Preparation method of artificial diamond synthesis graphite core column

A technology of artificial diamond and graphite core pillars, which is applied in other manufacturing equipment/tools, turbines, engine components, etc., can solve problems such as uncontrollability, growth discontinuity, affecting synthesis effect and crystal quality, and achieve low preparation costs , Ensure growth continuity, avoid diamond carbonization and impurity removal problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

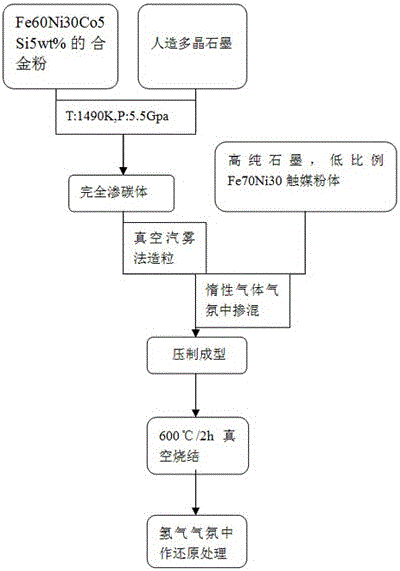

[0017] see figure 1 Shown: a method for preparing a graphite core column for synthetic diamond synthesis. Firstly, cementite is prepared, and then the prepared cementite is implanted into graphite alloy catalyst powder to obtain a graphite core column.

[0018] specific,

[0019] Step 1: Prepare cementite under high temperature and high pressure. The carbon source is artificial polycrystalline graphite, and Fe60Ni30Co5Si5wt% alloy powder is used. Under the conditions of temperature of 1490K and pressure of 5.5GPa, carbon atoms enter the alloy in the form of groups to form complete cementite;

[0020] Step 2: granulating the complete cementite obtained in step 1 by a vacuum vapor-mist method to obtain cementite particles;

[0021] Step 3: Mix the cementite particles obtained in step 2 with graphite alloy catalyst powder in an inert gas atmosphere. The graphite alloy catalyst powder is high-purity graphite powder with an iron-nickel catalyst powder accounting for 8%, and the ir...

Embodiment 2

[0026] A kind of preparation method of artificial diamond synthetic graphite core post, comprises the following steps:

[0027] Step 1: Prepare cementite under high temperature and high pressure. The carbon source is artificial polycrystalline graphite, and Fe63Ni25Co6Si6wt% alloy powder is used. Under the conditions of temperature of 1480K and pressure of 6GPa, carbon atoms enter the alloy in the form of groups to form complete cementite;

[0028] Step 2: granulating the complete cementite obtained in step 1 by a vacuum vapor-mist method to obtain cementite particles;

[0029] Step 3: Mix the cementite particles obtained in step 2 with the graphite alloy catalyst powder in an inert gas atmosphere. The graphite alloy catalyst powder is high-purity graphite powder with a ratio of 10% of the iron-nickel catalyst powder, and the iron-nickel catalyst powder is Fe70Ni30 ;

[0030] Step 4: Compress the mixed powder, sinter in a vacuum environment at 800° C. for 2 hours, and then pe...

Embodiment 3

[0032] A kind of preparation method of artificial diamond synthetic graphite core post, comprises the following steps:

[0033] Step 1: Prepare cementite under high temperature and high pressure. The carbon source is artificial polycrystalline graphite, and Fe58Ni27Co8Si7wt% alloy powder is used. Under the conditions of temperature of 1550K and pressure of 4GPa, carbon atoms enter the alloy in the form of groups to form complete cementite;

[0034] Step 2: granulating the complete cementite obtained in step 1 by a vacuum vapor-mist method to obtain cementite particles;

[0035] Step 3: Mix the cementite particles obtained in step 2 with the graphite alloy catalyst powder in an inert gas atmosphere. The graphite alloy catalyst powder is high-purity graphite powder with a ratio of 14% of the iron-nickel catalyst powder, and the iron-nickel catalyst powder is Fe70Ni30 ;

[0036] Step 4: Compress the mixed powder, sinter in a vacuum environment at 700° C. for 2 hours, and then pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com