Method and system for producing diesel oil from inferior oil material

A kind of oil and low-quality technology, applied in the field of low-quality oil production of diesel and systems, can solve the problems of poor quality of light diesel products, long processing process, etc., to overcome the problems of high cracking initiation temperature, good product quality, emission reduction and efficiency increase Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

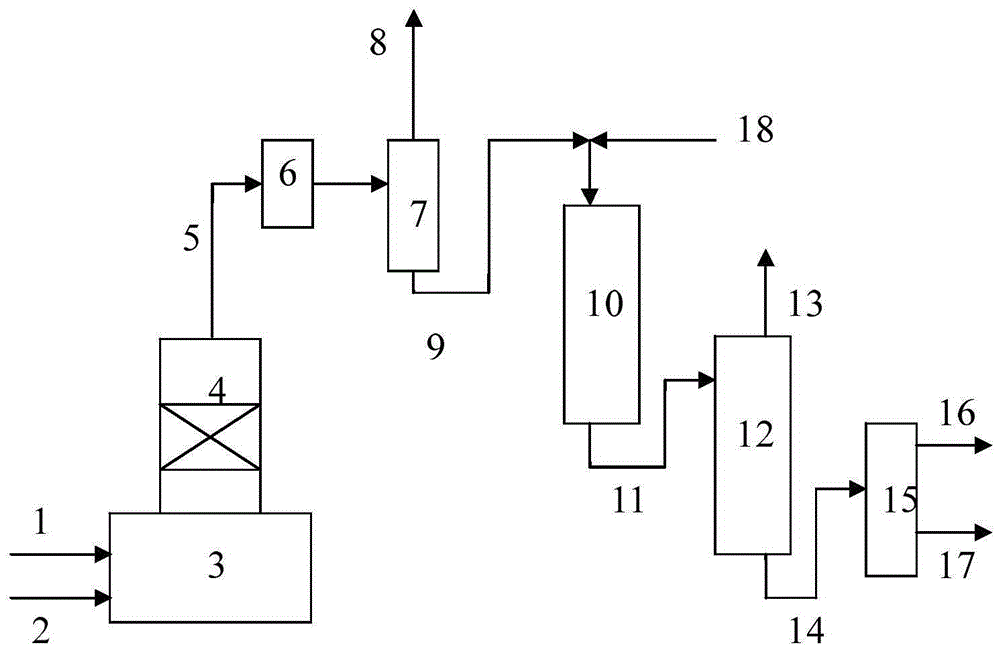

Method used

Image

Examples

Embodiment 1

[0096] Example 1 See Table 2 for the thermal cracking / catalytic reaction process conditions of ethylene tar and polyethylene mixed feedstock, the yields of the three products obtained, gas products, liquid products, and residues, and the properties of the whole fraction. The catalyst used in the catalytic reaction zone is a KIT-6 molecular sieve catalyst, and the catalyst consumption is 1.5wt% of ethylene tar. The conditions of the whole fraction hydrofining / hydrocracking process are shown in Table 3, wherein the hydroprotecting agent and the hydrofining catalyst , The volume ratio of the hydrocracking catalyst is 10:60:30. The properties of the gasoline fraction and diesel fraction obtained at the end of the reaction are shown in Table 4.

Embodiment 2

[0097] Embodiment 2 Compared with Embodiment 1, the catalyst used in the catalytic reaction zone is KIT-6 molecular sieve catalyst. The process conditions of the whole fraction hydrofining / hydrocracking are shown in Table 3, wherein the volume ratio of the hydrotreating agent, hydrofining catalyst, and hydrocracking catalyst is 15:50:35, and the reaction results are shown in Table 4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com