High-performance air cylinder sleeve and production technology and surface treatment method of high-performance air cylinder sleeve

A technology of production process and treatment method, applied in the direction of metal material coating process, coating, solid diffusion coating, etc., can solve problems such as failure, poor performance, difficulty in meeting the strength requirements of high-performance engine cylinder liner, etc., to prevent The effect of carbon deposition, tensile strength and elastic modulus improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

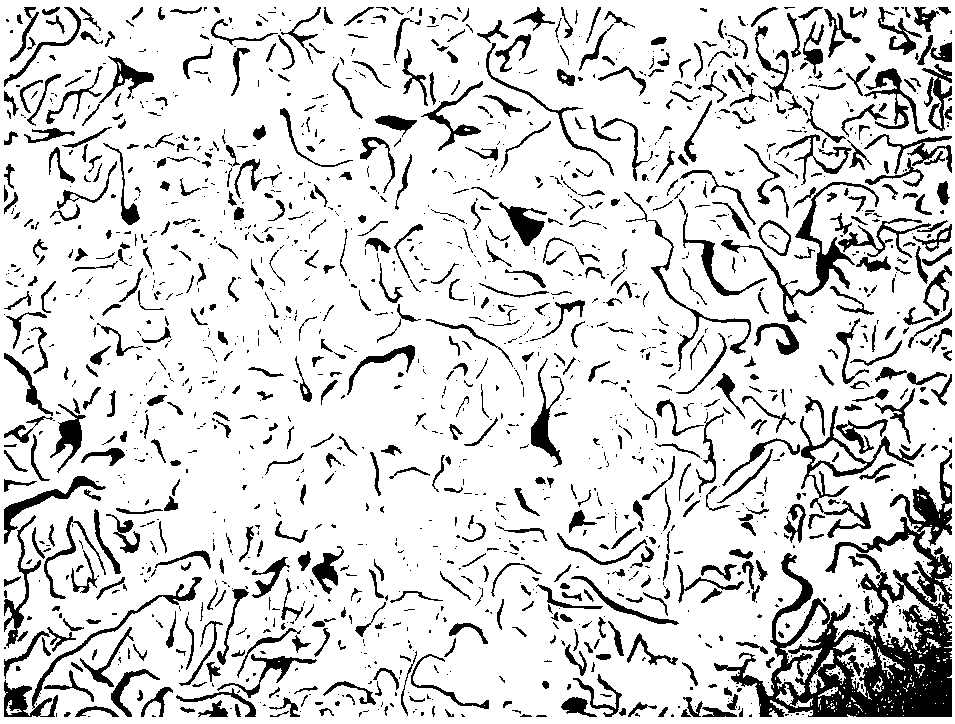

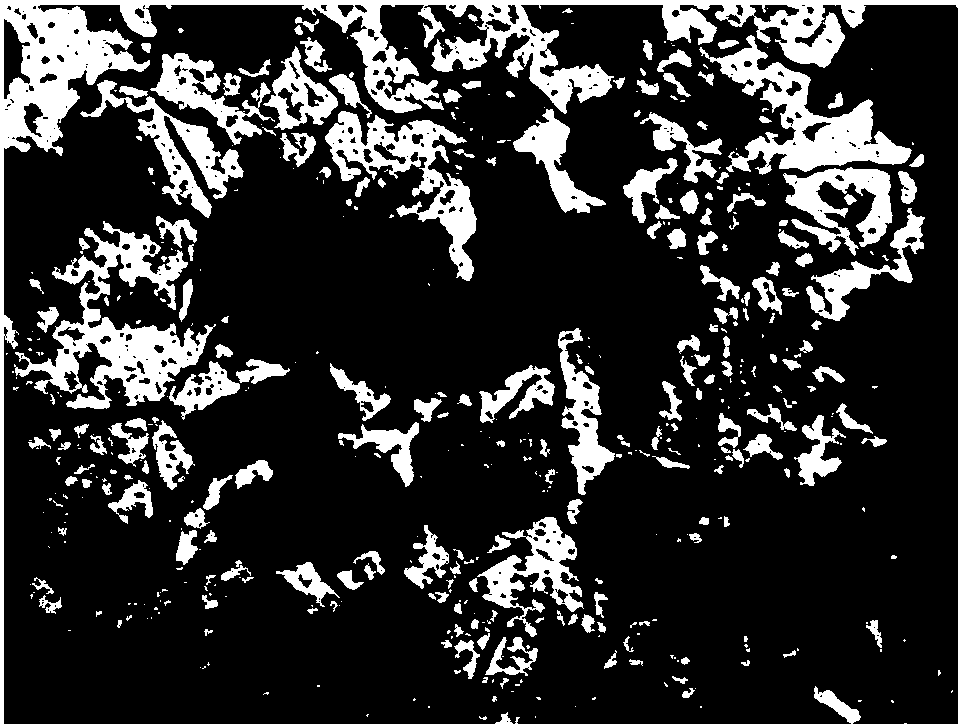

Image

Examples

Embodiment 1

[0057] 1) Composition design of the cylinder liner:

[0058] C 2.6, Si 3.15, P 0.5, S 0.05, Mn 1.8, Cu 1.7, Cr 0.6, Nb 0.65, and the balance is iron.

[0059] 2) Preparation of cylinder liner blanks:

[0060] The cylinder liner blank is produced by a water-cooled metal mold centrifugal casting method, the smelting temperature is 1450-1500° C., the smelted molten iron is left to stand for 15 minutes, and then inoculated. The inoculant used for the first inoculation is Ningxia Zhufeng 75SiFe, which is added in a downstream inoculation method. The amount added is 0.7% of the weight of molten iron, and the particle size is 1-2mm; the inoculant used for the second inoculation is Ningxia Zhufeng silicon strontium inoculation The mixture of silicon carbide inoculant and metallurgical silicon carbide (C content 28wt%, Si content 62wt%), the mass ratio of silicon strontium inoculant to metallurgical silicon carbide is 4:1. %, particle size 0.4 ~ 0.5mm. A single-station centrifugal p...

Embodiment 2

[0070] 1) Composition design of the cylinder liner:

[0071] C 2.56, Si 3.29, P 0.6, S 0.07, Mn 1.8, Cu 1.9, Cr 0.8, Nb 0.8, and the balance is iron.

[0072] 2) Preparation of cylinder liner blanks:

[0073] The cylinder liner blank is produced by a water-cooled metal mold centrifugal casting method, the smelting temperature is 1450-1500° C., the smelted molten iron is left to stand for 15 minutes, and then inoculated. The inoculant used for the first inoculation is Ningxia Zhufeng 75SiFe, which is added in a downstream inoculation method. The amount added is 0.7% of the weight of molten iron, and the particle size is 1-2mm; the inoculant used for the second inoculation is Ningxia Zhufeng silicon strontium inoculation The mixture of silicon carbide inoculant and metallurgical silicon carbide (C content 28wt%, Si content 62wt%), the mass ratio of silicon strontium inoculant to metallurgical silicon carbide is 4:1. %, particle size 0.4 ~ 0.5mm. A single-station centrifugal p...

Embodiment 3

[0083] Referring to Example 1 to prepare the cylinder liner, the only difference is that the surface treatment in step 3) is not performed after the blank is machined into a finished product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com