Corrosion-resistant and alkali-resistant treatment method for pipe piece connecting piece of metro

A connecting piece and corrosion-resistant technology, which is applied in the fields of multi-component metal co-infiltration and alkali-resistant treatment, can solve the problems of corrosion, high energy consumption of composite heat treatment technology, and thin coating, so as to improve economy and reduce the frequency of maintenance and replacement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Multi-element metal co-infiltration treatment of segmental joints, through zinc, aluminum and dilute elements at a temperature of 380-430 ° C, with the infiltration aid NH 4 Cl reacts chemically to form a variety of active metal atoms, which interpenetrate with the steel matrix to form a co-infiltration layer with a thickness of 40-50 μm. The co-infiltration layer consists of a small amount of δ phase in the transition layer, the zinc mass percentage of the transition layer is 25%, the middle layer is mainly composed of δ phase and a small amount of ferrite and pearlescent beads in the iron-based material. The mass percentage reaches 80%.

[0035] The outermost layer is dominated by duplex structure (Γ phase + α phase), and the mass percentage of zinc is more than 60%. After the above-mentioned multi-element metal co-infiltration, the joint resistance is 3mΩ, which is lower than the designed upper Limits (Table 1).

Embodiment 2

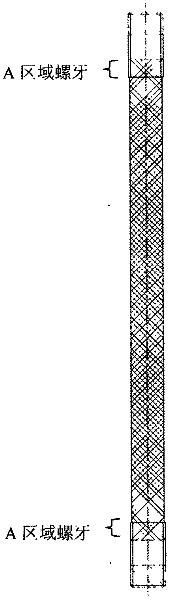

[0037] The alkali-resistant treatment of the segment connection is mainly to carry out the alkali-resistant treatment on the polished rod part and the middle thread of the bolt in the connection ( image 3 ). It is treated with SDF-202 alkali-resistant coating. Baking at 170-180°C for 15-20 minutes, the coating thickness is 10-12μm (see image 3 and instructions).

Embodiment 3

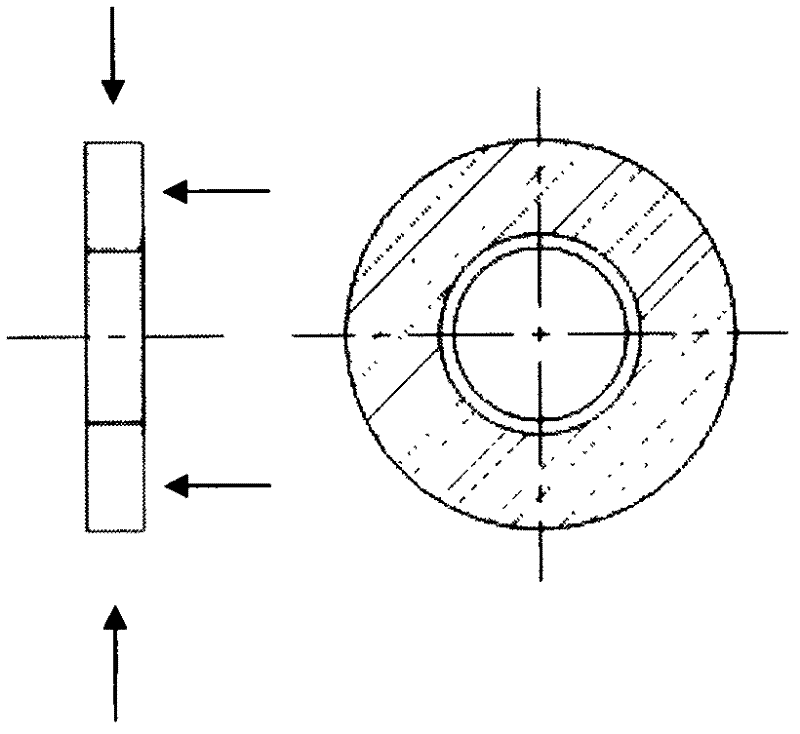

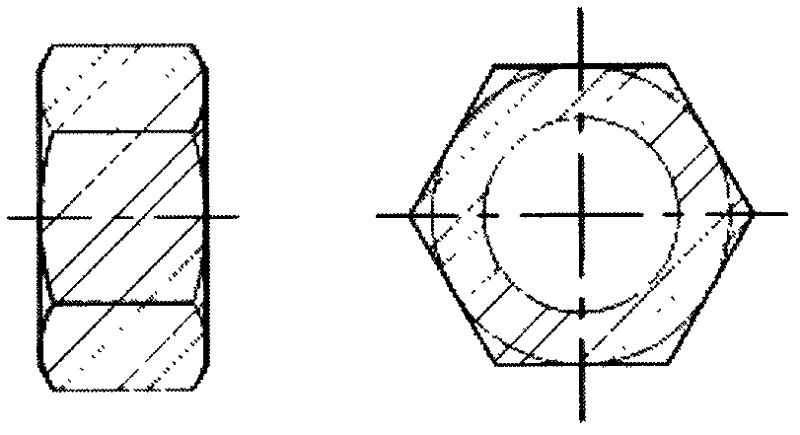

[0039] Both ends of bolts and nut gaskets are treated with JC-806 black alkali-resistant coating. Baking at 180-200°C for 15-20 minutes, the coating thickness is 10-12μm (see figure 1 , 2 and instructions). in particular figure 1 There is no alkali-resistant treatment in the ring-shaped area of 5mm outside the inner circle of the gasket.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com