Preparation method of N-type double-sided solar cell

A solar cell, N-type technology, applied in the field of solar cells, can solve the problems of increased process time, increased cost, and decreased yield, and achieve the effect of simplifying the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art. The wt% in the present invention represents the mass percentage (no problem). The front and back mentioned in the present invention are defined according to the usual viewing angle of those skilled in the art and for the convenience of description. The specific direction is not limited. Generally, it is facing the sun The side facing the sun is the front and the side facing away from the sun is the back.

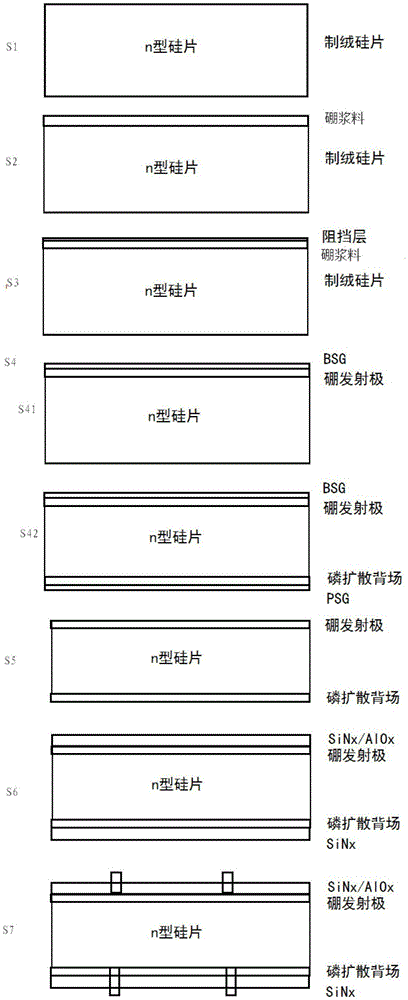

[0035] Refer to attached figure 1 As shown, the method for preparing an N-type solar cell of the present invention uses an N-type silicon wafer with a resistivity of 1-6 Ohmcm as a raw material, and performs steps S1 to S7 in sequence.

[0036] S1, making texture on the surface of the N-type silicon wafer to form a te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com