Preparation method of high-density and high-strength granular calcined coke

A powerful and granular technology, applied in the field of preparation of high-density and high-strength granular calcined coke, can solve the problems of increasing production costs, unfavorable economic benefits of enterprises, and unsatisfactory effects, and achieves reasonable pore distribution, stable product quality, and raw material performance requirements. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

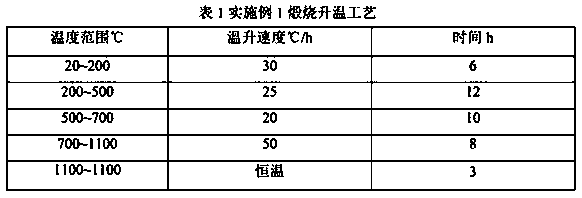

Embodiment 1

[0028] A method for preparing high-density and high-strength granular calcined coke, comprising the following steps:

[0029] S1. First pass the purchased Fushun petroleum coke raw coke through a 15-mesh sieve to obtain raw coke powder, and then crush the sieved raw coke powder until the particle size of the raw coke powder is less than 75 μm. The quality is 70%, and the green coke powder is reserved for later use, and the volatile matter in the green coke powder is 12.5%wt;

[0030] S2. Break the asphalt with a softening point of 295°C to a particle size of ≤100 μm, and prepare asphalt powder for later use;

[0031] S3. Add the asphalt powder obtained in step S2 to the raw coke powder obtained in step S1, wherein the quality of the asphalt powder accounts for 10% of the total mass of the two powder mixtures, and put the powder mixture into a three-dimensional mixer After mixing in the medium for 1h, pressed powder was obtained, and the volatile content in the pressed powder ...

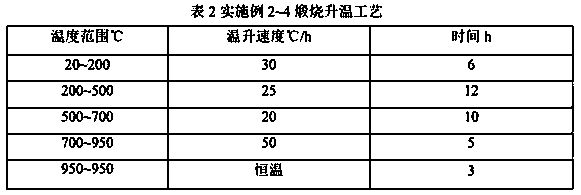

Embodiment 2

[0036] A method for preparing high-density and high-strength granular calcined coke, comprising the following steps:

[0037] S1. First pass the purchased Fushun petroleum coke raw coke through a 20-mesh sieve to obtain raw coke powder, and then crush the sieved raw coke powder until the particle size of the raw coke powder is less than 75 μm. The mass is 75%, and the green coke powder is reserved for later use, and the volatile matter in the green coke powder is 12.5%wt;

[0038] S2. Break the asphalt with a softening point of 110°C to a particle size of ≤150 μm, and prepare asphalt powder for later use;

[0039] S3. Add the asphalt powder obtained in step S2 to the raw coke powder obtained in step S1, wherein the quality of the asphalt powder accounts for 10% of the total mass of the two powder mixtures, and put the powder mixture into a three-dimensional mixer After mixing in the medium for 2 hours, pressed powder was obtained, and the volatile matter in the pressed powder...

Embodiment 3

[0044] A method for preparing high-density and high-strength granular calcined coke, comprising the following steps:

[0045] S1. First pass the purchased Jinzhou petroleum coke raw coke through a 18-mesh sieve to obtain raw coke powder, and then crush the sieved raw coke powder until the particle size of the raw coke powder is less than 75 μm. The quality is 80%, and the green coke powder is reserved for later use, and the volatile matter in the green coke powder is 11.8%wt;

[0046] S2. Crush the asphalt with a softening point of 110°C to a particle size of ≤180 μm, and prepare asphalt powder for later use;

[0047] S3. Add the asphalt powder obtained in step S2 to the raw coke powder obtained in step S1, wherein the quality of the asphalt powder accounts for 4% of the total mass of the two powder mixtures, and put the powder mixture into a three-dimensional mixer After mixing in the medium for 2 hours, pressed powder was obtained, and the volatile matter in the pressed pow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com