Hydrogenation method for ethylene tar

A technology for ethylene tar and hydrocracking, which is used in hydrotreating process, petroleum industry, processing of hydrocarbon oil, etc., can solve the problems of not being effectively treated and unable to treat ethylene tar fraction, etc., and achieve the effect of increasing added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

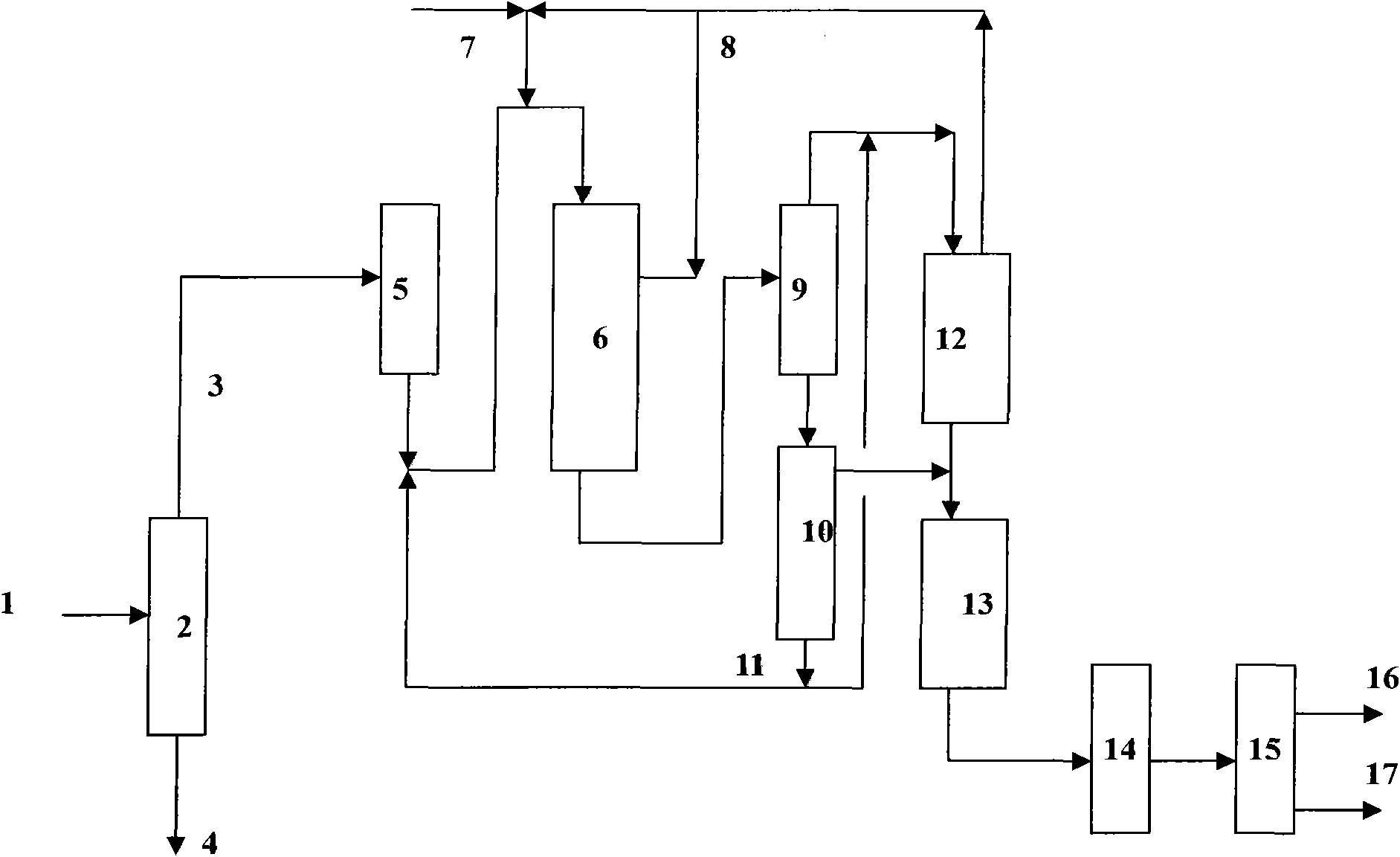

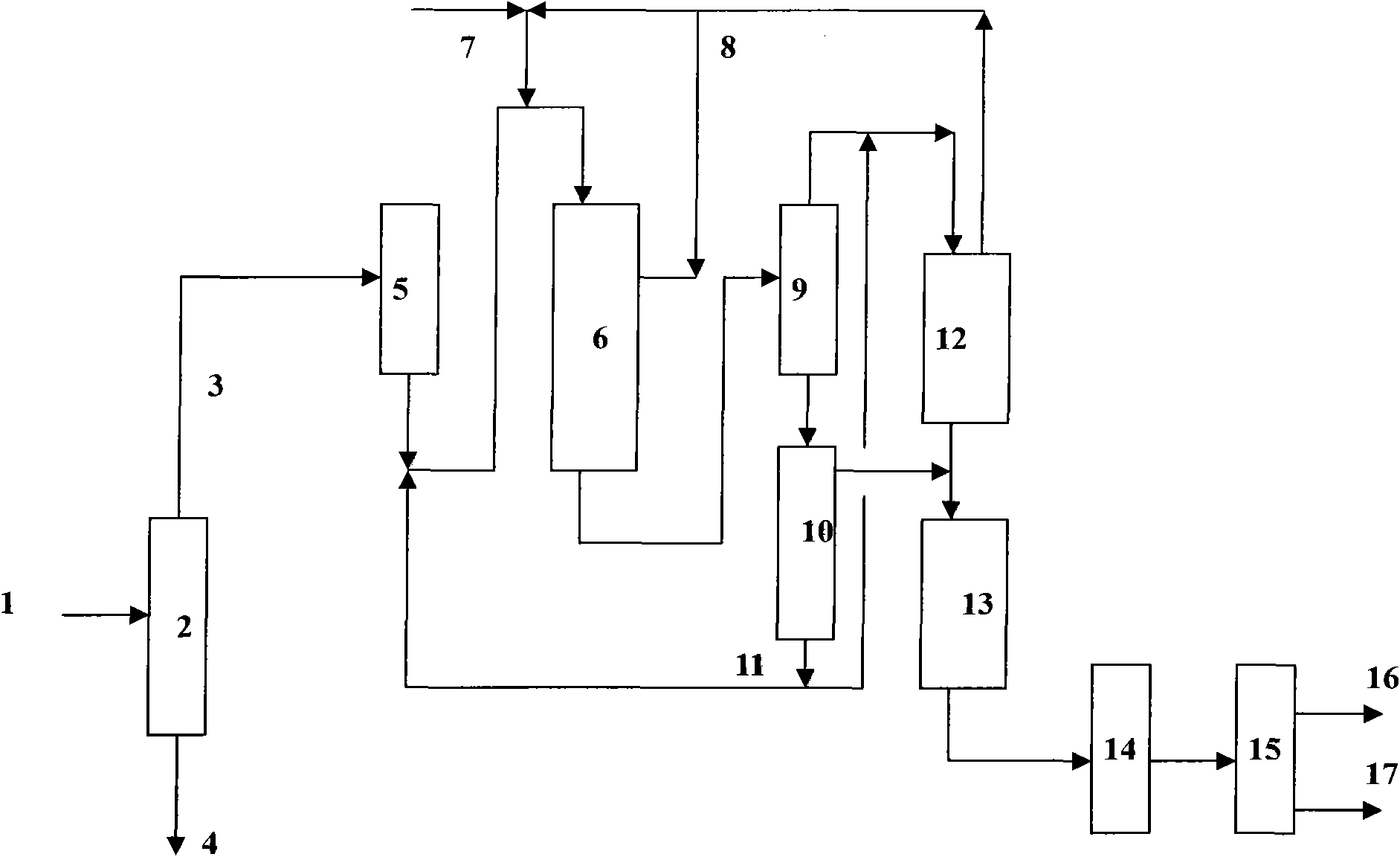

Method used

Image

Examples

Embodiment 1~3

[0054] The properties of the light and heavy fractions of ethylene tar used are shown in Table 2 and Table 4. Example The ethylene tar light fraction is treated by a series process. Two reactors are used. The first reactor is equipped with a hydrogenation protection agent FZC-103 and a hydrofining catalyst 3936, and the upper part of the second reactor is filled with a hydrogenation carbon removal catalyst HDC. -3. The first hydrocracking catalyst loaded in the middle is a hydrocracking catalyst containing amorphous silica-alumina and Y molecular sieve, and the second hydrocracking catalyst loaded in the lower part is a hydrocracking catalyst containing amorphous silica-alumina and β molecular sieve . In the embodiment, the volume ratio of FZC-103:3936:HDC-3:first hydrocracking catalyst:second hydrocracking catalyst is as follows: 12:23:23:21:21. The results of the reaction are shown in Table 3. In addition, the device has been tested for 5,000 hours, and the results show th...

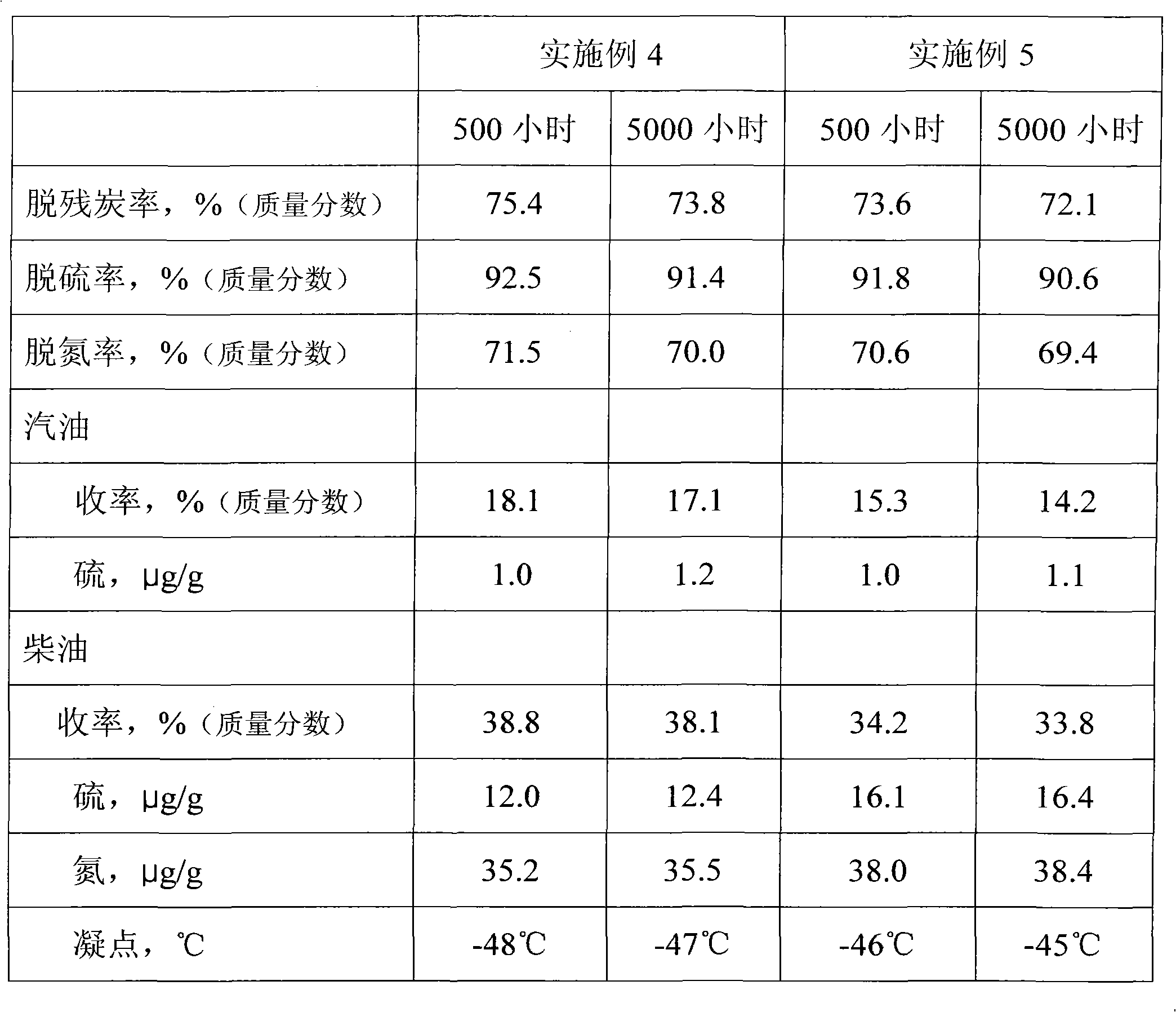

Embodiment 4

[0062] The heavy fraction of ethylene tar (see Table 4 for properties) passes through the hydrogenation protection catalyst, the hydrogenation deresidue catalyst and the hydrogenation conversion catalyst in sequence, and its volume ratio is 8:55:37, wherein the hydrogenation protection catalyst used is FZC-100 and FZC-102B, its volume ratio is 1: 2, the hydrogenation conversion catalyst such as the catalyst obtained in CN02109422.5 Example 1 is recorded as ZH1, and its properties are shown in Table 5.

[0063] Table 5 Composition and properties of hydroconversion catalysts

[0064]

[0065] The loading volume ratio of the used hydrodecarbonization catalyst HDC-1 and HDC-2 is 4:6. The loading order of the hydrogenation catalyst for the heavy fraction of ethylene tar is as follows: FZC-100, FZC-102B, HDC-1, HDC-2, ZH1. In this example, the process conditions for the hydrogenation of heavy fractions are as follows: the reaction pressure is 16MPa, the reaction temperatu...

Embodiment 5

[0067] Compared with Example 4, the loading volume ratio of the hydrodecarbonization catalysts HDC-1 and HDC-2 used was changed to 5:5, and the rest were the same as Example 4.

[0068] Table 6 Heavy fraction hydrogenation results

[0069]

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com