Processing method for by-products of ethylene equipment

A processing method and technology of an ethylene plant, which is applied in the processing field of by-products of an ethylene plant, can solve problems such as environmental pollution, low quality, and long process flow, and achieve the effects of simple process flow, good product quality, and increased added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

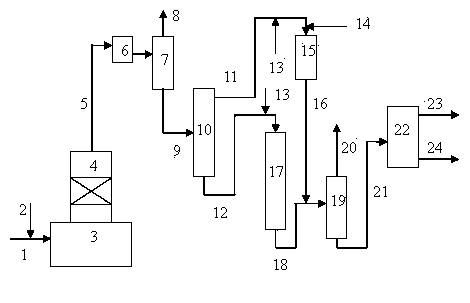

Image

Examples

Embodiment 1

[0044] See Table 3 for the thermal cracking / catalytic reaction process conditions of the ethylene tar and heavy benzene mixed raw materials, the yields of the gas products, liquid products, and residues, and the properties of the heavy fraction. The catalyst used in the catalytic reaction zone is HC-1 molecular sieve catalyst, and the catalyst dosage is 1.5wt% of ethylene tar. The light ends and ethylene cracking C 9 The hydrofinishing process conditions of component mixed raw materials are shown in Table 4, in which the volume ratio of pre-hydrofinishing catalyst to hydrofining catalyst is 3:1. The process conditions of the heavy fraction hydrofining / hydrocracking are shown in Table 5, wherein the volume ratio of the hydroprotecting agent, the hydrofining catalyst, and the hydrocracking catalyst is 10:60:30. The properties of the gasoline fraction and diesel fraction obtained at the end of the reaction are shown in Table 6.

Embodiment 2

[0046] Compared with Example 1, the catalyst used in the catalytic reaction zone is a ZSM-5 molecular sieve catalyst. The light ends and ethylene cracking C 9 The hydrofinishing process conditions of component mixed raw materials are shown in Table 4, in which the volume ratio of the pre-hydrofinishing catalyst to the hydrofining catalyst is 1:2. The conditions of the heavy fraction hydrofining / hydrocracking process are shown in Table 5, wherein the volume ratio of the hydrotreating agent, hydrofining catalyst, and hydrocracking catalyst is 15:50:35, and the reaction results are shown in Table 6.

Embodiment 3

[0048] Compared with Example 1, the catalysts used in the catalytic reaction zone are HC-1 molecular sieve catalyst and ZSM-5 molecular sieve catalyst, and the volume ratio of the two catalysts is 1:1. The light ends and ethylene cracking C 9 The hydrofinishing process conditions of component mixed raw materials are shown in Table 4, in which the volume ratio of the pre-hydrofinishing catalyst to the hydrofinishing catalyst is 1:1. The process conditions of the heavy fraction hydrofining / hydrocracking are shown in Table 5, wherein the volume ratio of the hydroprotecting agent, the hydrofining catalyst, and the hydrocracking catalyst is 10:60:30. The reaction results are shown in Table 6.

[0049]

[0050] Table 1 Properties of ethylene tar

[0051] crude oil name Ethylene tar Density (20℃), kg·m -3 1090.5 S, μg g -1 355 N, μg·g -1 187 Four components, wt% Saturation 2.57 Aroma 45.50 colloid 29.93 Asphaltenes 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com