Preparation method of diamond coated cutting tool

A diamond coating and diamond technology, applied in metal material coating technology, coating, superimposed layer plating, etc., can solve the problems of unfavorable industrial production and practical application, long time, etc., to improve the processing effect and reduce the edge Chipping and reduced processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

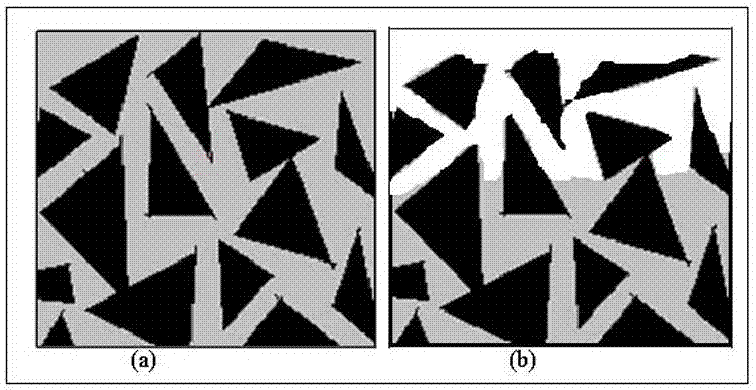

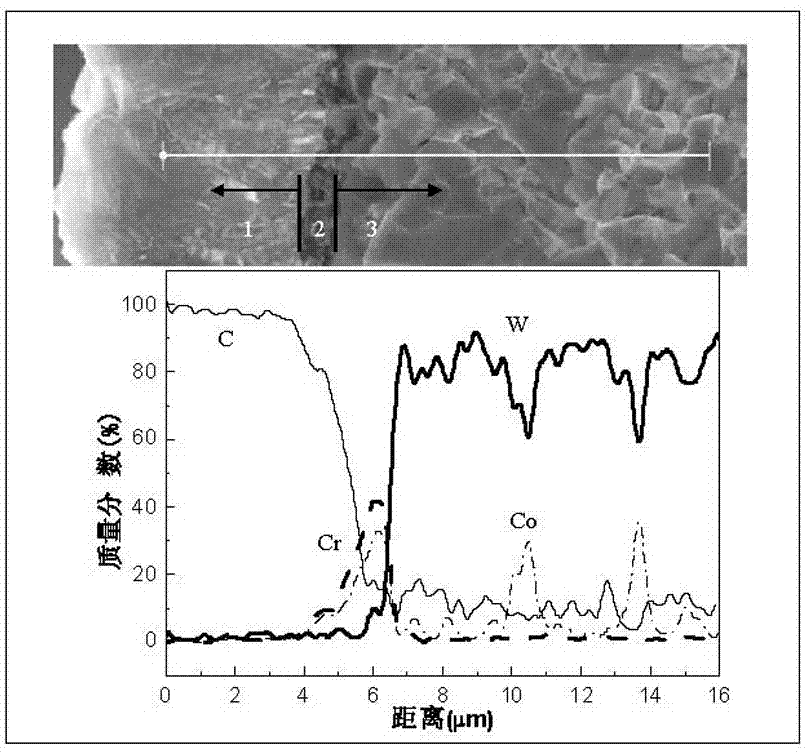

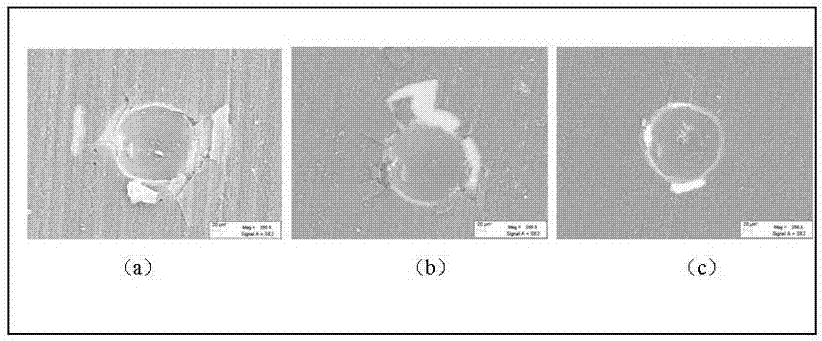

Method used

Image

Examples

Embodiment 1

[0035] A preparation method of a diamond-coated cutting tool of the present invention, comprising the following steps:

[0036] (1) Substrate selection: A cemented carbide blade with a WC grain size of 0.4 μm to 1.5 μm and a Co content of 6wt% is selected as the substrate material, and a flat blade with a blade size of 12mm×12mm×4mm.

[0037] (2) Substrate corrosion treatment:

[0038] (2.1) Alkali corrosion: Put the blade in step (1) into the alkaline solution for ultrasonic corrosion for 10 minutes, the alkaline solution is K 3 [Fe(CN) 6 ], KOH and H 2 Mixed solution of O, K 3 [Fe(CN) 6 ], KOH and H 2 The mass ratio of O was 1:1:20, and then sprayed with tap water for 3 minutes to remove the corrosive liquid on the surface of the substrate, then placed in pure water for ultrasonic cleaning for 5 minutes, and finally air-dried.

[0039] (2.2) Acid corrosion: put the air-dried blade in step (2.1) into the acid solution for 5 minutes, and the acid solution is HNO 3 、H 2...

Embodiment 2

[0048] A preparation method of a diamond-coated cutting tool of the present invention, comprising the following steps:

[0049] (1) Substrate selection: A cemented carbide rod with a WC grain size of 0.6 μm to 1.5 μm and a Co content of 6 wt% is selected as the tool substrate. According to the processing requirements of composite materials, the twist drill bit with double-vertex angle structure is prepared through grinding center processing, and the tool specification is φ3×28×φ6×70mm. Knives are cleaned to remove surface oil.

[0050] (2) Substrate corrosion treatment:

[0051] (2.1) Alkali corrosion: Put the tool obtained in step (1) into the alkaline solution for ultrasonic corrosion for 20 minutes, the alkaline solution is K 3 [Fe(CN) 6 ], KOH and H 2 Mixed solution of O, K 3 [Fe(CN) 6 ], KOH and H 2 The mass ratio of O was 1:1:50, and then sprayed with tap water for 3 minutes to remove the corrosive liquid on the surface of the tool, then put it into pure water for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Total thickness | aaaaa | aaaaa |

| Grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com