Method of manufacturing crystalline silicon solar cells using co diffusion of boron and phosphorus

A technology of solar cells and crystalline silicon, applied in the direction of final product manufacturing, sustainable manufacturing/processing, circuits, etc., can solve problems such as increasing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

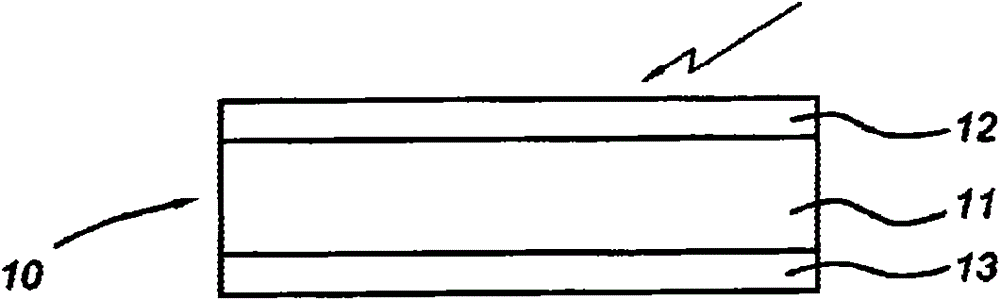

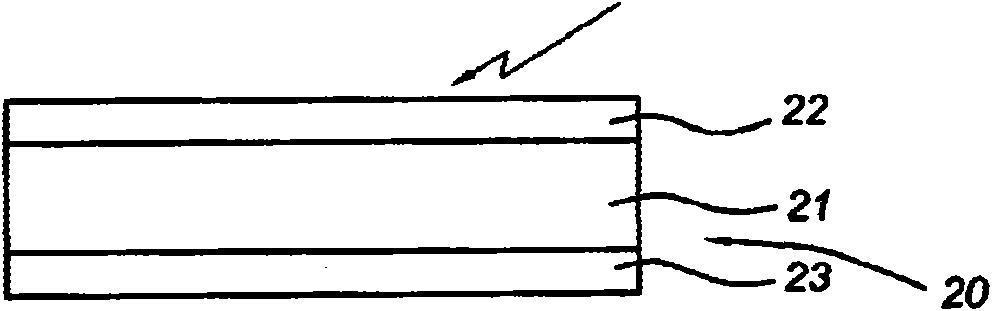

[0024] figure 1 Shown is an example of the structure of a solar cell made according to the method of one embodiment of the present invention. The solar cell 10 comprises an n-type silicon substrate 11 having a boron diffusion layer 12 on one side and a phosphorus diffusion layer 13 on the other side. It should be noted that the actual solar cell structure also has metal contacts and an anti-reflective coating, but these components are not shown in the diagram. figure 2 Shown is another embodiment of processing a p-type silicon substrate 21 to produce a phosphorus diffused layer 22 on one side and a boron diffused layer 23 on the other. figure 1 The solar cell is the preferred embodiment because its device characteristics are better than figure 2 . In the following description, discusses figure 1 Embodiments of the method of fabrication of solar cells (ie, n-type substrates) shown in .

[0025] The first step of the method is to produce a P-diffused layer on one side of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com