Attapulgite-based iron oxide red composite pigment and preparation method thereof

A technology of iron oxide red and composite pigments, applied in the direction of pigment paste, etc., can solve the problems of poor color performance of iron oxide red pigments, high toxicity of cadmium red pigments, low redness and brightness, etc., achieve superior pigment performance and improve dispersibility The effect of improving uniformity and color performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

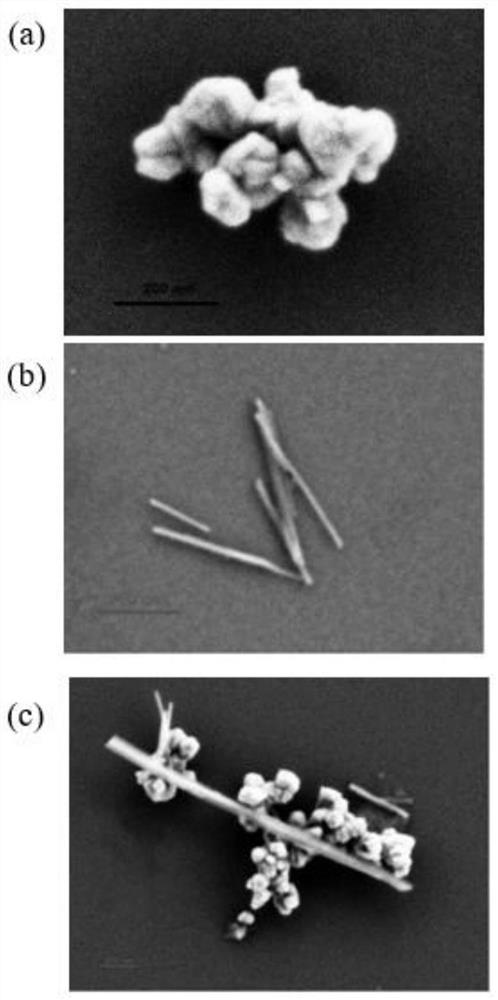

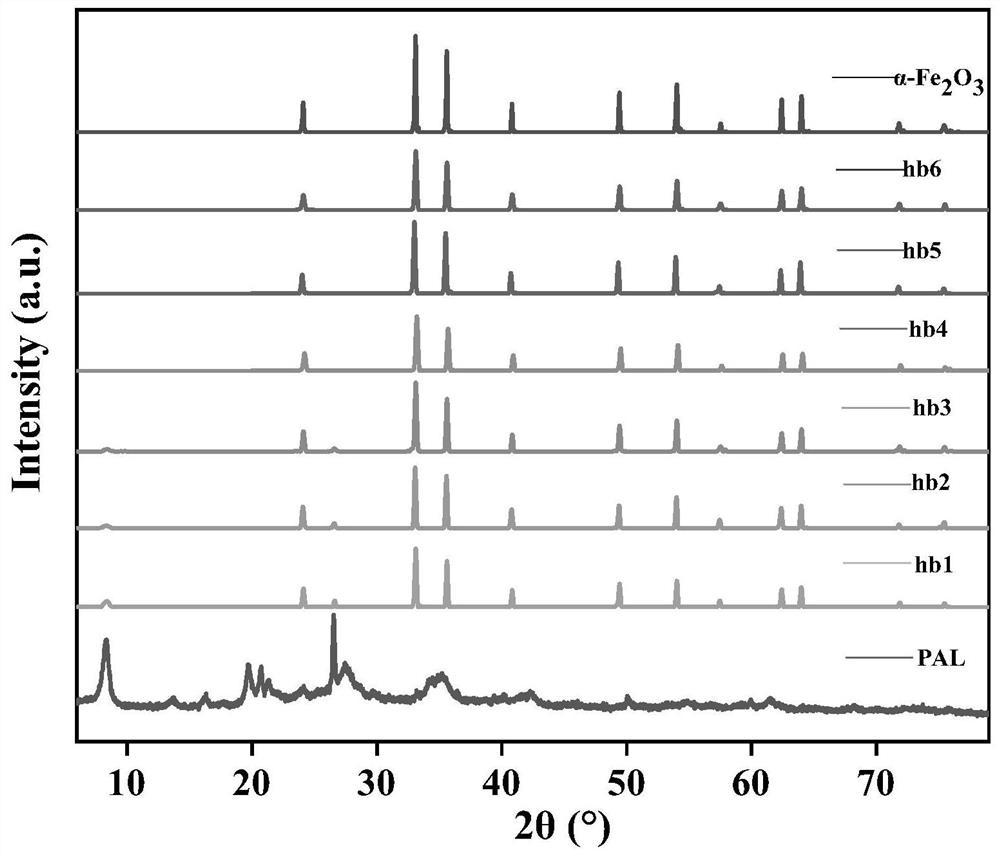

[0029] A new method for iron oxide red composite pigments, comprising the following steps: 1) adding 8% to 10% (mass fraction, the same below) attapulgite (No. 1) and 8% to 8% to two groups of deionized water respectively 10% red iron oxide (No. 2). 2) Add 0.08%-0.2% sodium hexametaphosphate to No. 1 solution, add 0.08%-0.2% anionic polymer and 0.5%-1% defoamer to No. 2 solution, and stir. 3) At the speed of 950-1250r / min, use a high-speed dispersing mixer to disperse the two groups of solutions for 60-75min. 4) Mix the two groups of solutions, add zirconia beads, grind and immobilize with a dispersing disc mixer for 60-90 minutes at a speed of 1350-1650 r / min. 5) drying, grinding and filtering to obtain attapulgite iron oxide red composite pigment (hb1).

Embodiment 2

[0031] A new method for iron oxide red composite pigments, comprising the following steps: 1) adding 4% to 5% attapulgite (No. 1) and 8% to 10% iron oxide red (2 No). 2) Add 0.08%-0.1% sodium hexametaphosphate to No. 1 solution, add 0.08%-0.2% anionic polymer and 0.4%-0.8% defoamer to No. 2 solution, and stir. 3) At the speed of 950-1200r / min, use a high-speed dispersing mixer to disperse the two groups of solutions for 60-75min. 4) Mix the two groups of solutions, add zirconia beads, grind and immobilize with a dispersing disc mixer for 60-90 minutes at a speed of 1350-1650 r / min. 5) drying, grinding and filtering to obtain attapulgite iron oxide red composite pigment (hb2).

Embodiment 3

[0033] A new method for iron oxide red composite pigments, comprising the following steps: 1) adding 0.5% to 1.5% attapulgite (No. 1) and 2% to 3% iron oxide red (2 No). 2) Add 0.05%-0.1% sodium hexametaphosphate to No. 1 solution, add 0.2%-0.3% anionic polymer and 0.2%-0.4% defoamer to No. 2 solution, and stir. 3) At the speed of 950-1250r / min, use a high-speed dispersing mixer to disperse the two groups of solutions for 60-75min. 4) Mix the two groups of solutions, add zirconia beads, grind and immobilize with a dispersing disc mixer for 60-90 minutes at a speed of 1350-1650 r / min. 5) drying, grinding and filtering to obtain the attapulgite iron oxide red composite pigment (hb3).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com