Putty for external wall spraying and preparation method of putty

A putty and exterior wall technology, applied in construction, building structure, covering/lining, etc., can solve the problems of difficult mechanized construction of exterior wall spray putty, high cost of formulation system, poor sandability, etc. Skeleton effect, the effect of improving sandability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

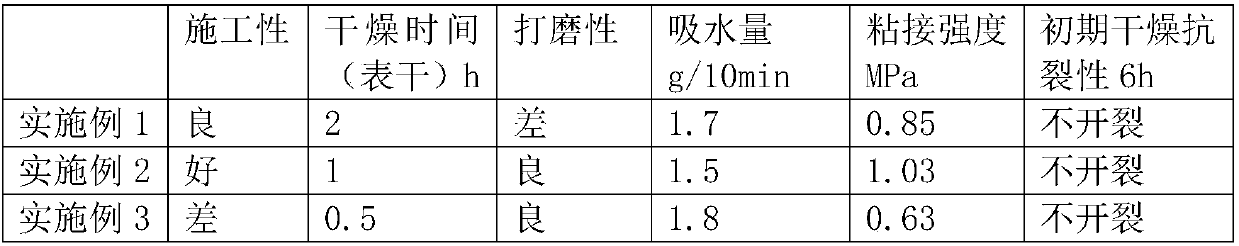

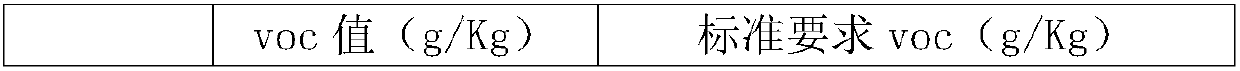

Embodiment 1

[0028] The formula of the external wall spray putty is calculated by mass: 265 parts of 325# gray cement, 290 parts of 325 mesh heavy calcium, 310 parts of 80-120 mesh snowflake white, 110 parts of 400 mesh talcum powder, 1 part of lignocellulose, fiber 6 parts of plain ether, 8 parts of rubber powder, 4 parts of F10 superplasticizer, 2 parts of 601 attapulgite and 4 parts of FP6 starch ether.

Embodiment 2

[0030] The formula of this external wall spraying putty is calculated by mass: 280 parts of gray cement, 279 parts of heavy calcium, 40 parts of 40-80 mesh snowflake white sand, 279 parts of 80-120 mesh snowflake white sand, 100 parts of talcum powder, 2 parts of lignocellulose 4 parts, 4 parts of cellulose ether, 6 parts of rubber powder, 4 parts of water reducer, 4 parts of attapulgite and 2 parts of starch ether.

Embodiment 3

[0032] The formula of the external wall spray putty is calculated by mass: 310 parts of 325# gray cement, 250 parts of 325 mesh heavy calcium, 50 parts of 40-80 mesh snowflake white sand, 260 parts of 80-120 mesh snowflake white sand, 106 parts of 400 mesh talcum powder 3 parts, 3 parts of lignocellulose, 3 parts of cellulose ether, 10 parts of rubber powder, 2 parts of water reducing agent, 3 parts of attapulgite and 3 parts of starch ether.

[0033] When the above-mentioned exterior wall spray putty is prepared, gray cement, heavy calcium and talcum powder are put into a mixer in turn for mixing, and then lignocellulose, cellulose ether, rubber powder, water reducer, attapulgite and starch ether are put in and mixed in turn, Finally, add snowflake white and mix evenly to obtain putty for exterior wall spraying.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com