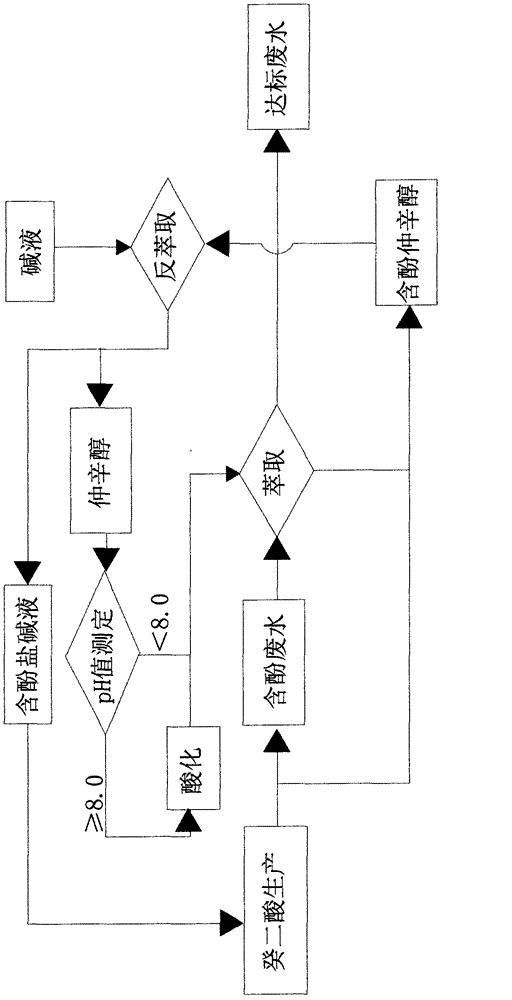

Waste water treatment process in sebacic acid production

A wastewater treatment and sebacic acid technology, which is applied in natural water treatment, extracted water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of small adsorption capacity of sulfonated coal, difficulty in regeneration of activated carbon, and short practical cycle of resin and other problems, to achieve the effect of short equilibrium time, rapid stratification, and avoiding secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The phenol-containing wastewater produced by sebacic acid and 2-octanol flow countercurrently into the extraction tank at the same time. The effective mass percentage of secondary octanol and phenol-containing wastewater is 1:10, three-stage countercurrent extraction, and the extraction temperature is 70°C. Before extraction, the phenolic value of secondary octanol was less than 10ppm, and the phenolic value of wastewater was about 4000ppm; after extraction, the phenolic value of secondary octanol increased to nearly 40000ppm, and the phenolic value of phenolic wastewater decreased to about 5ppm.

[0032] After extraction, the secondary octanol enters the stripping process for phenol recovery. The phenol-containing secondary octanol and the lye sodium hydroxide enter the extraction tank countercurrently at the same time, the concentration of the sodium hydroxide solution is 10%, and the molar ratio of the phenol content in the phenol-containing 2-octanol to the effectiv...

Embodiment 2

[0034] The phenol-containing wastewater produced by sebacic acid and 2-octanol flow countercurrently into the extraction tank at the same time. The effective mass percentage of secondary octanol and phenol-containing wastewater is 1:8, three-stage countercurrent extraction, and the extraction temperature is 80°C. Before extraction, the phenolic value of secondary octanol was less than 10ppm, and the phenolic value of wastewater was about 5000ppm; after extraction, the phenolic value of secondary octanol increased to nearly 50000ppm, and the phenolic value of phenolic wastewater decreased to about 5ppm.

[0035] After extraction, the secondary octanol enters the stripping process for phenol recovery. The phenol-containing secondary octanol and the lye sodium hydroxide enter the extraction tank countercurrently at the same time, the concentration of the sodium hydroxide solution is 20%, and the molar ratio of the phenol content in the phenol-containing 2-octanol to the effective...

Embodiment 3

[0037]The phenol-containing wastewater produced by sebacic acid and 2-octanol flow countercurrently into the extraction tank at the same time. The effective mass percentage of secondary octanol and phenol-containing wastewater is 1:6, three-stage countercurrent extraction, and the extraction temperature is 60°C. Before extraction, the phenolic value of secondary octanol was less than 10ppm, and the phenolic value of wastewater was about 5000ppm; after extraction, the phenolic value of secondary octanol increased to nearly 60000ppm, and the phenolic value of phenolic wastewater decreased to about 5ppm.

[0038] After extraction, the secondary octanol enters the stripping process for phenol recovery. The phenol-containing secondary octanol and the lye sodium hydroxide enter the extraction tank countercurrently at the same time, the concentration of the sodium hydroxide solution is 30%, and the molar ratio of the phenol content in the phenol-containing 2-octanol to the effective ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com