Machining technology of cam-mould special-shaped concave-mould

A processing technology and special-shaped technology, which is applied in the field of mold processing, can solve the problems that the mold contour cannot be guaranteed, the deformation amount is not the same, and the product contour cannot be guaranteed, so as to ensure the product contour, improve product quality, Guaranteed contour effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

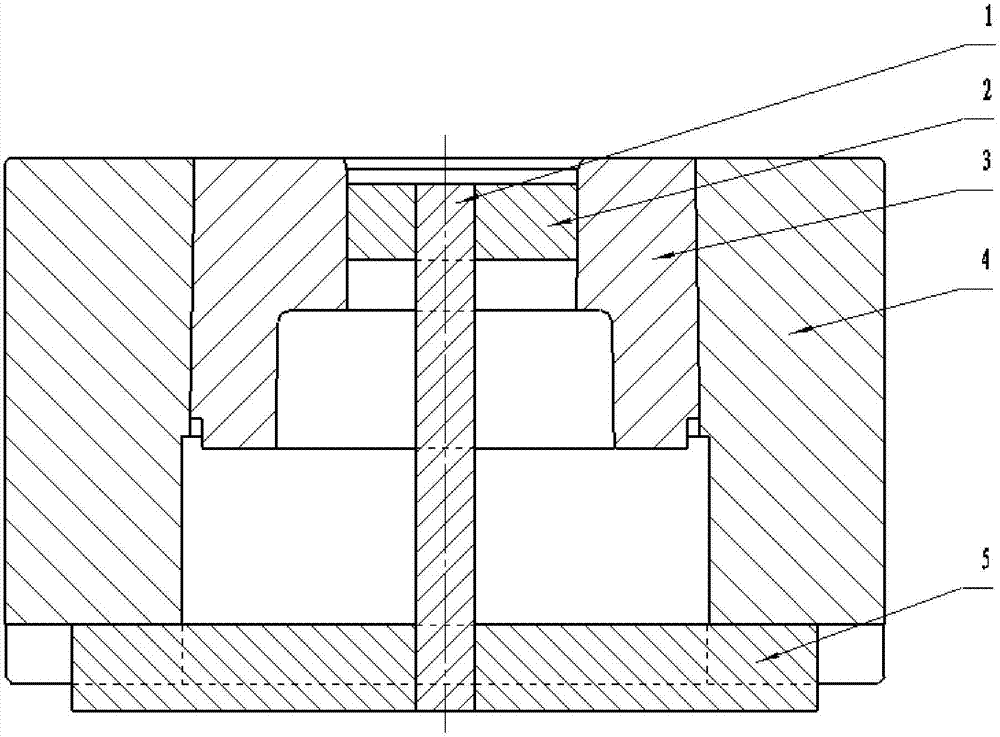

Image

Examples

Embodiment Construction

[0010] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0011] The processing technology of the special-shaped die of the cam die will be further described in detail below.

[0012] In the embodiment of the present invention, the specific processing technology is as follows: sawing material, rough turning, rough milling of special shape in machining center, heat treatment, CNC finish turning, flat grinding, pressure distribution, fine milling of special shape in machining center, grinding, decompression, S-N co-infiltration ,polishing.

[0013] One. Saw material, die among the present invention adopts common mold material.

[0014] 2. Rough car, conventional rough car.

[0015] 3. Machining center rough milling irregular shape, conventional milling irregular shape.

[0016] 4. Heat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com