Anticorrosive unhusked rice drying device

A drying device and anti-corrosion technology, which is applied in the direction of drying and preserving seeds, can solve the problems that the inner wall of the ground shell is easily corroded and pollutes rice, and achieves the effect of protecting against corrosion and pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

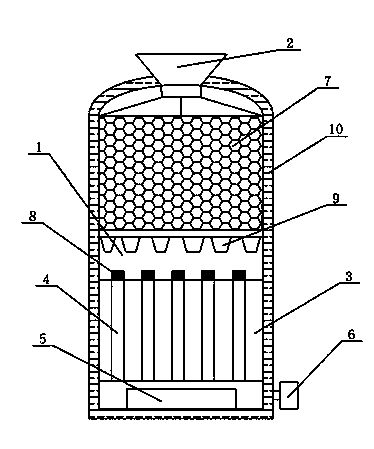

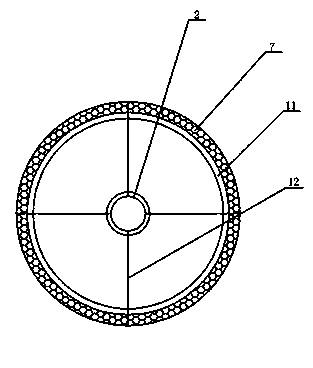

[0012] Below in conjunction with accompanying drawing and embodiment the technical solution of the present invention is further described:

[0013] like figure 1 and figure 2 As shown, the present invention provides a kind of anti-corrosion rice drying device, comprising a housing, a drying chamber 3, a preheating chamber 1 with a funnel-shaped feed inlet 2 at the top, and an electric heating chamber that can generate warm air (in the figure Not marked), the inner wall of the shell is provided with a layer of anti-corrosion layer 10, and a columnar steel mesh 7 with upper and lower openings is connected below the feed port 2. Water-absorbing cloth 11 is sleeved in the net 7, a plurality of material ejection outlets 9 are arranged under the columnar steel net 7, a stainless steel electric heating plate 5 is arranged in the electric heating chamber, and a centrifugal fan 6 is connected outside the electric heating chamber. A plurality of ventilation pipes 4 with through hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com