Method for processing ethylene tar

A technology of ethylene tar and processing method, which is applied in the petroleum industry, hydrotreating process, hydrocarbon oil treatment, etc. It can solve the problems that the ethylene tar fraction cannot be processed and has not been effectively processed, so as to save equipment investment and reduce the temperature rise of the device , the effect of reducing the content of aromatics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

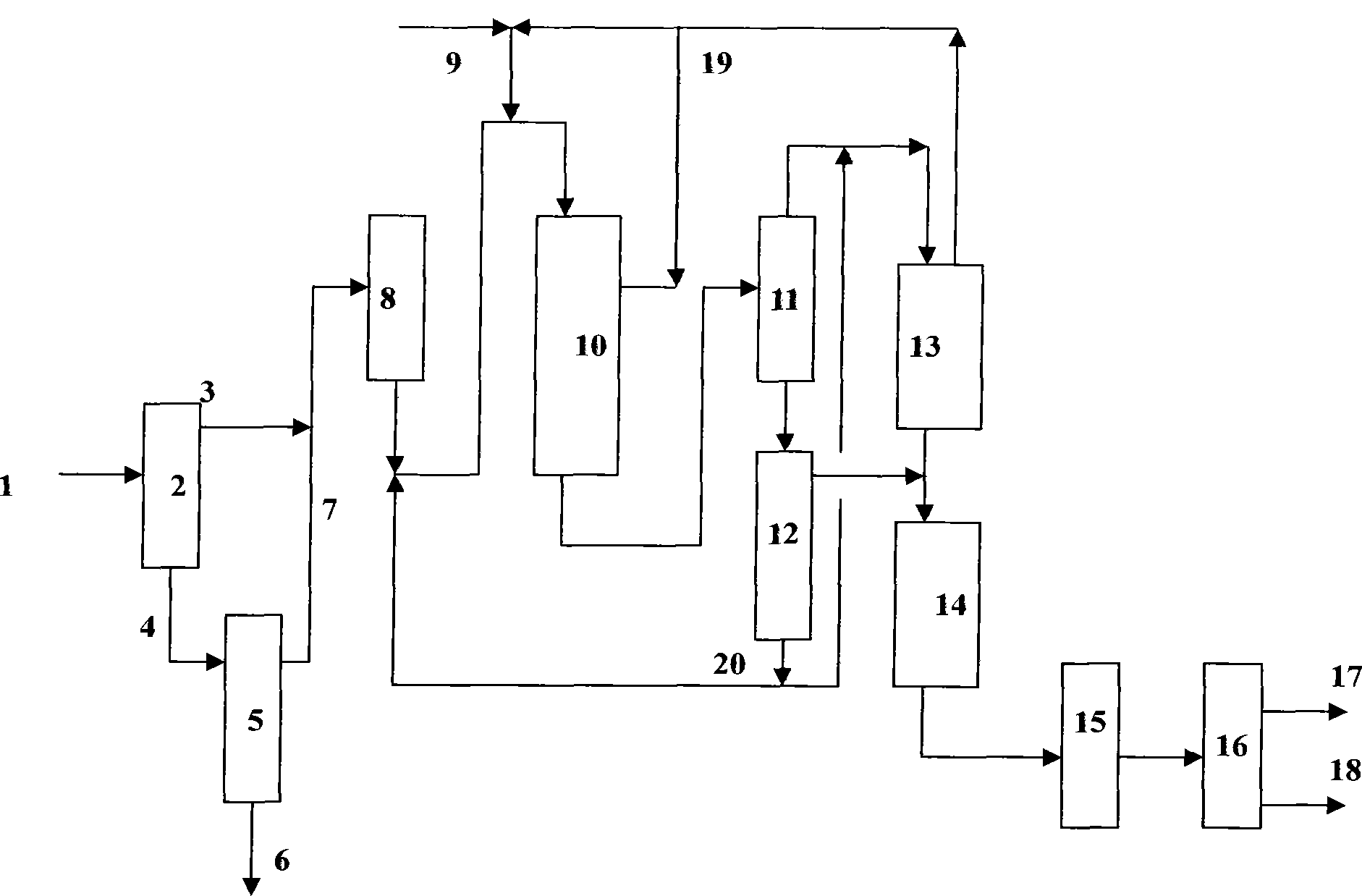

Image

Examples

Embodiment 1

[0046] Fractional distillation of ethylene tar into light fraction and heavy fraction, with a cut point of 430°C, wherein the heavy fraction is deasphalted with propane, the conditions are as follows: propane is used as solvent, the weight ratio of solvent to heavy fraction is 5:1, solvent extraction tower The pressure is 3.5MPa, the extraction temperature is 65°C, and the weight yield of deasphalted oil is 40%. The properties of deasphalted oil and light fraction mixed oil are shown in Table 2, and the properties of deoiled asphalt after deasphalting of ethylene tar heavy fraction are shown in Table 4.

[0047] The embodiment adopts a serial flow process and two reactors, the first reactor is equipped with hydrogenation protection agent FZC-103 and hydrofining catalyst 3936, and the second reactor is filled with hydrogenation carbon removal catalyst HDC-1, The lower part is loaded with hydrocracking catalyst A1 containing amorphous silica-alumina and Y molecular sieve. In Ex...

Embodiment 2

[0049] Compared with Example 1, the volume ratio of FZC-103:3936:HDC-1:hydrocracking catalyst A2 used becomes: 8:15:20:57. The operating conditions and the reaction results after 3000 hours of operation are shown in Table 3 .

Embodiment 3

[0051] Compared with Example 1, the volume ratio of FZC-103: 3936: HDC-1: hydrocracking catalyst B1: used becomes: 8: 15: 10: 67. The operating conditions and the reaction results after running for 3000 hours are shown in the table 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com