Technology for producing mosaic glass body

A preparation process and technology of glass gobs, which are applied in glass manufacturing equipment, glass molding, manufacturing tools, etc., can solve the problems of single structural characteristics of mosaic glass blanks, low regularity of mosaic glass blanks, and limited pattern decoration diversity, etc. , to achieve the effect of facilitating size adjustment, saving labor costs, and bright pattern effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

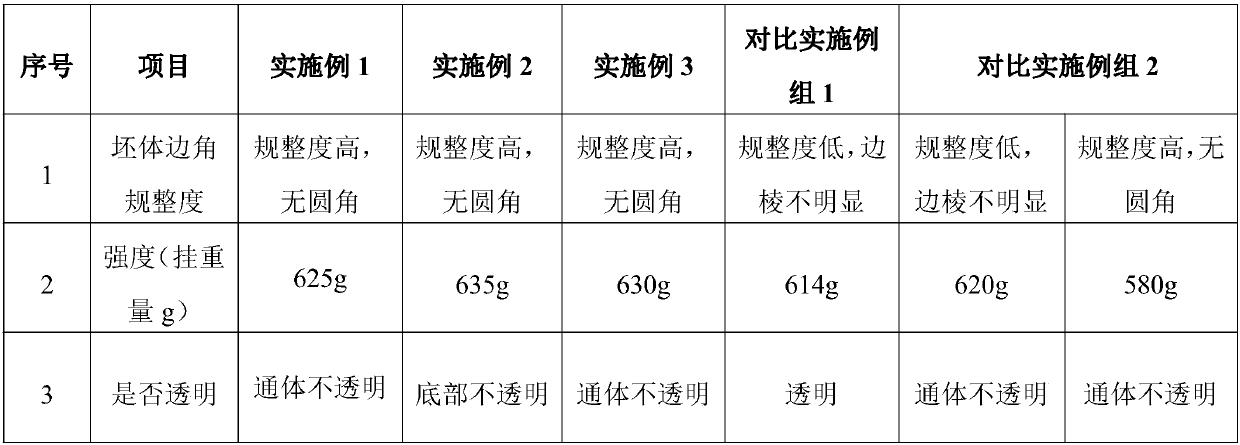

Examples

Embodiment 1

[0021] Embodiment 1-a kind of preparation technology of mosaic glass body, comprises the steps:

[0022] (1) Mix 95% raw glass powder and 5% waste glass powder evenly according to mass percentage to obtain a mixture;

[0023] (2) adding water ball milling to the mixture obtained in step (1) to obtain a slurry, and performing granulation and sieving to obtain a mixed green body powder;

[0024] (3) Put the mixed green body powder into a mold, press to form, and perform low-temperature firing at a temperature of 750° C. to obtain a mosaic glass body with a thickness of 1.45 mm.

Embodiment 2

[0025] Embodiment 2-a kind of preparation technology of glass mosaic, comprises the steps:

[0026] (1) Mix 80% raw glass powder and 20% waste glass powder evenly according to mass percentage to obtain a mixture;

[0027] (2) adding water ball milling to the mixture obtained in step (1) to obtain a slurry, and performing granulation and sieving to obtain a mixed green body powder;

[0028] (3) After putting the mixed green body powder into the mould, the green glass powder is arranged above the mixed green body powder, and uniformly pressed and formed, wherein the thickness of the green body is 1.55 mm;

[0029] (4) Glazing: The surface of the pressed mosaic glass body is applied with a low-temperature glaze under a constant pressure of 0.3Mpa, and the thickness of the glaze is 0.05mm;

[0030] (5) Inkjet printing: Inkjet printing is carried out on the surface of the mosaic glass body with low-temperature glaze applied;

[0031] (6) The ink-jet printed mosaic glass body was ...

Embodiment 3

[0032] Embodiment 3-a kind of preparation technology of glass mosaic, comprises the steps:

[0033] (1) Mix 90% raw glass powder and 10% waste glass powder evenly according to the mass percentage to obtain a mixture;

[0034] (2) adding water ball milling to the mixture obtained in step (1) to obtain a slurry, and performing granulation and sieving to obtain a mixed green body powder;

[0035] (3) Put the mixed green body powder into the mould, press and form, wherein the thickness of the green body is 1.50mm;

[0036] (4) Glazing: the surface of the pressed mosaic glass body is applied with a low-temperature glaze under a constant pressure condition of 2.5Mpa, and the thickness of the glaze is 0.15mm;

[0037] (5) Inkjet printing: Inkjet printing is carried out on the surface of the mosaic glass body with low-temperature glaze applied;

[0038] (6) The ink-jet printed mosaic glass body was fired at a low temperature of 780° C. to obtain a glass mosaic 2 with an opaque struc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com