Alumina carrier and its preparation method

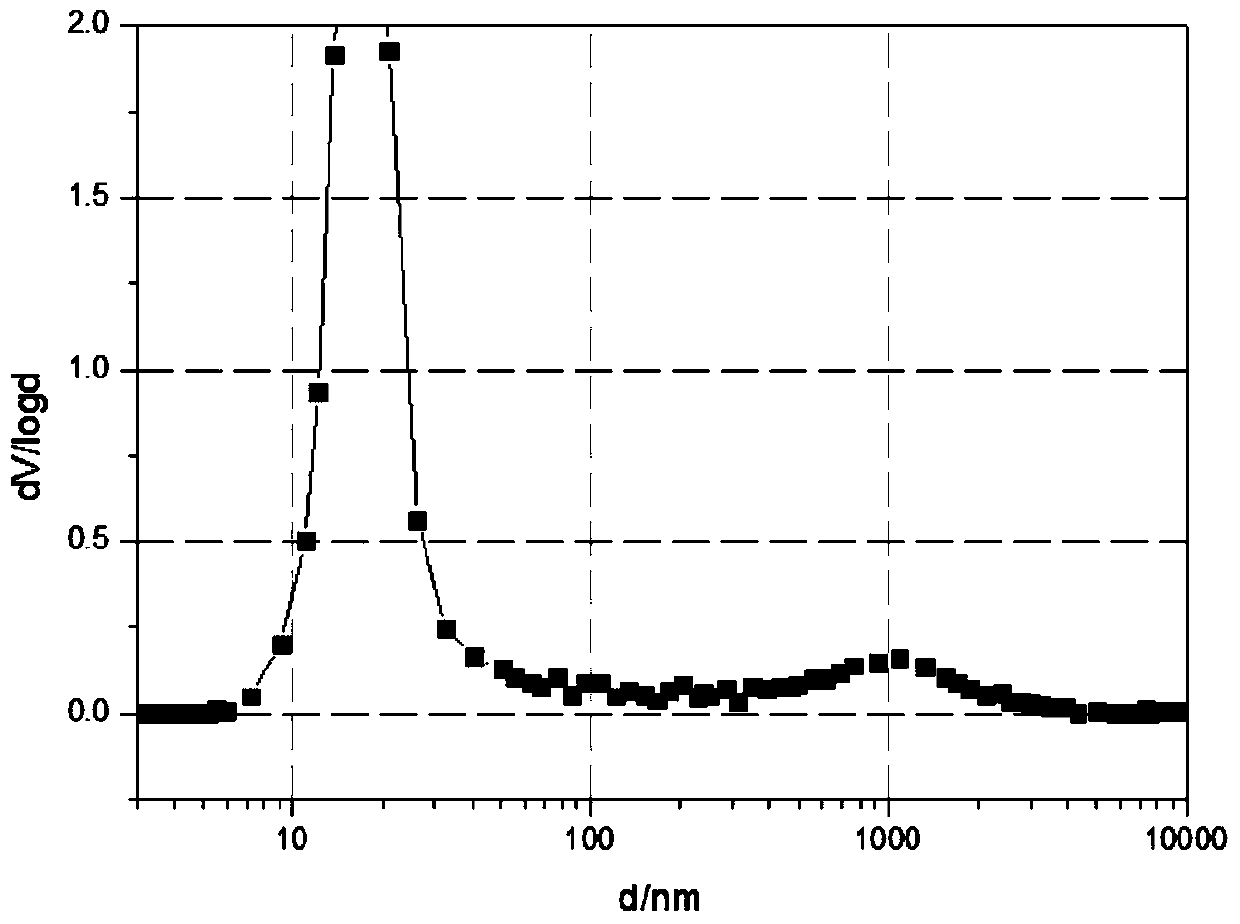

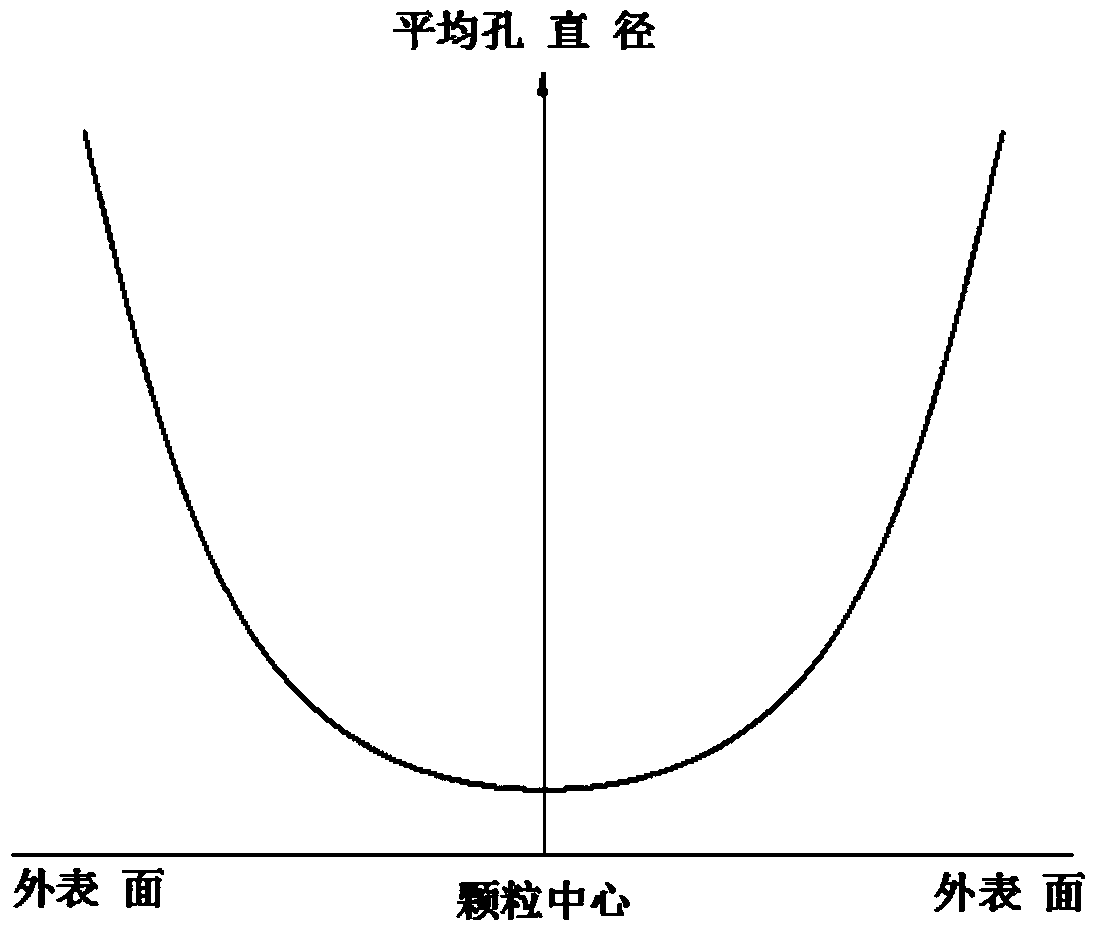

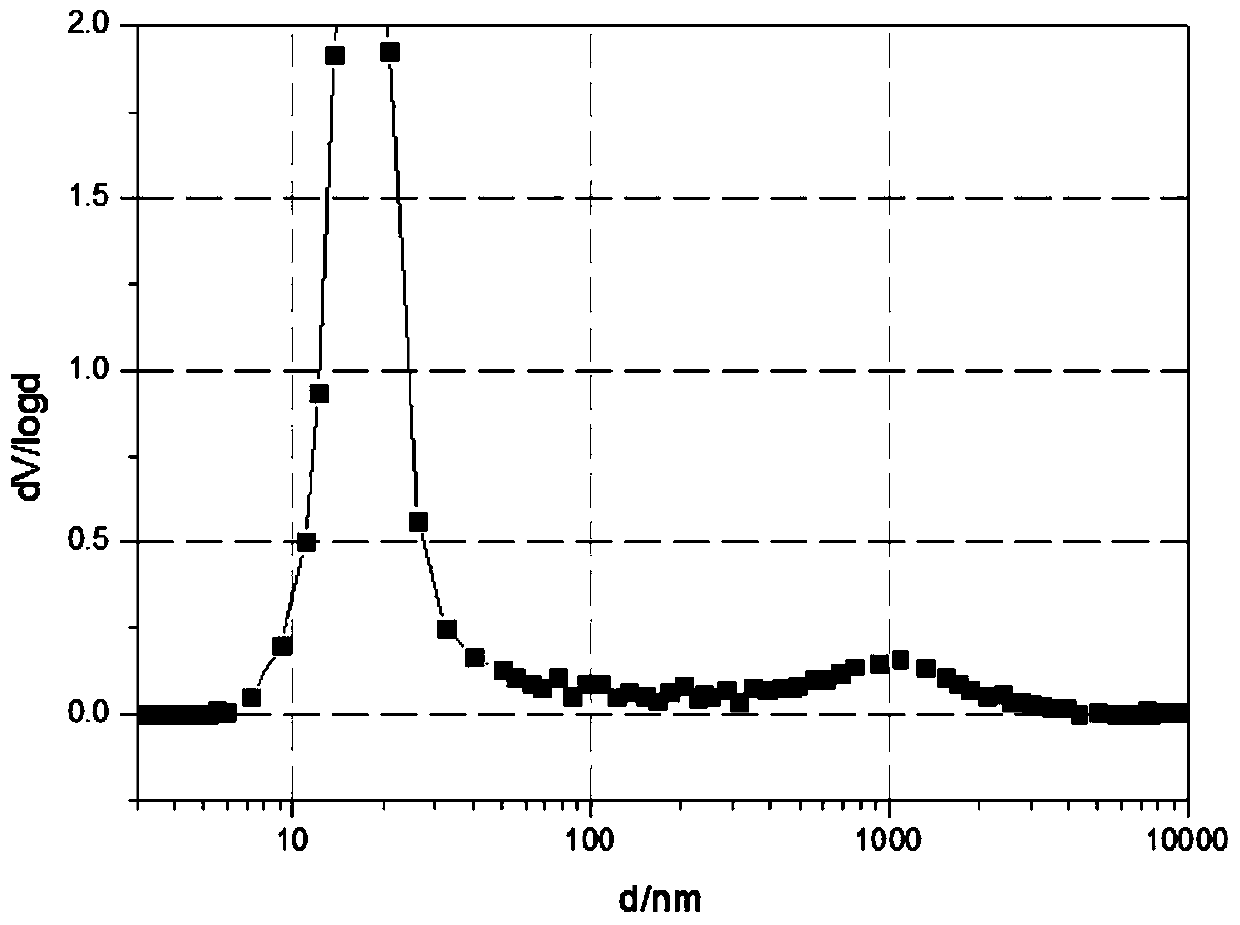

A technology of alumina carrier and boron compound, which is applied in the direction of catalyst carrier, chemical instrument and method, metal/metal oxide/metal hydroxide catalyst, etc., can solve the problem of increasing the pore volume and diameter of the carrier, destroying the structure of alumina particles, Reduce the problems of carrier pore volume and pore diameter, achieve better pore expansion effect, excellent diffusion performance, and high proportion of macropores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Weigh 500 g of macroporous pseudoboehmite dry rubber powder (dry basis content 71.5wt%) produced by Yantai Henghui Chemical Co., Ltd., and add hydroxypropyl powder with a viscosity of 150,000 mPa·s (referring to the viscosity of a 2% aqueous solution). 10.7g of methyl cellulose, 53.6g of polyvinyl alcohol powder with a specification of 17-88, mix well; dissolve 40.9g of boric acid in 570g of clean water, slowly add to the above-mentioned materials, knead into a plastic body, and then extrude in a single screw Extrude into a clover shape with a diameter of 1.6mm on a strip machine. Dry at 120°C for 2.0 hours, and process at 300°C for 3 hours. Take 100g of treated particles, spray 64.0g of deionized water evenly on the obtained alumina carrier at a speed of 30mL / min, and evenly add 16.0g of glacial acetic acid to the aforementioned deionized water at a speed of 4.0g / min while spraying water . After spraying to the saturated water absorption rate of the particles, let st...

Embodiment 2

[0053] Weigh the aforementioned pseudo-boehmite 500g, add 3.6g of hydroxypropyl methylcellulose with a viscosity of 150,000 mPa·s (referring to the viscosity of a 2% aqueous solution), and 28.6g of polyvinyl alcohol powder with a specification of 17-99 , and mix evenly; 20.5 grams of boric acid was dissolved in 570 g of clean water, molded and dried according to the aforementioned method, and treated at 200° C. for 4 hours. Take 100g of treated particles, spray 48.0g of 5.0wt% acetic acid solution evenly on the material, and finally spray 32.0g of 15.0wt% acetic acid solution on the obtained material, and let stand at 20°C for 3.0 hours . The same method as in Example 1 was dried and calcined to obtain carrier B, the properties of which are shown in Table 1.

Embodiment 3

[0055] Take by weighing 500g of the aforementioned pseudo-boehmite, add 17.9g of hydroxyethyl methylcellulose and 28.6g of boron oxide with a viscosity of 100,000 mPa·s (referring to the viscosity of a 2% aqueous solution) and mix uniformly; 31.0 grams of boric acid and the specification Dissolve 17.9 g of polyvinyl alcohol powder of 17-88 in 570 g of clean water, shape and dry according to the aforementioned method, and treat at 450° C. for 1 hour. Get 100g of processed particulate matter, spray 28.0g concentration of 1.0wt% nitric acid on the obtained material, continue to spray 28.0g concentration of 5.0wt% nitric acid solution on the material, and finally spray 24.0g concentration of 10.0wt% % nitric acid solution evenly sprayed on the material, 100 ° C for 0.5 hours. The same method as in Example 1 was dried and calcined to obtain carrier C, the properties of which are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com