Copper/tin/graphite multi-layer structure anode material for lithium-ion battery and preparation method of copper/tin/graphite multi-layer structure anode material

A lithium-ion battery, multi-layer structure technology, applied in battery electrodes, secondary batteries, structural parts, etc., can solve the problems of low specific capacity and insufficient cycle performance of graphite negative electrodes, and achieve high charge-discharge specific capacity and high-rate charge. The effect of excellent discharge performance, good electrical conductivity and cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

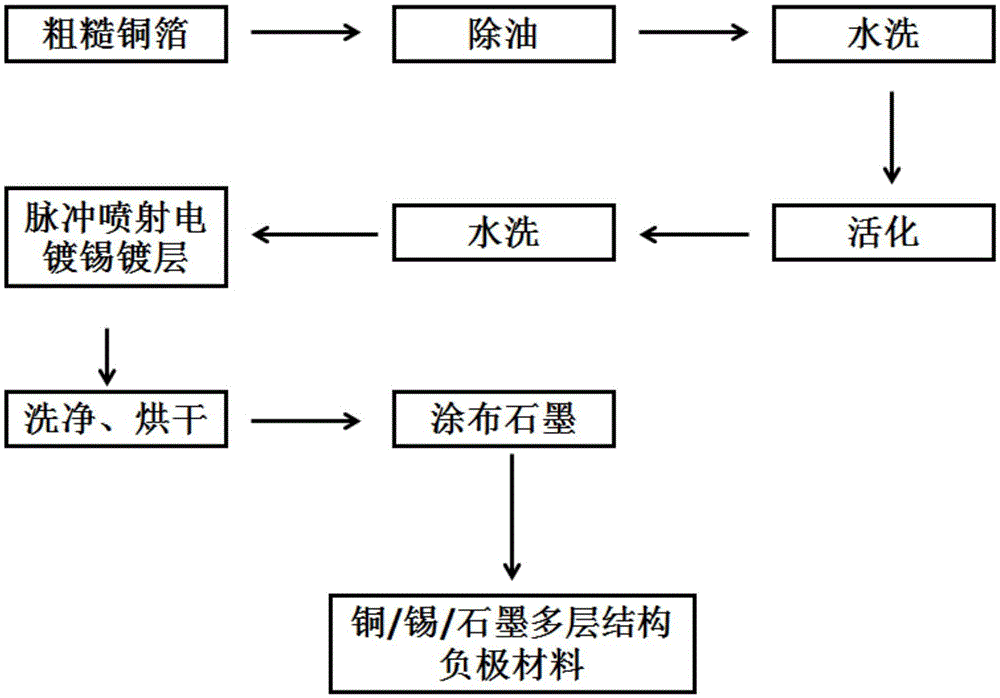

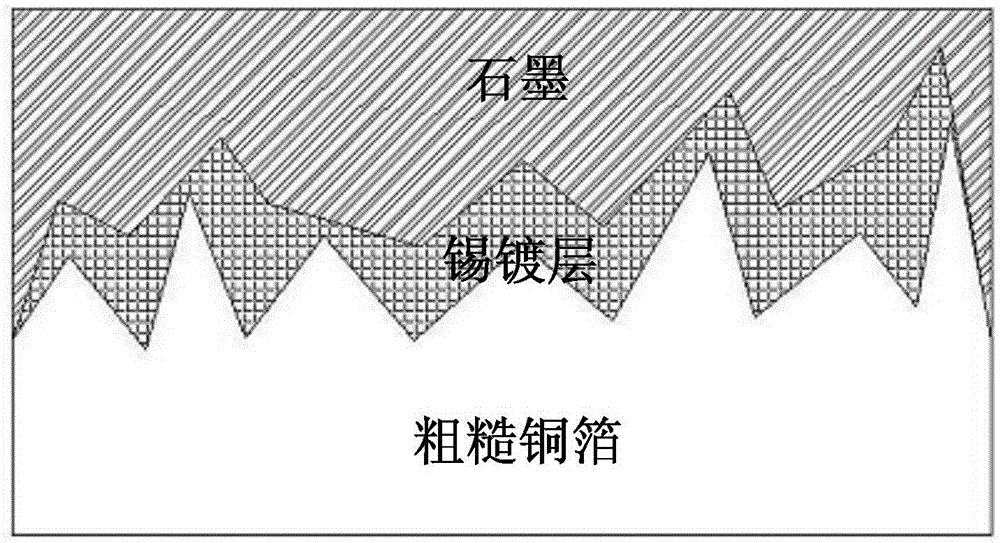

[0071] A rough copper foil with a thickness of 15 μm and a roughness of 0.4 μm was selected as the electroplating substrate.

[0072] 1. Surface pretreatment before plating: perform electrochemical degreasing and activation treatment on the base copper foil;

[0073]

[0074] Electrolytic degreasing current density: 5A / dm 2

[0075] Degreasing fluid temperature: 55°C;

[0076] Degreasing time: 30s;

[0077] After the oil is completely removed, put it into the activator to activate;

[0078] The activator is: H 2 SO 4 : 30ml / L;

[0079] Activation temperature: room temperature;

[0080] Activation time: 20s.

[0081] 2. Pulse jet plating tin coating with a thickness of 0.5 μm:

[0082]

[0083] Pulse electroplating process parameters: average current density: 5A / dm 2 ;

[0084]

[0085] 3. Rinsing and drying: Rinse the tinned copper foil after electroplating with distilled water, and then dry it.

[0086] 4. Coating graphite layer: Coating a 100 μm thick gr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com