Direct-current cable

A DC cable and wire technology, applied in power cables, insulated cables, cables, etc., can solve the problems of copper core cable creep, increased installation cost, and high copper core cable cost, meet the requirements of ensuring electrical conductivity and reduce product costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

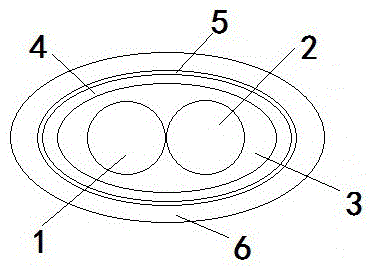

[0023] A DC cable, including a core material, the core material is made of twisted aluminum-based alloy wire and iron-based alloy wire, the core material is covered with a filler, the filler is a moisture-proof layer, and the moisture-proof layer is covered with a lightweight braided mesh , the outer protective layer is the light woven mesh,

[0024] The content of each element component of aluminum-based alloy wire rod is: Si1﹪, Sn0.8﹪, Nb0.6﹪, Cu0.5﹪, Cr0.3﹪, V0.2﹪, Mo0.06﹪, Ag0.05﹪, Ce0 .04﹪, Pr0.03﹪, Cd0.01﹪, the balance is Al,

[0025] The content of each element component of the iron-based alloy wire rod is: C0.03﹪Al0.8﹪, Mg0.7﹪, Sn0.5﹪, Zn0.4﹪, Cr0.2﹪, V0.2﹪, B0.06﹪, Sr0.04﹪, Y0.02﹪, La0.01﹪, Bi0.01﹪, the balance is Fe,

[0026] The moisture-proof layer is weighed and includes: 50 parts of butyl rubber, 10 parts of phthalate, 20 parts of xylene, 10 parts of propylene glycol methyl ether acetate, 7 parts of dicyclopentadiene, 40 parts of diatomaceous earth, hydroxide ...

Embodiment 2

[0030] A DC cable, including a core material, the core material is made of twisted aluminum-based alloy wire and iron-based alloy wire, the core material is covered with a filler, the filler is a moisture-proof layer, and the moisture-proof layer is covered with a lightweight braided mesh , the outer protective layer is the light woven mesh,

[0031] The content of each element component of aluminum-based alloy wire rod is: Si2﹪, Sn0.9﹪, Nb0.7﹪, Cu0.6﹪, Cr0.4﹪, V0.3﹪, Mo0.07﹪, Ag0.06﹪, Ce0 .05﹪, Pr0.04﹪, Cd0.02﹪, the balance is Al,

[0032] The content of each element component of the iron-based alloy wire rod is: C0.04﹪Al0.9﹪, Mg0.8﹪, Sn0.6﹪, Zn0.5﹪, Cr0.3﹪, V0.3﹪, B0.07﹪, Sr0.05﹪, Y0.03﹪, La0.02﹪, Bi0.02﹪, the balance is Fe,

[0033] The moisture-proof layer is weighed and includes: 50 parts of butyl rubber, 20 parts of phthalate, 30 parts of xylene, 20 parts of propylene glycol methyl ether acetate, 7 parts of dicyclopentadiene, 40 parts of diatomaceous earth, hydroxide ...

Embodiment 3

[0037] A DC cable, including a core material, the core material is made of twisted aluminum-based alloy wire and iron-based alloy wire, the core material is covered with a filler, the filler is a moisture-proof layer, and the moisture-proof layer is covered with a lightweight braided mesh , the outer protective layer is the light woven mesh,

[0038]The content of each element component of aluminum-based alloy wire rod is: Si1.5﹪, Sn0.85﹪, Nb0.65﹪, Cu0.55﹪, Cr0.35﹪, V0.25﹪, Mo0.065﹪, Ag0.055﹪ , Ce0.045﹪, Pr0.035﹪, Cd0.015﹪, the balance is Al,

[0039] The content of each element component of the iron-based alloy wire rod is: C0.035﹪Al0.85﹪, Mg0.75﹪, Sn0.55﹪, Zn0.45﹪, Cr0.25﹪, V0.25﹪, B0.065﹪, Sr0.045﹪, Y0.025﹪, La0.015﹪, Bi0.015﹪, the balance is Fe,

[0040] The moisture-proof layer is weighed and includes: 50 parts of butyl rubber, 15 parts of phthalate, 25 parts of xylene, 15 parts of propylene glycol methyl ether acetate, 7 parts of dicyclopentadiene, 40 parts of diatomac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com