Corrosion-resistant and alkali-resistant treatment method for pipe piece connecting piece of metro

A technology for connecting parts and segments, which is applied in the fields of multi-metal infiltration and alkali-resistant treatment, can solve the problems of high energy consumption, corrosion and poor wear resistance of composite heat treatment technology, reduce the frequency of maintenance and replacement, improve economical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Multi-element metal co-infiltration treatment of segmental joints, through zinc, aluminum and dilute elements at a temperature of 380-430 ° C, with the infiltration aid NH 4 Cl reacts chemically to form a variety of active metal atoms, which interpenetrate with the steel matrix to form a co-infiltration layer with a thickness of 40-50 μm. The co-infiltration layer consists of a small amount of δ phase in the transition layer, the zinc mass percentage of the transition layer is 25%, the middle layer is mainly composed of δ phase and a small amount of ferrite and pearlescent beads in the iron-based material. The mass percentage reaches 80%.

[0035] The outermost layer is dominated by duplex structure (Γ phase + α phase), and the mass percentage of zinc is more than 60%. After the above-mentioned multi-element metal co-infiltration, the joint resistance is 3mΩ, which is lower than the designed upper Limits (Table 1).

Embodiment 2

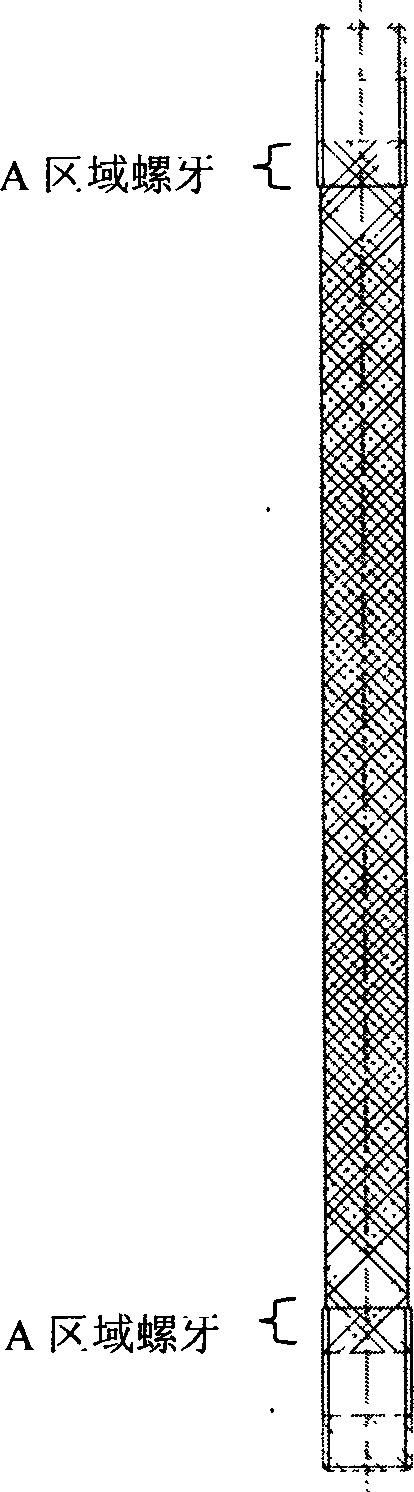

[0037] The alkali-resistant treatment of the segment connection is mainly to carry out the alkali-resistant treatment on the polished rod part and the middle thread of the bolt in the connection ( image 3 ). It is treated with SDF-202 alkali-resistant coating. Baking at 170-180°C for 15-20 minutes, the coating thickness is 10-12μm (see image 3 and instructions).

Embodiment 3

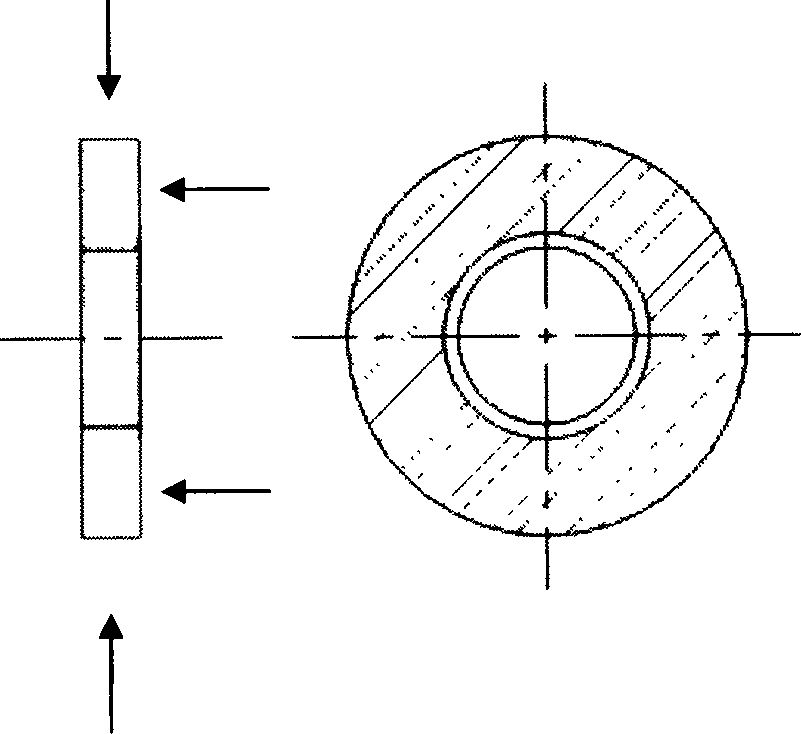

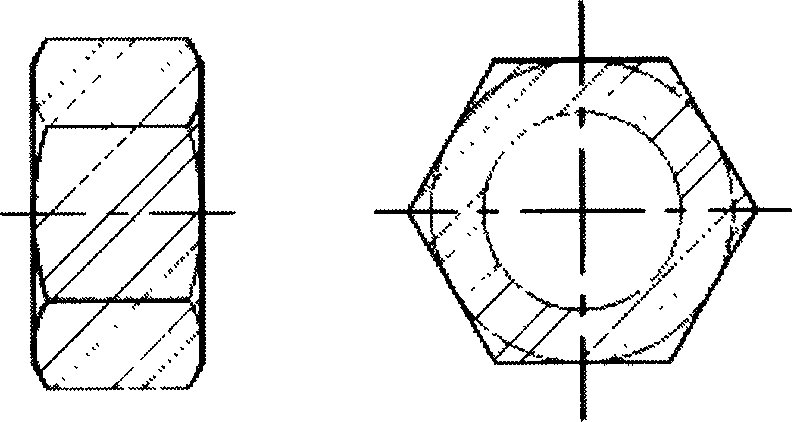

[0039] Both ends of bolts and nut gaskets are treated with JC-806 black alkali-resistant coating. Baking at 180-200°C for 15-20 minutes, the coating thickness is 10-12μm (see figure 1 , 2 and instructions). in particular figure 1 There is no alkali-resistant treatment in the ring-shaped area of 5mm outside the inner circle of the gasket.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com