Titanium alloy gear with ferroboron diffusion layer on surface and co-diffusion method thereof

A technology of boron-iron alloys and titanium alloys, which is applied to elements with teeth, belts/chains/gears, metal material coating processes, etc., can solve the problems of complex preparation methods of titanium alloy gears, poor surface wear resistance of titanium alloys, hydrogen atoms, etc. Easy to infiltrate and other problems, achieve process optimization, good wear resistance, and improve surface properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment l

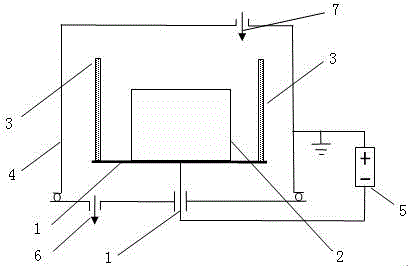

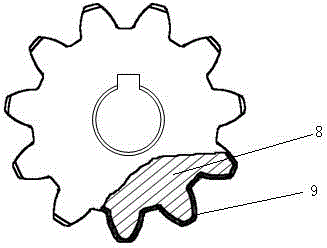

[0026] Plasma boronizing technology is used to form a boron-iron diffusion layer on the surface of gears made of Ti6Al4V alloy (α+β titanium alloy). The source electrode 3 composed of FeB and the Ti6Al4V gear are placed on the same cathode tray 1, the gear is centered, the source electrode is outside, and the distance between the two is 25 mm. Vacuumize to less than 1Pa, fill with argon to raise the pressure to 45Pa, apply a voltage of -690V between the cathode tray 1 and the vacuum container 4, so that the gear temperature rises to 850°C, keep the temperature for 3 hours, and slowly cool to room temperature with the furnace Serve.

[0027] The titanium alloy gear formed through the above process is still a Ti6Al4V alloy composed of α+β phase. The surface layer of each part of the gear tooth is a uniformly distributed iron-boroned layer with a thickness of 0.02mm. The boron content on the surface is 10.4%. The iron content is 20.3%, and the alloy element content gradually dec...

Embodiment 2

[0029] The boron-iron diffusion layer is formed on the surface layer of the gear made of Ti6Al4V alloy material by plasma boronizing technology. The source electrode 3 composed of FeB and the Ti6Al4V gear are placed on the same cathode tray 1, the gear is centered, the source electrode is outside, and the distance between the two is 25mm. Vacuumize to less than 1Pa, fill with argon to raise the pressure to 45Pa, apply a voltage of -780V between the cathode tray 1 and the vacuum container 4, and raise the temperature of the gear to 950°C, keep it warm for 10 hours, and slowly cool to room temperature with the furnace Serve.

[0030] The titanium alloy gear formed through the above process is still a Ti6Al4V alloy composed of α+β phase. The surface layer of each part of the gear tooth is a uniformly distributed iron-boroned layer with a thickness of 0.09mm. The boron content on the surface is 11.3%. The iron content is 28.6%, and the alloy element content gradually decreases fr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com