Manufacturing method for black silicon double-face cell

A technology of a double-sided cell and a manufacturing method, which is applied in the field of solar cells, can solve the problems of hindering the progress of industrialization, cumbersome processes, and improving the power generation of solar cells, and achieves the effects of increasing power output, improving absorption, and reducing reflectivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

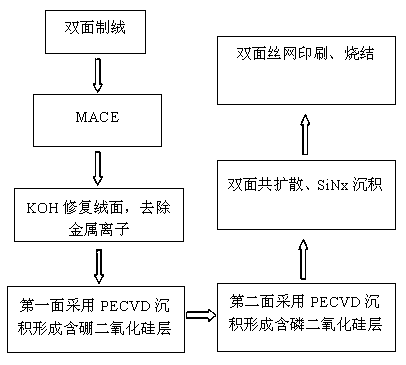

[0027] A method for manufacturing a black silicon double-sided battery, the specific steps are:

[0028] The P-type silicon chip used is 15.6cm×15.6cm, but not limited to this size; the resistivity is 1-3Ω·cm.

[0029] a. Carry out double-sided texturing of the silicon wafer;

[0030] b. Using metal-assisted catalytic etching to fabricate black silicon structures

[0031] Put the textured silicon wafer into AgNO 3 and HF mixed solution, AgNO 3 The concentration of HF is 0.001-0.2mol / L, the concentration of HF is 0.01-0.1mol / L, react at room temperature for 10-100s, after the reaction is completed, clean the silicon wafer, and then put HF and H 2 o 2 In the mixed solution, the concentration of HF is 1-5mol / L, H 2 o 2 The concentration is 0.1-2mol / L, react at room temperature for 50-200s;

[0032] c. Use acid to remove metal ions

[0033] Wash the silicon wafer obtained in step b, first react with 0.005-0.2mol / L KOH solution at 70°C for 50-200s, and then use 0.005-0.2mol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com