Preparation method of N-type double-sided battery

A double-sided cell and N-type technology, applied in the field of solar cells, can solve problems such as high maintenance costs, unfavorable process control, and reduced electrical performance, and achieve the effects of reducing production costs, improving conversion efficiency, and saving process time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

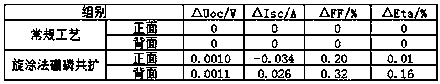

[0040] Embodiment 1: The present invention relates to a method for preparing an N-type double-sided battery. The silicon wafer size is 158mm*158mm. N-type silicon is selected for the following operations: ① Texturing; ② Spin-coating boron-phosphorus co-expansion; ③ HF cleaning; ④ Passive film deposited by AlOx and PECVD on the front side; ⑤ passivated film deposited by PECVD on the back side; ⑥ screen printing and sintering; ⑦ laser edge isolation;

[0041] The specific process of step ② in this embodiment is: use 1.5mL pre-wetting solution to coat first, and then use 0.5mL boron source for spin coating. The function of pre-wetting solution is to spread the boron source more quickly and effectively throughout the For the surface of the silicon wafer, in this embodiment, the model of prewetting liquid is PW-1, and the model of boron source is DS-2. After a step-by-step heating process, it is dried at 50°C, 100°C, 150°C, and 200°C for 8 seconds, so that the source liquid can be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com