diffusion and the back side B diffusion, two of the silicon wafers are in one group, each silicon wafer group is diffused in a vertical back-to-back manner, a paper-like solid state source B is inserted between the back surfaces of the two silicon wafers, and positive phosphorus diffusion is carried out on the front side by using phosphorus oxychloride; and high-temperature co-diffusion is carried outon the silicon wafers in a diffusion furnace, so that the front side of the silicon wafers forms an n+ doped layer and the back side forms a p+ doped layer. The problems of complex procedures and lowefficiency in the diffusion mode of separate deposition of the front and back sides of the silicon wafers in the background art are solved.

Owner:DONGFANG HUANSHENG PHOTOVOLTAIC (JIANGSU) CO LTD

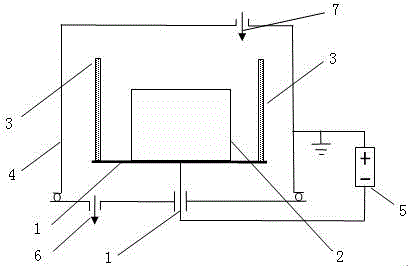

Titanium alloy gear with ferroboron diffusion layer on surface and co-diffusion method thereof

InactiveCN103147037AImprove surface propertiesHigh surface hardnessPortable liftingSolid state diffusion coatingRoom temperatureIron boride

The invention relates to a titanium alloy gear with a ferroboron diffusion layer on the surface and a co-diffusion method thereof. The method comprises the step of: by taking a titanium alloy gear as a workpiece and taking iron boride as a source, placing the titanium alloy gear and the iron boride on a negative disk to form a workpiece-source integral structure, wherein the negative electrode of a direct current power supply is connected to the negative disk, and the positive electrode of the direct current power supply is connected to a vacuum container; vacuumizing and introducing argon, applying a direct-current voltage to generate hollow negative glow discharge, migrating, adsorbing and spreading the sputtered boron, iron ion, atoms and particles into the gear to form an alloy layer, preserving the heat, slowly cooling to room temperature, thereby obtaining the titanium alloy gear with the ferroboron diffusion layer. The method disclosed by the invention is advanced in process and low in cost; and the prepared gear is strong in seizure resistance, good in wear resistance and long in service life.

Owner:TAIYUAN UNIV OF TECH

Rare-earth, carbon and nitrogen co-permeating agent and its preparation

The invention was involved in infiltrated agent of Ti-Al co-diffusion and its preparation. The infiltrated agent consist of 10-25% TiO2,2-25% Al powder, 30-80% Al2O3,0.3-2.8% infiltrated agent. Infiltrated agent was NH4Cl or other halide. The method of infiltrated agent of Ti-Al co-diffusion adopted solid powder embedded infiltration technology and the infiltration temperature adopted ladder temperature. Firstly, the substance was heated to 650-900deg.C for 1-5h. Secondly, it was heated to 900-1150deg.C for 2-8h. The infiltration layer of Ti-Al co-diffusion could be finished by the invention and the infiltration layer was smooth, bright and with high corrosion resistance.

Owner:靳重滨

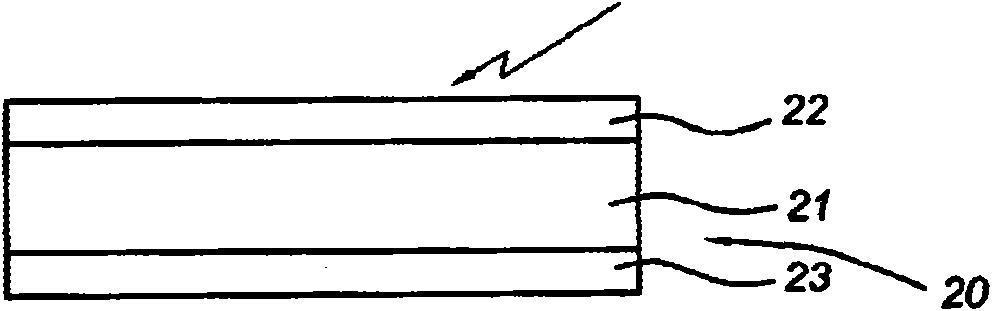

Screen-printable boron doping paste with simultaneous inhibition of phosphorus diffusion in co-diffusion processes

The present invention relates to a novel printable boron doping paste in the form of a hybrid gel based on precursors of inorganic oxides, preferably of silicon dioxide, aluminium oxide and boron oxide, in the presence of organic polymer particles, where the pastes according to the invention can be used in a simplified process for the production of solar cells, where the hybrid gel according to the invention functions both as doping medium and as diffusion barrier.

Owner:MERCK PATENT GMBH

High-performance air cylinder sleeve and production technology and surface treatment method of high-performance air cylinder sleeve

ActiveCN107686937AHigh tensile strengthIncrease elasticitySolid state diffusion coatingFriction reductionSulfur

The invention belongs to the field of air cylinder sleeves, and particularly relates to a high-performance air cylinder sleeve and a production technology and a surface treatment method of the high-performance air cylinder sleeve. The provided air cylinder sleeve comprises 2.3%-2.6% of C, 3.1%-3.4% of Si, 0.5%-0.8% of P, 0%-0.1% of S, 1.6%-1.9% of Mn, 1.7%-1.9% of Cu, 0.5%-0.9% of Cr, 0.6%-1.0% ofNb and the balance Fe. The provided surface treatment method comprises the steps that the surface of the above air cylinder sleeve is sequentially subjected to phosphating treatment and sulfur nitrogen carbon co-diffusion treatment, and the air cylinder sleeve obtained after surface treatment is obtained. The provided air cylinder sleeve has high tensile strength, and serious carbon deposition cannot happen during using. According to the provided surface treatment method, the mechanical strength of the air cylinder sleeve can be further improved, and the carbon deposition situation of the aircylinder sleeve during using is reduced; and meanwhile the cavitation erosion resistance, abrasion resistance and friction reduction performance of the air cylinder sleeve can be improved.

Owner:ZYNP GRP

Preparation method of multilayer composite modified layer with strong toughness on titanium alloy surface

InactiveCN101851744BImprove toughnessHigh bonding strengthVacuum evaporation coatingSputtering coatingAlloy substrateNitrogen gas

The invention relates to a preparation method of a multilayer composite modified layer with strong toughness on a titanium alloy surface, which belongs to the technical field of the surface modification and strengthening of metal materials. The invention is characterized by adopting a technical scheme that the unit diffusion of Mo and co-diffusion of Mo / N are alternately and cyclically carried out on the surface of a titanium alloy substrate to prepare the Mo / MoN multilayer composite modified layer with strong toughness. The preparation method comprises the following steps of coating a Mo bottom layer with the thickness thereof 4-6 mu m by diffusion on the surface of a workpiece firstly; then simultaneously introducing argon and nitrogen and coating a MoN layer with the thickness thereof 2-4 mu m by diffusion on the surface of the workpiece; cutting off the nitrogen supply, only introducing argon into a vacuum chamber, and continuing to coating a Mo layer with the thickness of 2-4 mu m by diffusion on the surface of the workpiece; by turning on and cutting off the nitrogen supply, continuing to alternately and cyclically coating MoN layers and Mo layers by diffusion on the surface of the workpiece, and enabling the most superficial layer of the multilayer composite layer to be the MoN layer to prepare the Mo / MoN multilayer composite layer with the modulation period of 2-4 mu m and the total thickness of 10-50 mu m; and taking out the workpiece after the workpiece cools in a furnace to the room temperature. The prepared Mo / MoN multilayer composite modified layer obviously improves the wear resistance of the titanium alloy under the high contact load condition.

Owner:TAIYUAN UNIV OF TECH

Corrosion-resistant and alkali-resistant treatment method for pipe piece connecting piece of metro

InactiveCN102409286BGuaranteed conductivity requirementsDoes not affect coordination resistanceSolid state diffusion coatingSpecial surfacesAlkaline waterRunning economy

The invention relates to a corrosion-resistant and alkali-resistant treatment method for a pipe piece connecting piece of a metro. The method is characterized by comprising the following steps of: performing multi-metal co-diffusion treatment on the pipe piece connecting piece to endow the pipe piece connecting piece with corrosion resistance and electrical conductivity; and performing different alkali-resistant treatment on special parts which may contact alkaline water after the pipe piece connecting piece is assembled, wherein the special parts comprise polished rod parts and middle threads of bolts in the pipe piece connecting piece, five thread parts and end faces at the two ends of each bolt, and exposed parts after nuts and gaskets are assembled. By the corrosion-resistant and alkali-resistant treatment method for the pipe piece connecting piece of the metro, the technical requirements of corrosion resistance, alkali resistance, electrical conductivity and the like of the pipe piece connecting piece of the metro are met, the maintenance and replacement frequency of components and parts in the running of the metro is greatly decreased at the same time, and the running economy of the metro is improved.

Owner:SHANGHAI DACROMET SURFACE TREATMENT

Surface treatment method for high-carbon steel part

ActiveCN105369193AAvoid crackingHigh surface hardnessSolid state diffusion coatingHigh carbonRare earth

The invention relates to a surface treatment method for a high-carbon steel part. Nitrogen-carbon rare earth co-diffusion is carried out on the part before metal cementation. Compared with the prior art, nitrogen-carbon rare earth co-diffusion pretreatment is carried out on the high-carbon steel part before metal cementation, carbon concentration higher than that of a base body, large lattice distortion and many defects are formed on the surface of a metal workpiece, and therefore diffusion of metal atoms and carbon atoms can be accelerated; and metal cementation is more efficient, and a cementation layer is dense and firm.

Owner:QINGDAO CHOHO IND CO LTD

Heat treatment process of 3Cr2W8V mold

InactiveCN108676990AHigh hardnessImprove toughnessSolid state diffusion coatingFurnace typesEconomic benefitsWear resistance

A heat treatment process of a 3Cr2W8V mold comprises the following steps of annealing, quenching, tempering, salt bath treatment and an ion sulphonitriding method. The heat treatment process of the 3Cr2W8V mold is optimized and adjusted, and the hardness, toughness and wear resistance of the 3Cr2W8V mold are effectively improved. In addition, after the 3Cr2W8V mold is subjected to ion sulphonitriding treatment, the wear resistance and occlusion resistance of a cavity are obviously improved, the service life of the mold is prolonged by 2-4 times compared with a mold not subjected to co-diffusion, the surface brightness of the product is obviously improved, the service life of the mold is prolonged, and economic benefits are increased.

Owner:XIJING UNIV

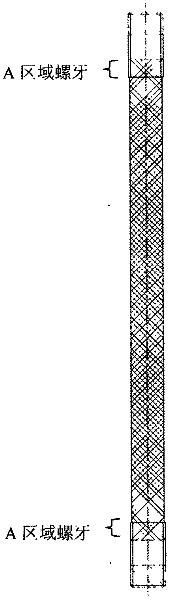

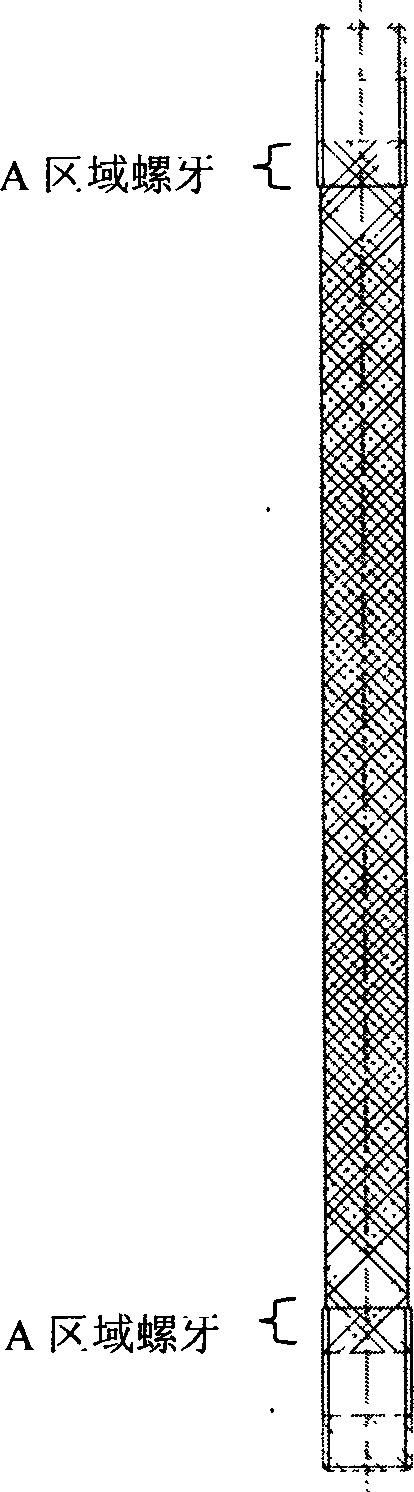

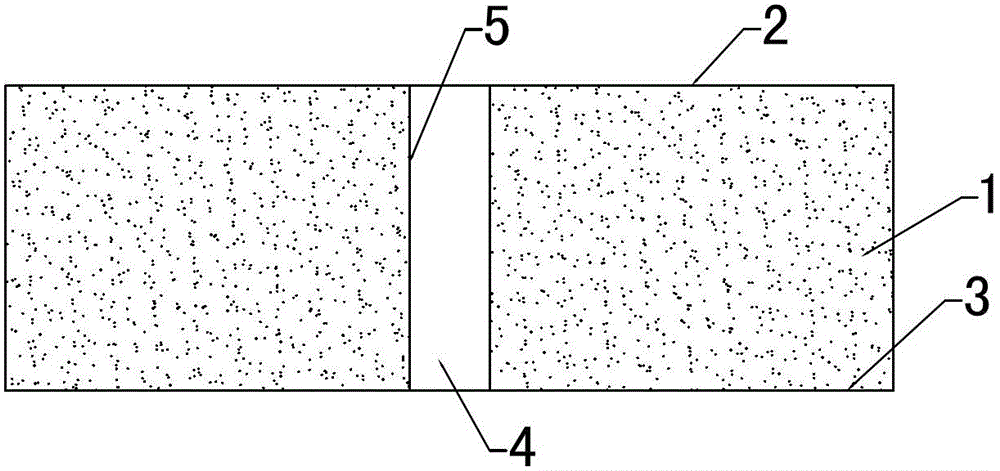

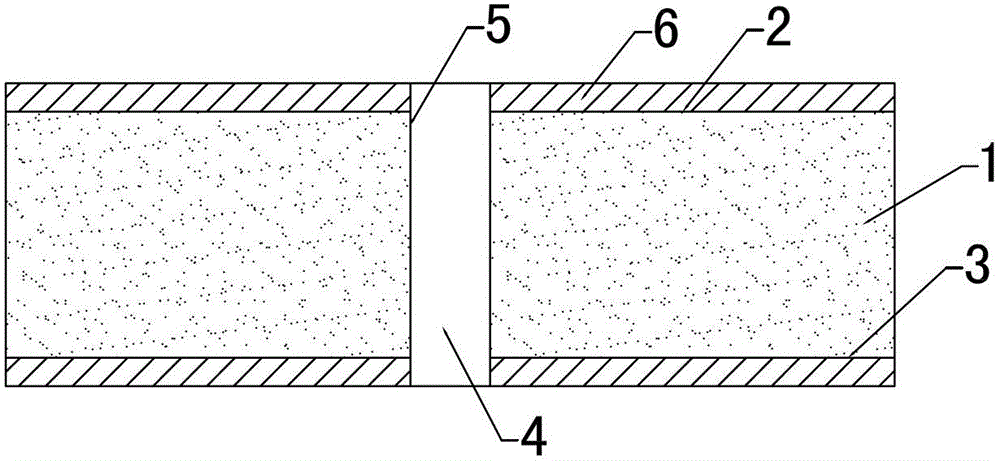

Preparing method for alloy co-diffusion and Dacromet composite antiseptic coating

ActiveCN106011740AUniform thicknessDense metallographic structureSolid state diffusion coatingAnti-corrosive paintsAlloyCo diffusion

The invention discloses a preparing method for an alloy co-diffusion and Dacromet composite antiseptic coating. The preparing method comprises the following steps that by mass, following co-diffusion agent raw materials are weighed; the weighed raw materials are evenly mixed, and then a co-diffusion agent is prepared; platy metal pieces with the surfaces cleaned thoroughly are stacked into a stack with the height similar to the width, a layer of co-diffusion agent is laid between every two adjacent platy metal pieces, and packaging and bundling are conducted; the packaged and bundled platy metal pieces are placed in a co-diffusion furnace to be heated and subjected to co-diffusion treatment for 2 h-3 h; Dacromet antiseptic raw materials are weighed, mixed and stirred evenly, pH is adjusted, and Dacromet antiseptic coating liquid is prepared; and the platy metal pieces obtained after alloy co-diffusion treatment are placed in a coating liquid immersing cage, then the coating liquid immersing cage is immersed in the Dacromet antiseptic coating liquid and then drained off to be sent into an online drying device, and baking is conducted for 1.5 h-2.5 h at the temperature of 300 DEG C-350 DEG C. The preparing method is suitable for treating the platy metal pieces in batches.

Owner:马克菲尔(长沙)新型支档科技开发有限公司

Machining technology of cam-mould special-shaped concave-mould

The invention provides a machining technology of a cam-mould special-shaped concave-mould. The machining technology sequentially comprises the following processes of material sawing, rough turning, special shape rough milling of a machining center, heat treatment, numerical-control finish turning, plane abrasion, pressure distribution, special shape finish milling of the machining center, grinding, pressure withdrawing, S-N co-diffusion, polishing and secondary pressure distribution. According to the machining technology of the cam-mould special-shaped concave-mould, the profile tolerance of the concave-mould after the follow-up special shape finish milling of the machining center is guaranteed through the pressure distribution process in the concave-mould machining technology, so that the profile tolerance of the concave-mould is ensured to be within 0.02 mm, therefore the profile tolerance of a cam forge piece is guaranteed, further the product profile tolerance after the follow-up heat treatment is conducted is ensured, and the production quality is improved.

Owner:JIANGSU SUNWAY PRECISION FORGING

Method of manufacturing crystalline silicon solar cells using co diffusion of boron and phosphorus

ActiveCN101919070BReduce overflowImprove qualityFinal product manufacturePhotovoltaic energy generationCrystalline siliconCo diffusion

The present invention provides a method of manufacturing a crystalline silicon solar cell, subsequently comprising: providing a crystalline silicon substrate having a first side and a second side opposite the first side; pre-diffusing Phosphorus into a first side of the substrate to render a Phosphorus diffused layer having an initial depth; blocking the first side of the substrate; - exposing a second side of the substrate to a Boron diffusion source; heating the substrate for a certain period of time and to a certain temperature so as to diffuse Boron into the second side of the substrate and to simultaneously diffuse the Phosphorus further into the substrate.

Owner:NEDERLANDSE ORG VOOR TOEGEPAST NATUURWETENSCHAPPELIJK ONDERZOEK TNO

Method for preparing double-faced back contact solar cell

ActiveCN102709389BImprove electrical performanceSimple preparation processFinal product manufactureSemiconductor devicesDopantPhosphor

The invention discloses a method for preparing a double-faced back contact solar cell, comprising following steps: (1) holing; (2) washing, and texturizing the front face and the back face of a silicon wafer; (3) arranging a first doping agent on the front face and in the hole of the silicon wafer, and arranging the first doping agent in the surrounding area of the hole in the back face of the silicon wafer, wherein the doping type of the first doping agent is opposite to that of the silicon wafer; (4) arranging a second doping agent in the non-hole surrounding area on the back face of the silicon wafer, wherein the doping type of the second doping agent is the same as that of the silicon wafer; (5) growing barrier layers on the front face and the back face of the silicon wafer; (6) annealing the silicon wafer at the temperature of 800 to 1000 DEG C, diffusing and making junctions; (7) etching peripheral junctions; (8) washing and removing the barrier layers; (9) arranging passivation anti-reflection films on the front face and the back face of the silicon wafer; and (10) arranging a porous metal electrode in the hole, printing and sintering. Adopting a method for arranging the doping agents, i.e. adopting the various type doping agents on two faces of the silicon wafer, the double-faced back contact solar cell realizes the co-diffusion of boron-phosphor in the presence of the barrier layers, thereby greatly simplifying process flows and reducing the production cost.

Owner:CSI CELLS CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com