Method for preparing 10 - hydroxy capric acid

A technology for the synthesis of hydroxydecanoic acid, which is applied in chemical instruments and methods, preparation of carboxylate salts, and preparation of organic compounds. Safe production, high heating efficiency, and energy-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

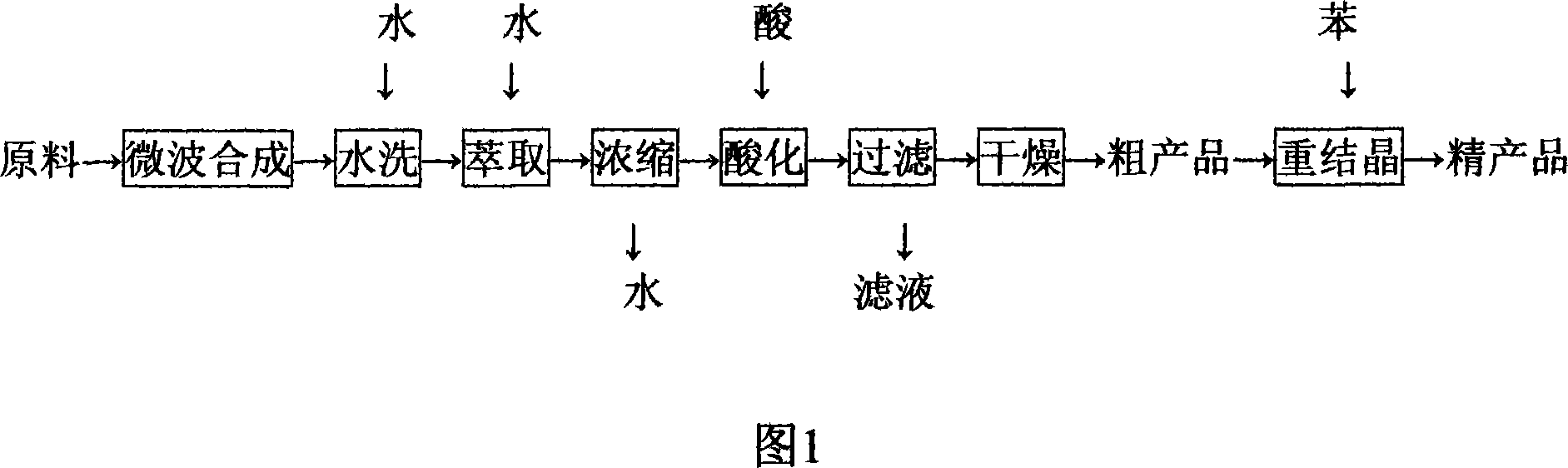

Method used

Image

Examples

Embodiment 1

[0018] 14g castor oil is mixed with 6g secondary octanol, and the mixture of above-mentioned castor oil and secondary octanol is dripped into microwave (microwave frequency is 2450MHz; microwave power is 300W) radiated to 15g secondary octanol under 120 ℃ at a constant rate of 1mL / min. In a mixture of octanol and 20 g of 75% (mass percentage) sodium hydroxide, stir evenly, keep the same microwave frequency and power, continue microwave radiation to make the reaction temperature 150-180° C., and keep reflux for 1 h. After the reaction, add 60mL of water to wash away the alkali and remove the water layer; the oil layer was extracted 4 times with hot water at 80-85°C, and the water layers were combined and acidified to pH 6.0-6.5 with 60-70% (mass percent) sulfuric acid, cooled To 30 ~ 40 ℃, continue to acidify until the Congo red test paper turns blue. Stand still for 4 hours, filter with suction, and dry at 65°C to obtain solid 10-hydroxydecanoic acid, the yield is: 4.5g, and t...

Embodiment 2

[0020] Castor oil 14g is mixed with 14g secondary octanol, and the mixture of above-mentioned castor oil and secondary octanol is dripped into microwave (microwave frequency is 2450MHz; Microwave power is 200W) radiation to 21g secondary octanol under 110 ℃ with 3mL / min drop rate In a mixture of 25 g of octanol and 70% (mass percentage) sodium hydroxide, stir evenly, continue microwave (microwave frequency: 2450 MHz; microwave power: 400 W) radiation to make the reaction temperature: 160-190 ° C, keep reflux for 1.5 h. After the reaction, add 50mL water to wash away the alkali, separate the water layer; extract the oil layer with hot water at 75-85°C for 4 times, and acidify the combined water layer with 60-70% (mass percent) sulfuric acid to pH6.0-6.5, and cool to 30 ~40°C, continue to acidify until the Congo red test paper turns blue. Stand still for 4 hours, filter with suction, and dry at 65°C to obtain solid 10-hydroxydecanoic acid, yield: 5.1 g, yield: 75%. White crysta...

Embodiment 3

[0022] Castor oil 14g is mixed with 4.2g secondary octanol, and the mixture of above-mentioned castor oil and secondary octanol is dripped into microwave (microwave frequency is 2450MHz; Microwave power is 400W) radiation to 21g In the mixture of 2-octanol and 70% (mass percentage) sodium hydroxide 20g, stir evenly, keep the same microwave frequency and power, continue microwave radiation to make the reaction temperature: 150-190°C, keep reflux for 2.5h. After the reaction, add 40mL water to wash away the alkali, separate the water layer; extract the oil layer with hot water at 75-85°C for 4 times, and acidify the combined water layer with 60-70% (mass percent) sulfuric acid to pH6.0-6.5, and cool to 30 ~40°C, continue to acidify until the Congo red test paper turns blue. Stand still for 4 hours, suction filter, and dry at 65°C to obtain solid 10-hydroxydecanoic acid, the yield is: 4.6g, and the yield is: 68%. White crystals are obtained after recrystallization from benzene, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| power | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com