Processing method of inferior heavy oil, hydrogenation protection catalyst and application

A low-quality heavy oil, hydrogenation protection technology, applied in catalyst protection, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc., can solve the problem of reduced mechanical strength and large pore volume ratio of hydrogenation protection catalysts , the problem of low demetallization rate of hydrogenation protection catalysts, etc., to achieve the effect of improving comprehensive economy, strong metal holding capacity, and uniform dispersion of active components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0052] In some embodiments, the preparation method of the carrier includes: firstly mixing alumina with a toluene solution of fullerene, then adding an extrusion aid, then extruding into a strip, and then drying and calcining.

[0053] Further, the amount of the fullerene is 0.1-0.6 wt % of the total mass of the carrier, preferably 0.2-0.5 wt %.

[0054] Further, the fullerene is formed by dissolving fullerene in toluene.

[0055] In the catalyst of the present invention, before the fullerene in the carrier is mixed with alumina, it is first dissolved in toluene. The dissolving temperature of the toluene is 20-40°C, the pressure is 0.10-0.25MPa, and the dissolution time is 20-40°C. is 3-10 min; the mass ratio of toluene and fullerene used for the toluene dissolving is 200-350:1.

[0056] Further, the fullerene adopts C60 fullerene powder, and the purity is ≥99.5wt%.

[0057] Further, the preparation method includes: mixing and stirring toluene and alumina to form the slurry ...

Embodiment 1

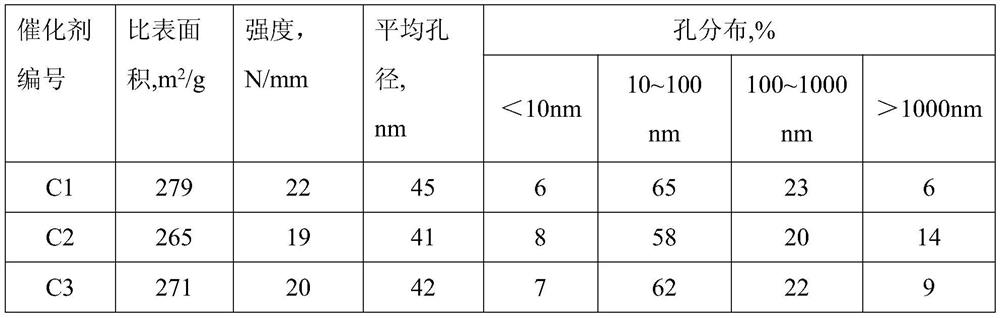

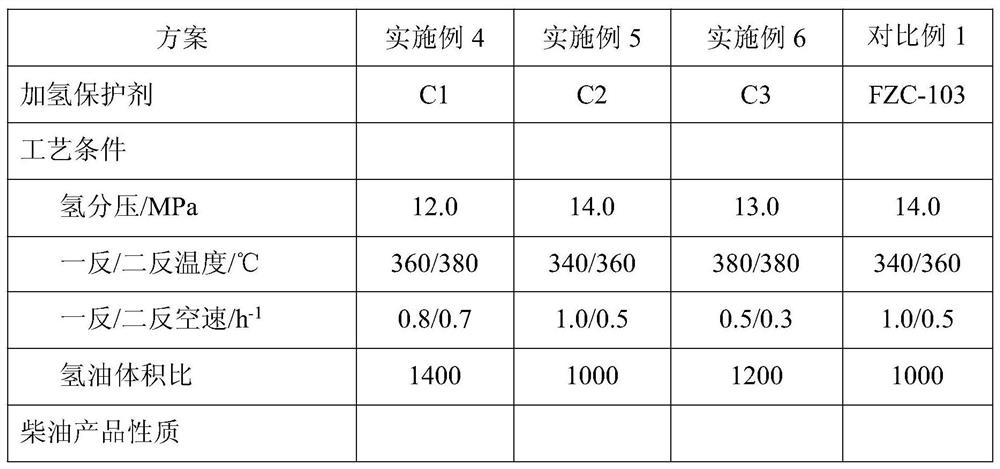

[0092] Example 1 Preparation of hydrogenation protection catalyst C1

[0093] (1) Preparation of catalyst carrier:

[0094] Dissolve 0.50 g of fullerene C60 powder with a purity of 99.5% with 138 g of toluene for 6 minutes at a pressure of 0.10 MPa and 30 °C to obtain a purple fullerene solution; the pore volume is 1.1-1.6 cm 3 / g of commercially available macroporous alumina powder 99g, add 20g of toluene and make into a slurry; add the fullerene solution to the slurry alumina at a drop rate of 3g / s, stir and mix thoroughly, and drop the fullerene during the process. Add an extrusion aid, such as citric acid, in an amount that meets the shape of the carrier, and then knead, roll, and extrude into a strip shape; dry the extruded strip carrier at room temperature, and then place it in an oven at 140°C Bake for 6 hours, and break it into about 3 to 5 mm for later use; put the drying strip in a muffle furnace, and bake it at 580° C. for 8 hours to obtain a carrier.

[0095] (2)...

Embodiment 2

[0097] The preparation of embodiment 2 hydrogenation protection catalyst C2

[0098] (1) Preparation of catalyst carrier:

[0099] Dissolve 0.40 g of fullerene C60 powder with a purity of 99.9% in 140 g of toluene at a pressure of 0.25 MPa and 40 ° C for 10 min to obtain a purple fullerene solution; the pore volume is 1.1 to 1.6 cm 3 / g of commercially available macroporous alumina powder 99g, add 33g of toluene and make into a slurry; add the fullerene solution to the slurry alumina at a drop rate of 5g / s, stir and mix thoroughly, and drop the fullerene during the process. Add extrusion aids, such as citric acid, in an amount that meets the requirements of the carrier molding, and then knead, roll, and extrude into strips; dry the extruded strip carriers at room temperature, and then place them in an oven at 160°C Bake for 4 hours, and break it into about 3-5 mm for later use; put the dry strip in a muffle furnace, and bake it at 450° C. for 15 hours to obtain a carrier.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com