Hydrotreatment method of inferior heavy oil, hydrogenation protection catalyst and application

A low-quality heavy oil, hydrogenation treatment technology, applied in the direction of hydrogenation treatment process, physical / chemical process catalyst, catalyst protection, etc., can solve the problem of large pore volume ratio, low demetallization rate of hydrogenation protection catalyst, hydrogenation protection catalyst mechanical Reduced strength and other issues, to achieve the effect of increased utilization, improved combined economy, and increased yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0055] In some embodiments, the preparation method of the carrier includes: firstly mixing alumina, naphthalene and fullerene solution, adding an extrusion aid, extruding into a strip, and then drying and calcining.

[0056] Further, the preparation method includes: first mixing aluminum oxide and naphthalene.

[0057] Further, the mass ratio of aluminum oxide to naphthalene is 3-5:1.

[0058] Further, the amount of the fullerene is 0.1-0.6 wt%, preferably 0.2-0.5 wt%, of the total mass of the carrier.

[0059] Further, the fullerene solution is made of fullerene through CS 2 dissolved to form.

[0060] In the catalyst of the present invention, before the fullerene in the carrier is mixed with alumina, it is subjected to CS 2 dissolved, the CS 2 The dissolution temperature used for dissolution is 20-40°C, the pressure is 0.10-0.25MPa, and the dissolution time is 3-10min; the CS 2 Dissolved CS 2 The mass ratio to fullerene is 100-200:1.

[0061] Further, the fullerene is...

Embodiment 1

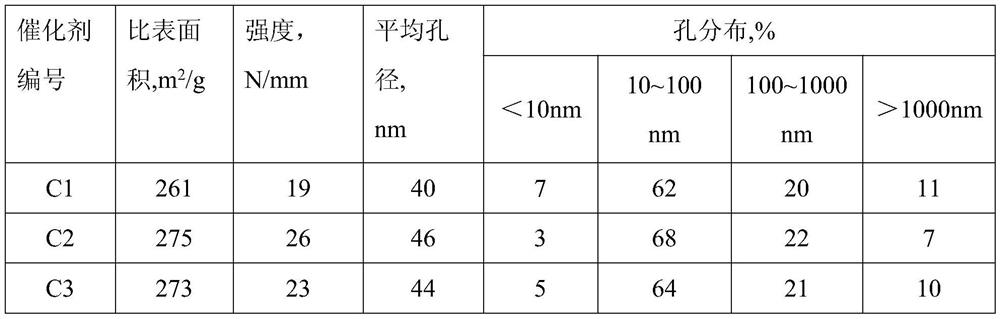

[0095] Example 1 Preparation of hydrogenation protection catalyst C1

[0096] (1) Preparation of catalyst carrier:

[0097] 0.30 g of fullerene C60 powder with a purity of 99.9%, under pressure 0.25 MPa, 30 ° C with 40 g CS 2 Dissolve for 6 min to obtain a fullerene solution; take 100 g of commercially available macroporous alumina powder with a pore volume of 1.1-1.6 ml / g, add 20 g of naphthalene and mix, then add it to the fullerene solution, stir and mix thoroughly, and add auxiliary The extruding agent, such as citric acid, is used in an amount to satisfy the carrier molding, and then kneading, rolling, and extruding into a strip; drying the extruded strip carrier at room temperature, and then using a heating rate of 5°C / h to set it. Bake in an oven at 70° C. for 4 hours, and break it into about 3-5 mm for later use; put the dried strips in a muffle furnace and bake at 600° C. for 6 hours to obtain a carrier.

[0098] (2) Preparation of catalyst:

[0099] Take the molyb...

Embodiment 2

[0100] The preparation of embodiment 2 hydrogenation protection catalyst C2

[0101] (1) Preparation of catalyst carrier:

[0102] 0.50 g of fullerene C60 powder with a purity of 99.5%, 50 g CS under pressure of 0.10 MPa and 20 °C 2 Dissolve for 10min to obtain a fullerene solution; take 90g of commercially available macroporous alumina powder with a pore volume of 1.1-1.6ml / g, add 30g of naphthalene and mix, add it to the fullerene solution, stir and mix thoroughly, and add auxiliary The extruding agent, such as citric acid, is used in an amount to satisfy the molding of the carrier, and then kneading, rolling, and extruding into a strip shape; drying the extruded strip carrier at room temperature, and then using a heating rate of 8°C / h to set it. Bake in an oven at 60° C. for 2 hours, and break it into about 3 to 5 mm for later use; put the dried strips in a muffle furnace and bake at 450° C. for 15 hours to obtain a carrier.

[0103] (2) Preparation of catalyst:

[0104]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com