Hydrogenation protection catalyst as well as preparation method and application thereof

A hydrogenation protection and catalyst technology, which is applied in the petrochemical field, can solve the problems such as the decrease of the mechanical strength of the carrier, the large addition amount, and the large particles, and achieve the effects of protecting the stability of the activity, improving the wear resistance, and improving the pore-enlarging effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] A method for preparing a hydrogenation protection catalyst, comprising the following steps:

[0040] (1) Mix and knead pseudo-boehmite, anthracene, biotite and extrusion aid evenly to obtain a mixture. in:

[0041] The added amount of the anthracene is 3.1-5.0% of the weight of the alumina carrier; the added amount of the biotite is 1.0-3.0% of the weight of the alumina carrier. The extrusion aid is one or more of starch, scallop powder, polyvinyl alcohol, methyl cellulose and polyethylene glycol, and its addition amount is 2 to 10 wt% based on the total weight of each component .

[0042] (2) Add the peptizing acid solution at 40-80°C to the mixture at a speed of 11-20g / min and knead evenly, after shaping, drying at 100-140°C, and roasting at 350-550°C for 5-10h, the alumina carrier is obtained . in:

[0043] The peptizing acid is one or more of nitric acid, phosphoric acid, citric acid, hydrochloric acid and acetic acid. The shaping is extruded into a cylindrica...

specific Embodiment

[0047] Preparation of hydrogenation protection catalyst C1: Take 50g of pseudo-boehmite, add 1.3g of anthracene, 0.7g of biotite, 3g of squash powder (extrusion aid), and knead evenly; add nitric acid (concentration of 60 %) aqueous solution, the addition rate is 20g / min, kneading, the addition amount is to meet the uniformity of kneading of the aforementioned four substances, extrude into a cylindrical strip with equal height-to-diameter ratio of 10mm, dry at 140°C for 7h, and roast at 400°C for 7.5h , to make an alumina carrier; then use cobalt nitrate to prepare an aqueous solution with a metal ion concentration of 10g / ml, add lauryl alcohol polyether to this solution to obtain an impregnating solution, which is used to impregnate the above alumina carrier for 7.5 hours, and then dry at 125°C 3h, 500 ℃ roasting 5h. The final composition of the catalyst is: 6.4wt% of cobalt oxide and the balance of aluminum oxide. Catalyst specific surface area 56m 2 / g, pore volume 0.56mL...

Embodiment 1

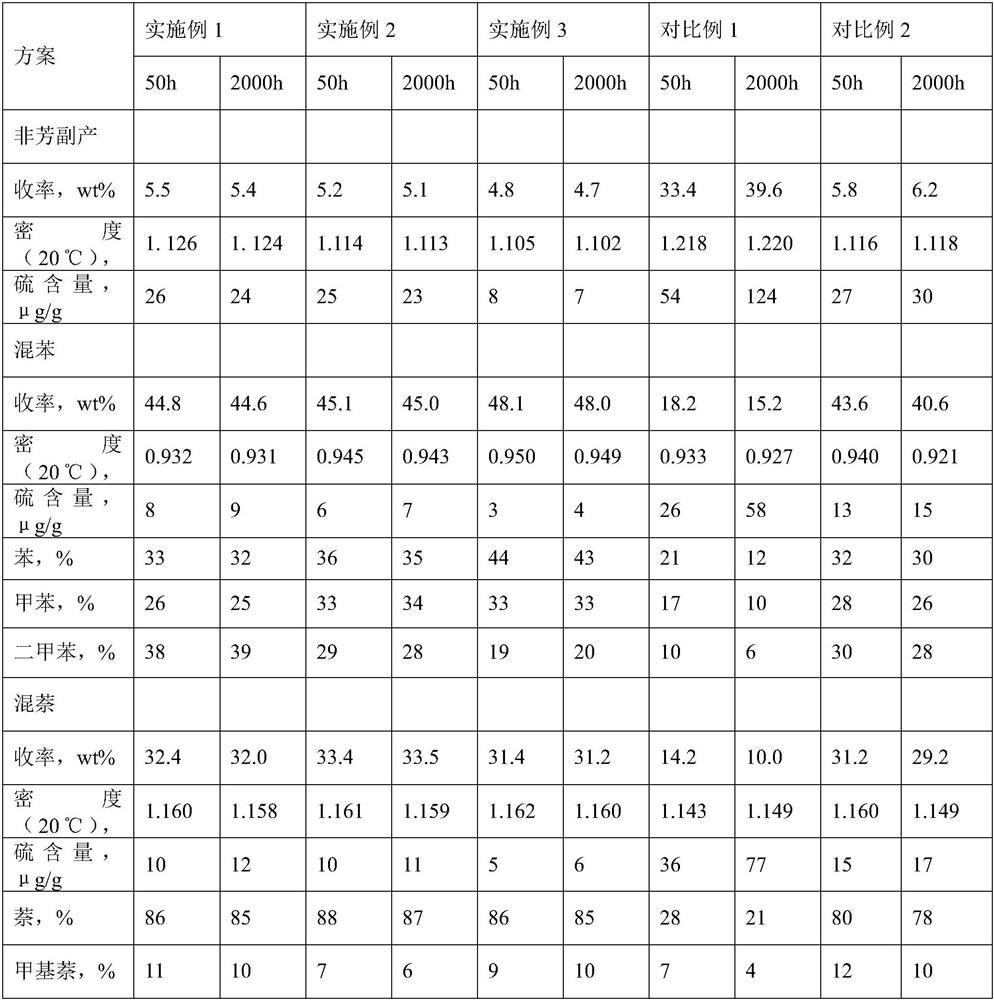

[0057] Example 1: Hydrogenation protection catalyst C1 and selective hydrofinishing catalyst 1010C are used, and the loading volume ratio is 1:3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com