Patents

Literature

43results about How to "Emission reduction and efficiency increase are beneficial" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

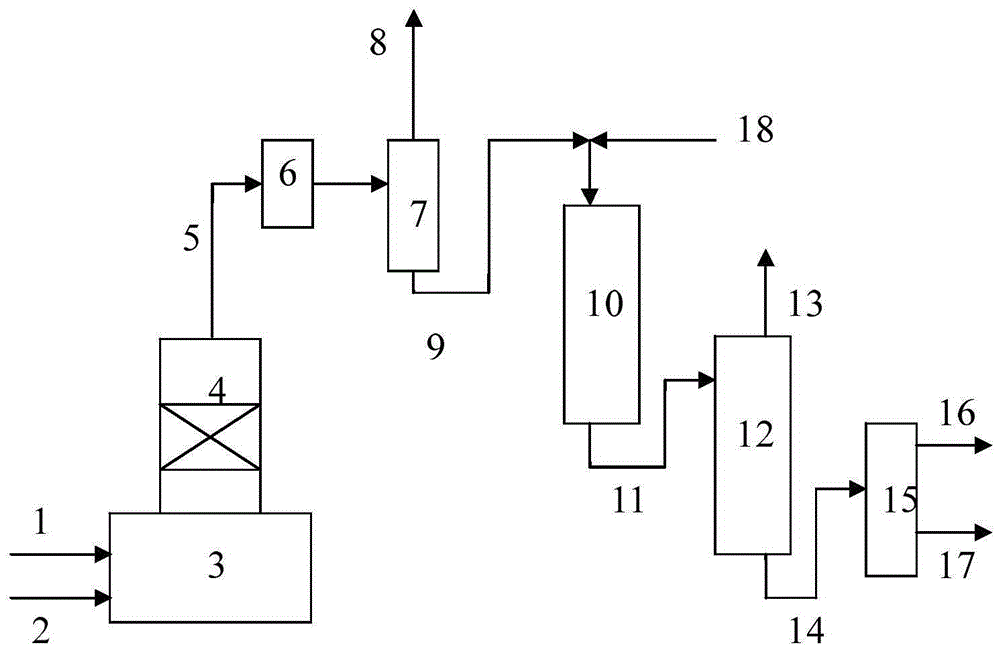

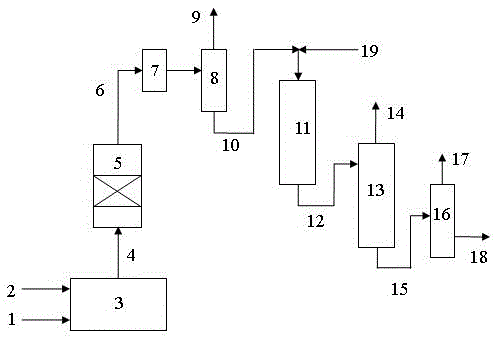

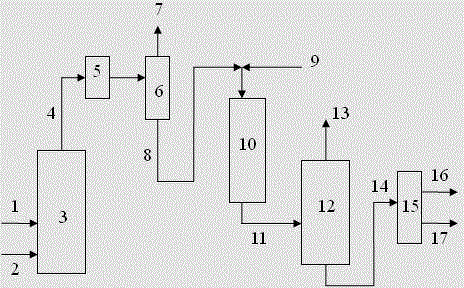

Method for processing ethylene tar

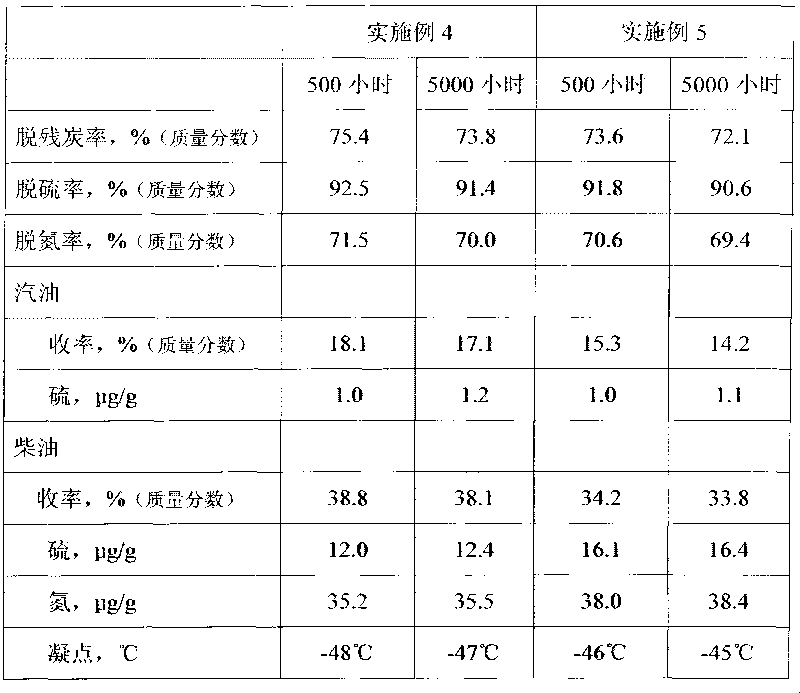

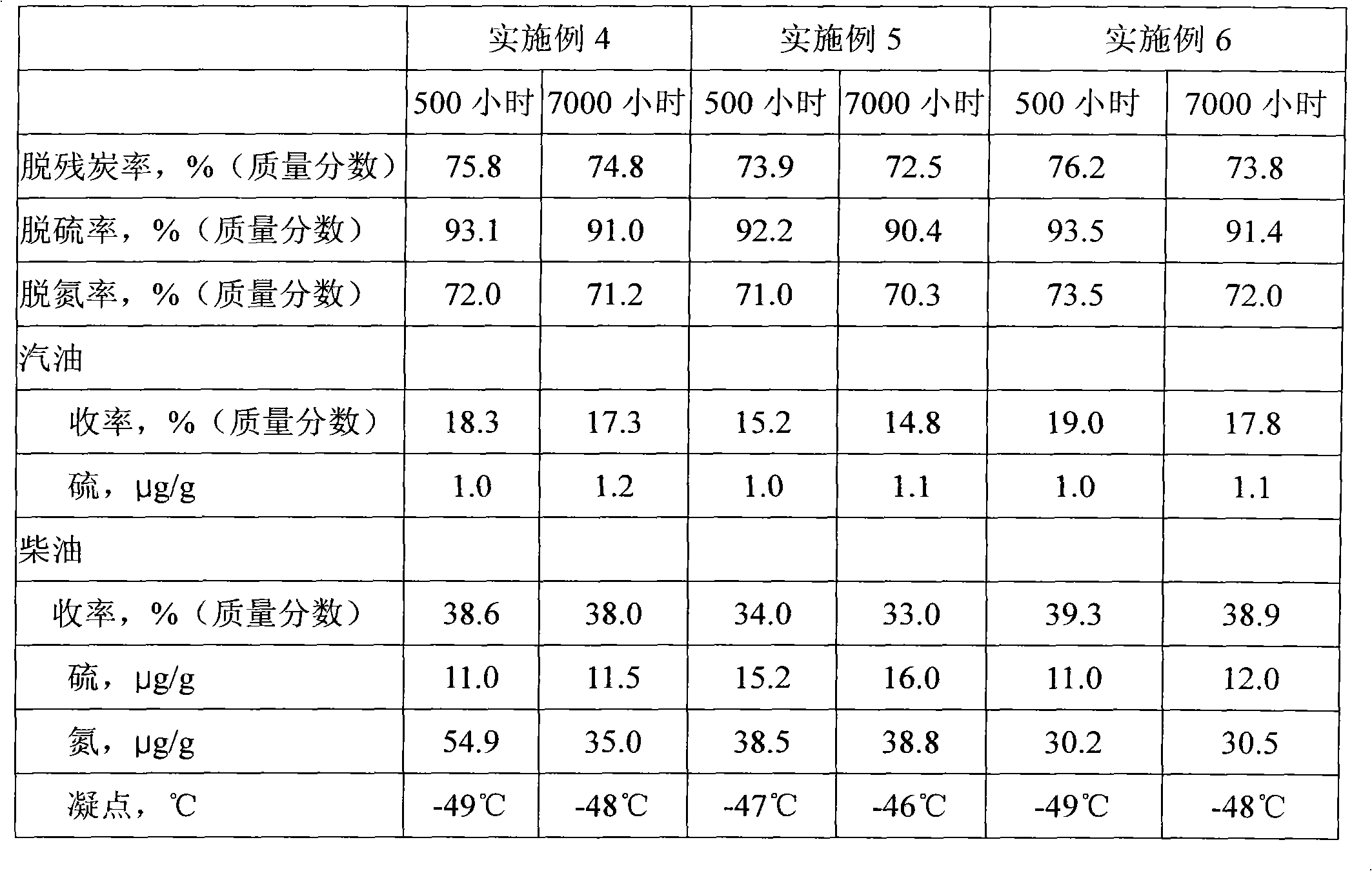

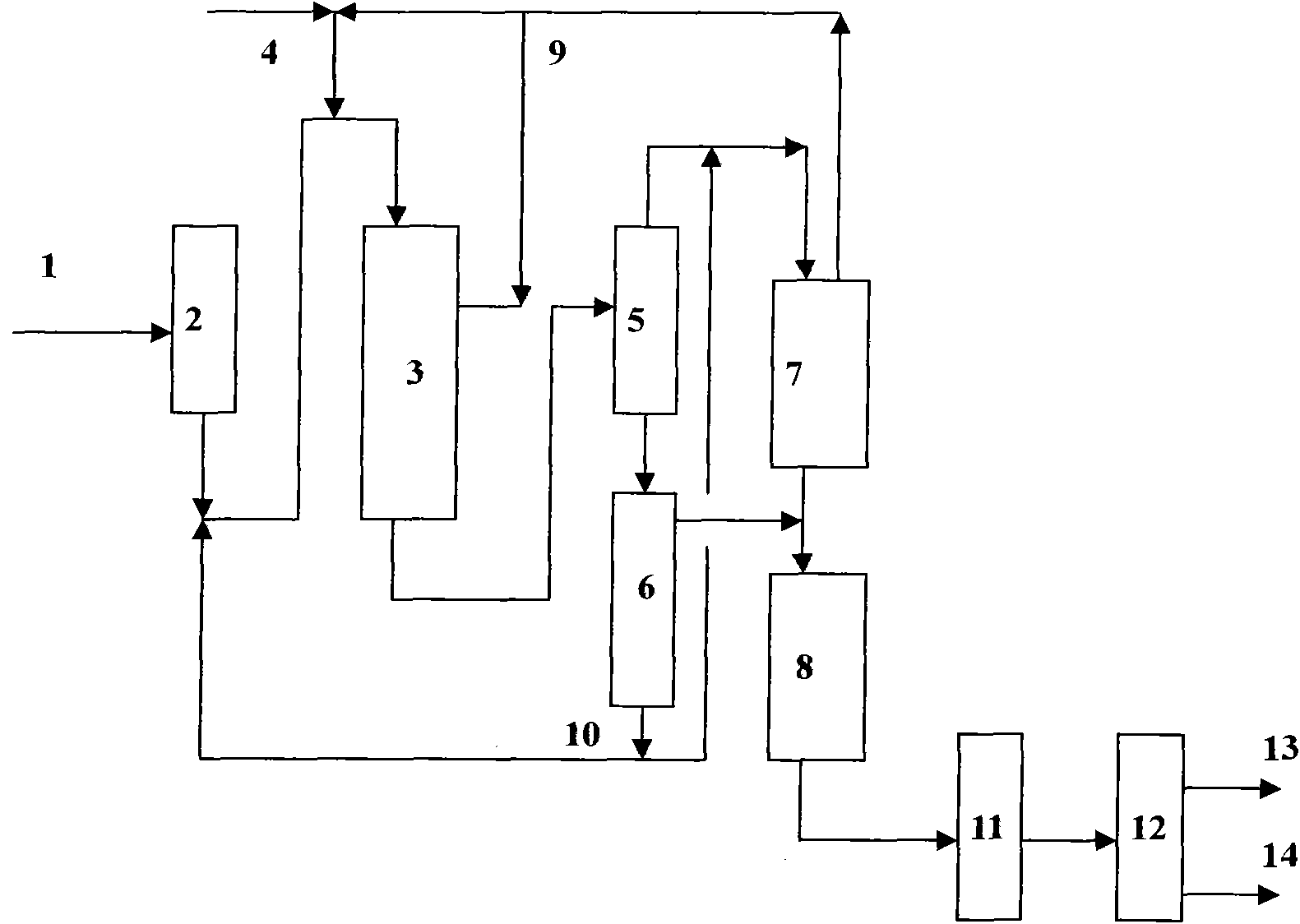

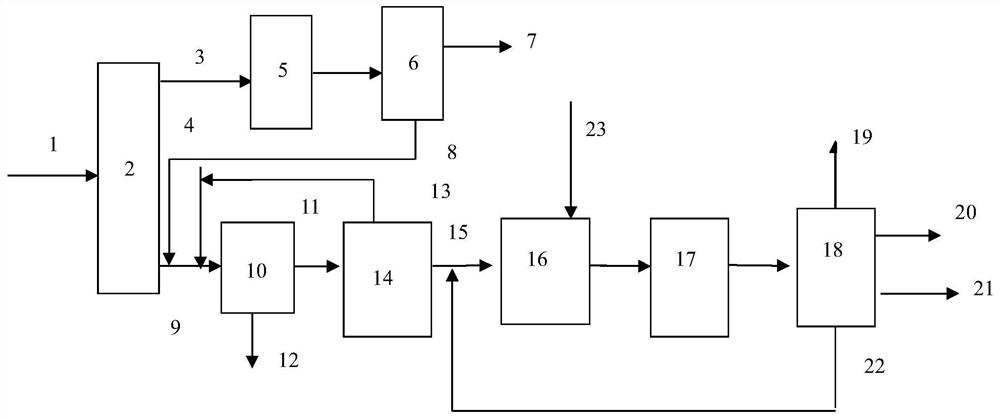

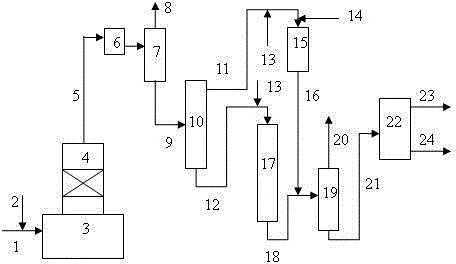

The invention discloses a method for processing ethylene tar, which selects an appropriate cutting point to fractionate the ethylene tar into a light fraction and a heavy fraction aiming at the characteristics of high content of arene, colloid and carbon residue in the ethylene tar. The light fraction passes through a hydrogenation protection reaction zone, a hydrofining reaction zone and a hydrocracking reaction zone sequentially to obtain a gasoline fraction and a diesel oil fraction; and the heavy fraction is used as a universal type carbon fiber asphalt stock. The method for processing the ethylene tar makes full use of the total fraction of the ethylene tar and increases the additional value of the ethylene tar. In addition, the method enables the arene after hydrostturation in the ethylene tar to open ring, crack moderately and / or isomerize by selecting two types of hydrocracking catalysts to perform grading loading so as to obtain the diesel oil fraction with condensation point less than -40 DEG C in high yield and obtain a side product high-octane gasoline fraction at the same time.

Owner:CHINA PETROLEUM & CHEM CORP +1

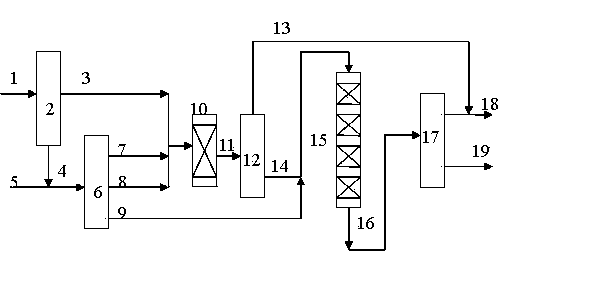

Hydro-cracking method for blending ethylene bottom oil

The invention discloses a hydro-cracking method for blending ethylene bottom oil, which is different from the method for processing the conventional ethylene bottom oil and comprises the following steps: blending an ethylene bottom oil light end into a conventional hydro-cracking raw material for hydro-cracking, in the presence of hydrogen, sequentially contacting the ethylene bottom oil light end with a hydro-guard catalyst, a hydro-refining catalyst, a hydro-residue carbon removing catalyst and a hydro-cracking catalyst; separating an effluent of hydro-cracking reaction to obtain light fuel oil. The method of the invention adopts a method of grading the hydrogenation catalyst, can process the ethylene bottom oil light end and produce diesel oil having a high cetane number and a low condensation point and a naphtha having high arene, and is not obviously changed in a BMCI value of tail oil and a smoke point of a jet fuel when compared with the conditions before blending the ethylene bottom oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for hydrogenating ethylene tar

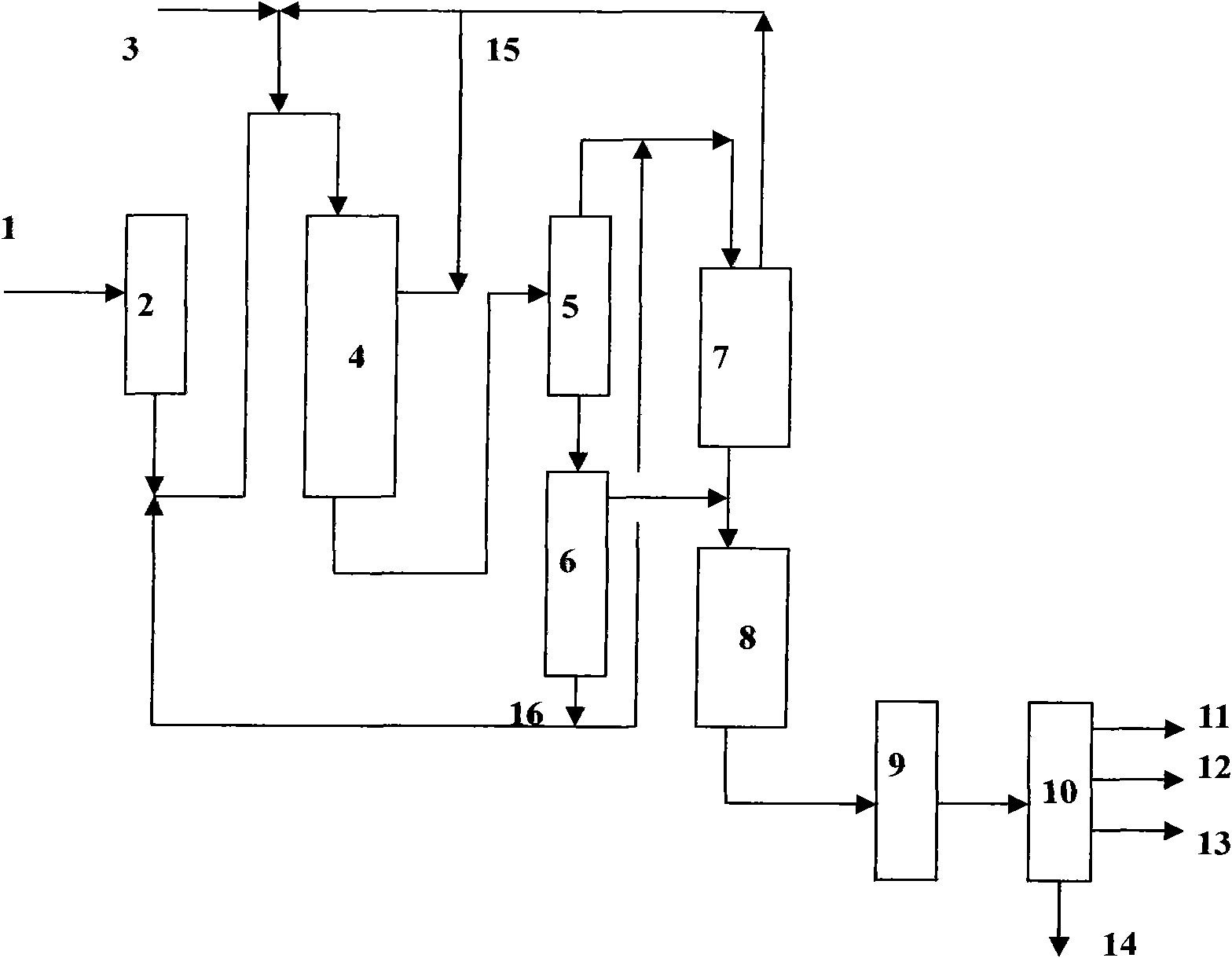

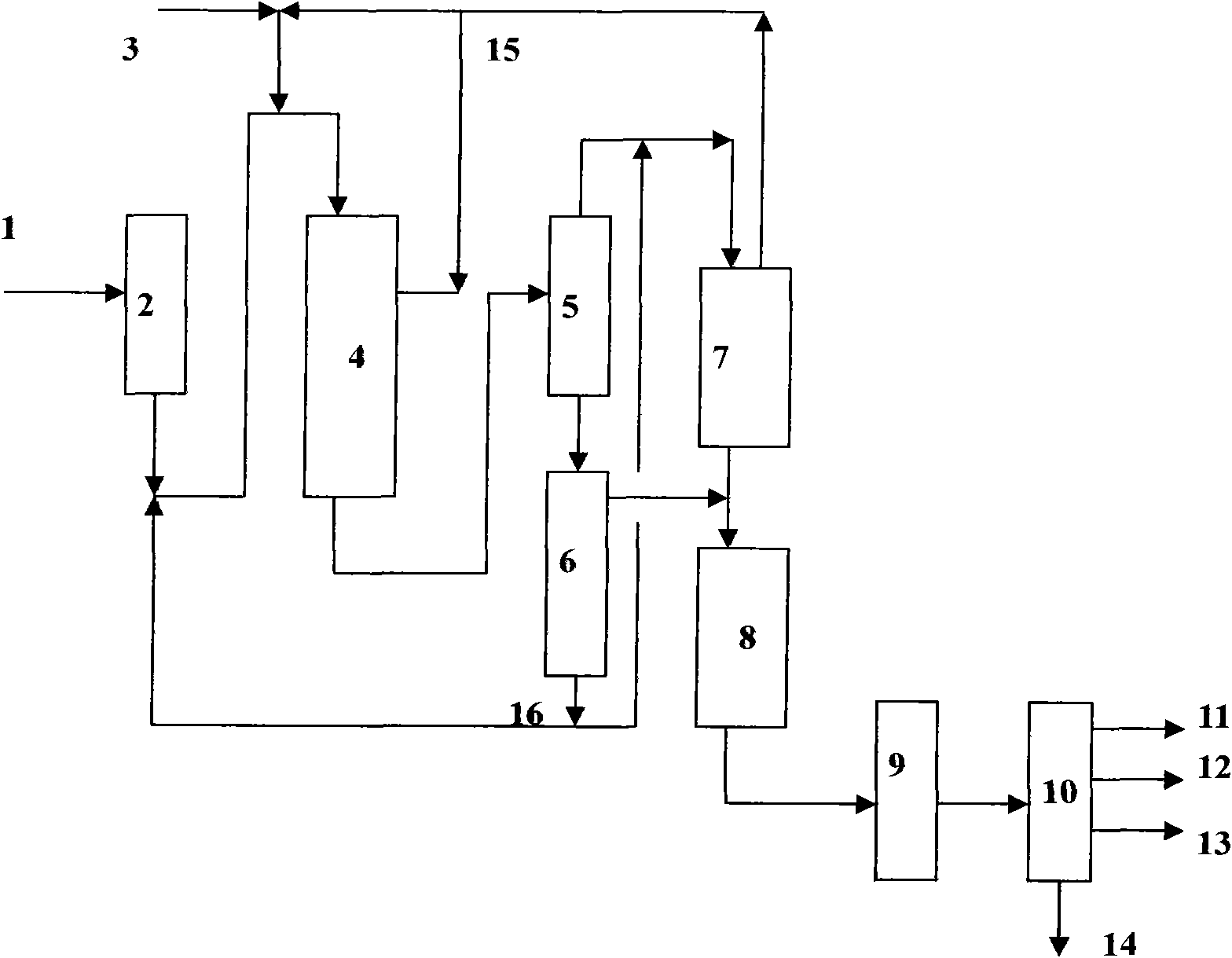

The invention discloses a method for hydrogenating ethylene tar, which selects an appropriate cutting point to fractionate the ethylene tar into a light fraction and a heavy fraction aiming at the characteristics of high content of arene, colloid, carbon residue and asphaltene in the ethylene tar. The light fraction passes through a hydrogenation protection catalyst, a hydrofining catalyst, a hydrogenation and carbon residue-removing catalyst and a hydrocracking catalyst sequentially to obtain a gasoline fraction and a diesel oil fraction; and the heavy fraction passes through the hydrogenation protection catalyst, the hydrogenation and carbon residue-removing catalyst and a hydro-conversion catalyst sequentially to obtain a gasoline fraction and a diesel oil fraction. According to the component characteristics of the light fraction and the heavy fraction of the ethylene tar, the method selects different hydrogenation schemes so as to convert the ethylene tar into fuel oil to a great extent, increase the additional value of the ethylene tar and make the device operate for a long time.

Owner:CHINA PETROLEUM & CHEM CORP +1

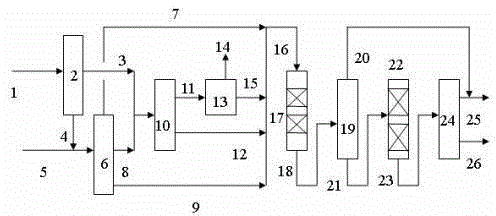

Hydrocracking method for blending ethylene tar

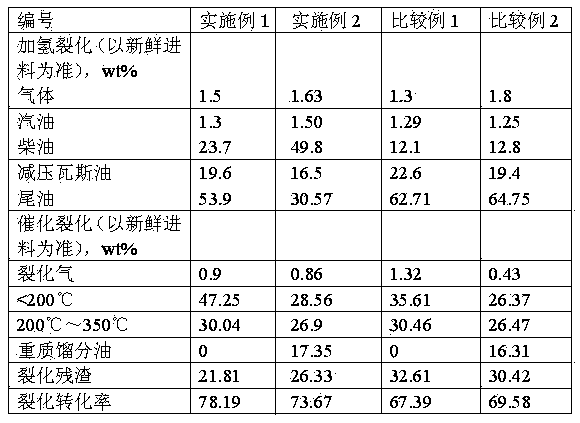

ActiveCN102234542AIncrease saturation rateHigh yieldTreatment with hydrotreatment processesChemistryLight crude oil

The invention discloses a hydrocracking method for blending ethylene tar, which comprises the following steps of: blending light fraction of ethylene tar into heavy distillate for hydrocracking, and contacting a hydrogenation protecting catalyst, a hydrogenation refining catalyst, a hydrogenation carbon residue removing catalyst and a hydrocracking catalyst in the presence of hydrogen to obtain hydrocracking crude oil, wherein partial hydrocracking crude oil is circulated and mixed with the light fraction and heavy distillate of the ethylene tar to enter a hydrocracking area, and the rest hydrocracking crude oil is future separated to obtain light fuel oil. By the method, the problem of high temperature rise of a hydrogenation reactor bed can be effectively solved; meanwhile, a method of grading the hydrogenation catalysts, the light fraction of the ethylene tar can be processed, and diesel with high cetane number and low condensation point and naphtha with high potential aromatic content can be produced; and compared with a state that the ethylene tar is not blended, the method has the advantage that the bureau of mines correlation index (BMCI) value of tail oil and the smoke point of jet fuel are not obviously changed.

Owner:CHINA PETROLEUM & CHEM CORP +1

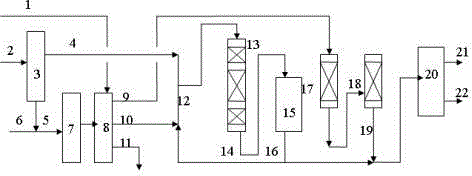

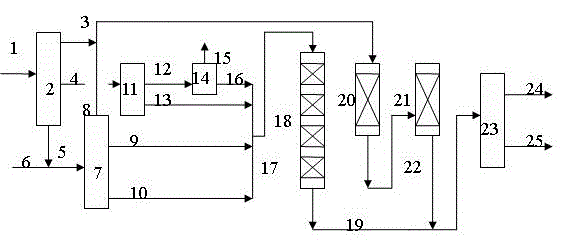

Method for hydrotreating ethylene tar

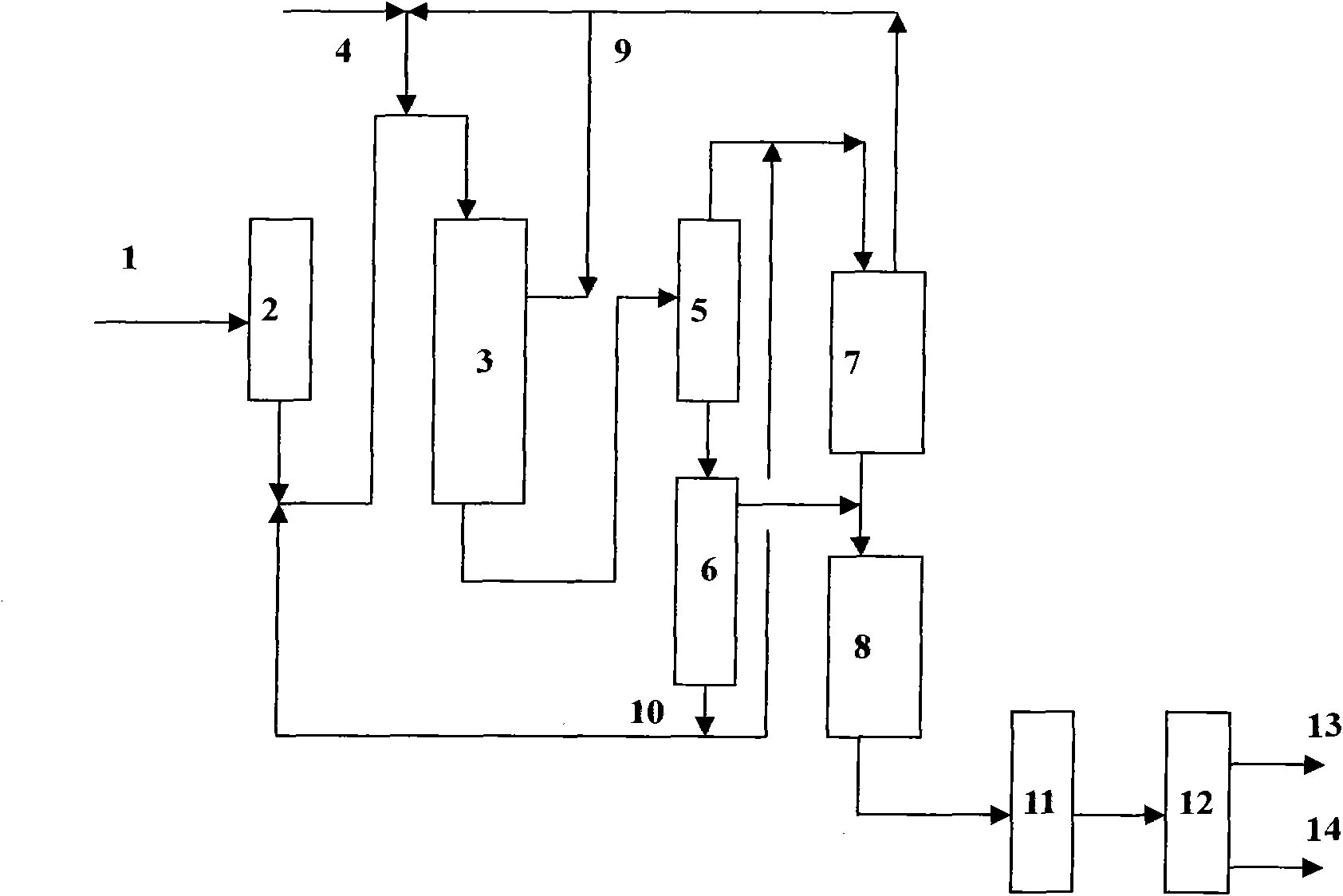

The invention discloses a method for hydrotreating ethylene tar, which comprises the following steps of: performing fractional distillation on the ethylene tar by selecting a proper cutting point to obtain light and heavy fractions; making the light fraction contact a hydrogenation protective agent, a hydrogenation refining catalyst, a hydrogenation carbon residue catalyst and a hydrocracking catalyst in turn, reacting to obtain products, and separating the products to obtain gasoline and diesel fractions; and making the heavy fraction contact a hydrogenation protecting catalyst, a hydrogenation carbon residue removing catalyst and a hydro-conversion catalyst in turn to obtain hydro-conversion generated oil, wherein partial hydro-conversion generated oil is circulated to enter a hydrogenation reaction area, and the rest hydro-conversion generated oil is separated to form gasoline and diesel fractions. In the method, according to composition characteristics of the light and heavy fractions of the ethylene tar, different hydrotreating schemes are selected, so that the ethylene tar is converted into fuel oil to the greatest extent, the problem of high temperature rise of a hydrogenation reactor bed can be effectively solved, the running period of the device is prolonged, full fractions of the ethylene tar are fully utilized and the added value of the ethylene tar is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

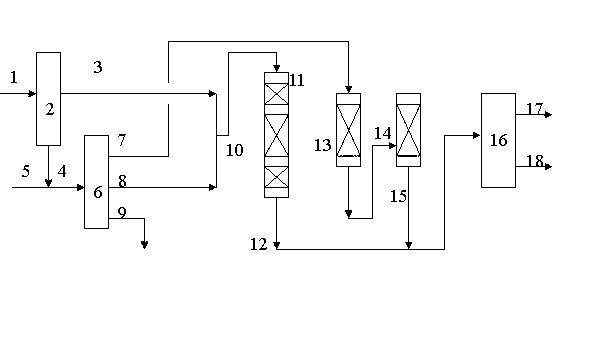

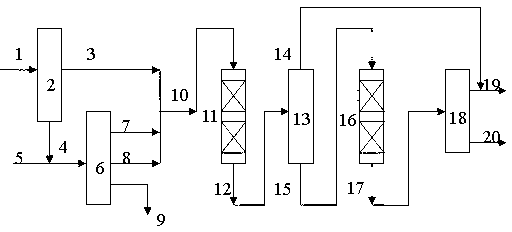

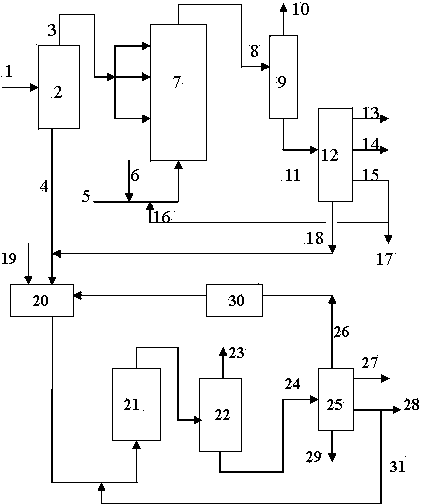

Method for producing clean fuel oil from ethylene tar

ActiveCN103102974AIncrease profitBroaden sources of raw materialsTreatment with hydrotreatment processesTarFuel oil

The invention discloses a method for producing clean fuel oil from ethylene tar. The method consists of: fractionating ethylene tar into light fraction and heavy fraction, mixing the heavy fraction with a conventional coking raw material, conducting delayed coking to obtain coker gasoline and coker diesel oil, performing hydrofining on the coker gasoline, mixing the coker diesel oil with the ethylene tar light fraction, subjecting the mixture to hydrotreating, and leaving the reaction effluent and the coker gasoline hydrofining product together to undergo separation by a fractionating tower, thus obtaining clean gasoline and diesel oil products. Directed at the characteristics of high content of aromatic hydrocarbon, colloid, carbon residue and asphaltene in ethylene tar, the method provided in the invention fractionates the ethylene tar into light fraction and heavy fraction, and adopts different processing processes according to the composition characteristics of each fraction, thus not only enhancing the utilization rate of ethylene tar, increasing the yield of light fuel oil, but also improving the product quality of light fuel oil, and enabling the equipment to run smoothly for a long period.

Owner:CHINA PETROLEUM & CHEM CORP +1

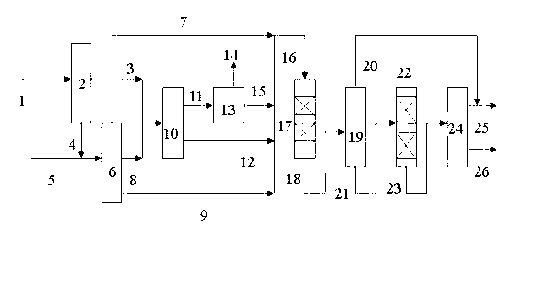

Treatment method of ethylene tar

ActiveCN103102976AImprove economic efficiencyAvoid concentrated heatDistillation purification/separationTreatment with hydrotreatment processesCrystallization PurificationGasoline

The invention discloses a treatment method of ethylene tar. The method consists of: fractionating ethylene tar into light fraction and heavy fraction, mixing the heavy fraction with a conventional coking raw material, conducting delayed coking to obtain coker gasoline, coker diesel oil and coker gas oil, mixing the coker diesel oil with the ethylene tar light fraction, performing rectification / crystallization purification to obtain naphthalene, mixing the naphthalene removed oil, naphthalene after-cut oil, with the coker gasoline and the coker gas oil, taking the obtained mixture as a hydrotreating raw material, leaving the material to undergo a hydrofining reaction, separating gasoline fraction I, subjecting the obtained fraction heavier than gasoline to hydrocracking so as to obtain gasoline fraction II and a diesel oil product, and mixing the gasoline fraction II with the gasoline fraction I so as to obtain a final gasoline product. Directed at the characteristics of high content of aromatic hydrocarbon, colloid, carbon residue and asphaltene in ethylene tar, the method provided in the invention fractionates the ethylene tar into light fraction and heavy fraction, and adopts different processing processes, thus increasing the added value of ethylene tar. While generating the chemical raw material naphthalene, the method also improves the product quality of light fuel oil, and also enables the equipment to run smoothly for a long period.

Owner:CHINA PETROLEUM & CHEM CORP +1

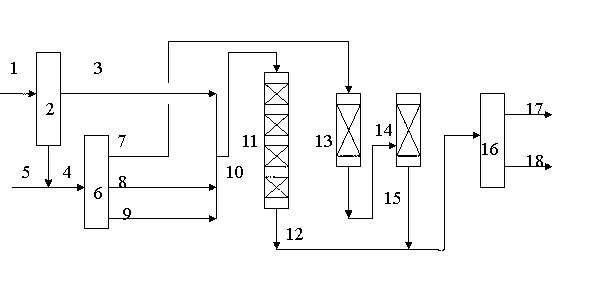

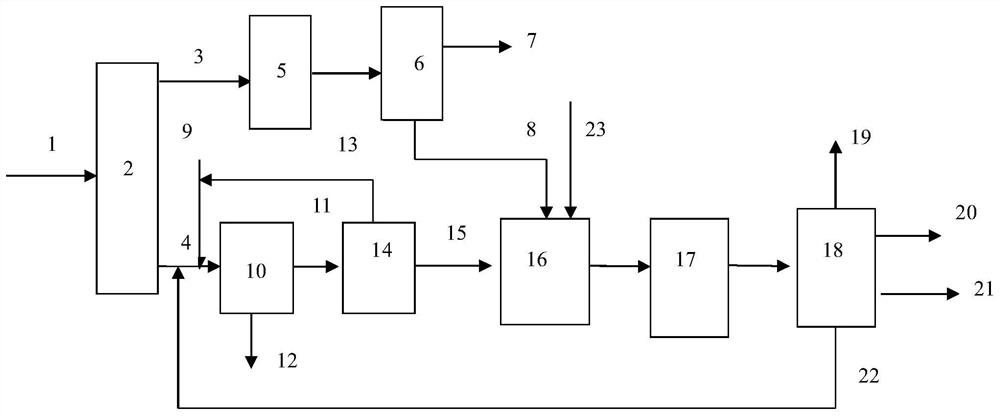

Method and system for producing diesel oil from inferior oil material

InactiveCN106520168AHigh yieldImprove product qualityLiquid hydrocarbon mixture productionNaphthaGas phase

The invention discloses a method and system for producing diesel oil from an inferior oil material. The method includes the steps: mixing the inferior oil material with waste plastics, then carrying out a pyrolysis reaction, then making an obtained pyrolysis gas contact with a catalyst and carrying out a catalytic reaction, separating the obtained catalytic reaction product to form a gas-phase product and a liquid-phase oil product, and hydrotreating the liquid-phase oil product to form naphtha and diesel oil. The obtained naphtha can go to an ethylene-removing cracking unit to be used as a cracking raw material, and the obtained diesel oil can be used as a qualified diesel oil product and leaves factories. The method has the advantages of simple process and cheap and easily obtained raw materials, can make full use of the waste plastics, the inferior oil material and other resources, and also is green and environmentally friendly; and the yield of light fuels can reach more than or equal to 95%, and the obtained diesel oil has good quality.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

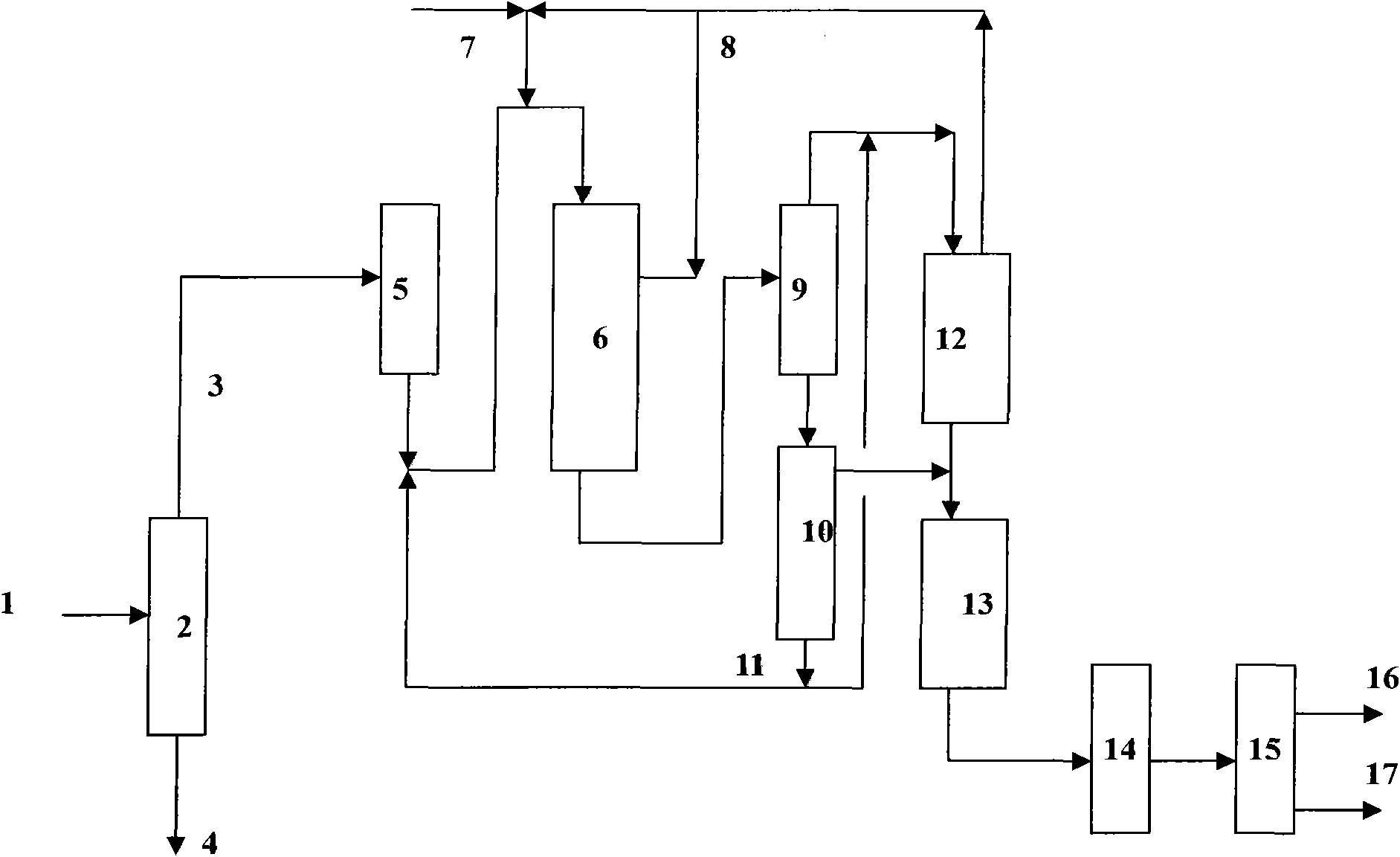

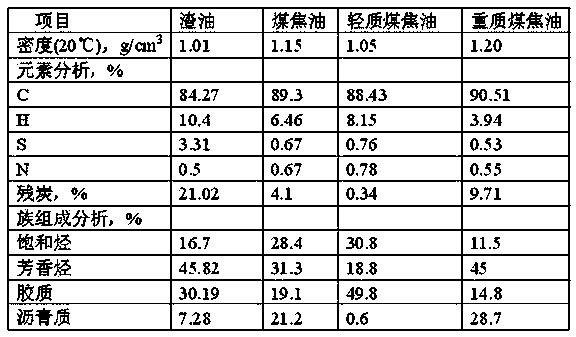

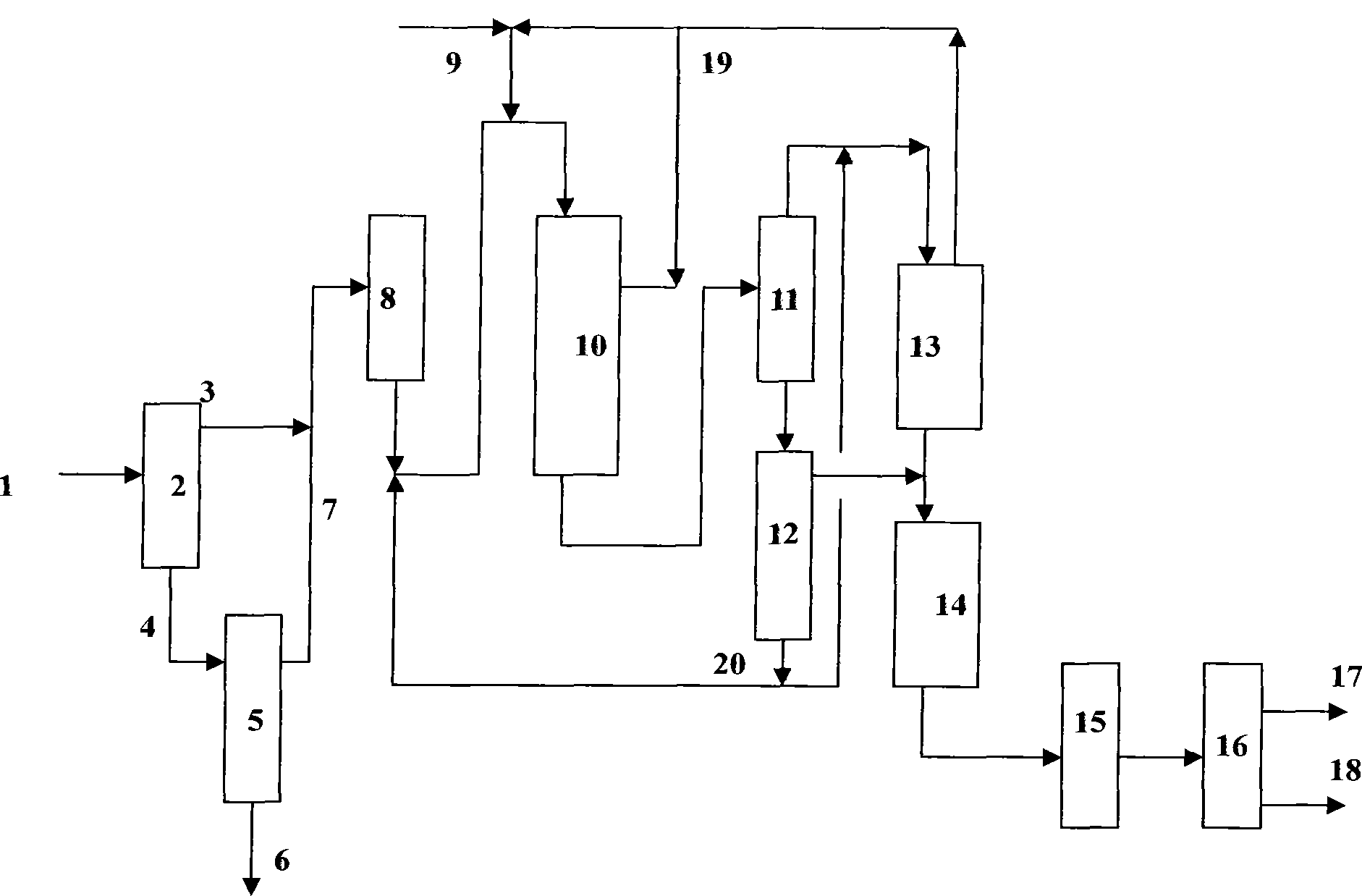

Coal tar and residuum hydrocracking-delayed coking combination processing method

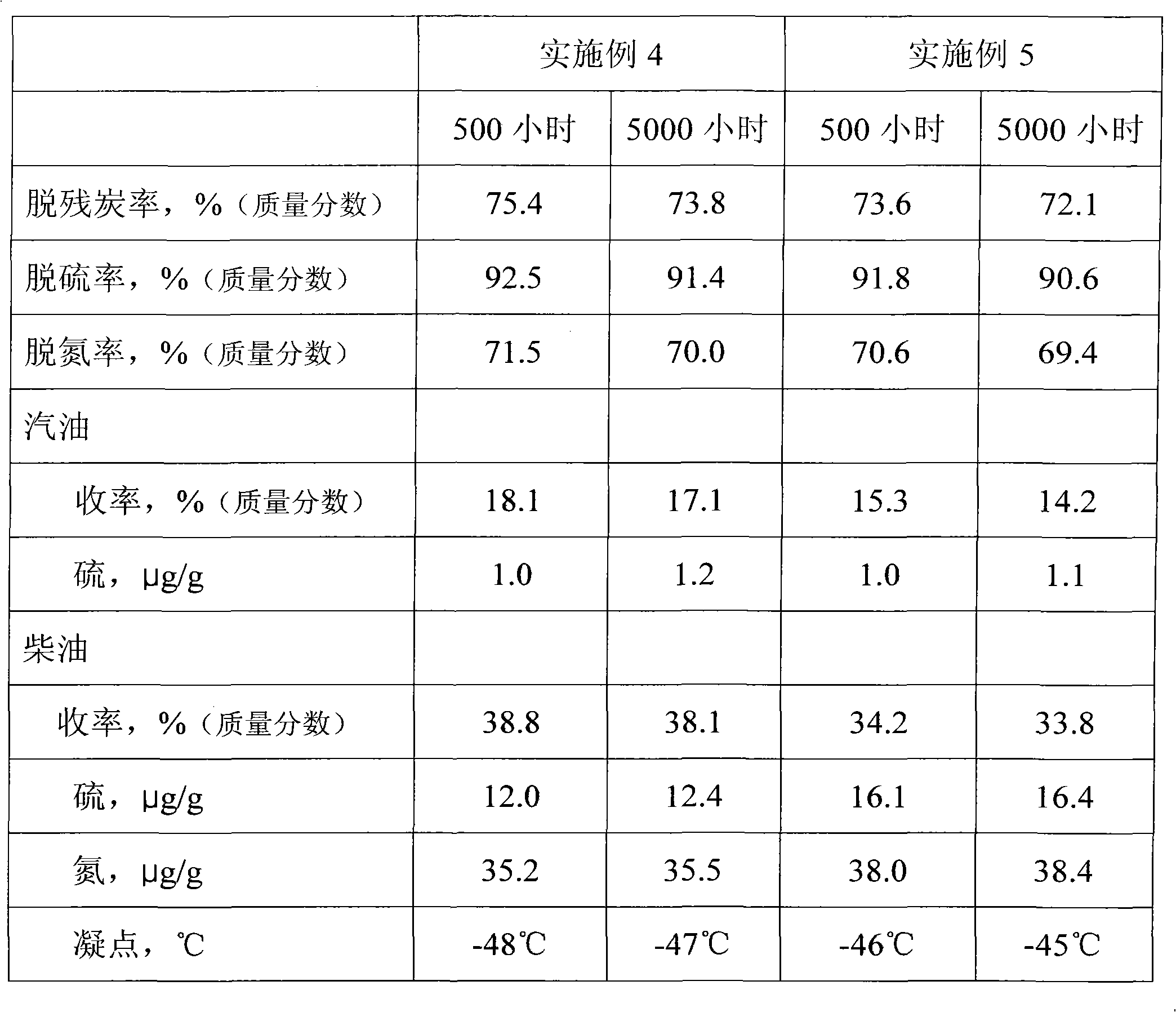

ActiveCN103773477AImprove conversion rateImprove stabilityTreatment with hydrotreatment processesHydrogenFluidized bed

The invention discloses a coal tar and residuum hydrocracking-delayed coking combination processing method which is as follows: light and heavy coal tar are obtained by reduced pressure distillation of coal tar; the light coal tar is mixed with and residuum, and enters a fluidized bed reactor together with hydrogen to contact a hydrocracking catalyst for hydrocracking reaction, a hydrocracked effluent is separated to obtain a gas and a liquid phase product, gasoline, diesel, vacuum gas oil and tail oil are obtained by fractionation of the liquid phase product; the tail oil and the heavy coal tar together enter a delayed coking unit for thermal cracking reaction to obtain coker dry gas, coker gasoline, coker diesel oil, coker gas oil and coke. The process method can improve the conversion rate of raw materials, reduce coking, increase the yield of light oil, and prolong the device operation cycle, and provides a processing method for low-added-value coal tar and residuum to improve the economical efficiency.

Owner:CHINA PETROLEUM & CHEM CORP +1

Processing method for by-products of ethylene equipment

The invention discloses a processing method for by-products of ethylene equipment. The method includes: mixing ethylene tar and heavy benzene, passing the mixture firstly through a thermal cracking reaction area and a catalytic reaction area, condensing the reaction effluent, then leading the condensed product into an oil-water separator to undergo gas-liquid separation so as to obtain a gas product and a liquid phase oil product respectively, remaining the residue generated during reaction in the cracking reaction area, collecting the gas product to serve as a fuel gas, fractionating the liquid phase oil product to obtain light fraction and heavy fraction, mixing the light fraction with ethylene cracked C9 fraction, then leading the mixture into a hydrofining reaction area, passing the heavy fraction through the hydrofining reaction area and a hydrocracking reaction area in order, mixing the hydrocracking product with the light fraction hydrofining product and bringing the mixture into a separation system to undergo separation, thus obtaining gasoline and diesel fractions. According to the method provided by the invention, full-range ethylene tar can be fully utilized, and the obtained gasoline fraction yield is greater than 70%, the obtained gasoline and diesel have good quality, and the added value of ethylene tar is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for producing light fuel oil from ethylene tar

ActiveCN103102977AIncrease profitImprove product qualityTreatment with hydrotreatment processesLighter fuelGasoline

The invention discloses a method for producing light fuel oil from ethylene tar. The method consists of: fractionating ethylene tar into light fraction and heavy fraction, mixing the heavy fraction with a conventional coking raw material, conducting delayed coking to obtain coker gasoline, coker diesel oil, and coker gas oil, performing hydrofining on the coker gasoline, mixing the coker diesel oil with the ethylene tar light fraction, subjecting the mixture to hydrotreating, and leaving the product and the coker gasoline hydrofining product together to undergo separation, thus obtaining clean gasoline and diesel oil products. Directed at the characteristics of high content of aromatic hydrocarbon, colloid, carbon residue and asphaltene in ethylene tar, the method provided in the invention fractionates the ethylene tar into light fraction and heavy fraction, and adopts different processing processes, thus not only enhancing the utilization rate and the additional value of ethylene tar, increasing the yields of gasoline and diesel oil, improving the product quality of light fuel oil, and also enabling the equipment to run smoothly for a long period.

Owner:CHINA PETROLEUM & CHEM CORP +1

A method for producing clean fuel oil from waste plastics and high aromatic components

ActiveCN104611060BHigh yieldMelt and mix wellTreatment with hydrotreatment processesHydrocarbon oils treatment productsPtru catalystFluid phase

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for increasing yield of clean fuel oil

ActiveCN103773497AIncrease profitBroaden sources of raw materialsTreatment with hydrotreatment processesProcess engineeringFuel oil

The invention discloses a method for increasing the yield of clean fuel oil. The method comprises the following steps: subjecting ethylene tar to fractionation so as to obtain a light fraction and a heavy fraction, mixing the heavy fraction with a conventional coking raw material, then subjecting the mixture to a delay coking treatment so as to obtain a coking product, transporting the coking product and a C9 component from an ethylene device into a coking distillation tower, carrying out a distillation treatment so as to obtain a coking gasoline fraction and a coking diesel oil fraction, carrying out a hydro-refining treatment on the obtained coking gasoline fraction, mixing the coking diesel oil fraction with the ethylene tar light fraction, then subjecting the mixture to a hydro-treatment, and separating the products so as to obtain a gasoline product and a diesel oil product. The method fully utilizes the ethylene tar and C9 fraction, improves the utilization rate of by-products of ethylene device, prominently improves the yield and quality of lightweight fuel oil, and is beneficial for yield increasing of high quality clean fuel oil for refineries.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for producing light fuel oil from ethylene tar

ActiveCN103102979AImprove product qualityBroaden sources of raw materialsTreatment with hydrotreatment processesLighter fuelGasoline

The invention discloses a method for producing light fuel oil from ethylene tar. The method is as below: fractionating ethylene tar into a light fraction and a heavy fraction; mixing the heavy fraction with a conventional coking raw material, and subjecting the mixture to delayed coking to obtain coker gasoline, coker diesel and coker gas oil; mixing the coker gasoline and the coker diesel with the light fraction of the ethylene tar, and subjecting the mixture to a hydrofining reaction; distilling the product to obtain a gasoline fraction I and a fraction heavier than the gasoline; subjecting the fraction heavier than the gasoline to a hydrogenation treatment to obtain light fuel oil, and distilling to obtain a gasoline fraction II and a diesel product; and mixing the gasoline fraction I and the gasoline fraction II to obtain a final gasoline product. The method provided by the invention utilizes the characteristics of high contents of ethylene tar aromatic hydrocarbons, colloid, carbon residue and glial and asphaltene of ethylene tar to fractionate the ethylene tar into the light fraction and the heavy fraction; different processing methods are employed to improve the added value of ethylene tar, increase yield of gasoline and diesel, improve product quality of light fuel oil and realize long-period stable operation of devices.

Owner:CHINA PETROLEUM & CHEM CORP +1

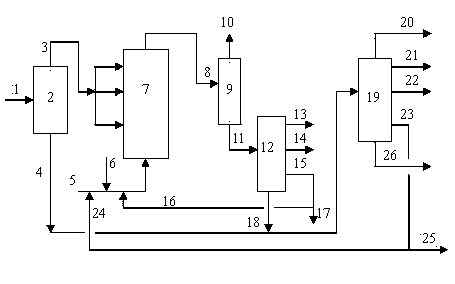

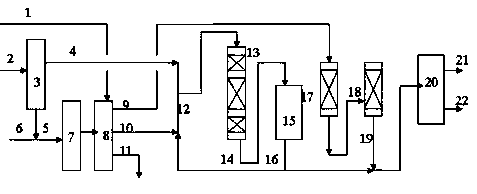

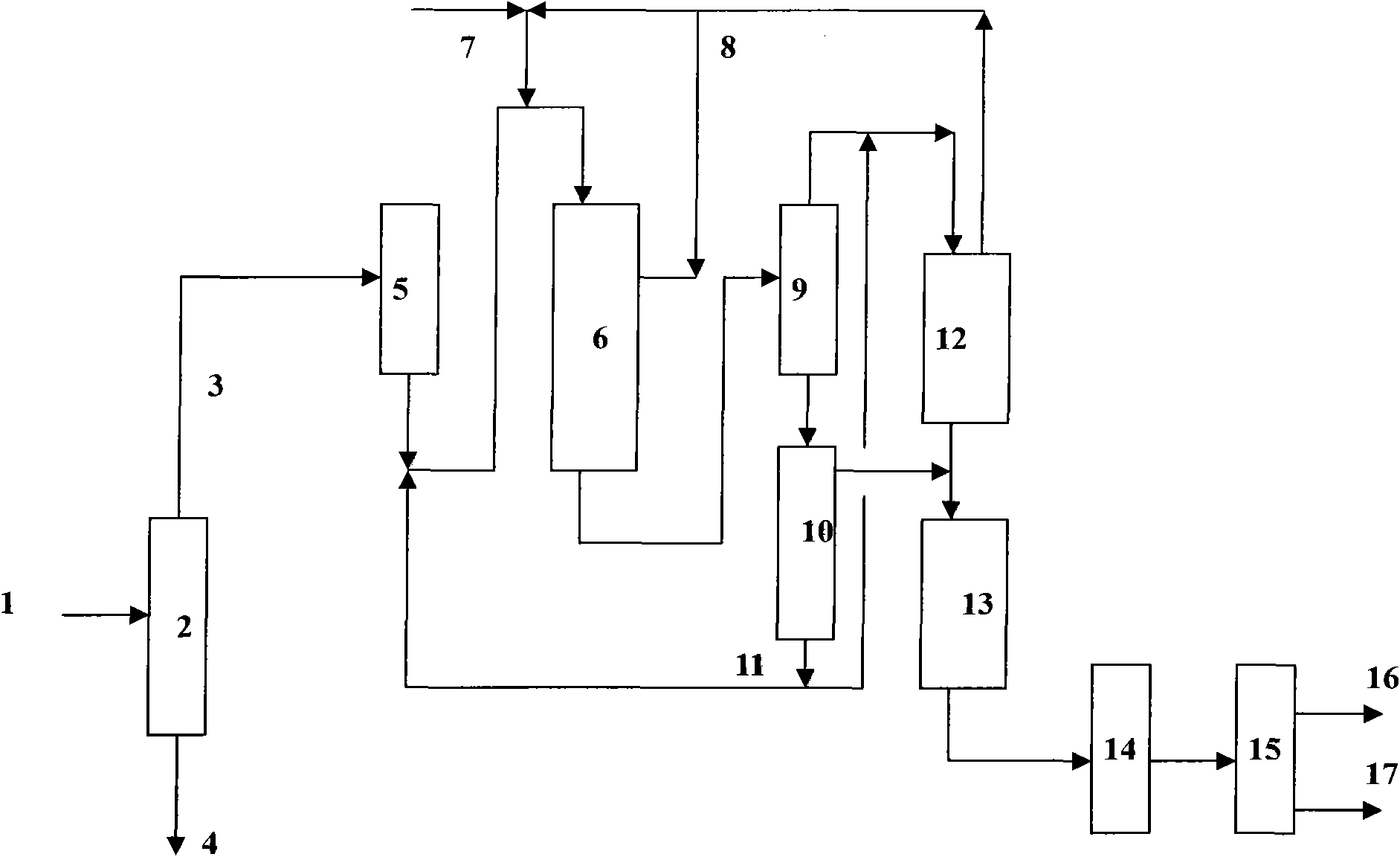

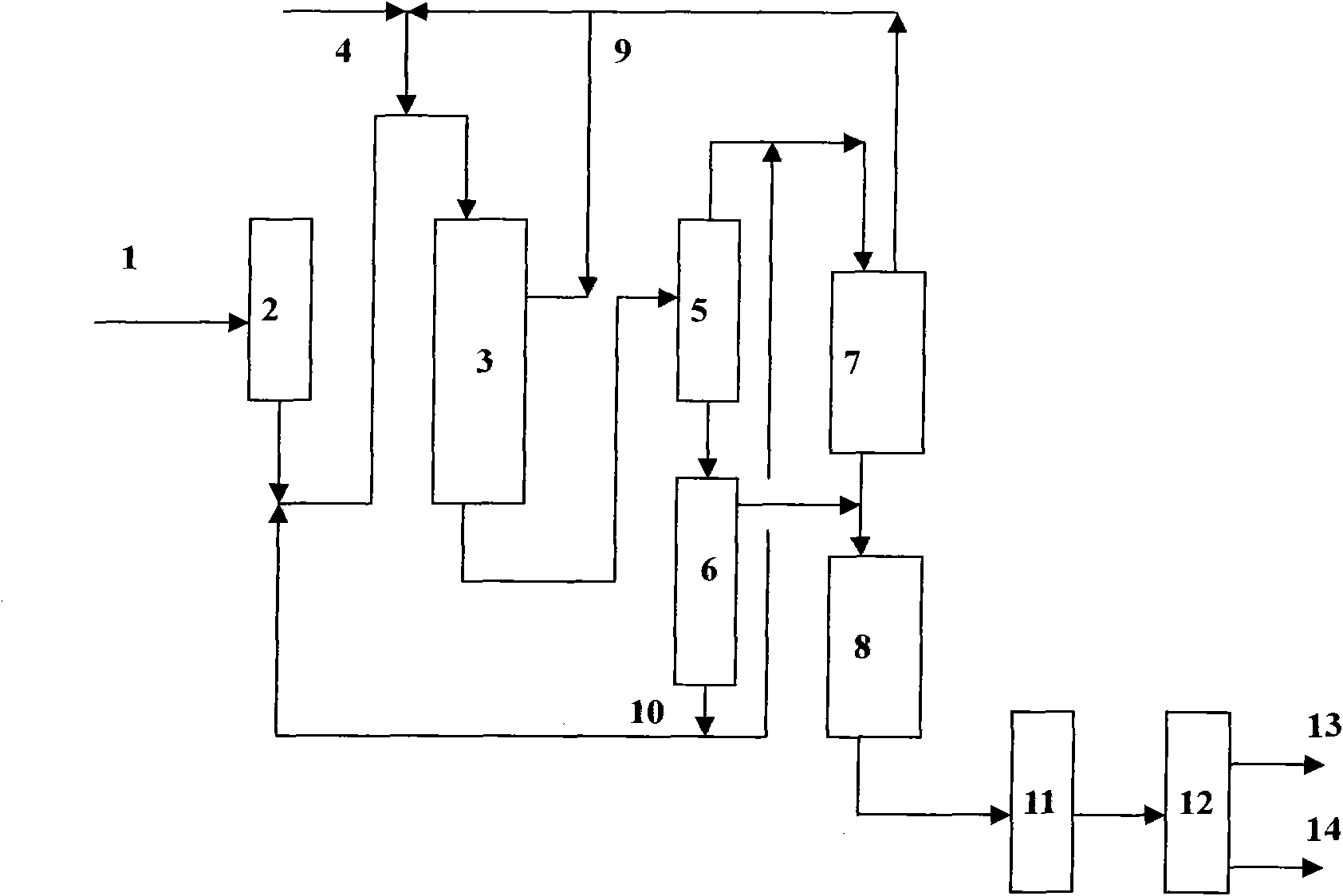

Hydrogenation method for ethylene tar

ActiveCN102234537AIncrease added valueHigh yieldTreatment with hydrotreatment processesHydrogenation reactionTar

The invention discloses a hydrogenation method for ethylene tar, which comprises the following steps of: performing fractional distillation on the ethylene tar by selecting a proper cutting point to obtain light and heavy fractions; making the light fraction contact a hydrogenation protecting catalyst, a hydrogenation refining catalyst, a hydrogenation carbon residue removing catalyst and a hydrocracking catalyst in turn, and reacting to obtain hydrocracking generated oil, wherein partial hydrocracking generated oil is circulated and mixed with the light fraction of the ethylene tar to enter a hydrogenation reaction area, and the rest hydrocracking generated oil is separated to form gasoline and diesel fractions; and making the heavy fraction contact a hydrogenation protecting catalyst, a hydrogenation carbon residue removing catalyst and a hydro-conversion catalyst preferably in turn, and separating to obtain gasoline and diesel fractions. In the method, according to composition characteristics of the light and heavy fractions of the ethylene tar, different hydrotreating schemes are selected, so that the ethylene tar is converted into fuel oil to the greatest extent, the problem of high temperature rise of a hydrogenation reactor bed can be effectively solved, the running period of the device is prolonged, full fractions of the ethylene tar are fully utilized and the added value of the ethylene tar is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrocracking-catalytic cracking combined treatment method for coal tar and residual oil

ActiveCN104250567AImprove solvencyImprove conversion rateTreatment with hydrotreatment processesChemistryDistillation

The invention discloses a hydrocracking-catalytic cracking combined treatment method for coal tar and residual oil. The method includes: subjecting coal tar to pressure reduced distillation so as to obtain light coal tar and heavy coal tar; mixing the light coal tar with the residual oil, then conducting hydrocracking reaction, separating the hydrogenation cracking effluent to obtain a gas and a liquid product, and fractionating the liquid product to obtain gasoline, diesel, pressure reduced gas oil and tail oil; mixing the tail oil obtained by hydrocracking with heavy coal tar, then carrying out catalytic cracking reaction under supercritical conditions so as to obtain cracked gas, light distillate oil, heavy distillate oil and cracking residual oil. The method provided by the invention can improve the conversion rate of raw materials, reduce coking, increase the yield of light oil, extend the depth, slow down the deep condensation reaction of heavy raw material oil in a catalytic cracking device and prolong the service life of a catalytic cracking catalyst, thus providing a processing method for improving the economical efficiency of residual oil and coal tar with low added value.

Owner:CHINA PETROLEUM & CHEM CORP +1

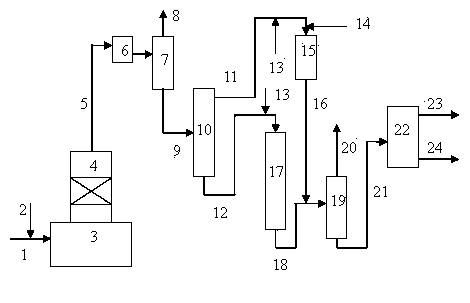

Method for hydrotreating ethylene tar

ActiveCN102234538BIncrease added valueHigh yieldTreatment with hydrotreatment processesHydrogenation reactionGasoline

The invention discloses a method for hydrotreating ethylene tar, which comprises the following steps of: performing fractional distillation on the ethylene tar by selecting a proper cutting point to obtain light and heavy fractions; making the light fraction contact a hydrogenation protective agent, a hydrogenation refining catalyst, a hydrogenation carbon residue catalyst and a hydrocracking catalyst in turn, reacting to obtain products, and separating the products to obtain gasoline and diesel fractions; and making the heavy fraction contact a hydrogenation protecting catalyst, a hydrogenation carbon residue removing catalyst and a hydro-conversion catalyst in turn to obtain hydro-conversion generated oil, wherein partial hydro-conversion generated oil is circulated to enter a hydrogenation reaction area, and the rest hydro-conversion generated oil is separated to form gasoline and diesel fractions. In the method, according to composition characteristics of the light and heavy fractions of the ethylene tar, different hydrotreating schemes are selected, so that the ethylene tar is converted into fuel oil to the greatest extent, the problem of high temperature rise of a hydrogenation reactor bed can be effectively solved, the running period of the device is prolonged, full fractions of the ethylene tar are fully utilized and the added value of the ethylene tar is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for producing clean fuel oil employing ethylene bottom oil and heavy benzol

ActiveCN104560153AIncrease added valueTake advantage ofTreatment with plural serial stages onlyTreatment with hydrotreatment processesFractionationFuel oil

The invention discloses a method for producing fuel oil employing ethylene bottom oil and heavy benzol. The method comprises the following steps: mixing ethylene bottom oil with heavy benzol, and processing in a thermal cracking reaction zone; condensing obtained pyrolysis gas and feeding to a separator for gas-liquid separation to respectively obtain a gas product and liquid-phase oil, wherein the residues generated in the reaction process are left in the thermal cracking reaction zone, and can be used as solid fuel; collecting a gas product as a fuel gas; processing the oil-phase oil in a hydrotreating reaction zone and a hydrocracking reaction zone, and separating the obtained hydrocracking product to obtain a gasoline fraction and a diesel fraction; or carrying out fractionation on the oil-phase oil to obtain a light fraction and a heavy fraction, processing the obtained heavy fraction in the hydrotreating reaction zone and the hydrocracking reaction zone, and separating the obtained hydrocracking product to obtain the gasoline fraction and the diesel fraction. According to the method disclosed by the invention, the process is simple; the whole ethylene bottom oil fraction can be fully utilized; the yield of the light fuel can be not lower than 85%; the obtained diesel is good in quality; and the yield of ethylene and propylene is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

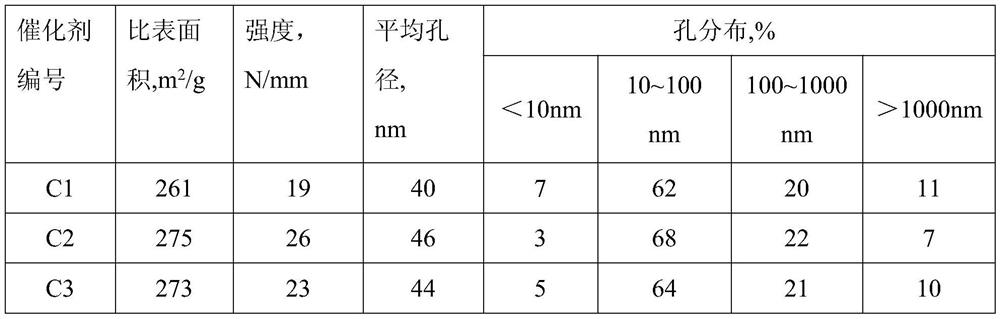

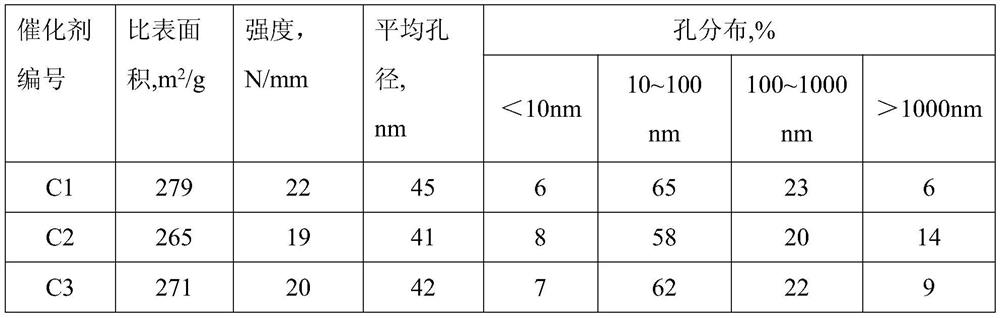

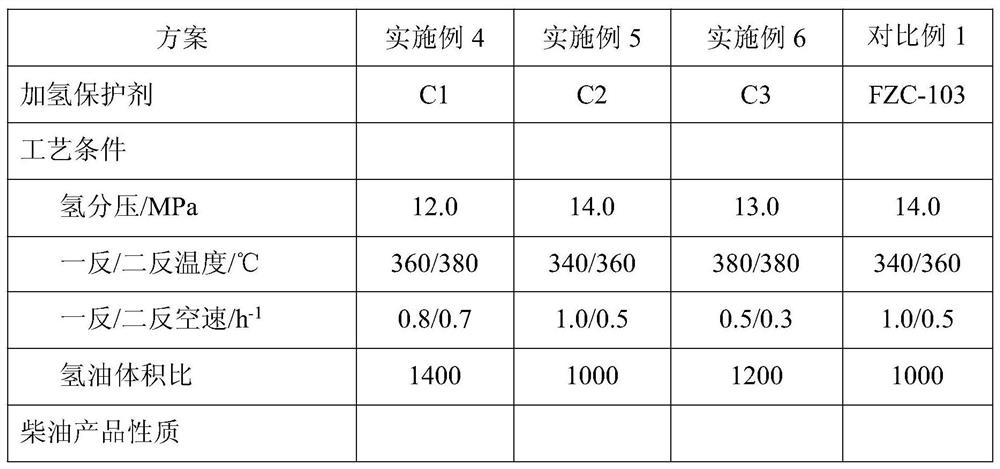

Hydrogenation protection catalyst as well as preparation method and application thereof

PendingCN114452978AGood reaming effectProtect activity stabilityHydrocarbon purification/separationHydrocarbonsActive agentAqueous solution

The invention relates to the field of petrifaction, and discloses a hydrogenation protection catalyst as well as a preparation method and application thereof. The hydrogenation protection catalyst comprises an alumina carrier and a metal oxide active component, and the preparation method comprises the following steps: uniformly mixing and kneading pseudo-boehmite, anthracene, biotite and an extrusion aid to obtain a mixture; uniformly mixing and kneading a peptizing acid solution and the mixture, shaping, drying and roasting to obtain an aluminum oxide carrier; adding a nonionic surfactant into the precursor aqueous solution of the metal oxide active component to form a mixed solution; and impregnating the alumina carrier in the mixed solution, drying, and roasting to obtain the hydrogenation protection catalyst. Anthracene is used as a pore-enlarging agent, and a better pore-enlarging effect is achieved. The mechanical strength of the carrier can be improved; on the other hand, the activity stability of the downstream main catalyst can be better protected. According to the hydrogenation protection catalyst, inferior heavy oil can be completely utilized, and the obtained mixed aromatic hydrocarbon product is high in yield and low in impurity content.

Owner:NINGBO ZHONGJIN PETROCHEM CO LTD

Method for hydrogenating ethylene tar

The invention discloses a method for hydrogenating ethylene tar, which selects an appropriate cutting point to fractionate the ethylene tar into a light fraction and a heavy fraction aiming at the characteristics of high content of arene, colloid, carbon residue and asphaltene in the ethylene tar. The light fraction passes through a hydrogenation protection catalyst, a hydrofining catalyst, a hydrogenation and carbon residue-removing catalyst and a hydrocracking catalyst sequentially to obtain a gasoline fraction and a diesel oil fraction; and the heavy fraction passes through the hydrogenation protection catalyst, the hydrogenation and carbon residue-removing catalyst and a hydro-conversion catalyst sequentially to obtain a gasoline fraction and a diesel oil fraction. According to the component characteristics of the light fraction and the heavy fraction of the ethylene tar, the method selects different hydrogenation schemes so as to convert the ethylene tar into fuel oil to a great extent, increase the additional value of the ethylene tar and make the device operate for a long time.

Owner:CHINA PETROLEUM & CHEM CORP +1

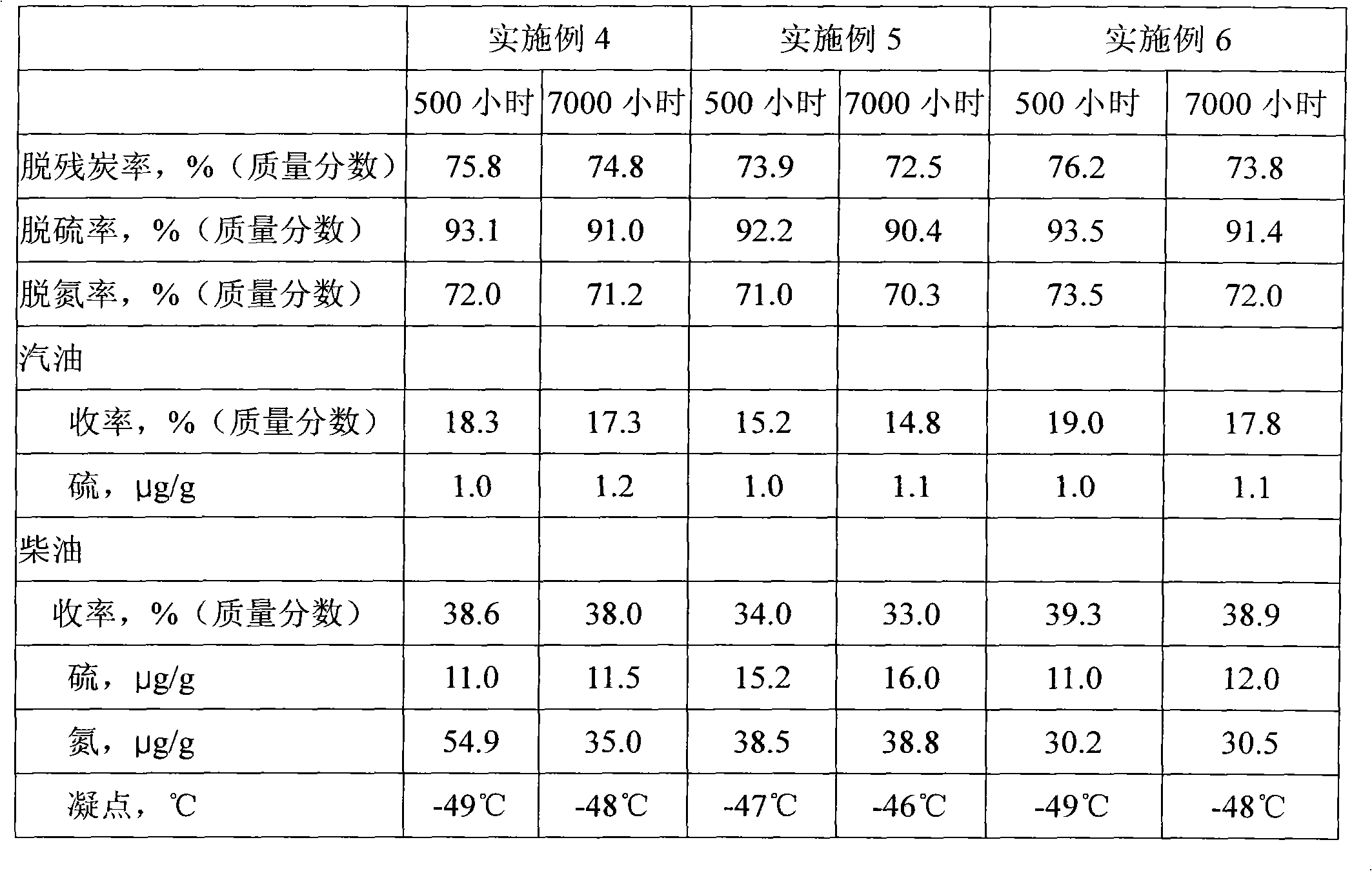

Hydrotreatment method of inferior heavy oil, hydrogenation protection catalyst and application

ActiveCN112574780AIncrease profitImprove combined economicsCatalyst protectionTreatment with hydrotreatment processesPtru catalystFixed bed

The invention discloses a hydrotreatment method of inferior heavy oil, a hydrogenation protection catalyst and application. The hydrotreatment method comprises the following steps: carrying out fractionation treatment on inferior heavy oil to obtain a heavy fraction and a light fraction, uniformly mixing the heavy fraction and naphthalene rear fractions in the light fraction, and carrying out solvent extraction on the obtained mixture to obtain an aromatic-rich component and a colloid component; and making the aromatic-rich component and the hydrogenation tail oil contact with a hydrogenationprotection catalyst, and carrying out a hydrogenation protection reaction, a hydrofining reaction and a hydrocracking reaction to realize hydrotreatment of inferior heavy oil, wherein the hydrogenation protection catalyst comprises a metal active component and a carrier, wherein the carrier is mainly formed by mixing fullerene, naphthalene and aluminum oxide, carrying out extrusion molding, dryingand roasting. The processing method disclosed by the invention solves the problem that a fixed bed hydrogenation process cannot be directly adopted due to high asphaltene content in the inferior heavy oil, so that the inferior heavy oil full fraction is fully utilized, and the comprehensive economy of the inferior heavy oil is improved.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Processing method of inferior heavy oil, hydrogenation protection catalyst and application

ActiveCN112574779AIncrease profitImprove economyCatalyst protectionTreatment with hydrotreatment processesPtru catalystFixed bed

The invention discloses a processing method of inferior heavy oil, a hydrogenation protection catalyst and application. The processing method comprises the following steps: carrying out fractionationtreatment on inferior heavy oil to obtain a heavy fraction and a light fraction, and then carrying out solvent extraction on the heavy fraction to obtain an aromatic-rich component and a colloid component; and uniformly mixing the aromatic-rich component and the naphthalene rear fraction in the light fraction, making the obtained mixture contact with a hydrogenation protection catalyst, and carrying out a hydrogenation protection reaction, a hydrofining reaction and a hydrocracking reaction to achieve processing of inferior heavy oil, wherein the hydrogenation protection catalyst comprises a metal active component and a carrier, the carrier is mainly formed by mixing a toluene solution of fullerene and slurry alumina, carrying out extrusion molding, drying and roasting, and the metal active component comprises a metal oxide. The processing method disclosed by the invention solves the problem that a fixed bed hydrogenation process cannot be directly adopted due to high asphaltene content in the inferior heavy oil, so that the inferior heavy oil full fraction is fully utilized, and the comprehensive economy of the inferior heavy oil is improved.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

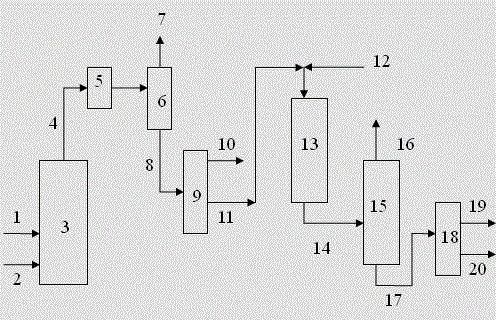

Processing method for by-products of ethylene equipment

ActiveCN103789037BIncrease added valueHigh yieldTreatment with hydrotreatment processesBenzeneGasoline

The invention discloses a processing method for by-products of ethylene equipment. The method includes: mixing ethylene tar and heavy benzene, passing the mixture firstly through a thermal cracking reaction area and a catalytic reaction area, condensing the reaction effluent, then leading the condensed product into an oil-water separator to undergo gas-liquid separation so as to obtain a gas product and a liquid phase oil product respectively, remaining the residue generated during reaction in the cracking reaction area, collecting the gas product to serve as a fuel gas, fractionating the liquid phase oil product to obtain light fraction and heavy fraction, mixing the light fraction with ethylene cracked C9 fraction, then leading the mixture into a hydrofining reaction area, passing the heavy fraction through the hydrofining reaction area and a hydrocracking reaction area in order, mixing the hydrocracking product with the light fraction hydrofining product and bringing the mixture into a separation system to undergo separation, thus obtaining gasoline and diesel fractions. According to the method provided by the invention, full-range ethylene tar can be fully utilized, and the obtained gasoline fraction yield is greater than 70%, the obtained gasoline and diesel have good quality, and the added value of ethylene tar is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

A method for increasing production of clean fuel oil

ActiveCN103773497BExpand sourceIncrease profitTreatment with hydrotreatment processesGasolineFuel oil

The invention discloses a method for increasing the yield of clean fuel oil. The method comprises the following steps: subjecting ethylene tar to fractionation so as to obtain a light fraction and a heavy fraction, mixing the heavy fraction with a conventional coking raw material, then subjecting the mixture to a delay coking treatment so as to obtain a coking product, transporting the coking product and a C9 component from an ethylene device into a coking distillation tower, carrying out a distillation treatment so as to obtain a coking gasoline fraction and a coking diesel oil fraction, carrying out a hydro-refining treatment on the obtained coking gasoline fraction, mixing the coking diesel oil fraction with the ethylene tar light fraction, then subjecting the mixture to a hydro-treatment, and separating the products so as to obtain a gasoline product and a diesel oil product. The method fully utilizes the ethylene tar and C9 fraction, improves the utilization rate of by-products of ethylene device, prominently improves the yield and quality of lightweight fuel oil, and is beneficial for yield increasing of high quality clean fuel oil for refineries.

Owner:CHINA PETROLEUM & CHEM CORP +1

Processing method of ethylene tar

ActiveCN103102978BBroaden sources of raw materialsImprove product qualityTreatment with hydrotreatment processesLighter fuelGasoline

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydro-cracking method for blending ethylene bottom oil

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for processing ethylene tar

Owner:CHINA PETROLEUM & CHEM CORP +1

Treatment method of ethylene tar

ActiveCN103102976BBroaden sources of raw materialsImprove product qualityDistillation purification/separationTreatment with hydrotreatment processesGasolineHydrogen treatment

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for producing clean fuel oil from ethylene tar

ActiveCN103805248BIncrease profitImprove product qualityTreatment with hydrotreatment processesWaxLighter fuel

The invention discloses a method for producing clean fuel oil from ethylene tar. The method is as follows: fractionating the ethylene tar into a light fraction, a middle fraction and a heavy fraction, mixing the heavy fraction with a conventional coking raw material, conducting delayed coking to obtain coker gasoline, coker diesel oil and coker wax oil, mixing the obtained coker gasoline with the ethylene tar light fraction, leaving the mixed material to undergo hydrofining, performing rectification / crystallization purification on the middle fraction to obtain naphthaline, mixing naphthaline removal oil after naphthaline extraction and naphthaline post-fraction oil with the coker diesel oil and the coker wax oil for hydrotreating, and separating an obtained product and the hydrofining product of the coker gasoline and the ethylene tar light fraction to obtain gasoline diesel oil products. Directed at the characteristics of high content of aromatic hydrocarbons, colloid, carbon residue and asphaltene in the ethylene tar, the method provided in the invention fractionates the ethylene tar into the light fraction, the middle fraction and the heavy fraction, and adopts different processing processes, thus not only enhancing the additional value of the ethylene tar, improving the product quality of light fuel oil in the same time of obtaining of the chemical raw material naphthaline, but also enabling the equipment to run smoothly for a long period.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for processing ethylene tar

ActiveCN102234539BIncrease added valueTake advantage ofTreatment with hydrotreatment processesFiberCarbon fibers

Owner:CHINA PETROLEUM & CHEM CORP +1

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com