Method for preparing lincomycin hydrochloride

A technology of lincomycin hydrochloride and its production method, applied in chemical instruments and methods, sugar derivatives, sugar derivatives, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

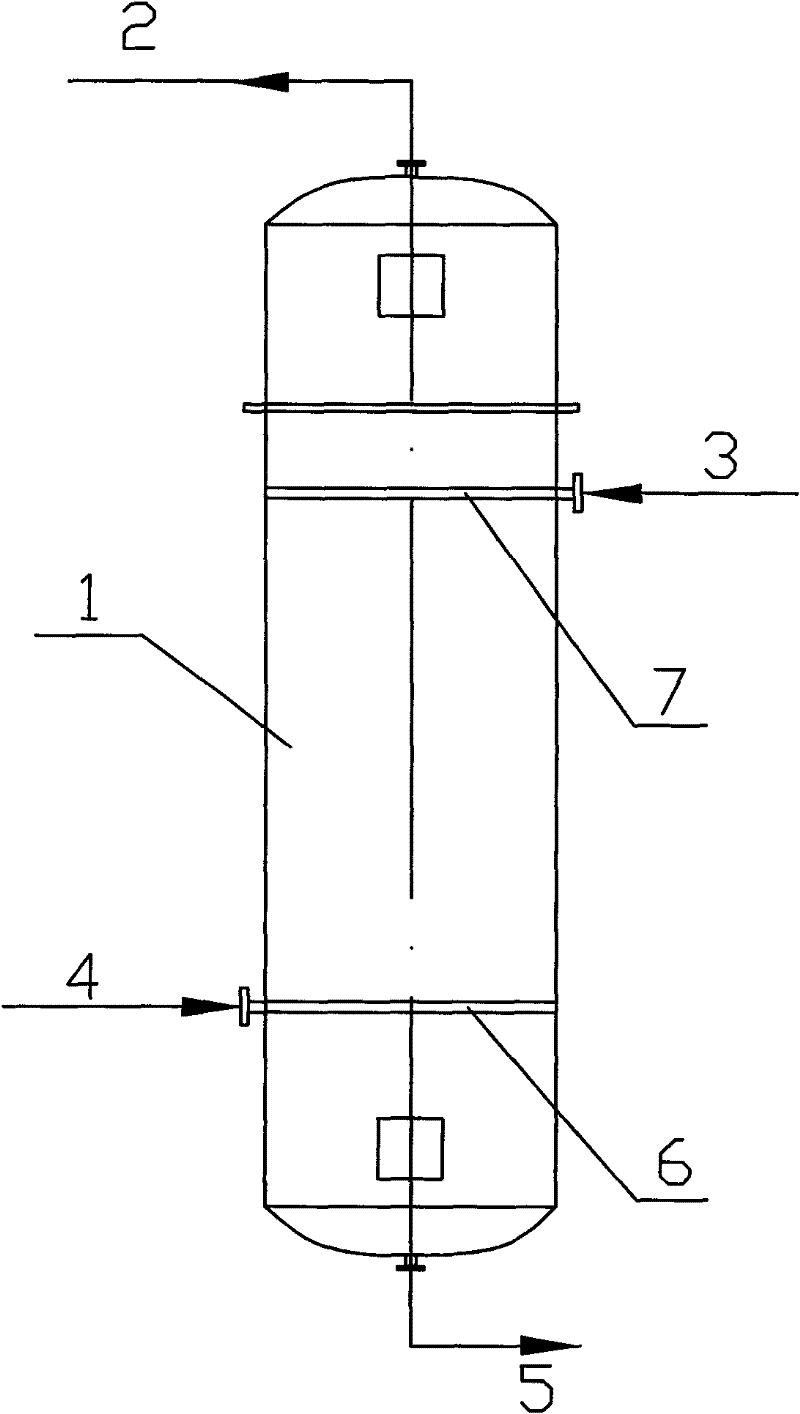

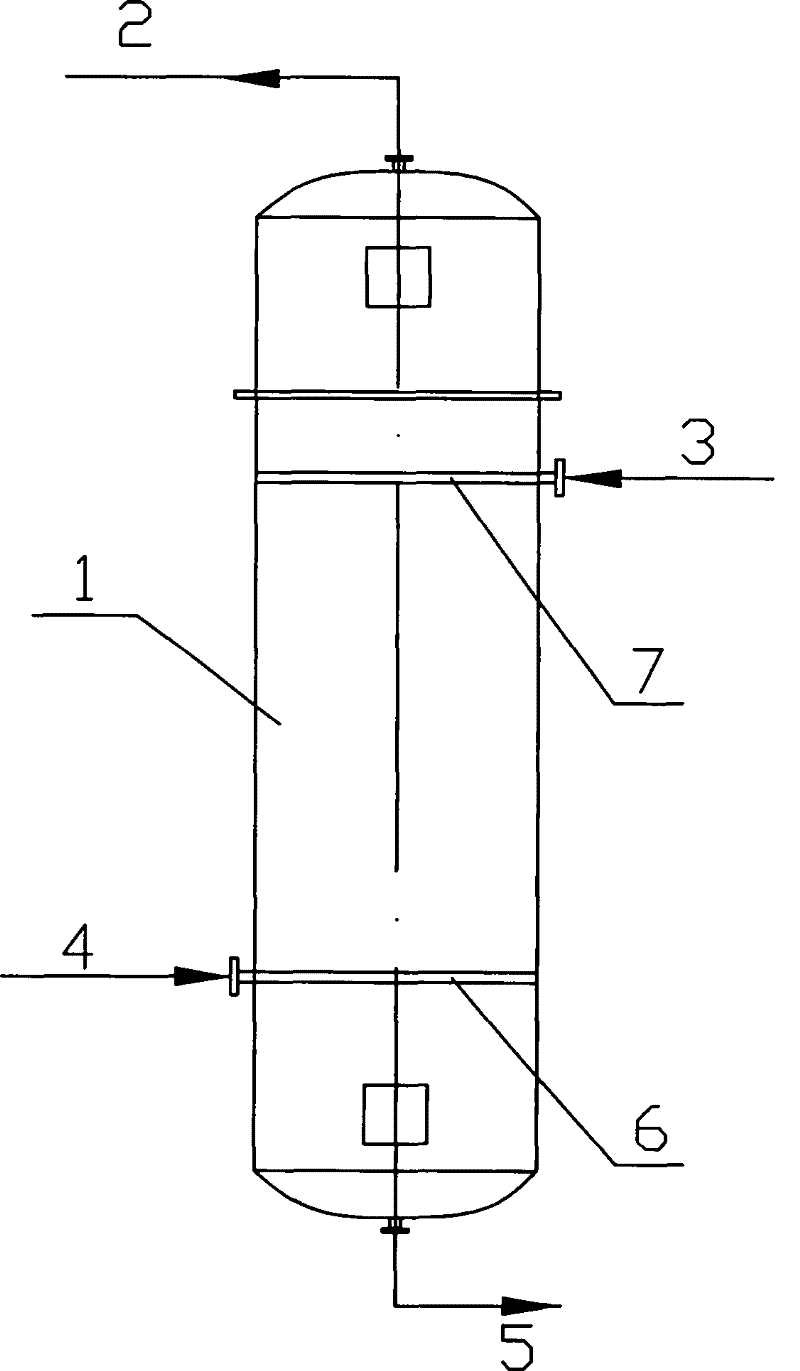

[0022] Embodiment 1. A special extraction tower device for lincomycin hydrochloride,

[0023] The structure of the extraction tower is as figure 1 As shown, the special extraction tower device for lincomycin hydrochloride is an extraction tower 1 composed of a closed container, the top of the extraction tower is provided with an extractant outlet 2, the upper part of the side of the extraction tower is provided with an aqueous solution inlet 3, and the lower part of the side of the extraction tower is provided with a secondary Octanol inlet 4, extraction waste liquid outlet 5 is provided at the bottom of the extraction tower. A distributor 6 and a distributor 7 are sequentially provided in the extraction tower to communicate with the inlet 4 of the secondary octanol and the inlet 3 of the aqueous solution, respectively, so that the incoming aqueous solution and secondary octanol are uniformly distributed in the container. The distributor is a coil connected with the aqueous s...

Embodiment 2

[0025] Dissolve 400 kg of lincomycin hydrochloride product with lincomycin hydrochloride B component ≤ 1.0% to 80000 μg / ml with purified water, and adjust the pH value to 10-11 with flake NaOH. Enter the upper part of the above-mentioned lincomycin hydrochloride aqueous solution extraction tower, and simultaneously pass through the secondary octanol of aqueous solution volume 1 / 2 from the bottom of the extraction tower to extract, and most of lincomycin hydrochloride is transferred in the secondary octanol phase (extraction liquid), flows out from the top of the tower, and the raffinate phase waste liquid contains more lincomycin hydrochloride B components and less lincomycin hydrochloride, and flows out from the bottom of the tower.

[0026] Add purified water to the extract and use hydrochloric acid to adjust the pH value to 2-4 for back extraction, transfer lincomycin into the water phase, and separate the lower layer of the water phase extract after standing still. Slowly ...

Embodiment 3

[0029] Dissolve 400 kg of lincomycin hydrochloride product with lincomycin B component ≤ 1.0% in purified water to 100000 μg / ml, and adjust the pH value to 10-11 with flake NaOH. Enter the upper part of the above-mentioned lincomycin hydrochloride aqueous solution extraction tower, and simultaneously pass through the secondary octanol of aqueous solution volume 1 / 3 from the bottom of the extraction tower to extract, and most of lincomycin hydrochloride is transferred in the secondary octanol phase (extraction liquid), flows out from the top of the tower, and the raffinate phase waste liquid contains more lincomycin hydrochloride B components and less lincomycin hydrochloride, and flows out from the bottom of the tower.

[0030] Add purified water to the extract and use hydrochloric acid to adjust the pH value to 2-4 for back extraction, transfer lincomycin into the water phase, and separate the lower layer of the water phase extract after standing still. Slowly add 10-12 times...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com