Smoke cooling control method and system in dedusting process of electric furnace

A technology of flue gas cooling and control method, which is applied to furnace control devices, furnaces, furnace components, etc., can solve the problem of high consumption cost of flue gas cooling, and achieve the effect of facilitating falling and conveying and ensuring drying.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] In order to fully understand the purpose, features and effects of the present invention, the present invention will be described in detail through the following specific embodiments, but the present invention is not limited thereto.

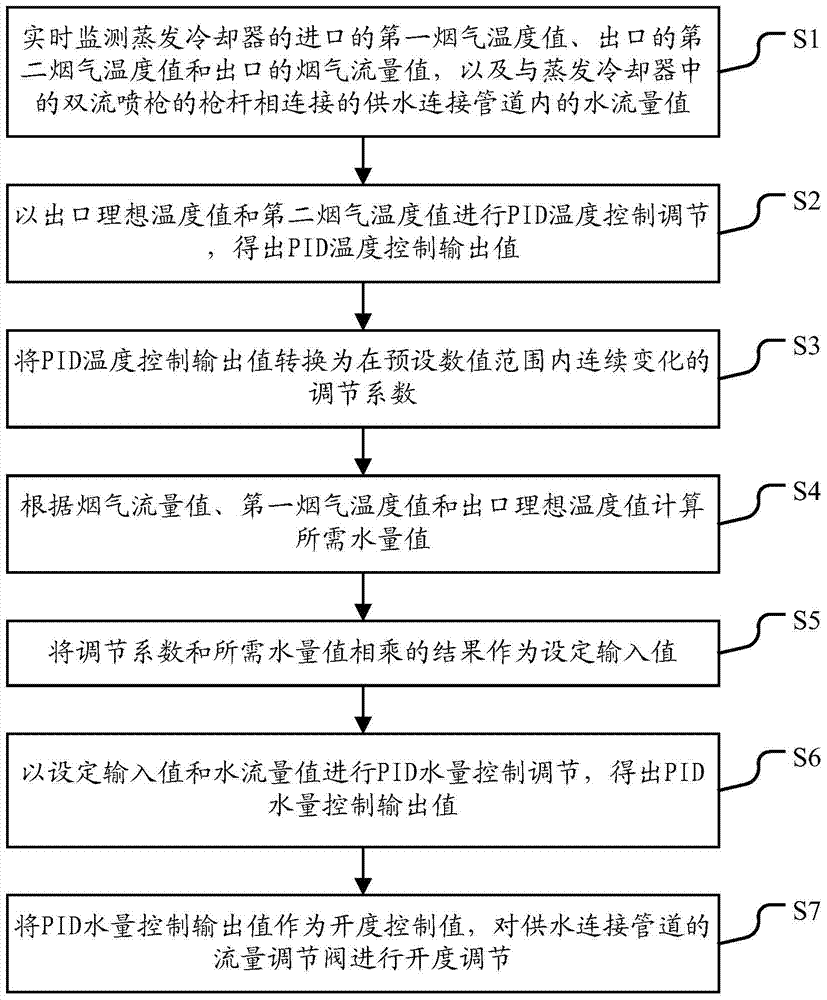

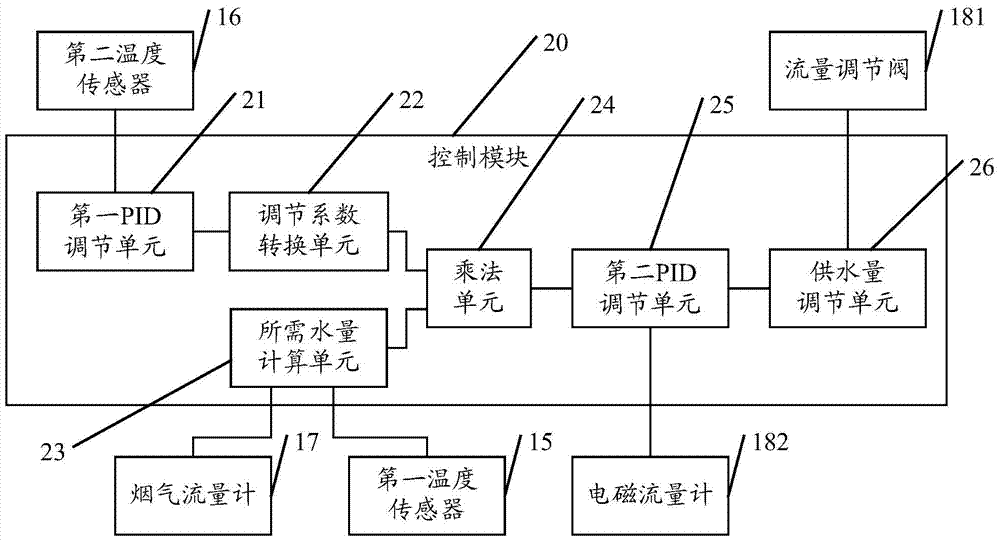

[0058] The first embodiment of the present invention provides a flue gas cooling control method in the process of electric furnace dust removal, the flue gas cooling control method is applied to the flue gas cooling control system used in the electric furnace dust removal process, the flue gas cooling control system includes The dual-flow spray gun of the evaporative cooler performs feedback control according to the outlet temperature to cool and remove high-temperature flue gas.

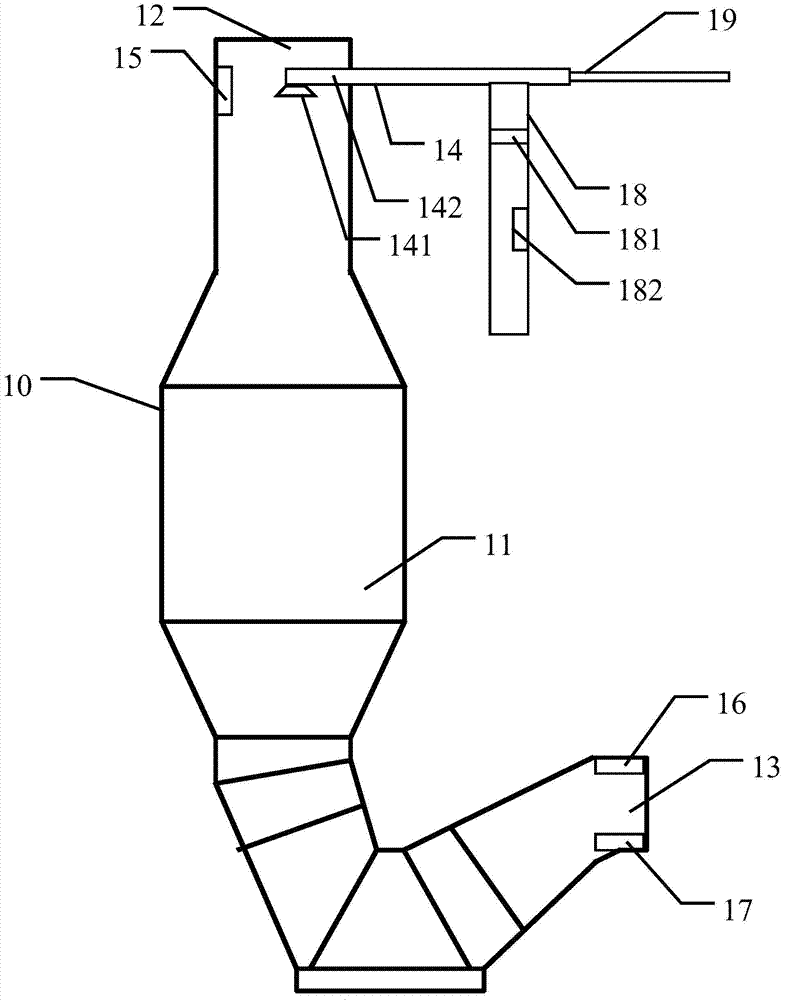

[0059]figure 1 is the structural diagram of the evaporative cooler of the embodiment of the present invention, as figure 1 As shown, the evaporative cooler 10 includes: a cylinder body 11, an inlet 12 and an outlet 13 arranged on the cylinder body 11, a double-f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com