Preparation method of super capacitor

A supercapacitor and electrode technology, which is applied in the field of supercapacitor preparation, can solve the problems of preparation process and complex equipment, and achieve the effects of simple preparation method, simplified production process, and reduced internal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

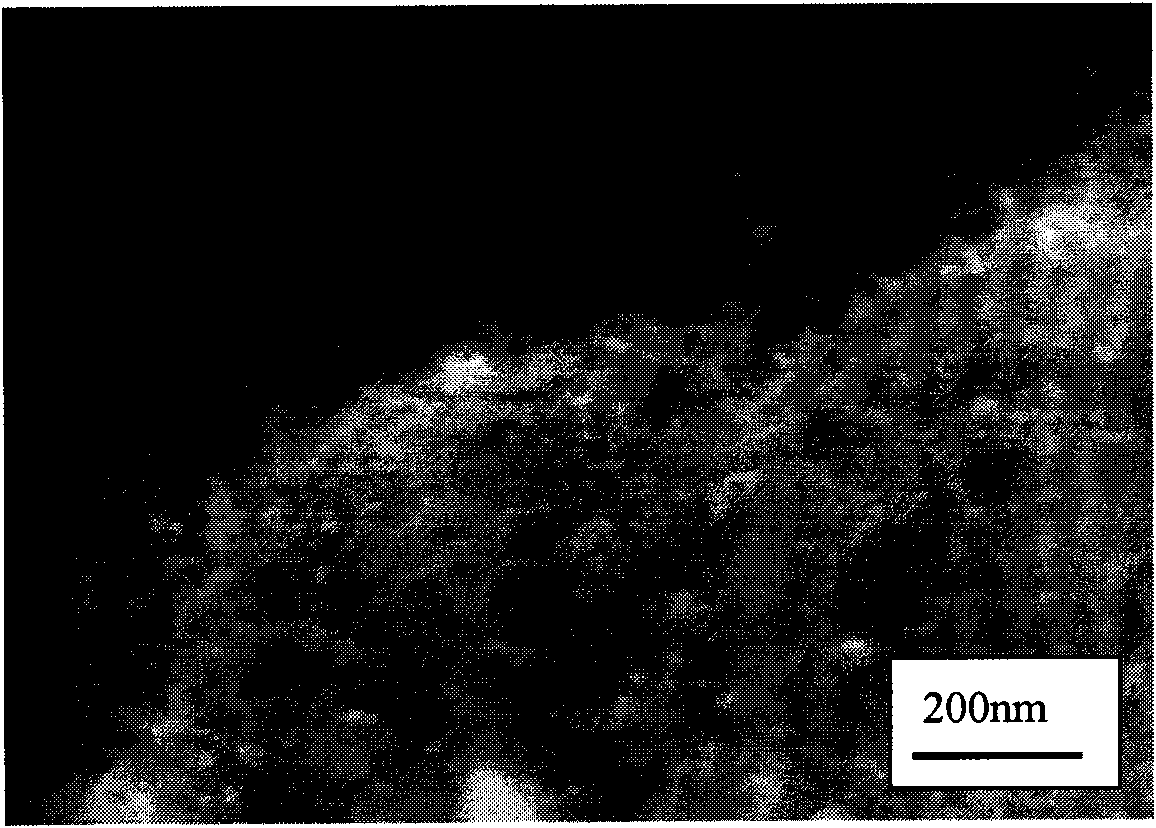

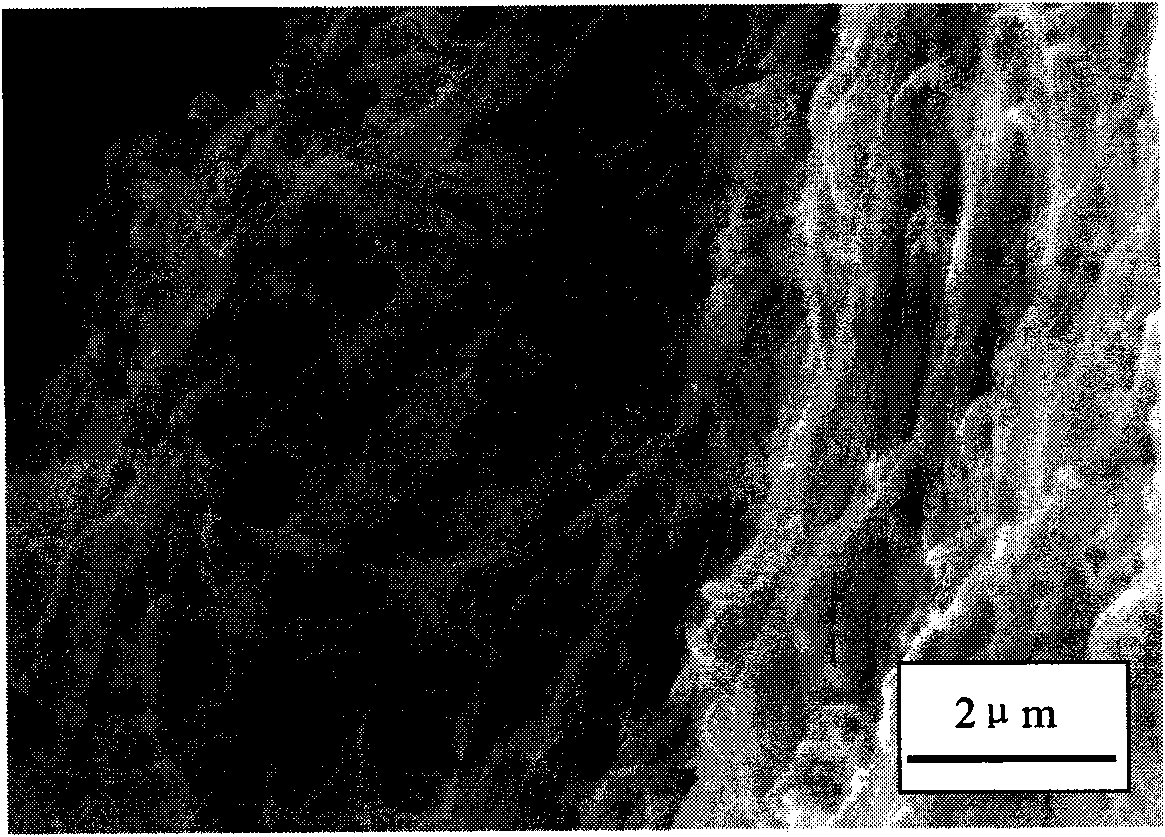

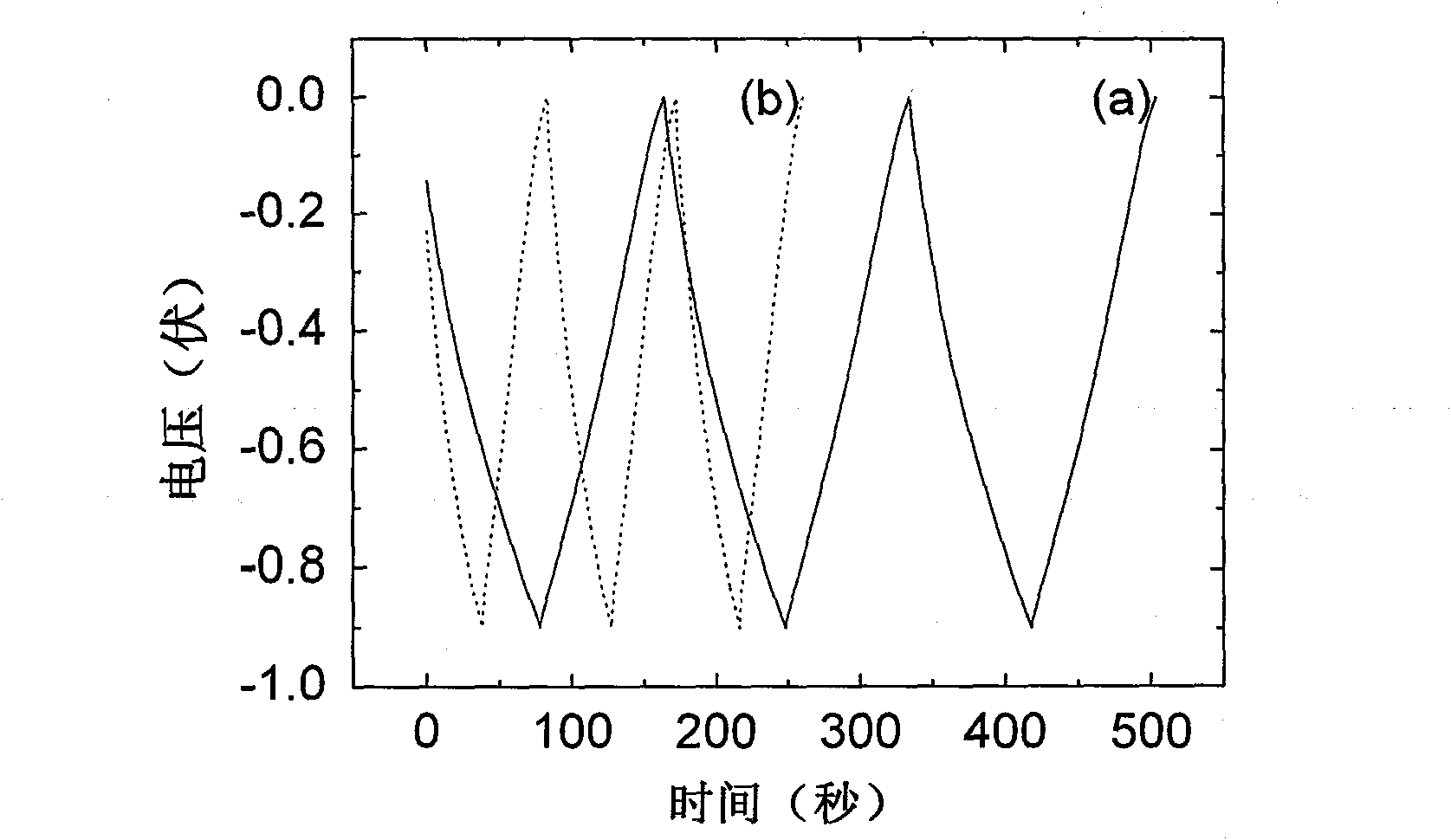

[0019] Embodiment one: (1) the nickel foam is cut into 10mm*10mm rectangular small pieces; (2) it is placed on the porcelain boat, and then the thermocouple probe and the porcelain boat are put into a suitable area of the CVD reaction furnace; (3) Introduce argon (Ar) to remove the air in the CVD reaction furnace and serve as a protective atmosphere. The flow rate is 200ml / min, and the air is ventilated for 40 minutes to ensure that the air is exhausted; (4) raise the temperature of the CVD reaction furnace to 620°C , and then the reaction gas acetylene (C 2 h 2 ), the flow control was 30ml / min, and the reaction was 10 minutes; (5) turn off the acetylene gate, continue to feed argon to make it drop to normal temperature, then take out the foamed nickel with carbon nanotubes; (6) take out the foamed nickel Nickel is directly used as an electrode of a supercapacitor, and finally assembled into a supercapacitor. The 80,000-fold scanning electron micrograph of the carbon nanot...

Embodiment 2

[0020] Embodiment two: In this embodiment, the reaction furnace is heated up to 550° C., and then the reaction gas acetylene (C 2 h 2 ), flow control is 40ml / min, reacts 1 minute; Other reaction conditions are with embodiment one.

Embodiment 3

[0021] Embodiment Three: In this embodiment, the reaction furnace is brought to 650° C., and then the reaction gas acetylene (C 2 h 2 ), flow control is 25ml / min, reacts 15 minutes; Other reaction conditions are with embodiment one.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com