Manufacturing method of PERT crystalline silicon solar cell using novel doping mode

A manufacturing method and technology for solar cells, which are applied to circuits, photovoltaic power generation, electrical components, etc., can solve problems such as low efficiency and complicated procedures, and achieve the effects of reducing procedures, improving efficiency, and saving costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A method for manufacturing a PERT crystalline silicon solar cell using a novel doping method, comprising the following steps:

[0026] (1) Silicon wafer 1 single-sided texturing, cleaning: select P-type silicon wafer 1, and use a mass fraction of 1.0% sodium hydroxide solution to chemically etch the surface of P-type silicon wafer 1 at 78 ° C to prepare a pyramid shape The suede surface is cleaned with hydrofluoric acid with a mass fraction of 12% to remove surface impurities;

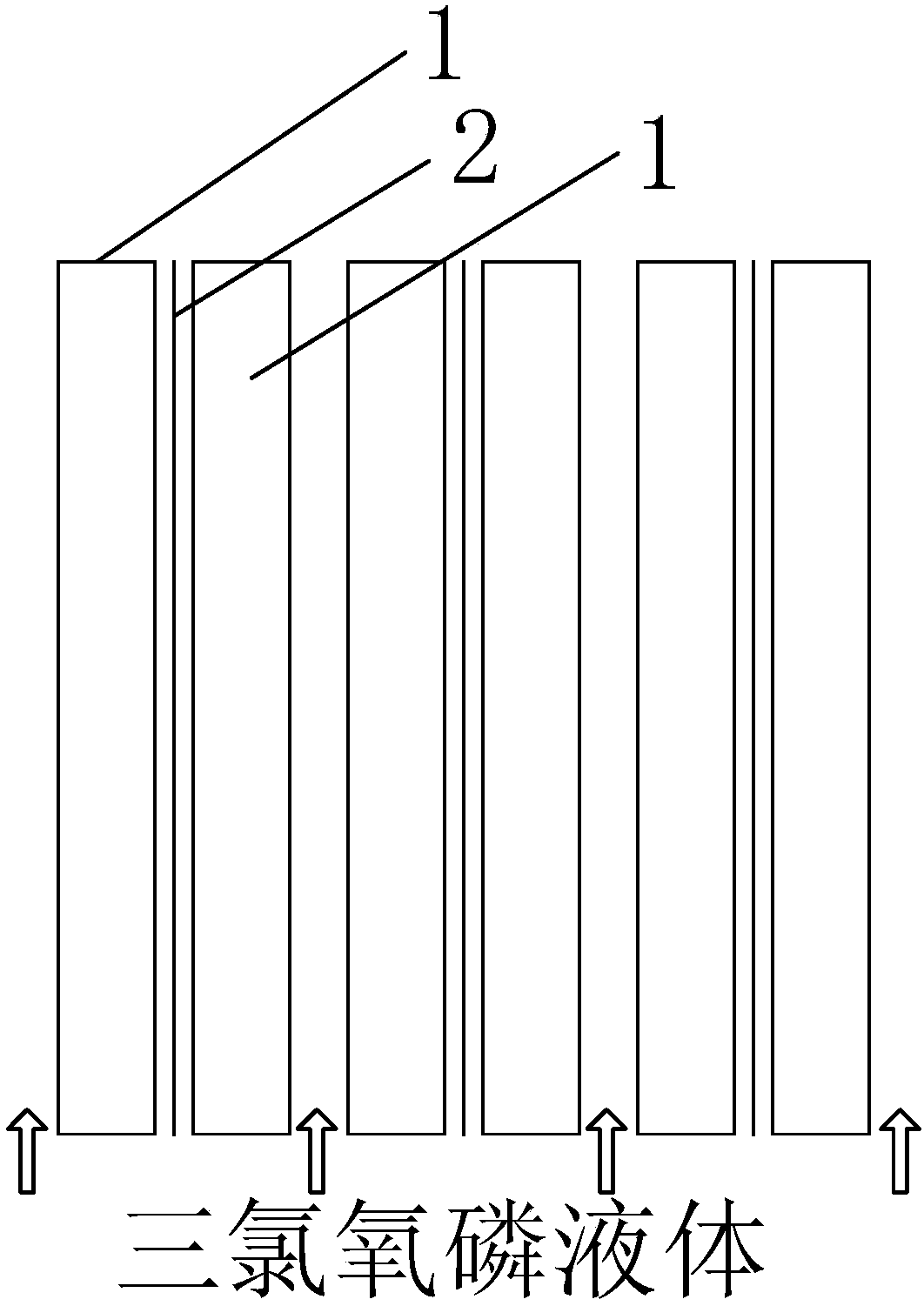

[0027] (2) B, P co-expansion process is adopted, the front P is diffused, and the back B is diffused. Two silicon wafers 1 form a group, and each group of silicon wafers 1 is diffused in a vertical back-to-back manner. Insert the paper-like solid source B source 2 (available in the market), and carry out front phosphorus diffusion by passing phosphorus oxychloride on the front; push the diffusion furnace to perform high-temperature co-diffusion, so that an n+ doped layer is formed on the front o...

Embodiment 2

[0035] A method for manufacturing a PERT crystalline silicon solar cell using a novel doping method, comprising the following steps:

[0036] (1) Silicon wafer 1 single-sided texturing, cleaning: select P-type silicon wafer 1, and use a mass fraction of 1.4% sodium hydroxide solution to chemically etch the surface of P-type silicon wafer 1 at 82°C to prepare a pyramid shape The suede surface is cleaned with hydrofluoric acid with a mass fraction of 18% to remove surface impurities;

[0037] (2) B, P co-expansion process is adopted, the front P is diffused, and the back B is diffused. Two silicon wafers 1 form a group, and each group of silicon wafers 1 is diffused in a vertical back-to-back manner. Insert the paper-like solid source B source 2, and use phosphorus oxychloride on the front side to carry out front-side phosphorus diffusion; push the diffusion furnace to perform high-temperature co-diffusion, so that an n+ doped layer is formed on the front side of the silicon waf...

Embodiment 3

[0045] A method for manufacturing a PERT crystalline silicon solar cell using a novel doping method, comprising the following steps:

[0046] (1) Silicon wafer 1 single-sided texturing, cleaning: select P-type silicon wafer 1, and use a mass fraction of 1.2% potassium hydroxide solution to chemically etch the surface of P-type silicon wafer 1 at 80 ° C to prepare a pyramid shape The suede surface is cleaned with 15% hydrofluoric acid to remove surface impurities;

[0047] (2) B, P co-expansion process is adopted, the front P is diffused, and the back B is diffused. Two silicon wafers 1 form a group, and each group of silicon wafers 1 is diffused in a vertical back-to-back manner. Insert the paper-like solid source B source 2, and use phosphorus oxychloride on the front side to carry out front-side phosphorus diffusion; push the diffusion furnace to perform high-temperature co-diffusion, so that an n+ doped layer is formed on the front side of the silicon wafer 1, and a p+ dope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com