Modified double-liquid paste injection material

A two-liquid grouting and modification technology, which is applied in the field of soft ground reinforcement and anti-seepage water plugging grouting in underground engineering, can solve the problems of poor durability, poor corrosion resistance, and unstable structure, and achieve good durability and improved compactness. degree and strength, porosity reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~6

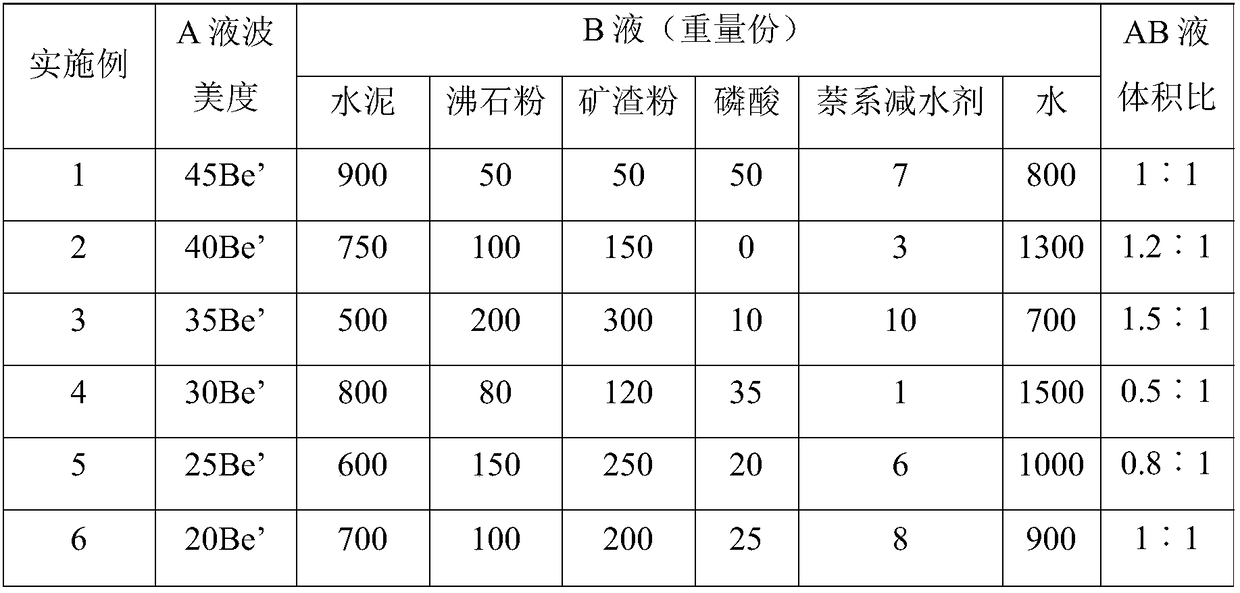

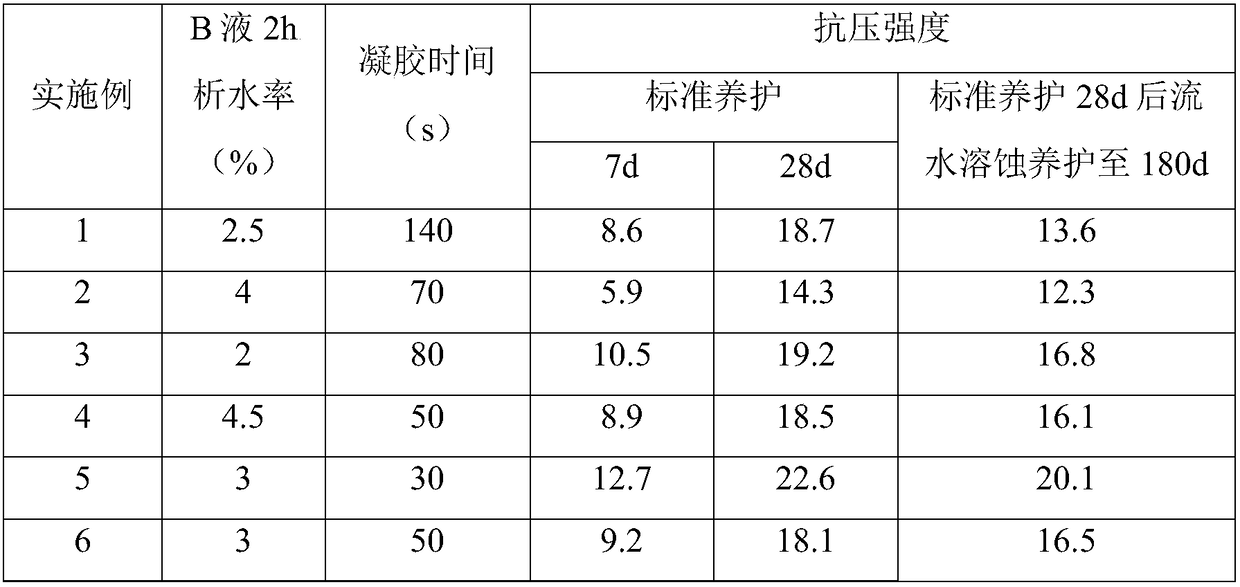

[0016] A liquid preparation: choose the required concentration of water glass solution. Preparation of liquid B: Measure according to the required parts by mass, first add phosphoric acid, naphthalene-based water reducer, zeolite powder and slag powder to the water, stir well, then add cement, continue stirring evenly. Mix liquid A and liquid B uniformly according to the required volume ratio to obtain the finished grouting material. The distribution ratio of each group in Examples 1-6 is shown in Table 1.

[0017] Table 1 The distribution ratio of each component of the modified two-liquid grouting material

[0018]

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com